Low-cost high-conductivity electrode flat steel and smelting method thereof

A high-conductivity, electrode flat steel technology, applied in the direction of improving process efficiency, can solve problems such as restricting development and unable to reduce production costs, and achieve the effects of improving purity, reducing crystal defects, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

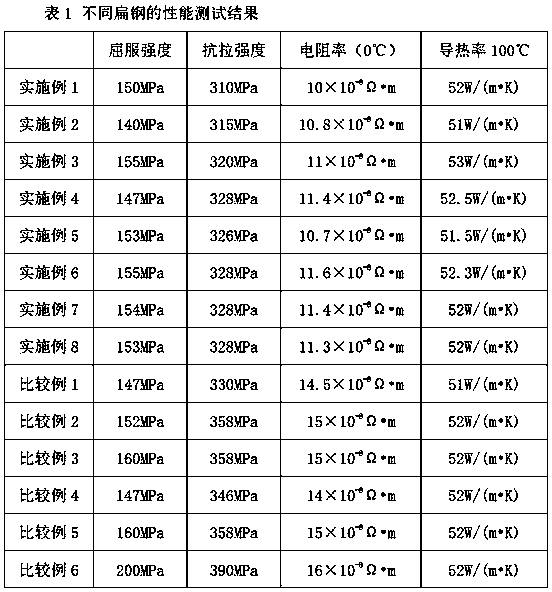

Examples

Embodiment 1

[0032] The low-cost and high-conductivity flat steel described in this embodiment contains 0.004% by weight of C, 0.05% of Si, 0.14% of Mn, 0.02% of P, 0.01% of S, and the rest is Fe.

[0033] Embodiment 1 smelting method comprises the steps:

[0034] (1) Mix hot-charged molten iron with scrap steel to obtain initial molten steel. The initial molten steel is mixed with hot charging molten iron and scrap steel in proportion, and the weight of scrap steel does not exceed 15% of the total amount added. Before the initial molten steel enters the converter, the content of Si is 0.04%, the content of P is 0.01%, the content of S is 0.05%, and the temperature of the molten steel is 1500°C.

[0035] (2) The molten steel in step (1) is transferred to the converter through the mixed iron furnace and smelted at 1655 ° C for 30 minutes; when tapping, the synthetic slag accounting for 0.3% of the mass of the molten steel at the time of tapping is slag washed, and the synthetic slag The c...

Embodiment 2

[0040] The low-cost and high-conductivity flat steel described in this embodiment contains 0.005% by weight of C, 0.03% of Si, 0.1% of Mn, 0.015% of P, 0.009% of S, and the rest is Fe.

[0041]The smelting method of embodiment 2 comprises the steps:

[0042] (1) Mix hot-charged molten iron with scrap steel to obtain initial molten steel. The initial molten steel is mixed with hot charging molten iron and scrap steel in proportion, and the weight of scrap steel does not exceed 15% of the total amount added. Before the initial molten steel enters the converter, the content of Si is 0.03%, the content of P is 0.008%, the content of S is 0.05%, and the temperature of the molten steel is 1450°C.

[0043] (2) The molten steel in step (1) is transferred to the converter through the mixed iron furnace and smelted at 1660 ° C for 32 minutes; when tapping, add synthetic slag accounting for 0.4% of the mass of the molten steel at the time of tapping for slag washing, and the synthetic s...

Embodiment 3

[0048] The low-cost and high-conductivity flat steel described in this embodiment contains 0.005% by weight of C, 0.05% of Si, 0.12% of Mn, 0.02% of P, 0.008% of S, and the rest is Fe.

[0049] The smelting method of embodiment 3 comprises the steps:

[0050] (1) Mix hot-charged molten iron with scrap steel to obtain initial molten steel. The initial molten steel is mixed with hot charging molten iron and scrap steel in proportion, and the weight of scrap steel does not exceed 15% of the total amount added. Before the initial molten steel enters the converter, the content of Si is 0.02%, the content of P is 0.008%, the content of S is 0.05%, and the temperature of the molten steel is 1600°C.

[0051] (2) The molten steel in step (1) is transferred to the converter through the mixing furnace and smelted at 1665°C for 34 minutes; when tapping, add synthetic slag accounting for 0.35% of the mass of the molten steel at the time of tapping for slag washing, and the synthetic slag ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com