Integrated optical circuit structure fiber-optic gyroscope and work method thereof

A fiber optic gyroscope and integrated optical circuit technology, applied in Sagnac effect gyroscope and other directions, can solve the problems of low coupling efficiency of optoelectronic devices, high power consumption of fiber optic gyroscope system, low precision of fiber optic gyroscope system, etc., and it is easy to achieve parameters such as structure. Adjusting, reducing the difficulty of the assembly process, and the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

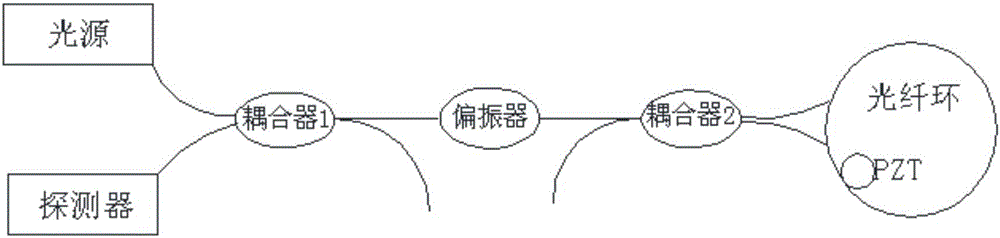

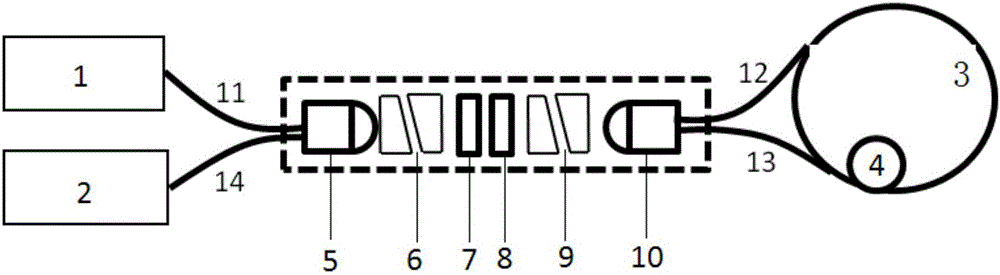

[0032] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0033] see figure 2 , a fiber optic gyroscope with an integrated optical path structure, including an SLED light source 1, the light source 1 adopts a coaxial package or a butterfly package, the SLED light source 1 is connected to a first lens 5 through a first optical fiber 11, and the rear side of the first lens 5 is sequentially provided with The first polarization beam splitter 6, the Faraday rotator 7, the polarizer 8, the second polarization beam splitter 9 and the second lens 10, and the first lens 5, the first polarization beam splitter 6, the Faraday rotator 7, the polarizer 8, The second polarization beam splitter 9 and the second lens 10 are combined together by packaging, the angle between the polarization direction of the polarizer 8 and the polarization direction of the light passing through the first polarization beam splitter 6 is 45 degrees, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com