Five-axle linkage electrolytic and mechanical combination polishing machine for curved surfaces

A technology of electrolytic machinery and composite curved surfaces, which is applied in the direction of surface polishing machine tools, electrolytic processes, electrolytic components, etc., can solve the problems of affecting the health of operators, the difficulty of mechanical polishing to meet the requirements, and the difficulty of realizing polishing actions, etc., so as to improve the process. Controllability and polishing quality, power distribution is easy to control, and the effect of reducing the risk of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

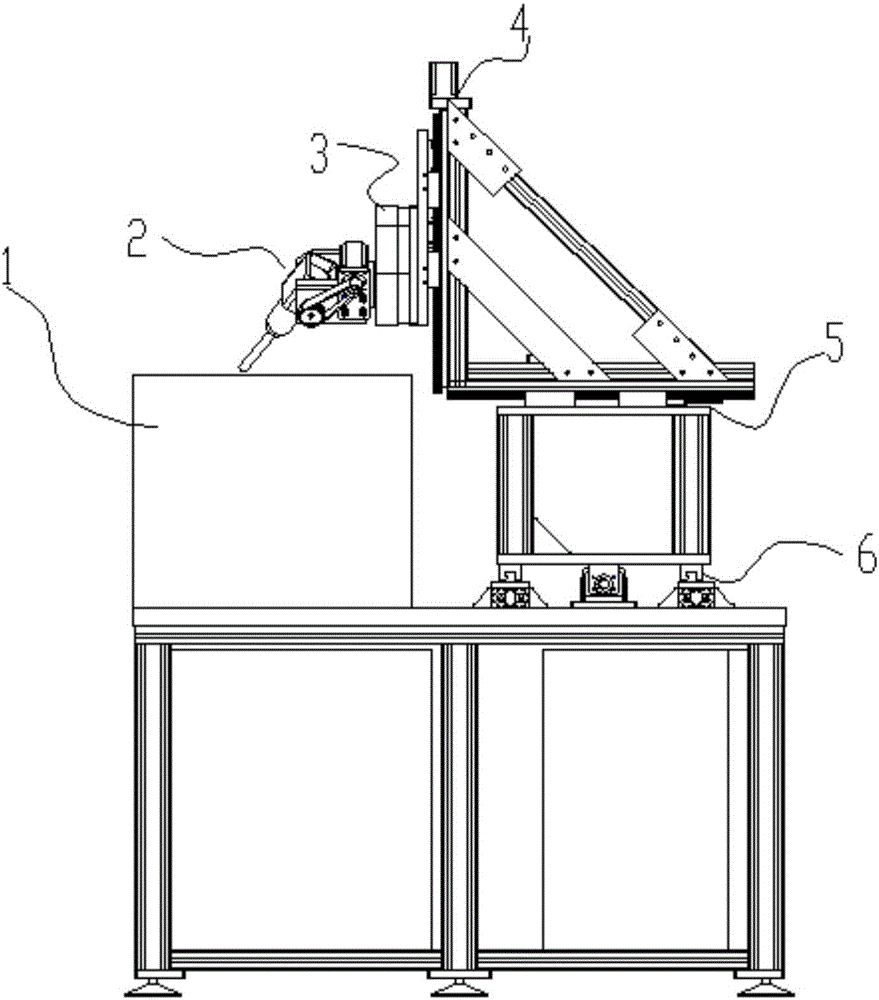

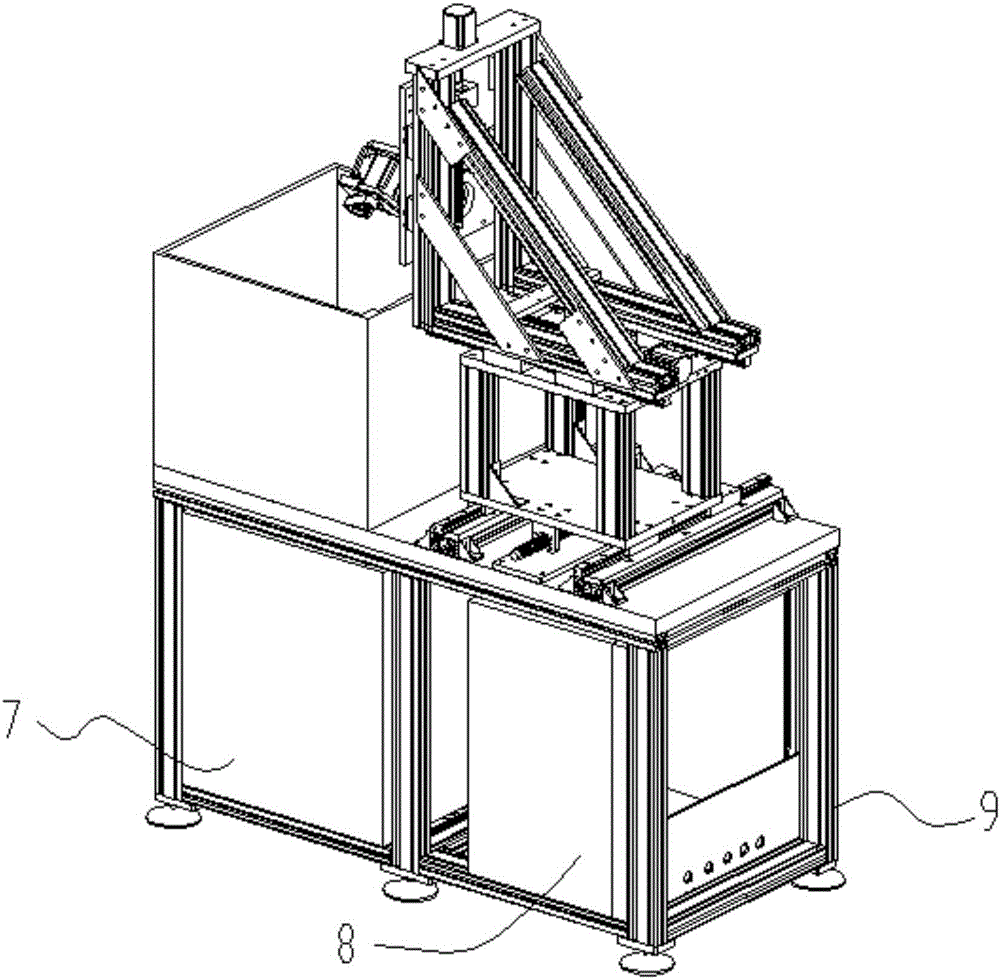

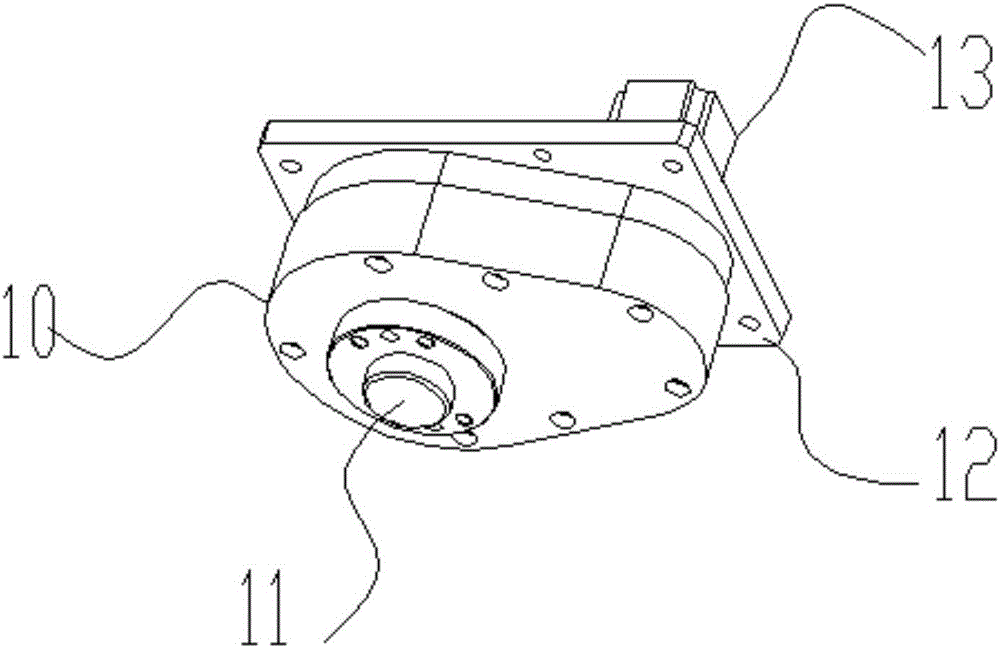

[0022] The invention discloses a five-axis linkage electrolytic mechanical compound curved surface polishing machine with a rotating polishing head, such as Figure 1-4 As shown, it includes a polishing spindle 16, a workbench, a working water tank 1 and an electrolytic power supply. The polishing spindle is installed on a five-axis linkage main frame. A polishing head including a conductive metal core and a non-conductive abrasive skin is mounted. The positive pole of the electrolysis power supply is electrically connected to the worktable, the negative pole of the electrolysis power supply is electrically connected to the conductor metal core of the polishing head, and the workbench is insulated from the polishing head. During electrolytic polishing, the working water tank is filled with electrolyte, the workpiece is fixed on the workbench, and the workpiece and polishing head are immersed in the electrolyte. The conductive metal core is used for electrolytic polishing, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com