Flame-retardant composition and flame-retardant synthetic resin composition

A synthetic resin and composition technology, applied in the field of flame retardant synthetic resin composition and flame retardant composition, can solve the problems of harmful gas generation, achieve excellent flame retardancy and weather resistance, reduce corrosion risk, and heat resistance excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

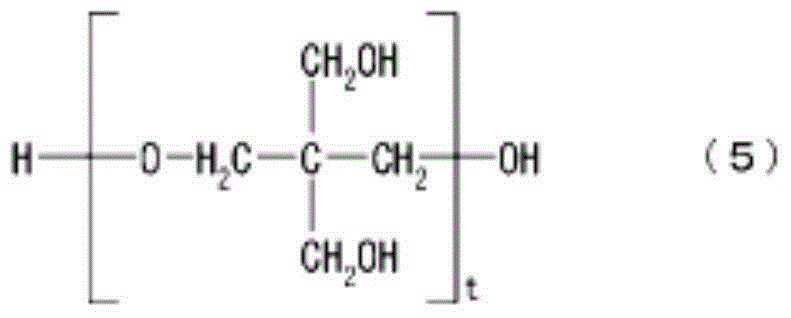

Method used

Image

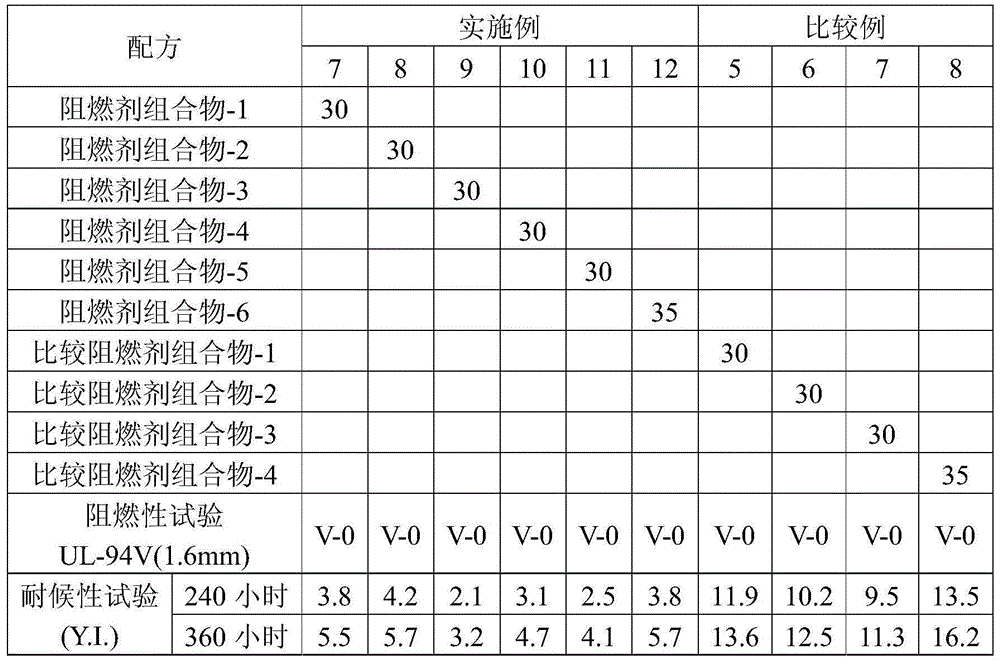

Examples

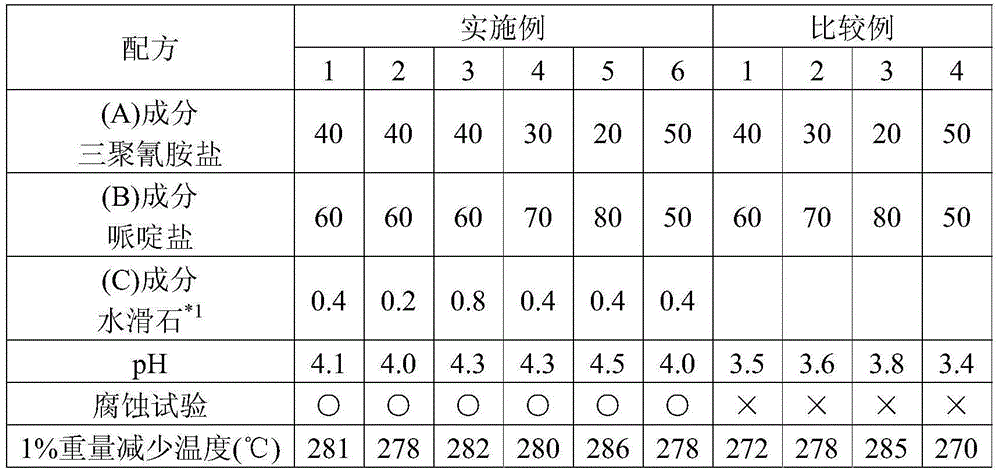

Embodiment 1~6 and comparative example 1~4

[0125] (A) component and (B) component were produced by the following method.

manufacture example 1

[0127] (A) Ingredient: Melamine salt

[0128] Melamine orthophosphate was heated and condensed in a solid state at 220° C. for 6 hours to produce a melamine salt mainly composed of melamine pyrophosphate. The melamine salt was used directly without refining. The purity of melamine pyrophosphate in the melamine salt is 98.5%.

[0129] The purity was determined by using an HPLC device (pump; SSC-3150, RI detector; ERC-7515A) manufactured by Senshu Science Co., Ltd., a column oven (CO-965) manufactured by JASCO Corporation, and an OHpak column (SB-802.5HQ) manufactured by Shodex Corporation. Determination.

manufacture example 2

[0131] (B) Ingredient: piperazine salt

[0132] Piperazine orthophosphate was heated and condensed in a solid state at 250° C. for 1 hour to produce a piperazine salt mainly composed of piperazine pyrophosphate. The piperazine salt was used directly without purification. The purity of piperazine pyrophosphate in the piperazine salt was 99.0%.

[0133] The purity was determined by using an HPLC device (pump; SSC-3150, RI detector; ERC-7515A) manufactured by Senshu Science Co., Ltd., a column oven (CO-965) manufactured by JASCO Corporation, and an OHpak column (SB-802.5HQ) manufactured by Shodex Corporation. Determination.

[0134] Next, the flame retardant composition of the example was adjusted according to the formulation described in Table 1. Similarly, the flame retardant composition of the comparative example was adjusted according to the formulation described in Table 1.

[0135] In addition, the pH of the flame retardant composition obtained above was measured by the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com