Arrangement for injecting and affixing a reinforcing or anchoring element in a rock wall

a technology for reinforcing or anchoring elements and rock walls, which is applied in earth-moving drilling, mining structures, construction, etc., can solve problems such as cracks in seals, cracks in cement “plugs”, and failure to meet the requirements of appointing personnel,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

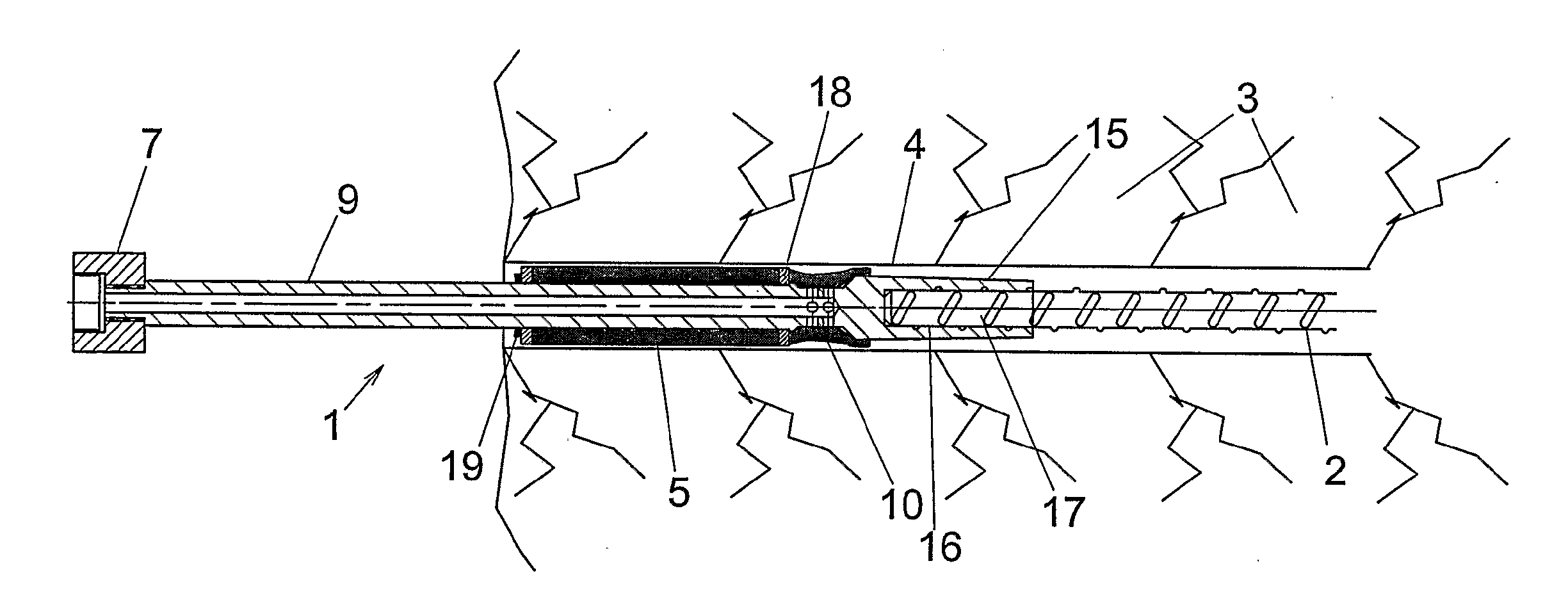

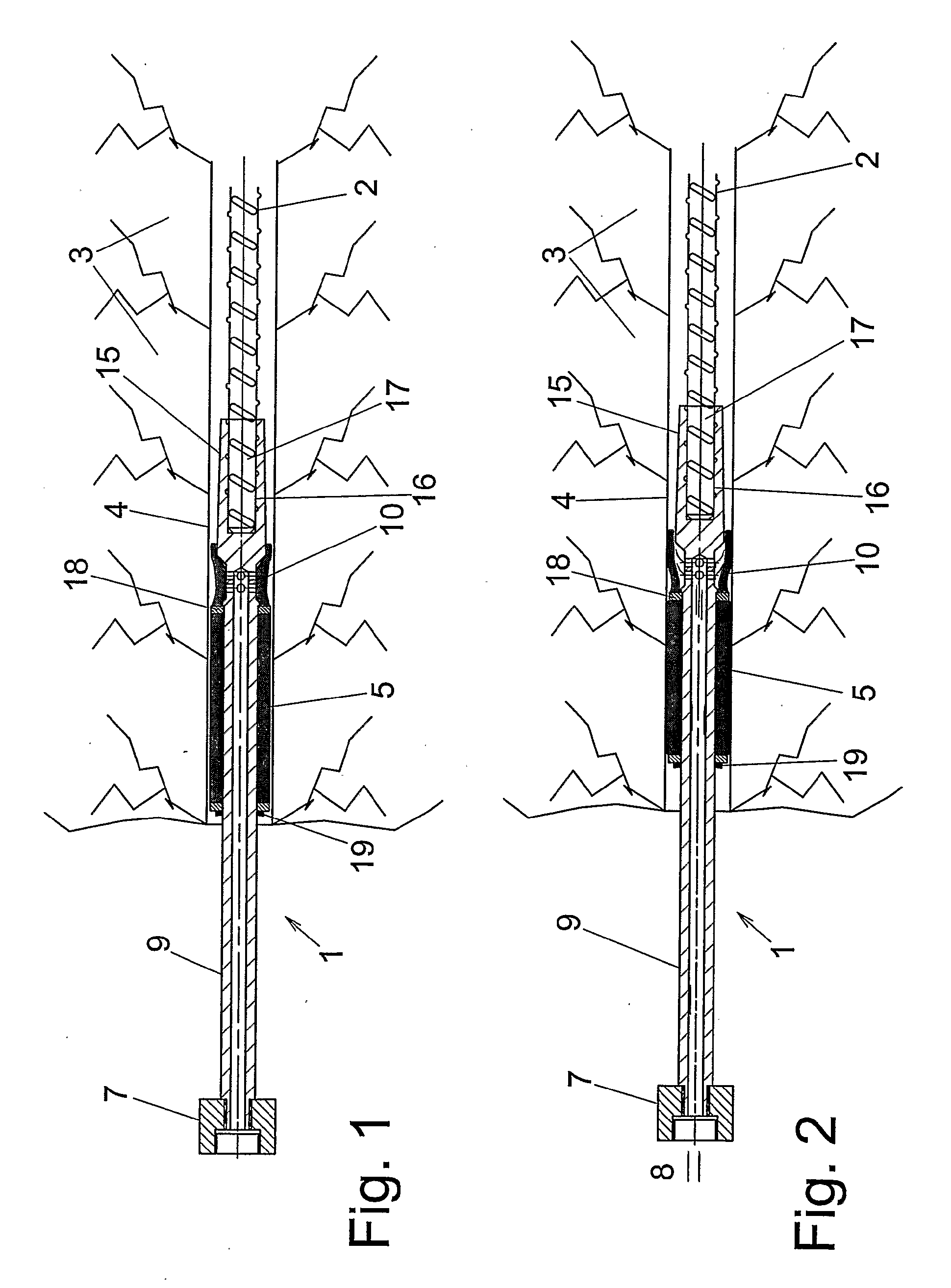

[0044]FIGS. 1 and 2 illustrate an arrangement 1 for injecting and securing a reinforcing element and / or anchoring element 2 in a rock wall 3, in accordance with the present invention. For the sake of simplicity the arrangement will be referred to solely as an injection means in the following text. Correspondingly, the reinforcing and / or anchoring element 2 will be referred to solely as the reinforcing element in the following text. This should in no way be understood as limiting the scope of the invention. The reinforcing and / or anchoring element 2 may also consist of solid iron material or a hollow tube.

[0045]FIGS. 1 and 2 show a first embodiment of the injection means 1 coupled to the reinforcing element 2, wherewith the mutually coupled members are together inserted into a hole 4 in a rock wall 3. The injection means constitutes a separate unit. The illustrated first embodiment of the injection means 1 includes a first variant of a packer-type expandable seal, namely a mechanical...

second embodiment

[0051]The inventive method will now be described with reference to FIGS. 5:1-8 and 6:1-6, these figures being related to the first and the second embodiment respectively.

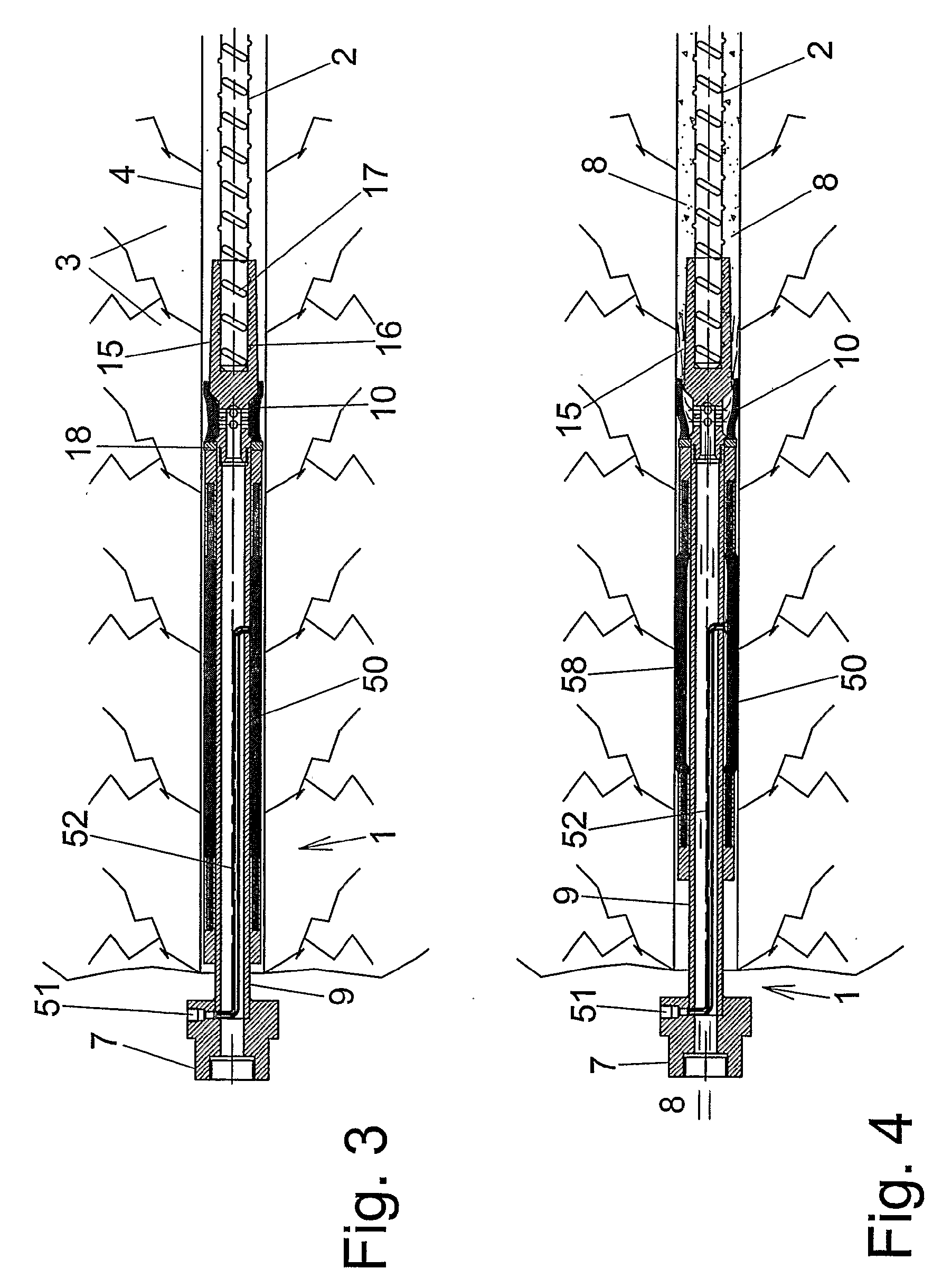

[0052]FIGS. 5:1 and 6:1 illustrate respectively a rock wall 3 in which a hole 4 has been drilled, this being the normal procedure. FIGS. 5:2 and 6:2 illustrate respectively the insertion of a reinforcing and / or anchoring element 2 into the hole 4 in the rock wall 3. The element 2 is coupled to an injection means 1 which constitutes a separate unit and includes a means 15 for coupling the injection means 1 to the reinforcing and / or anchoring element 2, connecting means 7 being intended for connection to a means for the supply of injection medium 8, an injection medium check valve 10 and an expandable seal 5 and 51 respectively.

[0053]FIG. 6:2 also shows the expansion of the seal 50 of the injection means, which in this case is achieved with the aid of a delivered hydraulically or pneumatically pressurized medium, such...

third embodiment

[0059]FIGS. 7 and 8 illustrate an injection means 1 and the attachment of a reinforcing element and / or anchoring element 62 in a rock wall 3, in accordance with the present invention. This embodiment differs from the two earlier embodiments, primarily by virtue of the fact that the coupling means 65 is also hollow, i.e. provided with a through-passing aperture or bore. In this case, the check valve 10 is located between the front end of the injection pipeline and the aperture in the coupling means 65. When also including a hollow reinforcing element 62, this enables injection medium to be fed right up to the innermost end of the reinforcing element, where the medium is then pressed out into the hole 4. It is then possible, in particular, to allow the reinforcing element 62 to comprise a drill rod that has an internal channel, i.e., in principle, a thick-walled pipe which is fitted with a drill bit 63 at its front end. This embodiment can thus be used to first drill the hole 4 in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com