Wind Turbine With Improved Cooling

a wind turbine and cooling technology, applied in the direction of machines/engines, liquid fuel engines, electric generator control, etc., can solve the problems of environmental pollution, blockage, clogging and blocking of air heat exchanges, etc., and achieve the effect of increasing improving the cooling effect of the nacell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

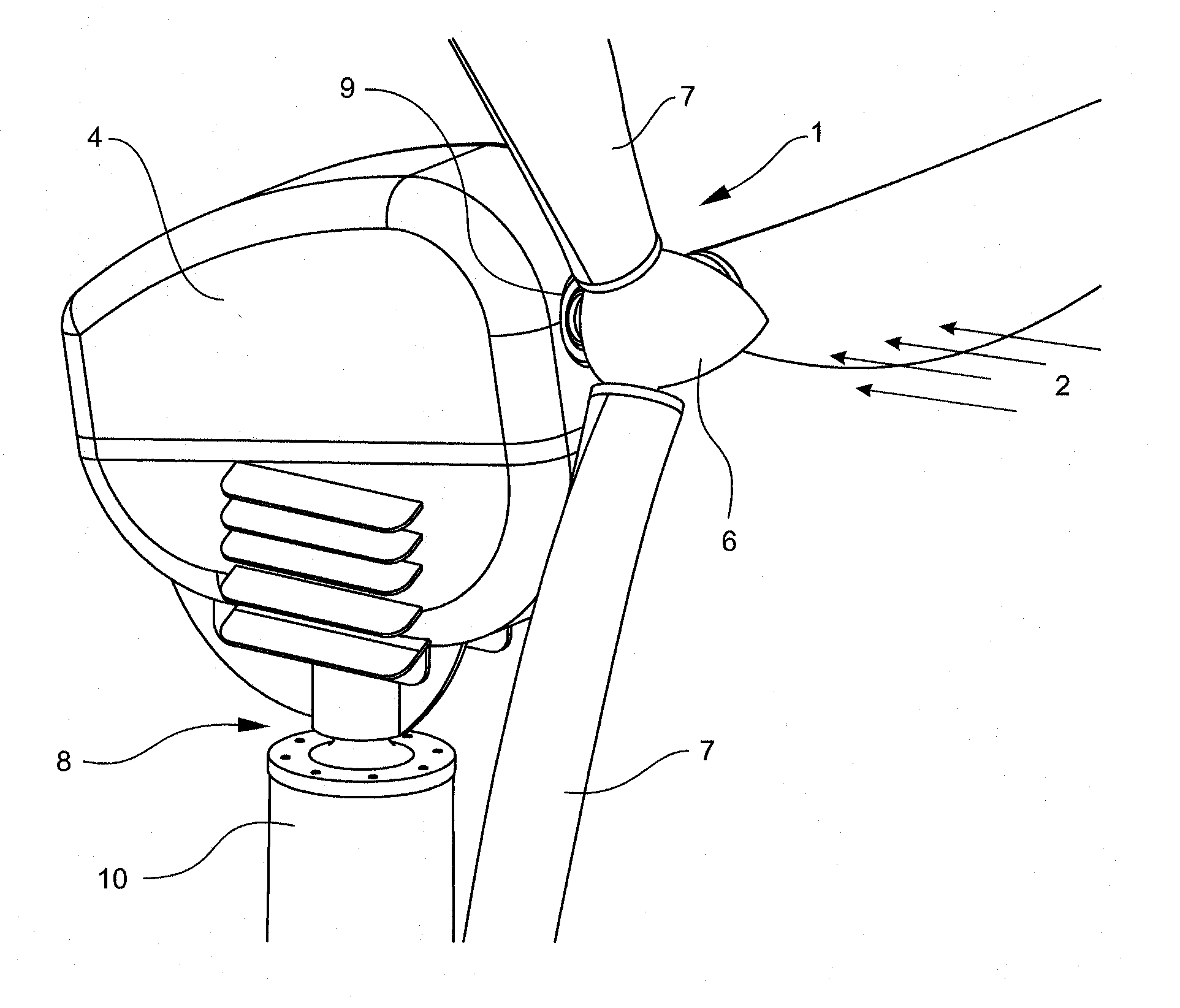

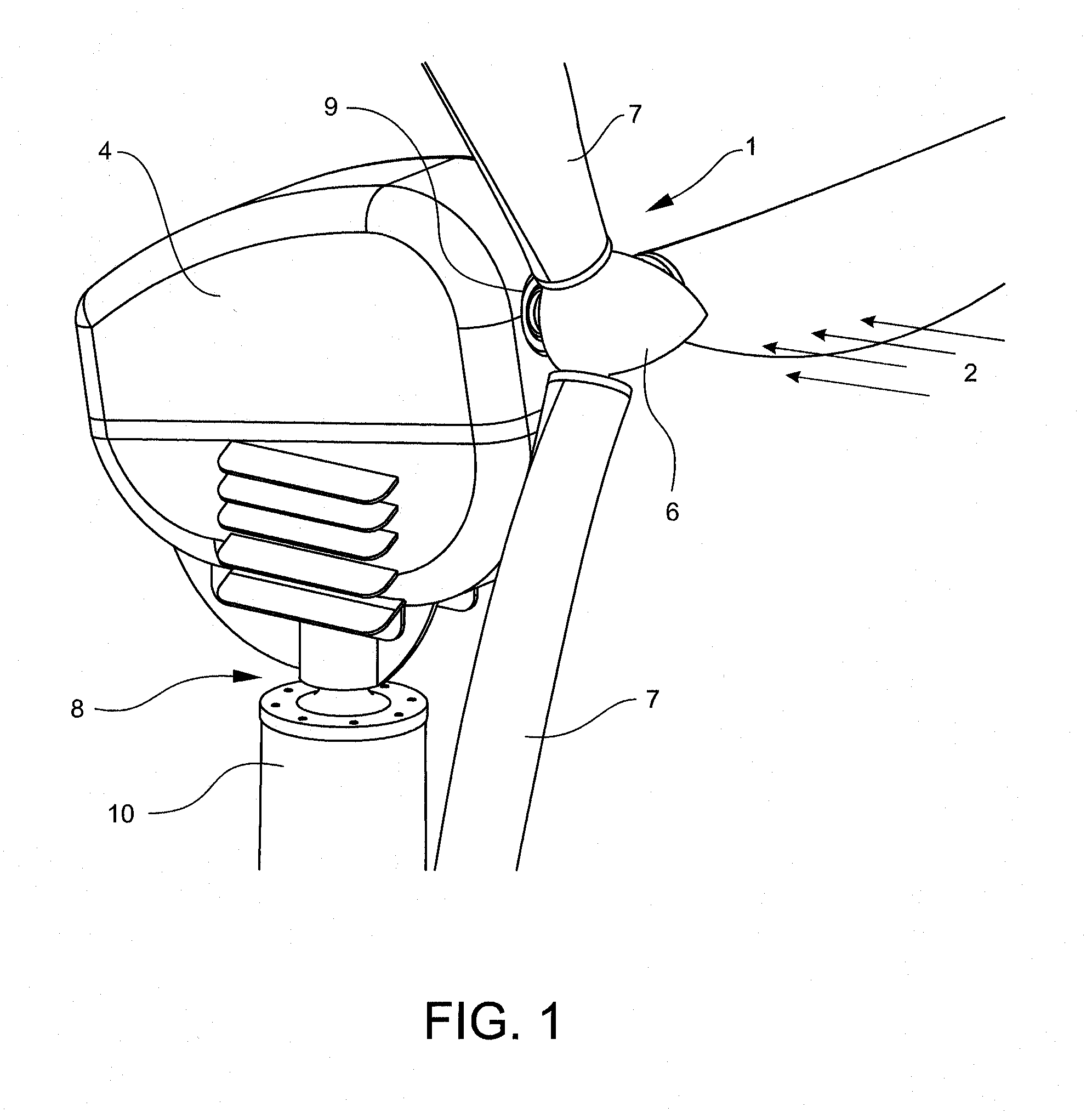

[0021]With reference now to the drawings, and particularly to FIG. 1, there is shown a side view of a wind turbine 1. The wind turbine 1 preferably includes a nacelle 4, a rotor 6, a pivot system 8 and a tower 10. The nacelle 4 is pivotally retained on a top of the tower10 with the pivot system 8. A bottom portion of the tower 10 is anchored in the ground (not shown). The nacelle 4 houses a rotor drive shaft, generator and other components of the wind turbine 1. The components found in the nacelle 4 are well known in the art and need not be shown or explained in detail. The rotor 6 extends from an end of a rotor drive shaft 9. The rotor 6 includes a plurality of blades 7 and the rotor drive shaft 9.

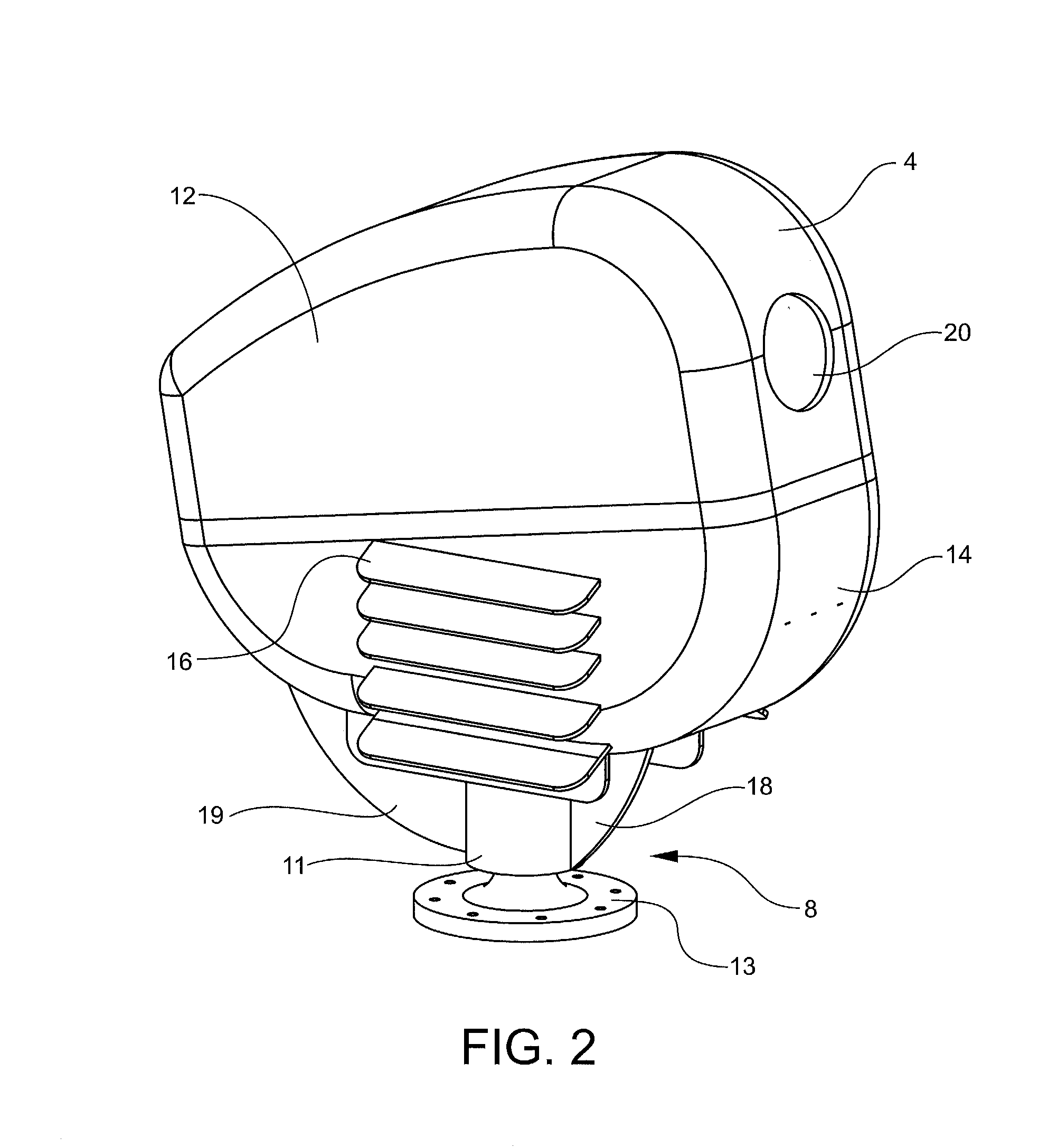

[0022]With reference to FIGS. 2-3, the nacelle 4 includes a shaft housing 12, a reservoir housing 14 and a plurality of external cooling fins 16. The shaft housing 12 may be secured to the reservoir housing 14 with any suitable method. The rotor drive shaft 9 is inserted through a drive s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com