Electro-hydraulic control system of hydrodynamic-mechanic automatic transmission and control method of electro-hydraulic control system

A technology of automatic transmission and hydraulic machinery, applied in the direction of mechanical equipment, transmission device control, transmission device, etc., can solve the problems of large shifting impact, lower stability, poor output pressure stability, etc., achieve smooth shifting, improve shifting Gear stability and shift quality, the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Preferred embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and are used together with the embodiments of the present invention to explain the principles of the present invention.

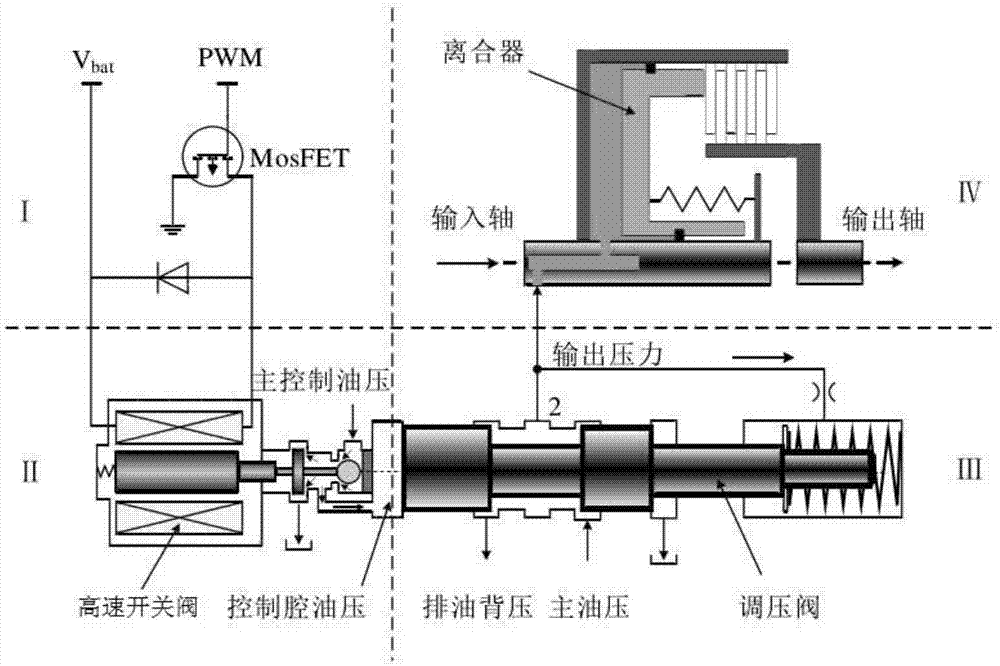

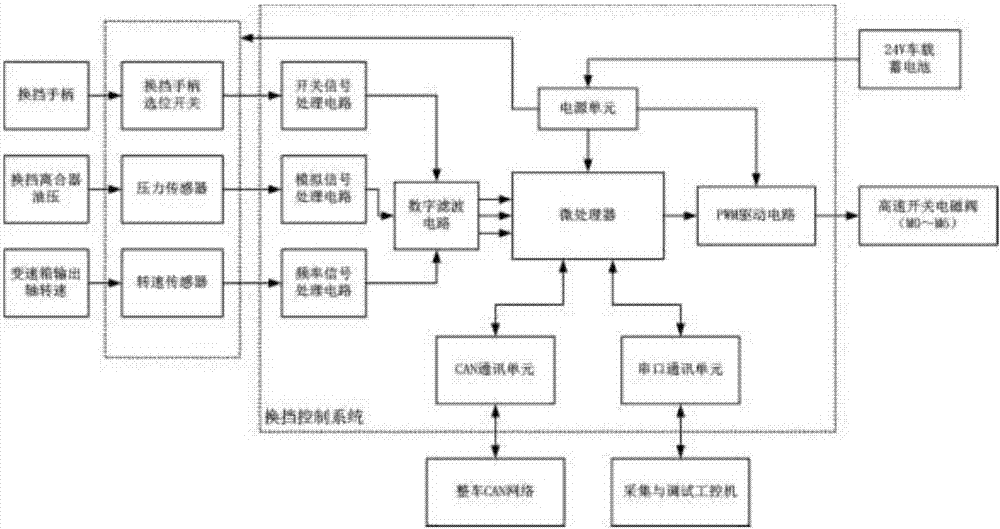

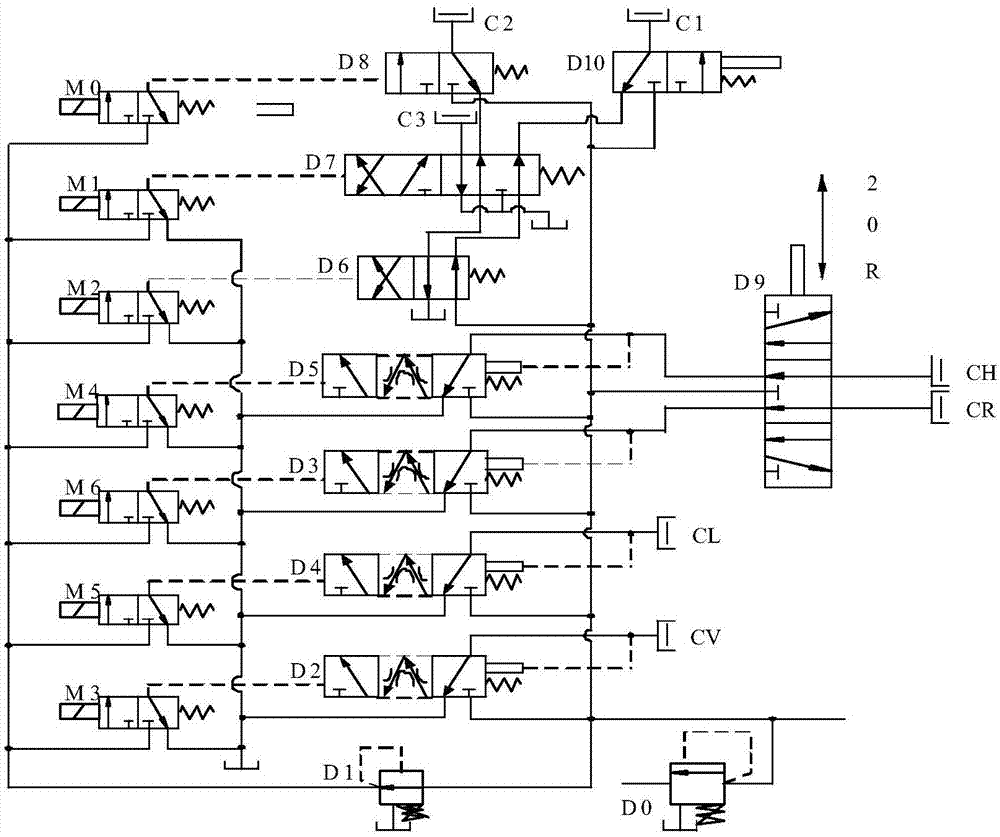

[0036] According to a specific embodiment of the present invention, an electro-hydraulic control system of a hydraulic-mechanical automatic transmission is disclosed, including: a shift control system, a shift handle, more than two solenoid valves, and a hydraulic shift valve group; The gear control system is respectively connected with the shift handle and the solenoid valve through cables, and the solenoid valve is connected with the hydraulic shift valve group; the hydraulic shift valve group is controlled by the solenoid valve, thereby controlling the clutch piston to charge and discharge oil, so as to realize the engagement and operation of the clut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com