Gear tooth surface processing device and gear manufacturing method

A processing device and gear manufacturing technology, applied in the direction of gear tooth manufacturing tools, gear tooth manufacturing devices, abrasive surface adjustment devices, etc., can solve problems such as difficult to finely control processing pressure, avoid grinding burns, and improve surface roughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

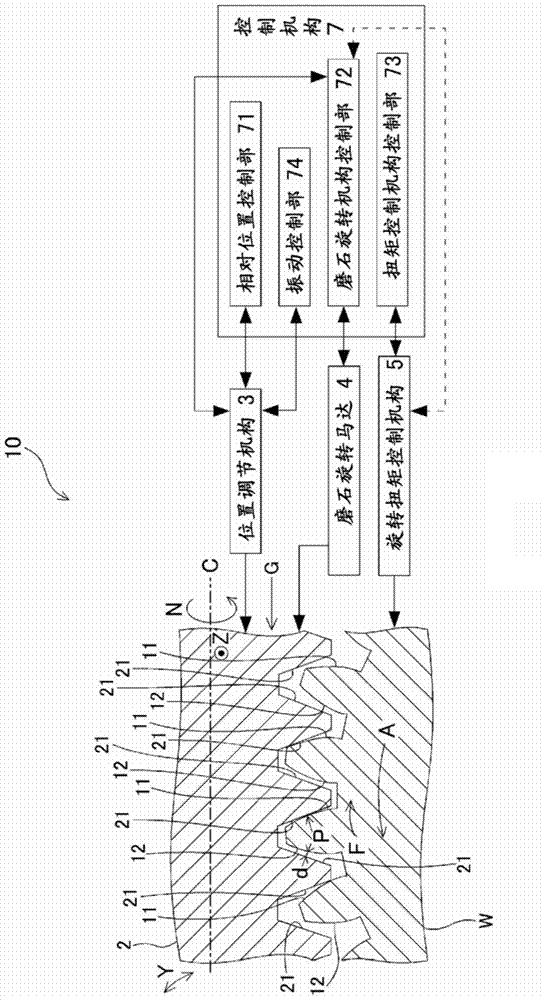

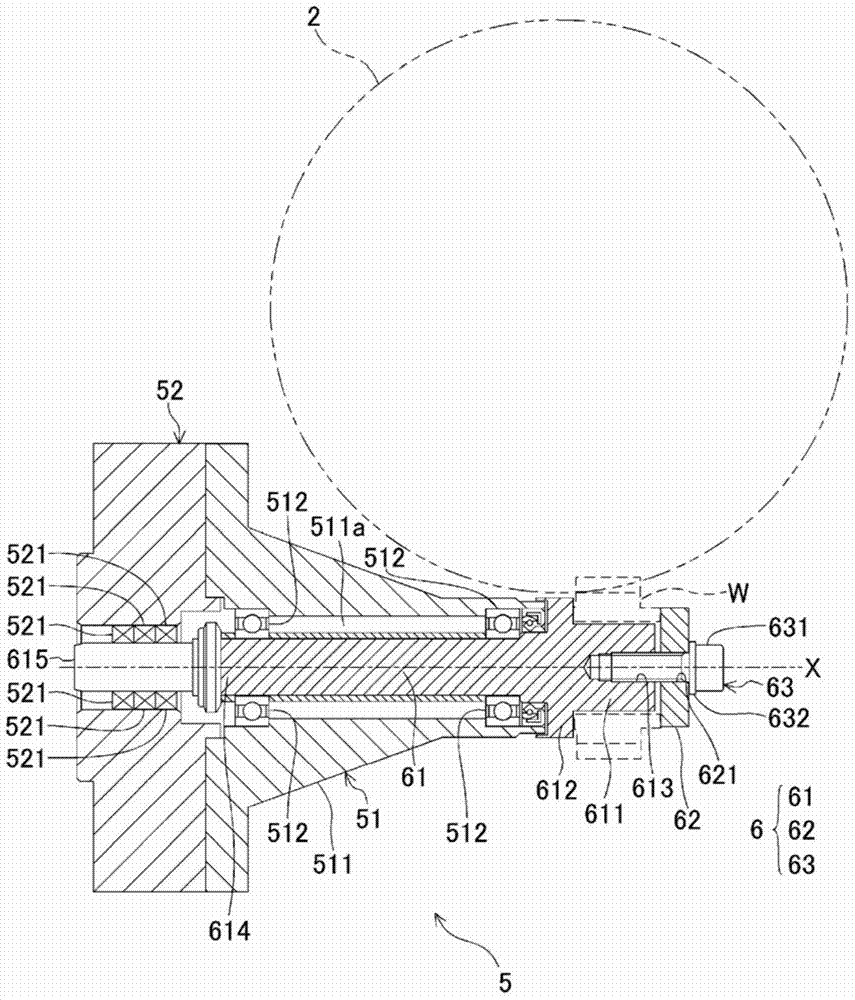

[0063] Such as figure 1 As shown, the tooth surface processing device 10 of the first embodiment has a grindstone (helical toothed grindstone) 2, a position adjustment mechanism 3, a grindstone rotation motor (grindstone rotation mechanism) 4, a rotation torque control mechanism 5, and a control mechanism 7.

[0064] As the grindstone 2, a spiral grindstone in which the angle of the teeth of the helical toothed grindstone is increased is used. In addition, the grindstone 2 uses an elastic material that can deform the grindstone tooth surface 21 along the shape of the processed tooth surface 11 of the gear W to be processed. The tooth thickness of the grindstone 2 is smaller than the width of the tooth groove of the gear W to be machined. The grindstone 2 is rotatably supported by the attachment base with the rotation axis C as a rotation center (the figure is omitted).

[0065] The grindstone rotating motor 4 rotates the grindstone 2 around the rotation axis C via a speed reducti...

Embodiment approach 2

[0090] The tooth surface processing device of the second embodiment has basically the same structure and effects as the tooth surface processing device 10 of the first embodiment. Hereinafter, the description will focus on the different structures and effects.

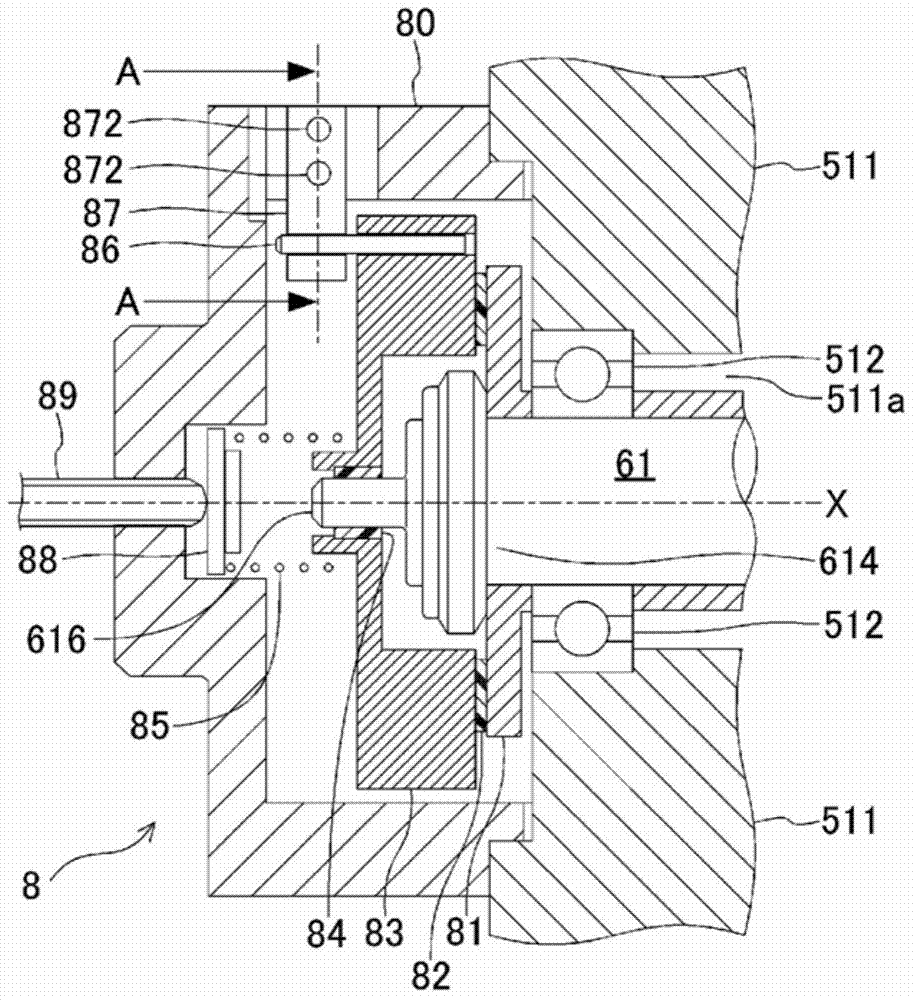

[0091] The adjustment member 9 of the tooth surface processing device of the second embodiment is different from the adjustment members 52 and 8 used in the tooth surface processing device 10 of the first embodiment. The adjusting member 9 used in the tooth surface processing device of the second embodiment is such as Figure 8 As shown, one end is inserted into the gear W to be processed, and the other end 614 side of the shaft portion 61 is provided in a state rotatable with respect to the bearing portion (not shown). The adjustment member 9 has a torque generating motor 91 that generates torque at the other end, and has a first measuring member 92, a second measuring member 93, and a torsional vibration damping body 94...

Embodiment 1

[0098] Here, Picture 10 It is a figure which shows the system structure of the tooth surface processing apparatus of this Example 1. In addition, Picture 10 The tooth surface processing device of Example 1 exemplified in the above is a device in which the grindstone 2 and the gear W to be processed rotate synchronously.

[0099] In the tooth surface processing device of the first embodiment, a grindstone rotating motor 4 as a spindle motor is connected to the grindstone 2, and the spindle motor 4 can be used to drive the helical grindstone 2 to rotate. In addition, a built-in detector 4a is provided in the spindle motor 4, and the rotation amount of the grindstone 2 can be grasped. On the other hand, the gear to be machined W is connected to the servomotor 18 for driving via the C-axis 16 and the timing belt 17, and the gear to be machined W can also be driven to rotate by the servomotor 18 for driving. Furthermore, the grindstone 2 connected to the spindle motor 4 and the gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com