A parameter design method of tooth profile grinding temperature uniform macrostructure forming grinding wheel

A technology of grinding temperature and forming grinding wheel, which is applied in the field of machinery, can solve the problems of grinding micro-cracks, tooth surface hardness changes, affecting gear strength, service life and reliability, etc., to prevent grinding burns and realize grinding Temperature, the effect of ensuring the grinding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

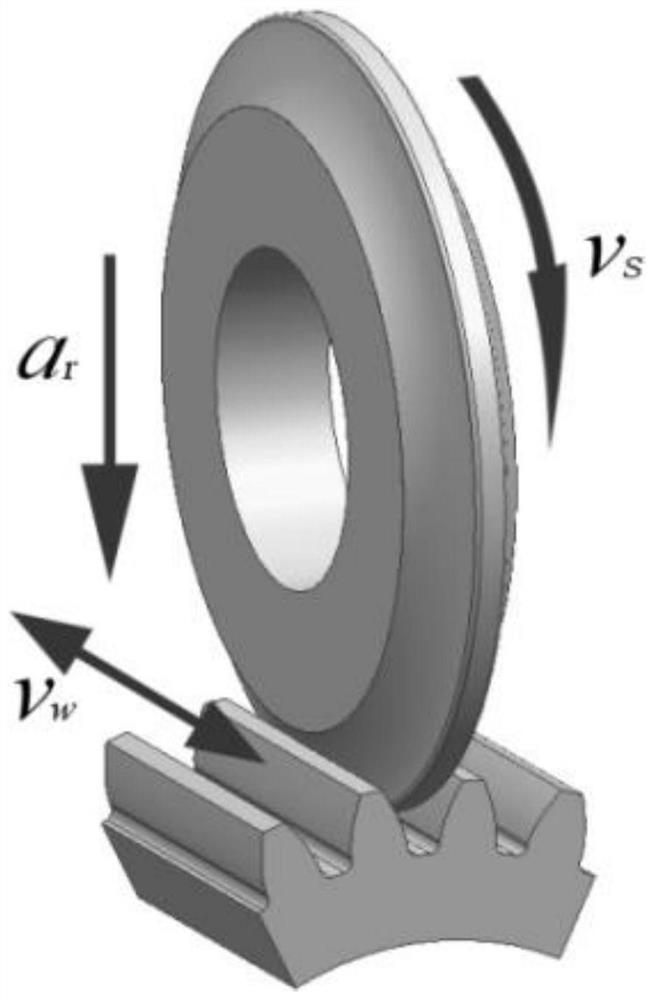

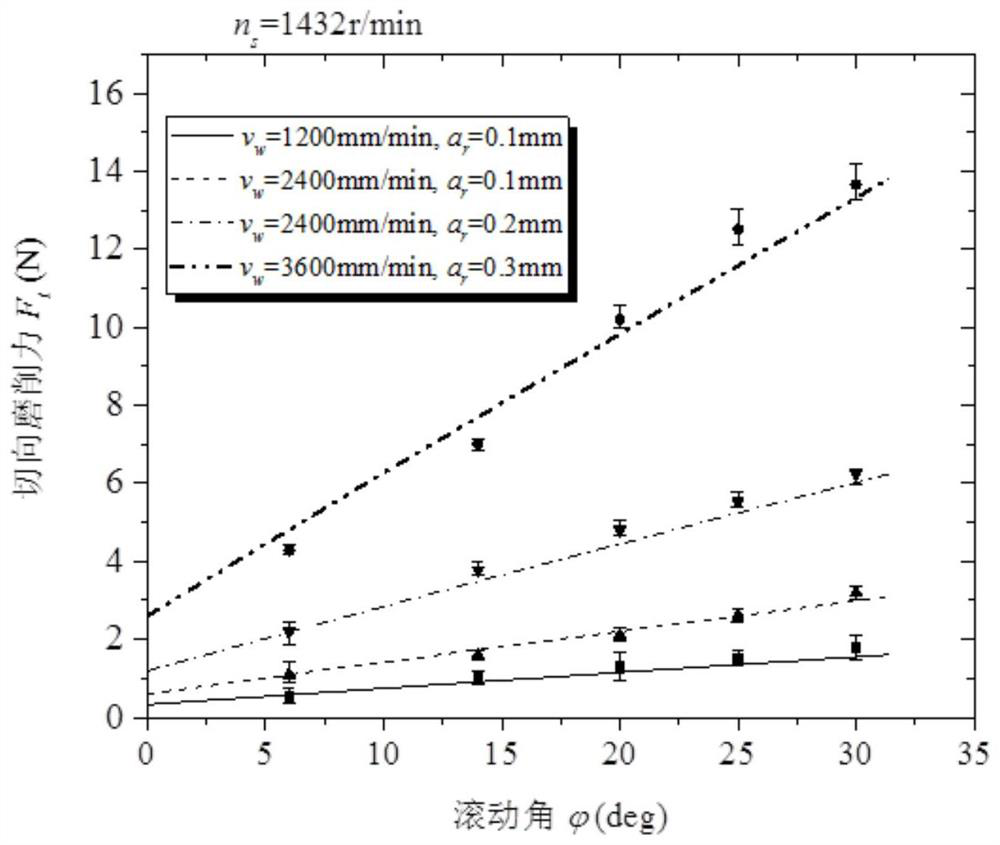

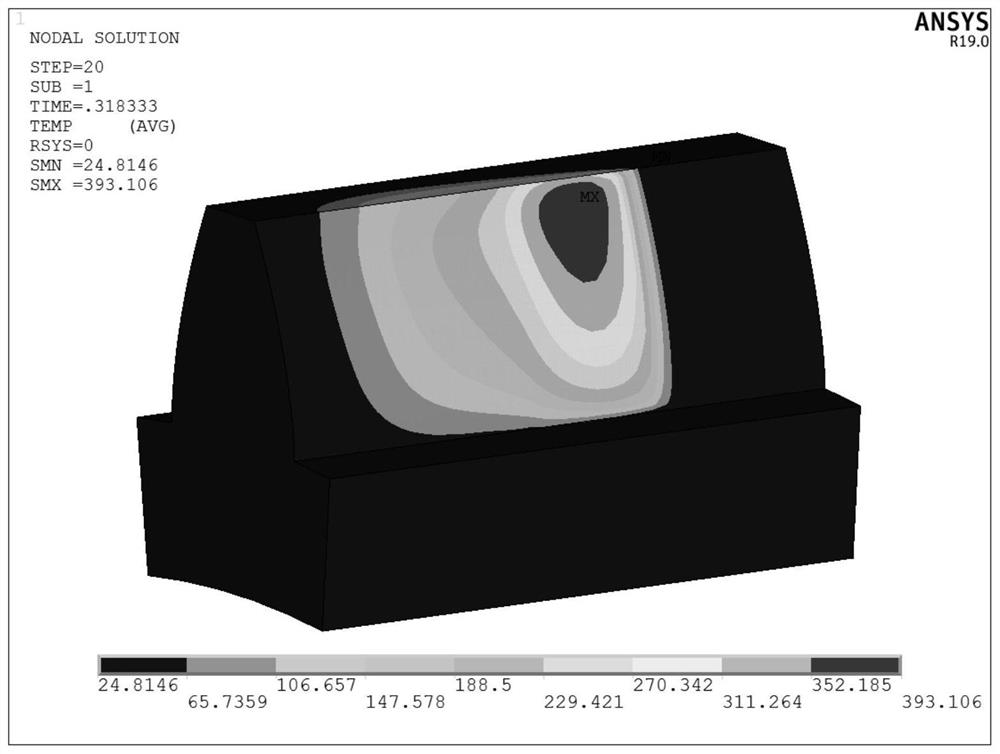

[0046] This embodiment provides a method for designing parameters for profile grinding temperature uniformity of a shaped grinding wheel, which is based on analytical modeling of the intermittent grinding temperature of a circumferentially grooved grinding wheel; establishing the structural parameters, grinding parameters and grinding temperature of the working surface of the grinding wheel The associated model of the gear forming grinding wheel is combined with the contact relationship between the gear forming grinding wheel and the workpiece, and the parametric design of the gear forming grinding wheel is carried out for the purpose of uniformizing the grinding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com