Grinding and edge cutting device of composite material

A composite material and grinding technology, which is applied in the direction of grinding drive devices, grinding machine parts, grinding/polishing equipment, etc., can solve the problems of layered defects and high cost of the processed section, and achieve cutting cost reduction and edge trimming The effect of increased efficiency and efficient grinding and cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention are described below in conjunction with the accompanying drawings.

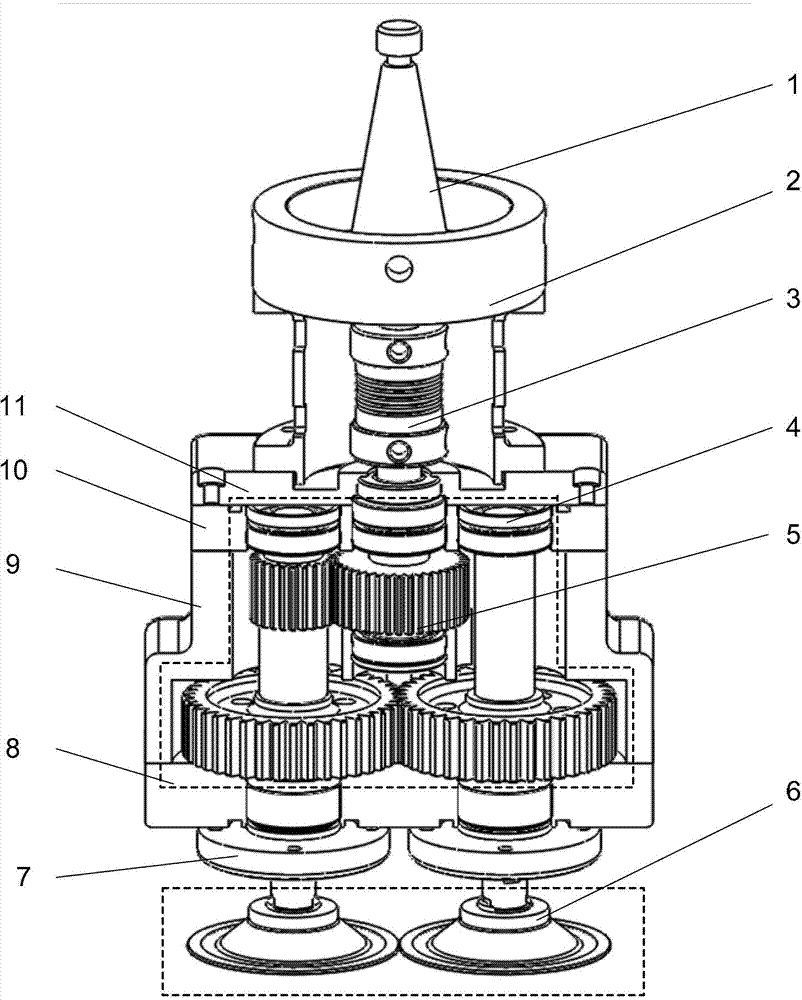

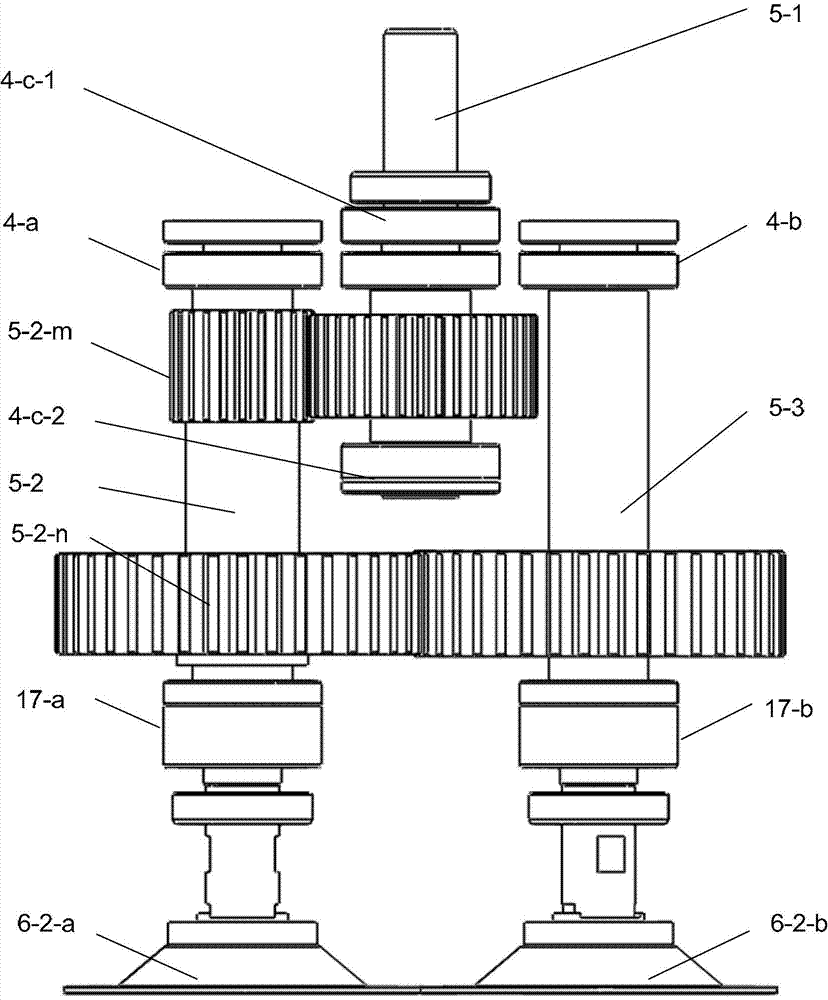

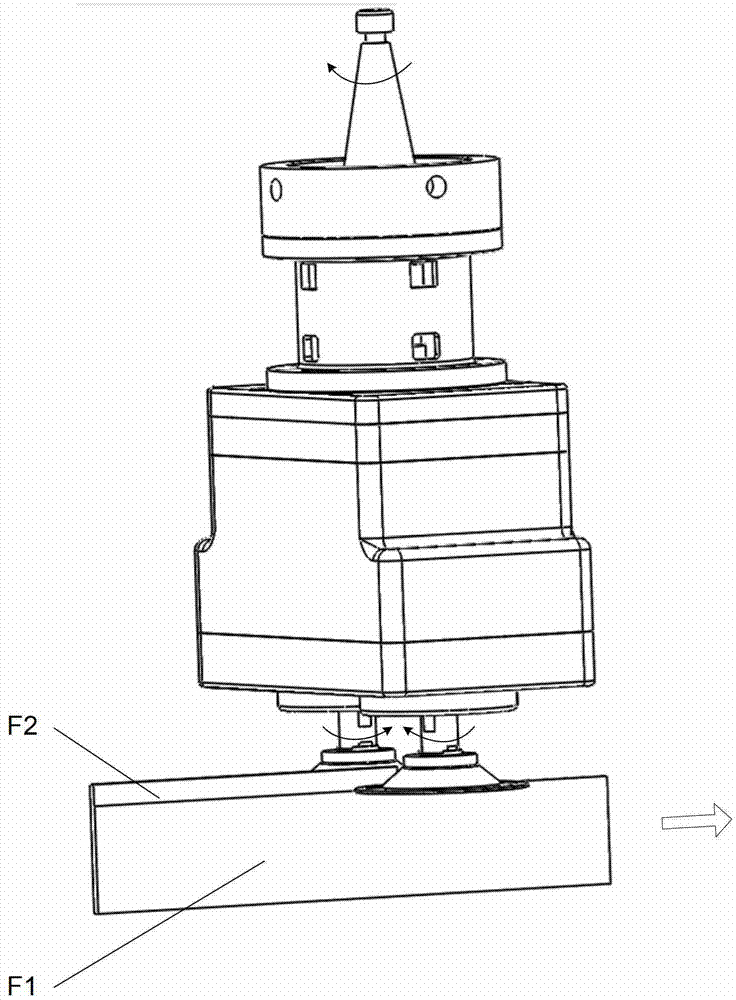

[0030]figure 1 It is a structural schematic diagram of a carbon fiber composite material grinding method trimming device according to an embodiment of the present invention. The motion conversion part 5 relies on the lower box 8, the middle box 9 and the upper box 10 stably installed in the housing through the bearing support system (4, 17). The upper end cover 11 and the lower end cover 7 are hermetically connected to the upper and lower boxes respectively. The housing connection part 2 is installed on the housing part, and the tool part 6 is installed on the two output ends of the motion conversion part 5 .

[0031] like figure 1 , Figure 4 As shown, the upper end cover 11 and the upper end cover 10 are centrally connected through the reference transfer flange 13, and the anti-rotation flange 2-2 of the shell connecting part 2 is centeredly connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com