A kind of optical curve grinding wheel and its preparation method

An optical curve grinding and grinding wheel technology, which is applied in the direction of grinding/polishing equipment, abrasives, grinding devices, etc., can solve the problems of inability to carry out batch production of chamfering grinding wheels, unstable performance, and changes in grinding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

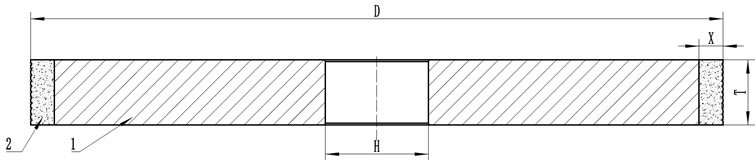

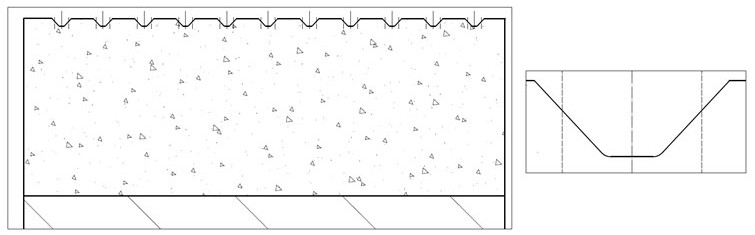

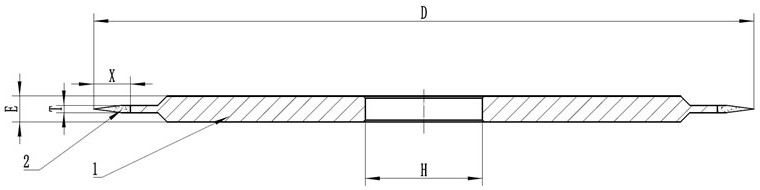

[0033] like image 3 As shown, an optical curve grinding wheel includes a stainless steel substrate 1 and an abrasive layer 2, wherein the abrasive layer 2 includes abrasive materials and a metal bond, and is specifically composed of the following raw materials in parts by weight: 35 parts of copper powder, tin powder 25 parts, silver powder 10 parts, cubic boron nitride 30 parts (400 mesh).

[0034] The thickness of the abrasive layer 2 is lower than that of the substrate 1, and the edge of the abrasive layer 2 is designed with sharp corners, which is more convenient for dressing the chamfering grinding wheel. In the present invention, the emery wheel model that adopts is 14E1 , where: D represents the diameter of the grinding wheel, T represents the thickness of the abrasive layer, H represents the diameter of the inner hole of the grinding wheel, E represents the total thickness of the grinding wheel substrate, and X represents the width of the abrasive layer.

[0035] T...

Embodiment 2

[0044] For the optical curve grinding wheel provided in this embodiment, compared with Embodiment 1, the formulation of the abrasive layer is adjusted as follows:

[0045] The abrasive layer is composed of the following raw materials in parts by weight: 30 parts of copper, 25 parts of tin, 5 parts of silver powder, and 40 parts of cubic boron nitride; the mesh size of the cubic boron nitride is 280 mesh.

[0046]Compared with the preparation method of the optical curve grinding wheel in Example 1, the preparation parameters of the adjusted part are as follows:

[0047] Step 1) Take 5 parts of copper powder, 5 parts of silver powder, 40 parts of abrasive, and the mixing time of the abrasive layer in the three-dimensional mixer is 20h;

[0048] Step 4) in a heat resistant steel mold at 2500kg / cm 2 pressure to suppress;

[0049] Step 5) In a twin-body hot pressing sintering furnace, the temperature is raised to 500°C at a rate of 100°C / h, and the temperature is maintained for 2...

Embodiment 3

[0051] Compared with Example 1, the optical curve grinding wheel provided by the present embodiment adjusts the formulation of the abrasive layer as follows:

[0052] The abrasive layer is made of the following raw materials by weight: 33 parts of copper, 26 parts of tin, 6 parts of silver powder, and 35 parts of cubic boron nitride; the cubic boron nitride mesh number is 400 meshes.

[0053] Compared with the preparation method of the optical curve grinding wheel in Example 1, the preparation parameters of the adjusted part are as follows:

[0054] Step 1) Take 3 parts of copper powder, 6 parts of silver powder, 35 parts of abrasive, and the mixing time of the abrasive layer in the three-dimensional mixer is 10h;

[0055] Step 4) in a heat-resistant steel mold at 2000kg / cm 2 pressure to suppress;

[0056] Step 5) The temperature is raised to 450°C at a rate of 100°C / h in a twin-body hot pressing sintering furnace and kept for 1.5h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com