Automatic electrodeless bulb sealing machine

An automatic sealing machine and light bulb technology, which is applied in the direction of electric tube/light off, etc., can solve the problems of many cutting and welding wastes, low work efficiency, large gas consumption, etc., and achieves good welding quality, improved production efficiency, and high degree of mechanization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

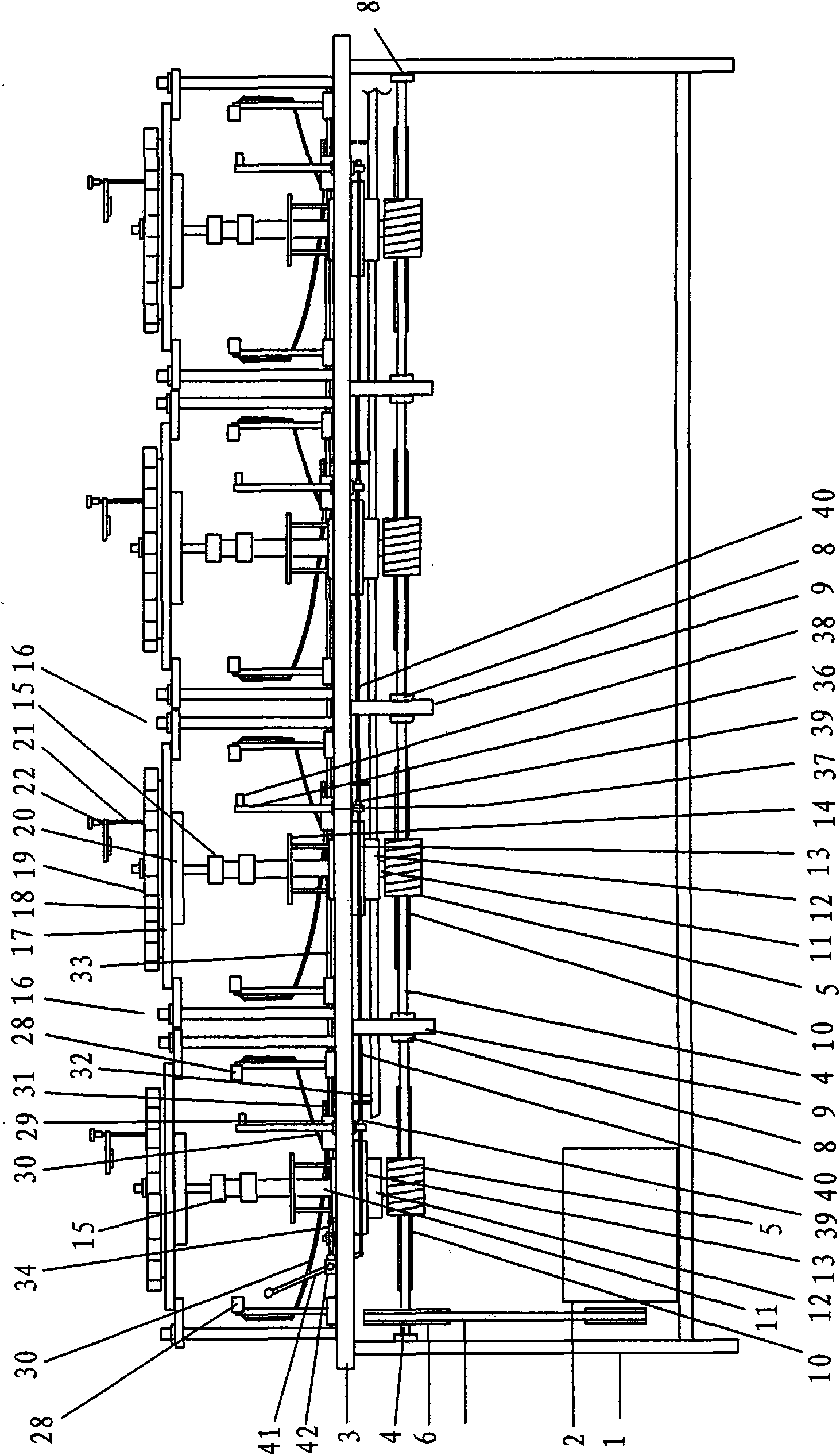

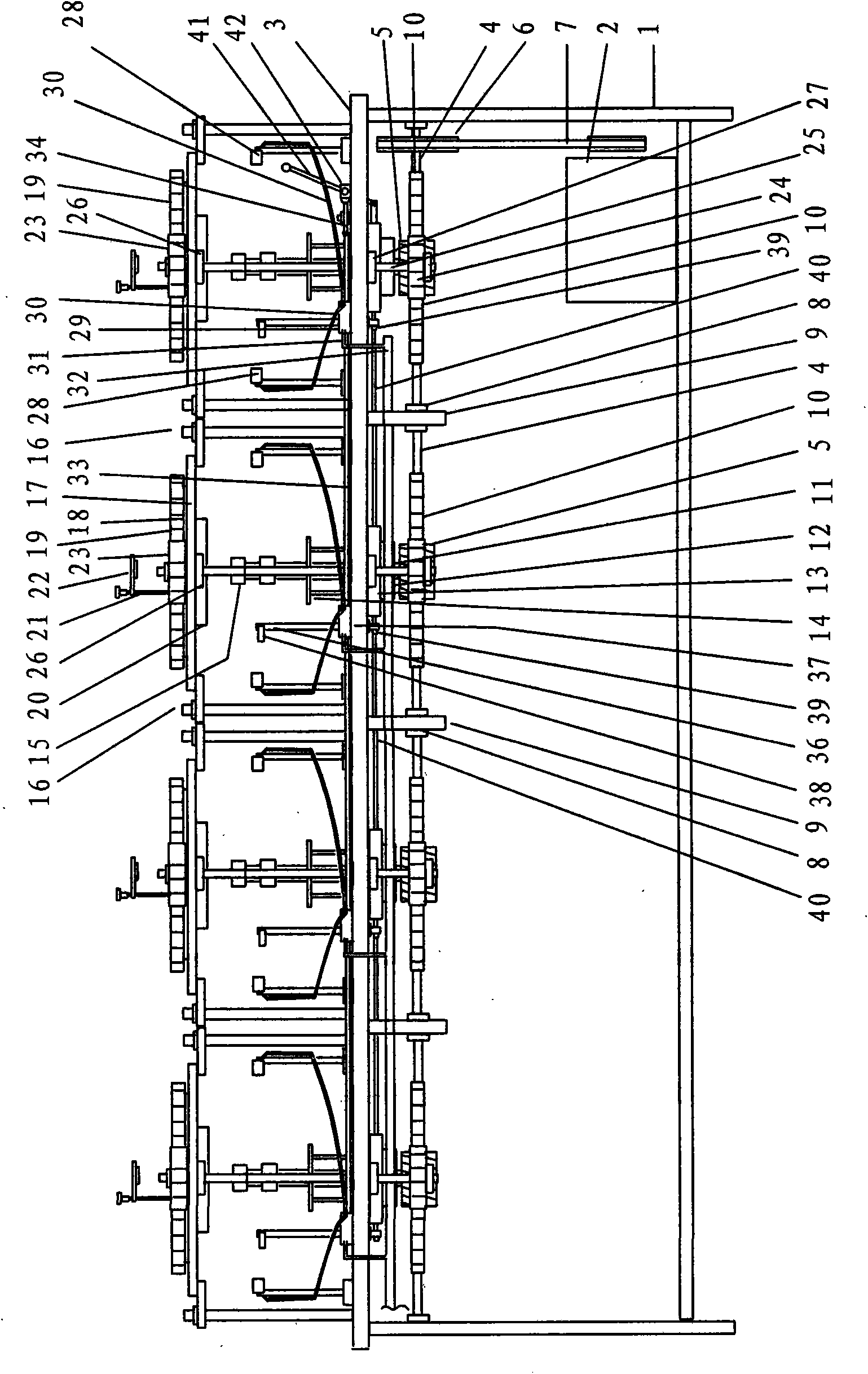

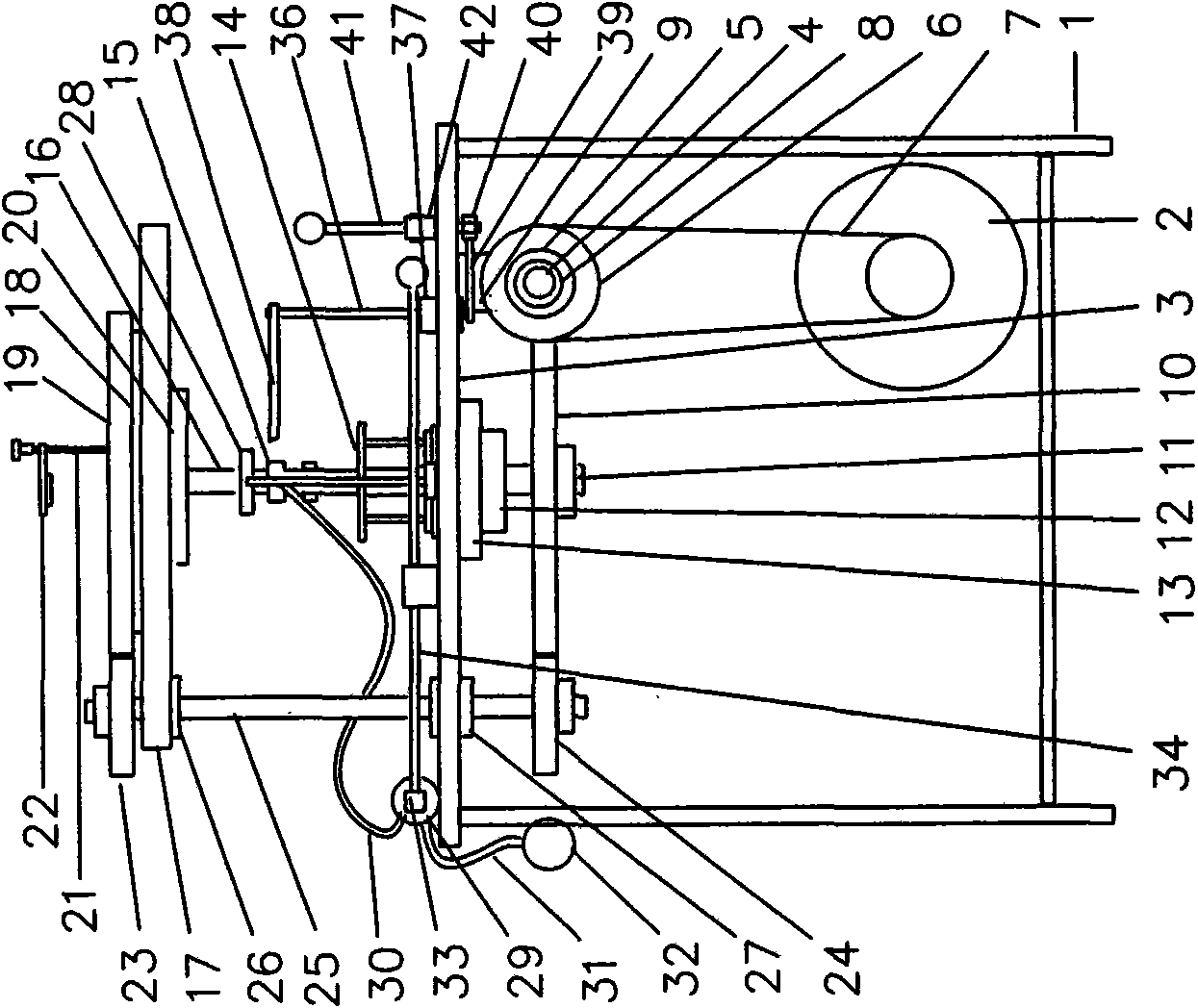

[0012] Figure 1-4 The lower left side of the frame 1 shown in the figure is provided with a motor 2, the motor is equipped with a motor pulley, the upper side of the frame is provided with a workbench 3, and the front lower side of the workbench is equipped with a worm gear shaft 4, and the worm gear shaft is provided with Many groups of driving worm gears 5, the worm gear shaft on the left side of the driving worm gear are provided with a worm shaft pulley 6, and the worm shaft pulley is connected on the motor pulley by a transmission belt 7. The bottom end of the workbench is equipped with a support 9, and the worm gear shaft is installed on the inboard of the frame and the support by the worm gear bearing 8. The rear side of the worm gear shaft is provided with multiple sets of vertical shafts 11, and the vertical shafts are installed on the workbench by the vertical shaft bearings 12 and bearing sleeves 13. The lower end of the vertical shaft is equipped with a passive he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com