Full-automatic electrodeless lamp sealing machine

A technology of electrodeless lamps and sealing machines, which is applied in the direction of electric tube/lamp closing, etc., which can solve the problems of low production efficiency, uncompact connection between processes, and different diameters of sealing parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

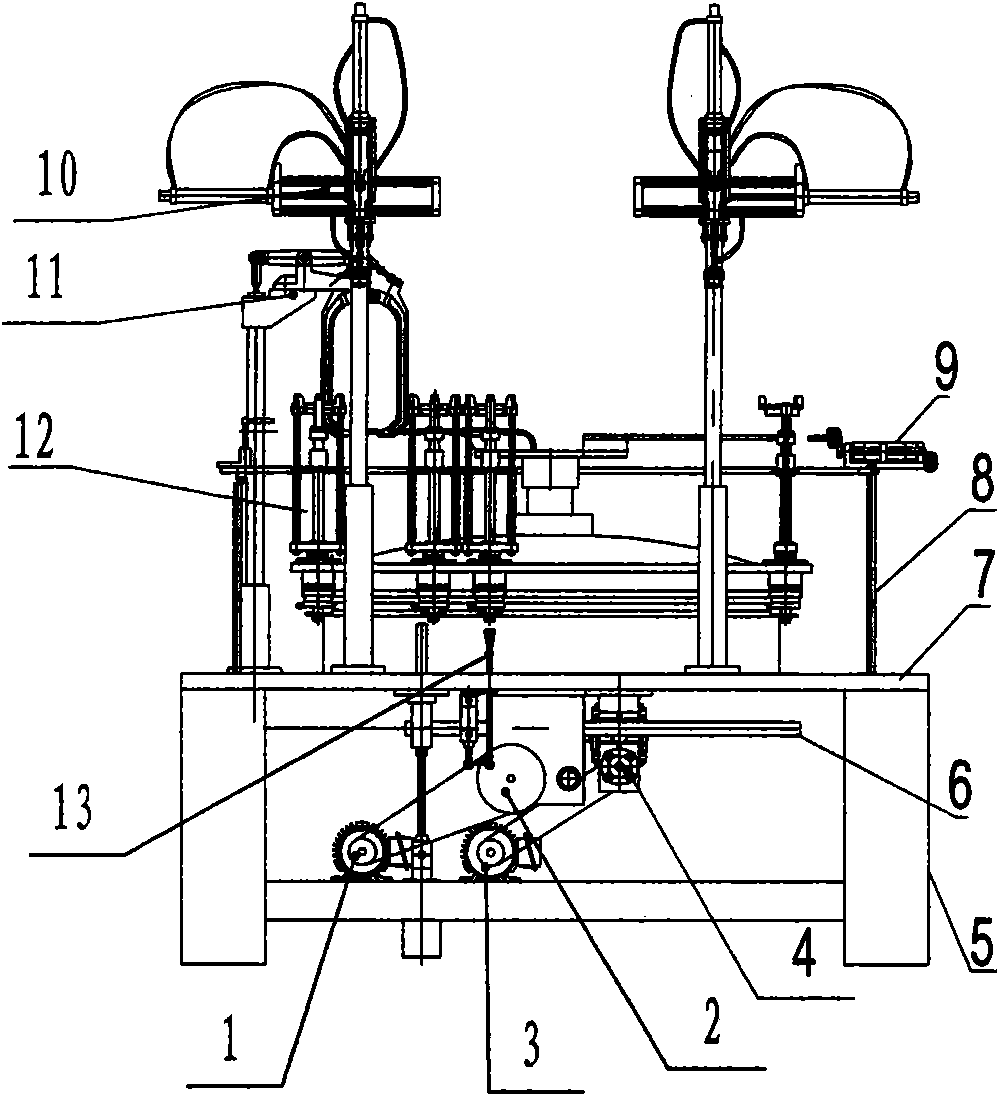

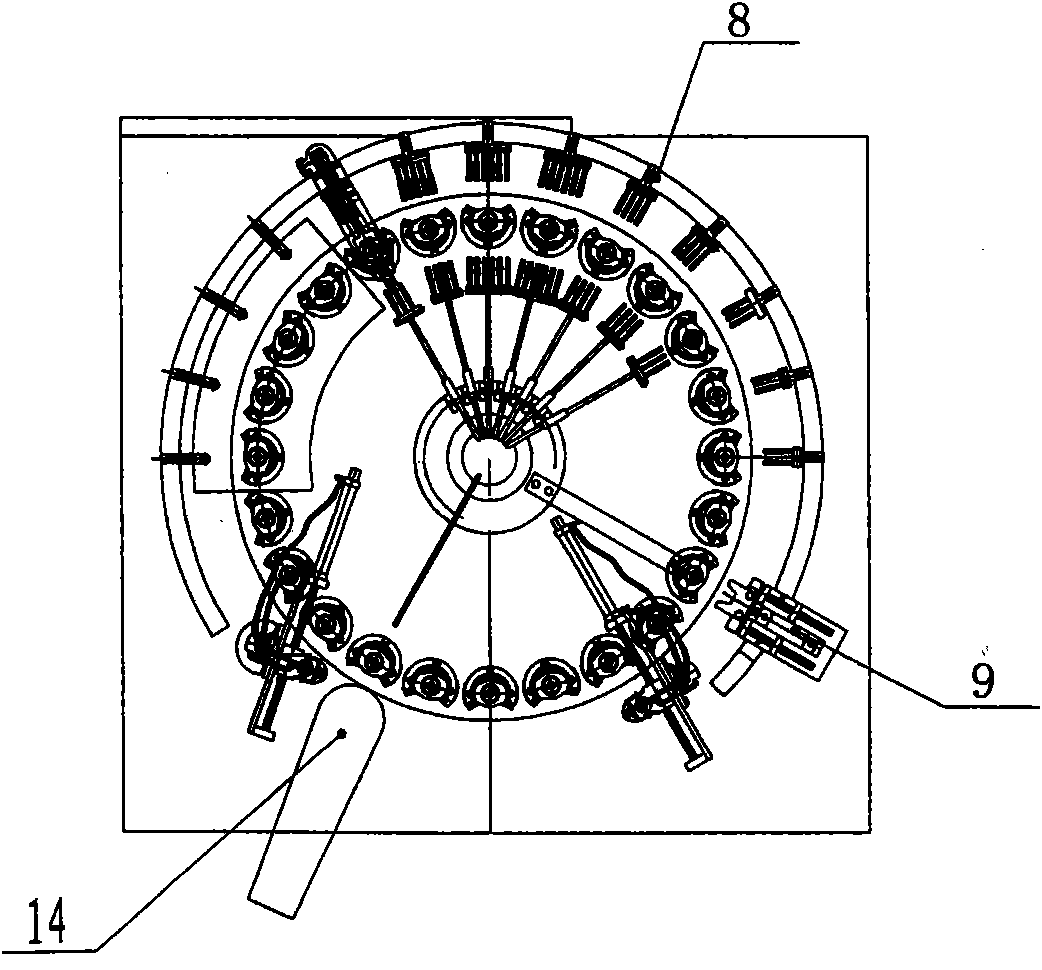

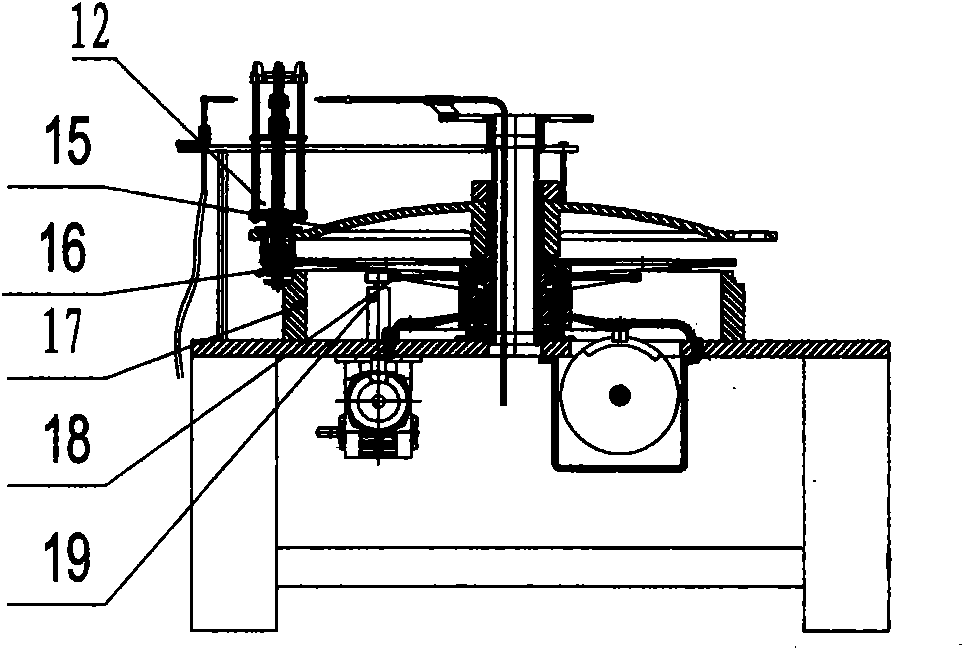

[0019] refer to figure 1 , figure 2 with image 3 , The present invention comprises frame 5 and main motor 1, auxiliary motor 3, speed reducer 4, manipulator 10, mold clamping mechanism 11, shaping mechanism 9, blowing exhaust pipe 14, blowing device 13. A surface 7 is arranged above the frame 5, and a main motor 1, an auxiliary motor 3, a reducer 4, a shift cam pulley 2, and a shift cam 6 are installed at the lower end of the table 7, and the main motor 1 and the shift cam pulley 2 connection, the auxiliary motor 3 is connected with the reducer 4, the reducer 4 is connected with the transposition cam 6, and the runway 17, the fire frame 8, the exhaust pipe 14, the blower device 13, the clamping mechanism 11, and the manipulator are installed on the table 7 10. Shaping mechanism 9 is housed on fire frame 8, and station 12 is housed on runway 7 top, and big aluminum plate 15, big toothed plate 16, bevel toothed plate 19 are housed on station 12, and a lower end of big tooth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com