Patents

Literature

69results about "Non-electron-emitting control electrodes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

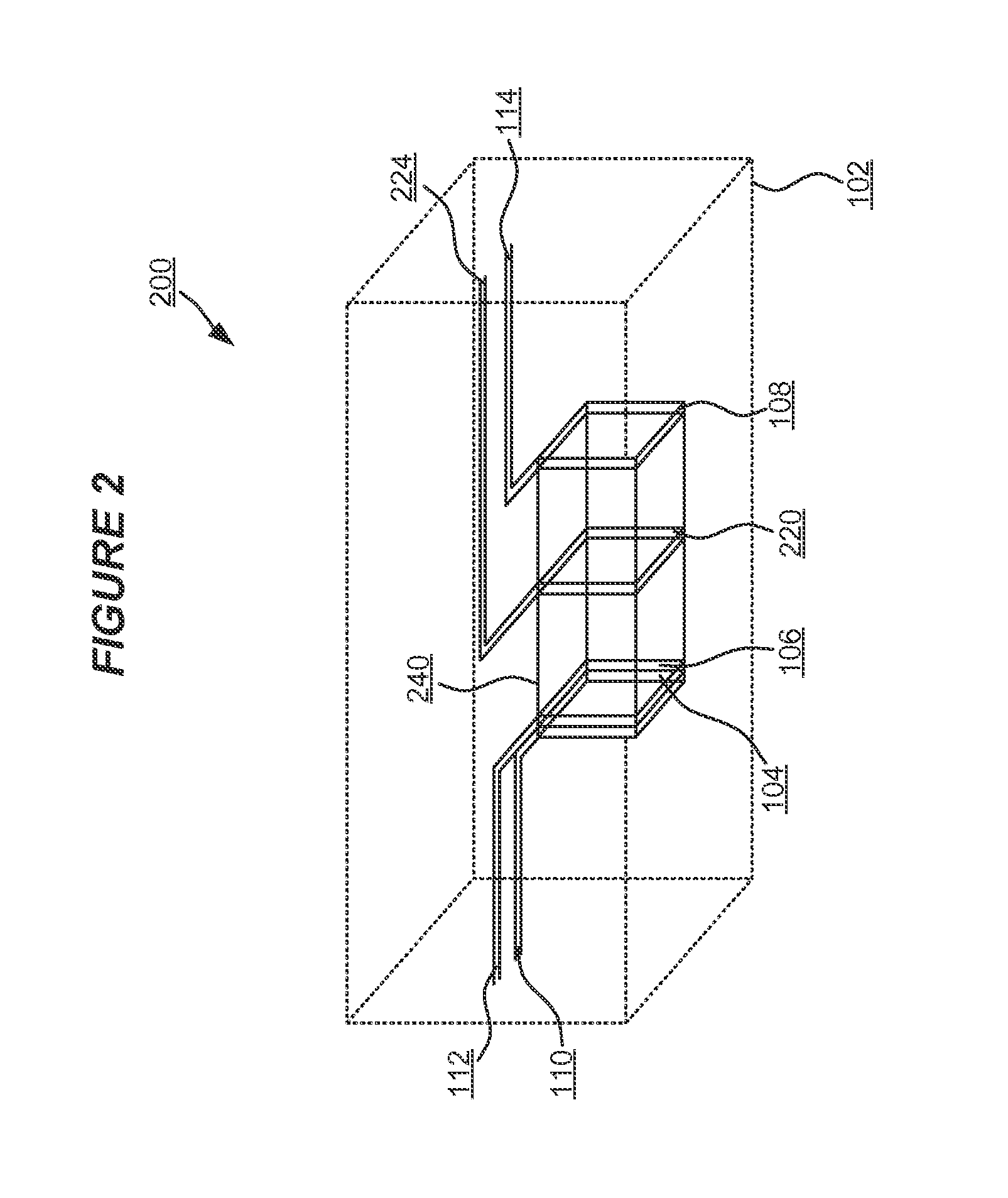

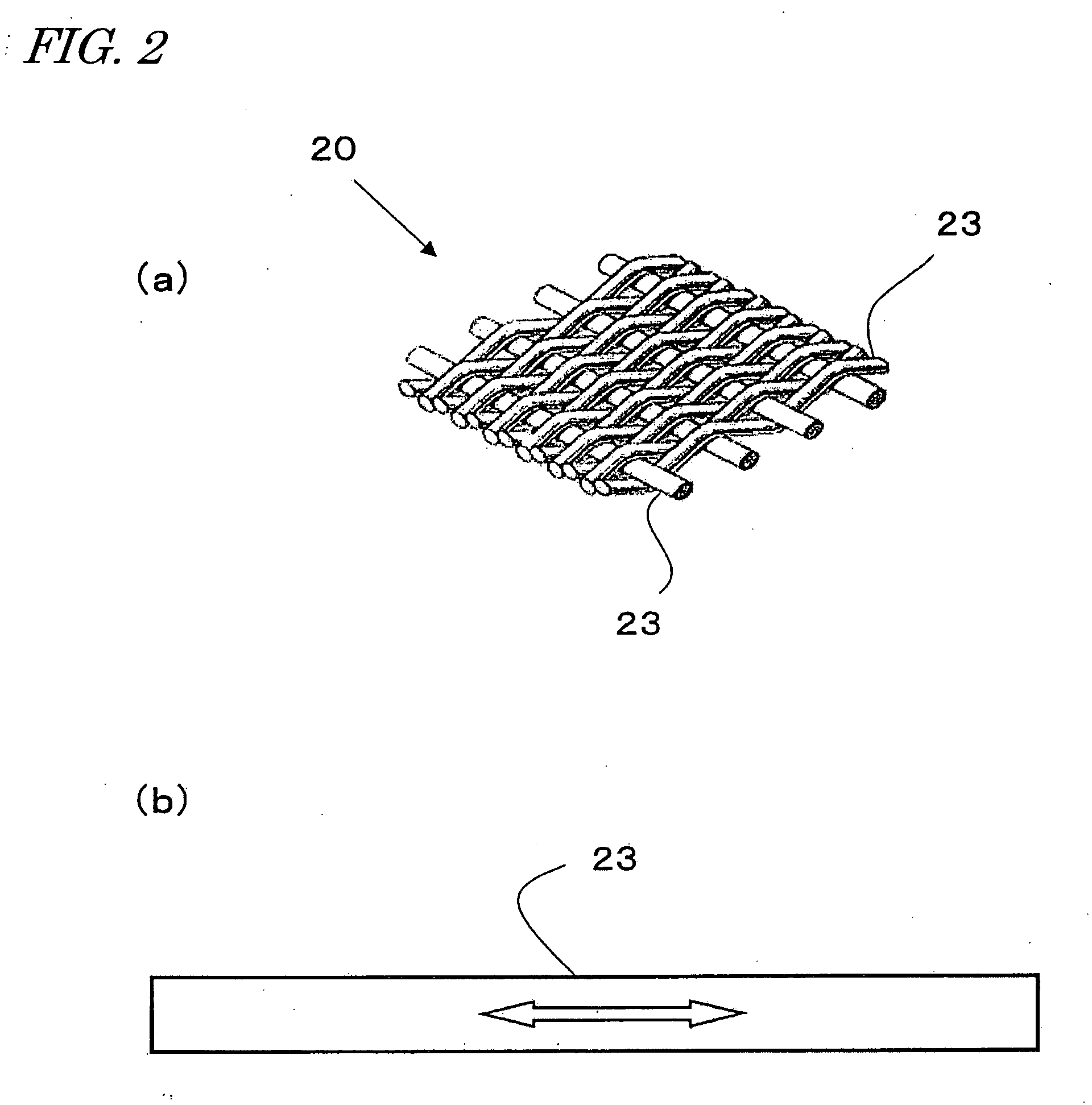

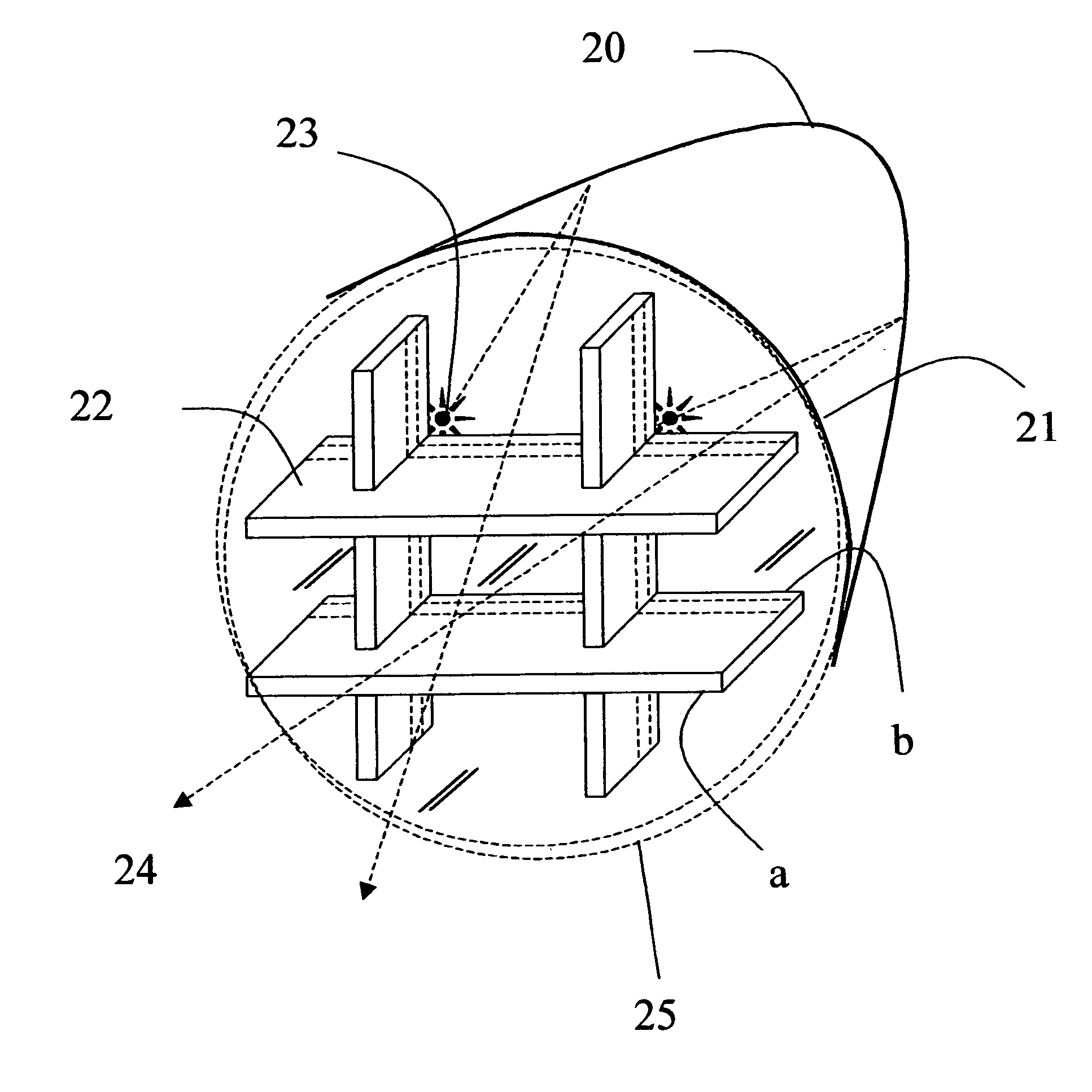

Triodes using nanofabric articles and methods of making the same

Vacuum microelectronic devices with carbon nanotube films, layers, ribbons and fabrics are provided. The present invention discloses microelectronic vacuum devices including triode structures that include three-terminals (an emitter, a grid and an anode), and also higher-order devices such as tetrodes and pentodes, all of which use carbon nanotubes to form various components of the devices. In certain embodiments, patterned portions of nanotube fabric may be used as grid / gate components, conductive traces, etc. Nanotube fabrics may be suspended or conformally disposed. In certain embodiments, methods for stiffening a nanotube fabric layer are used. Various methods for applying, selectively removing (e.g. etching), suspending, and stiffening vertically- and horizontally-disposed nanotube fabrics are disclosed, as are CMOS-compatible fabrication methods. In certain embodiments, nanotube fabric triodes provide high-speed, small-scale, low-power devices that can be employed in radiation-intensive applications.

Owner:NANTERO

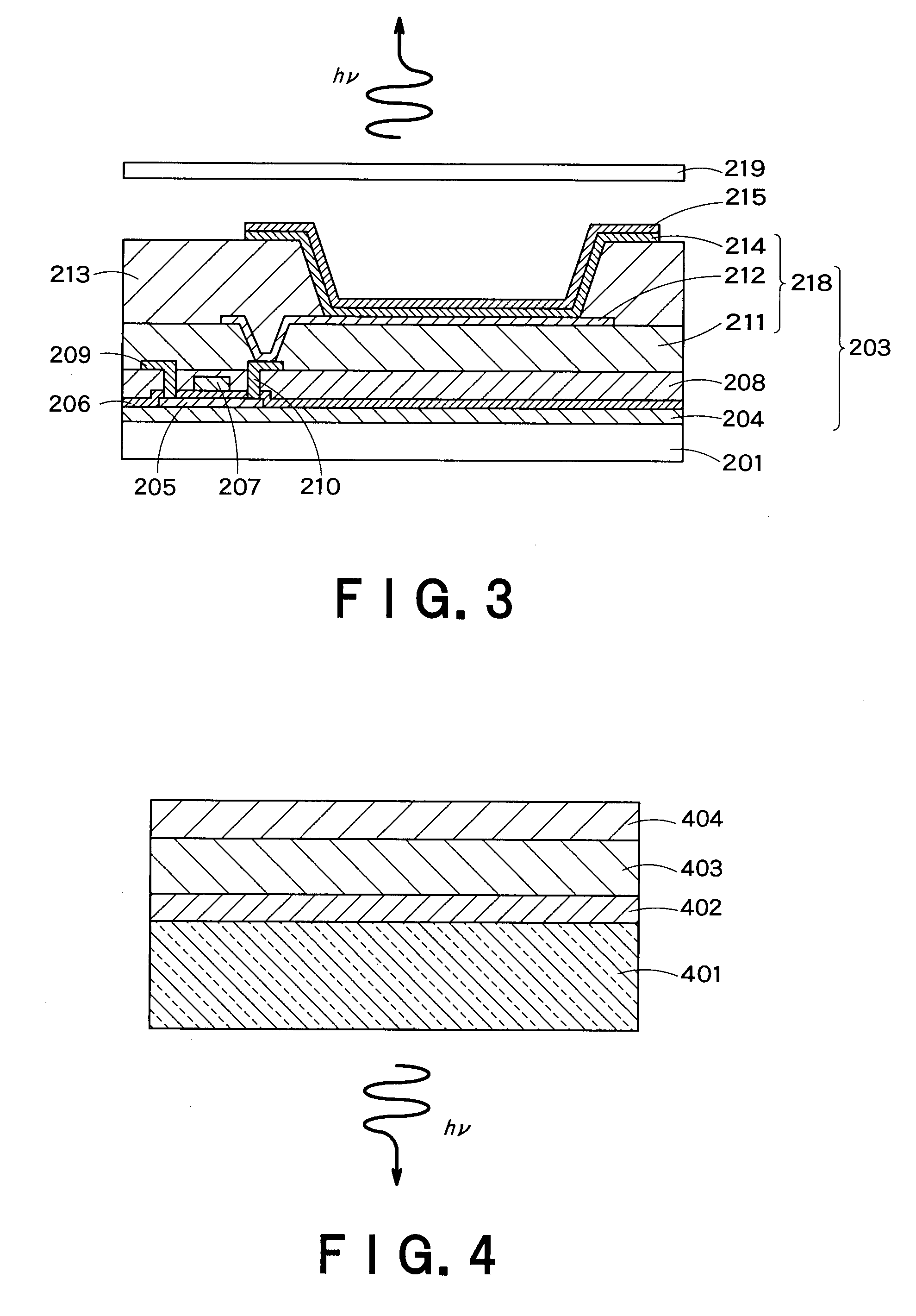

Displaying device and lighting device employing organic electroluminescence element

InactiveUS20090236962A1Shape is not particularly restrictedInhibition is effectiveControl electrodesSolid-state devicesDisplay deviceEffect light

Owner:KK TOSHIBA

Printed active device

ActiveUS20150270089A1Reduce manufacturing costLow costAdditive manufacturing apparatusControl electrodesElement spaceElectrical connection

Owner:BRITISH TELECOMM PLC

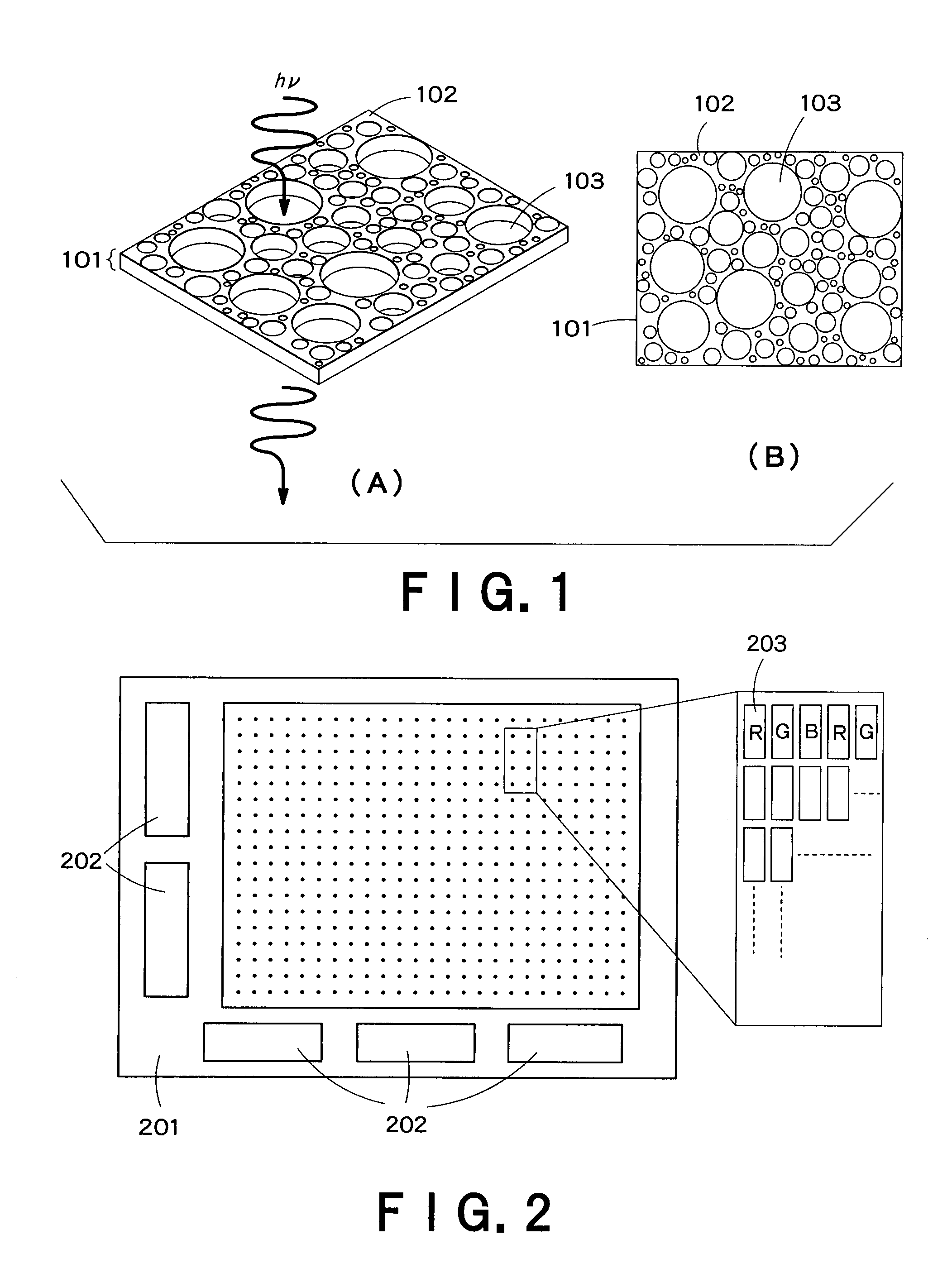

Information storage

InactiveUS20060072427A1Increase speedImprove accuracyRead-only memoriesRecord information storageHigh energyPotential difference

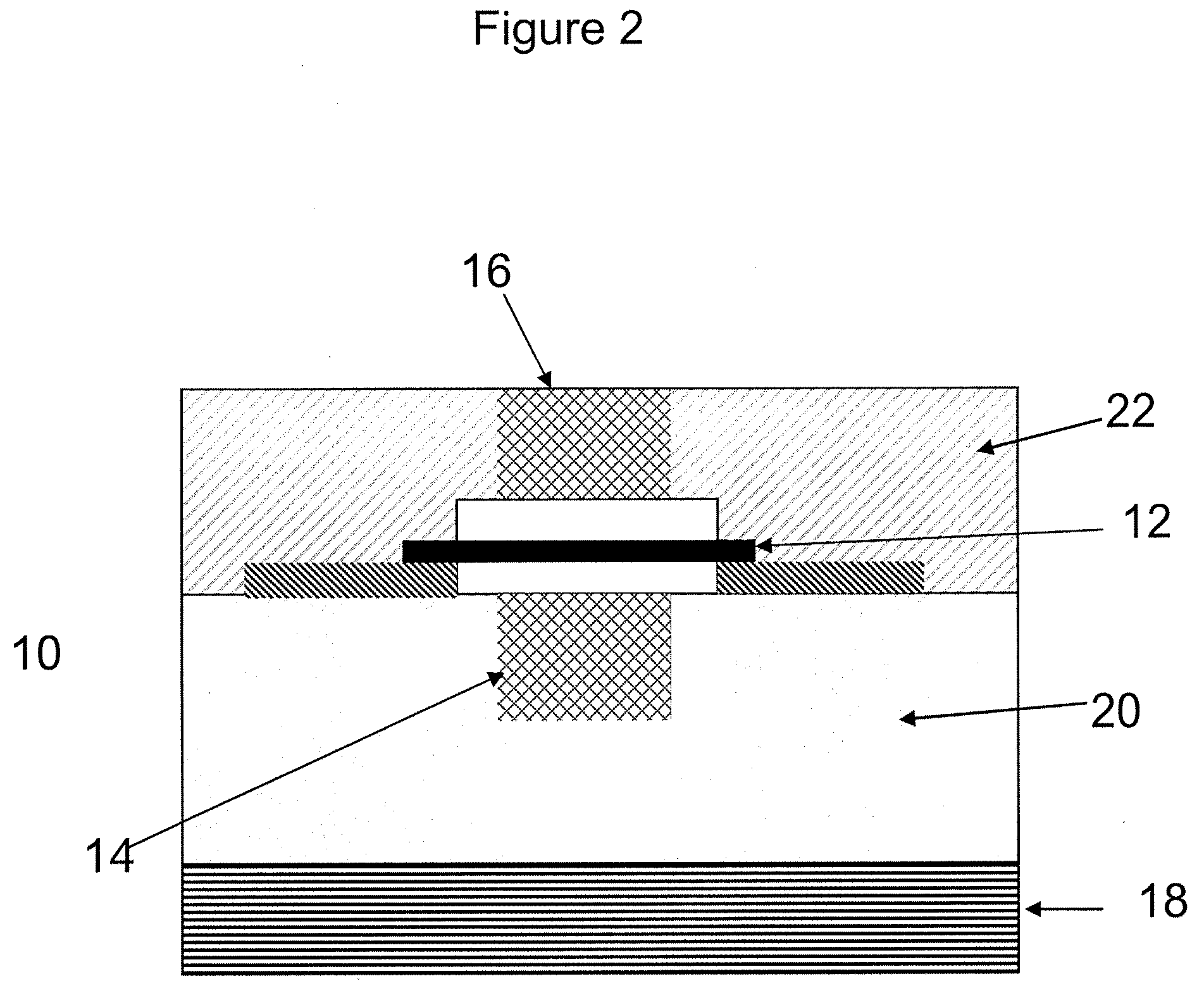

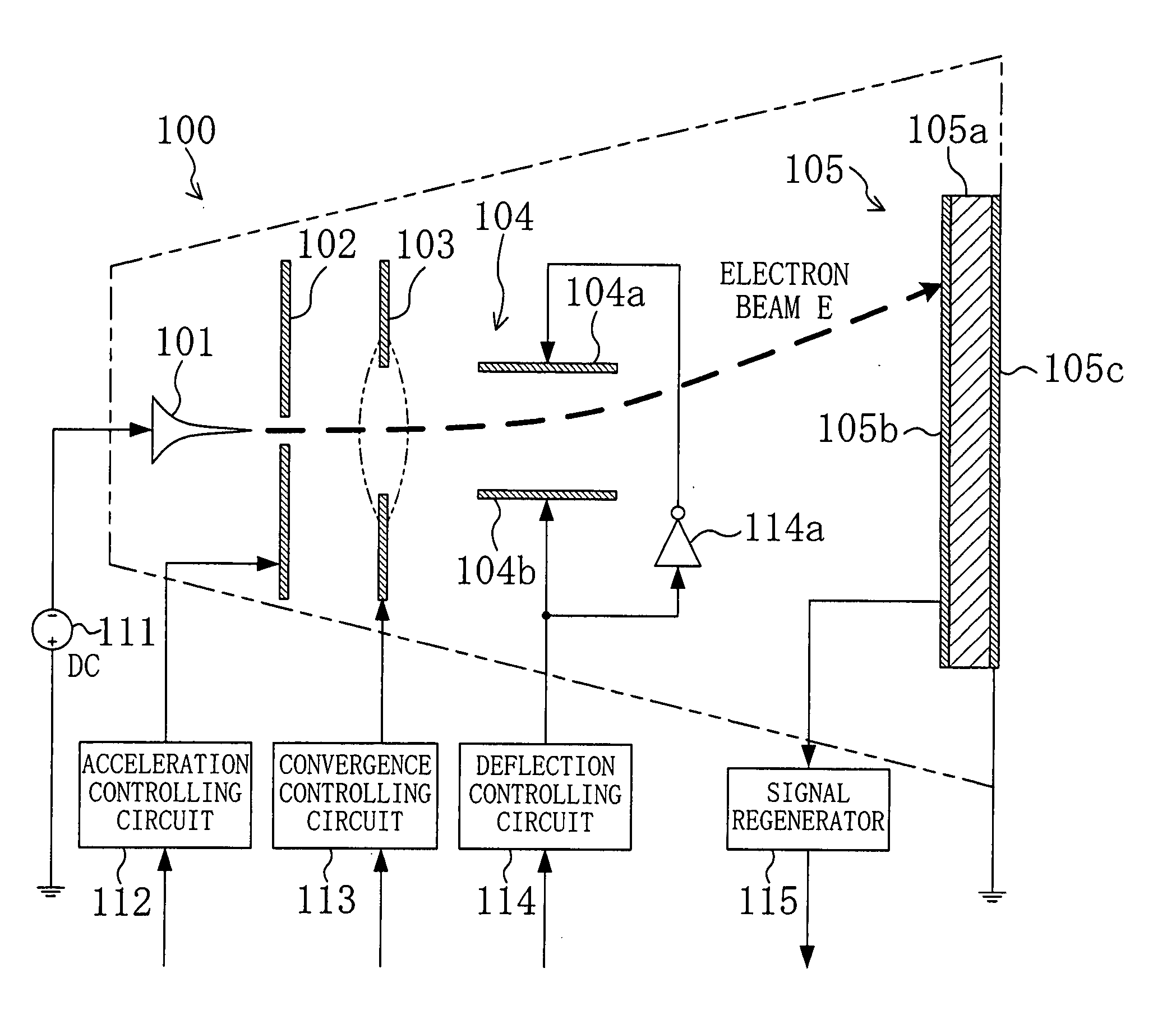

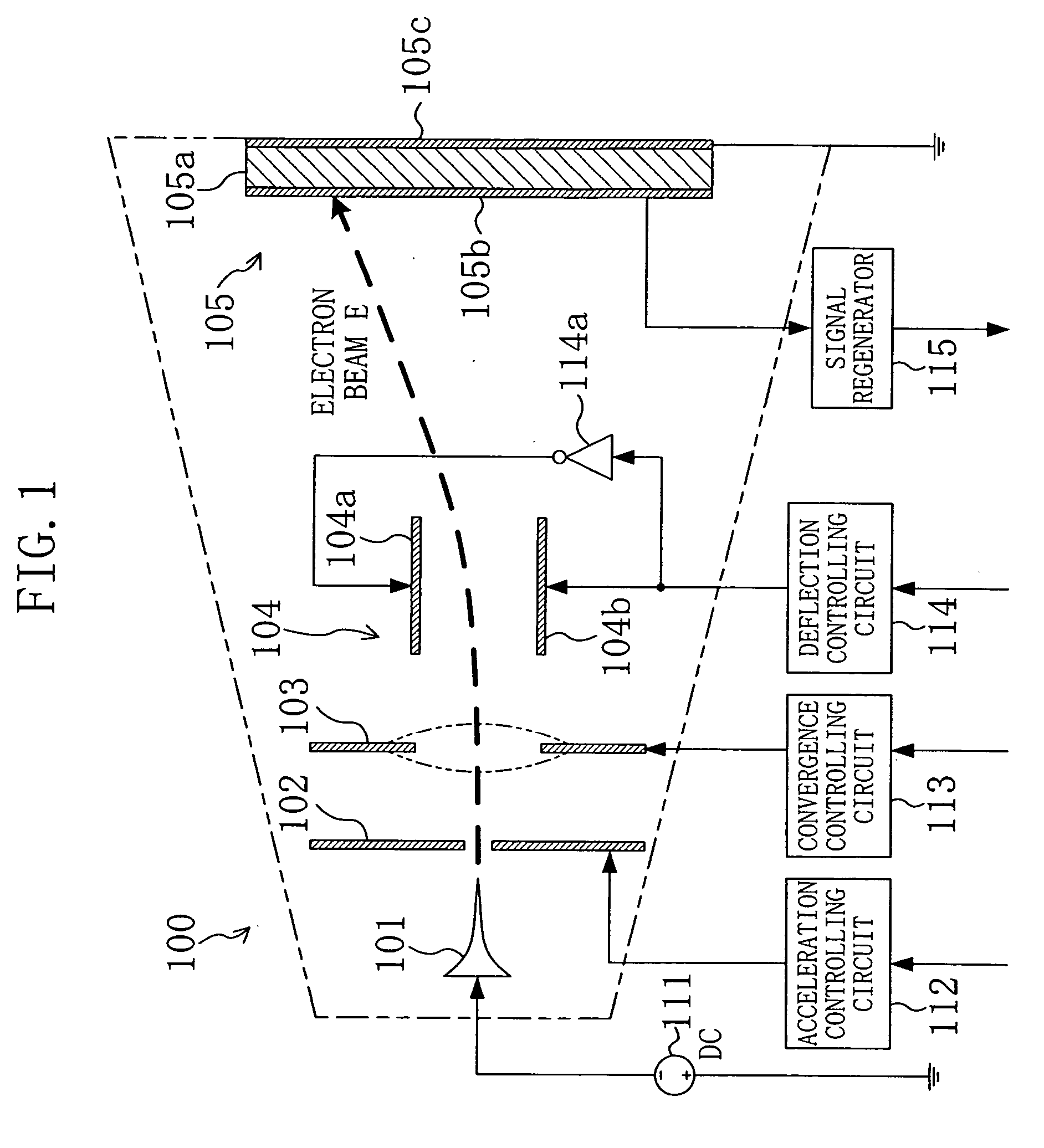

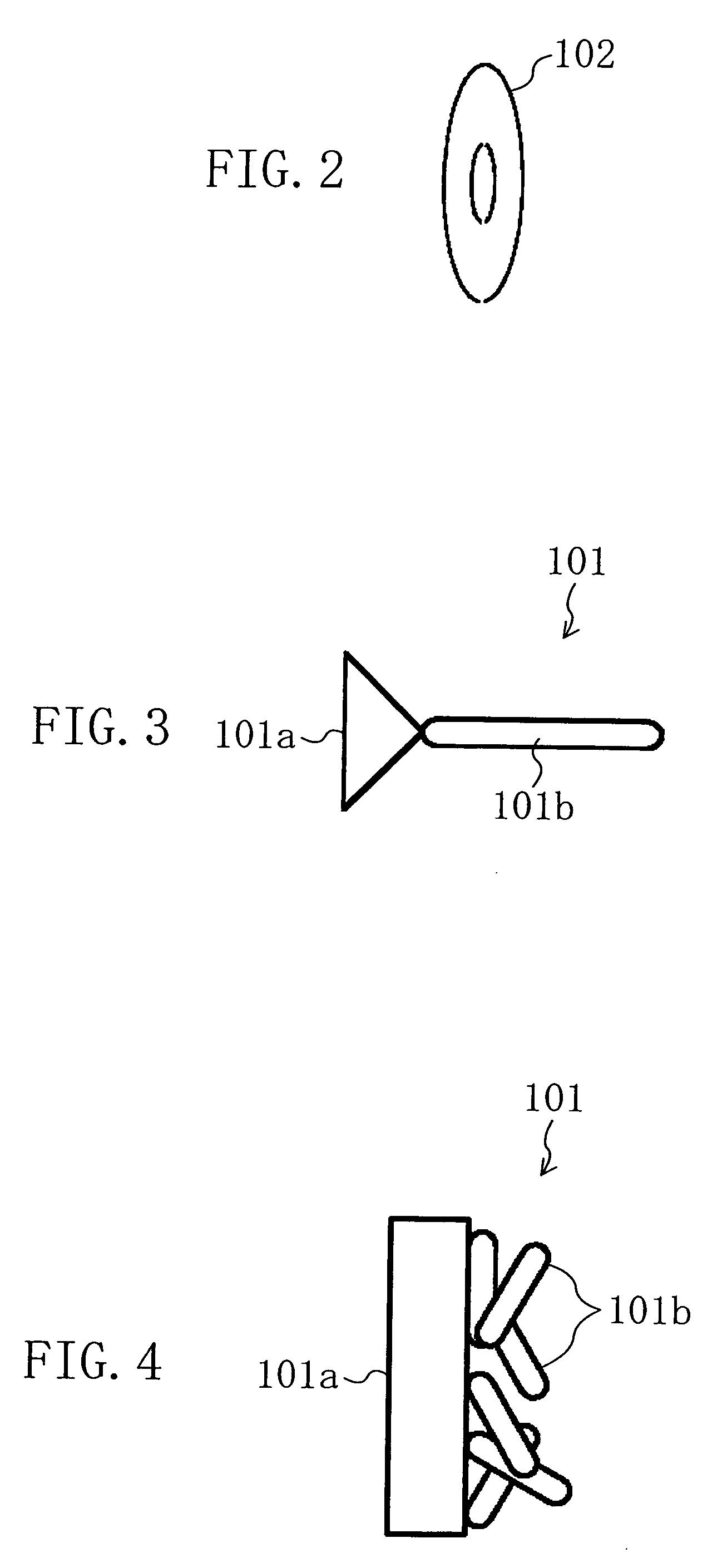

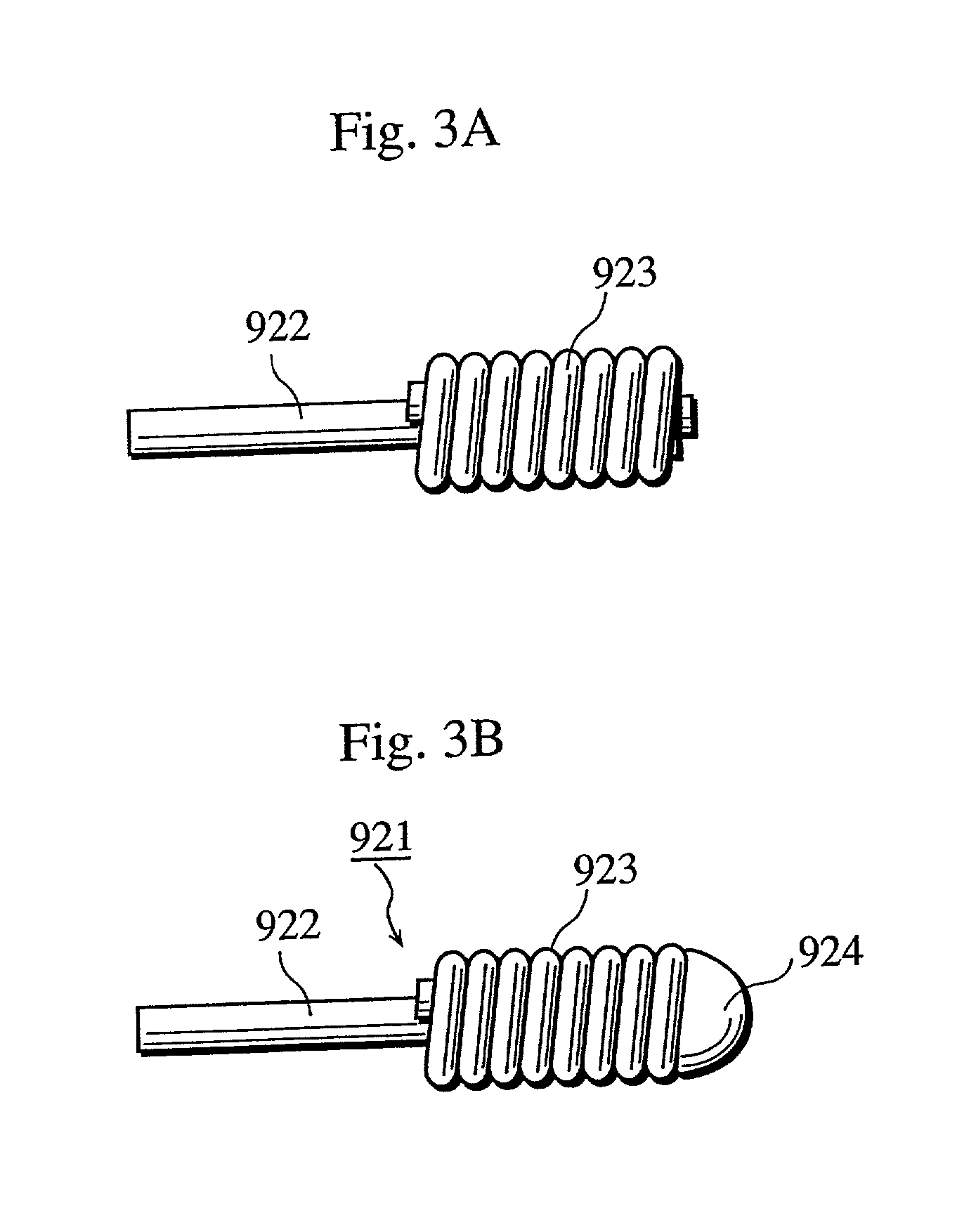

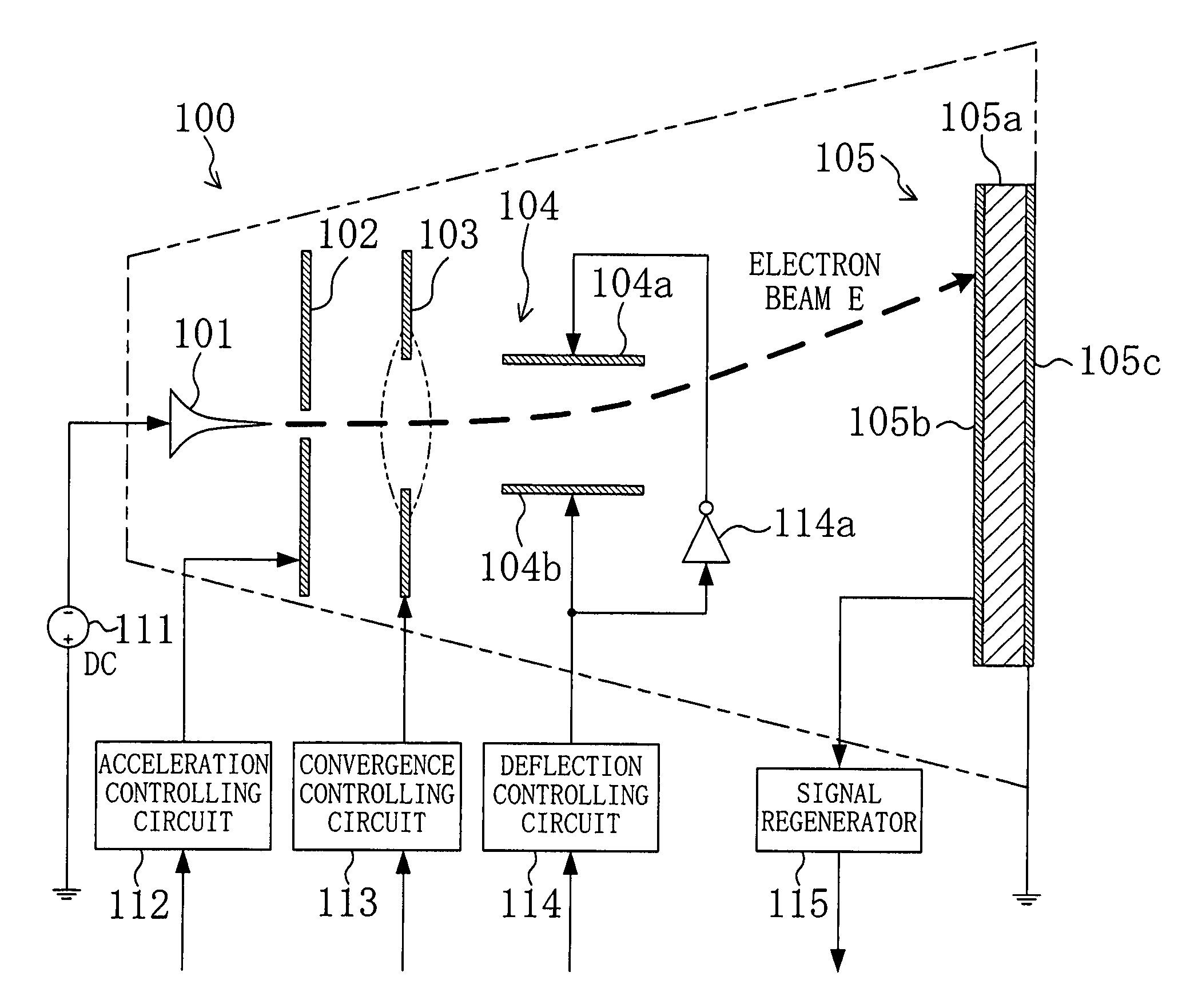

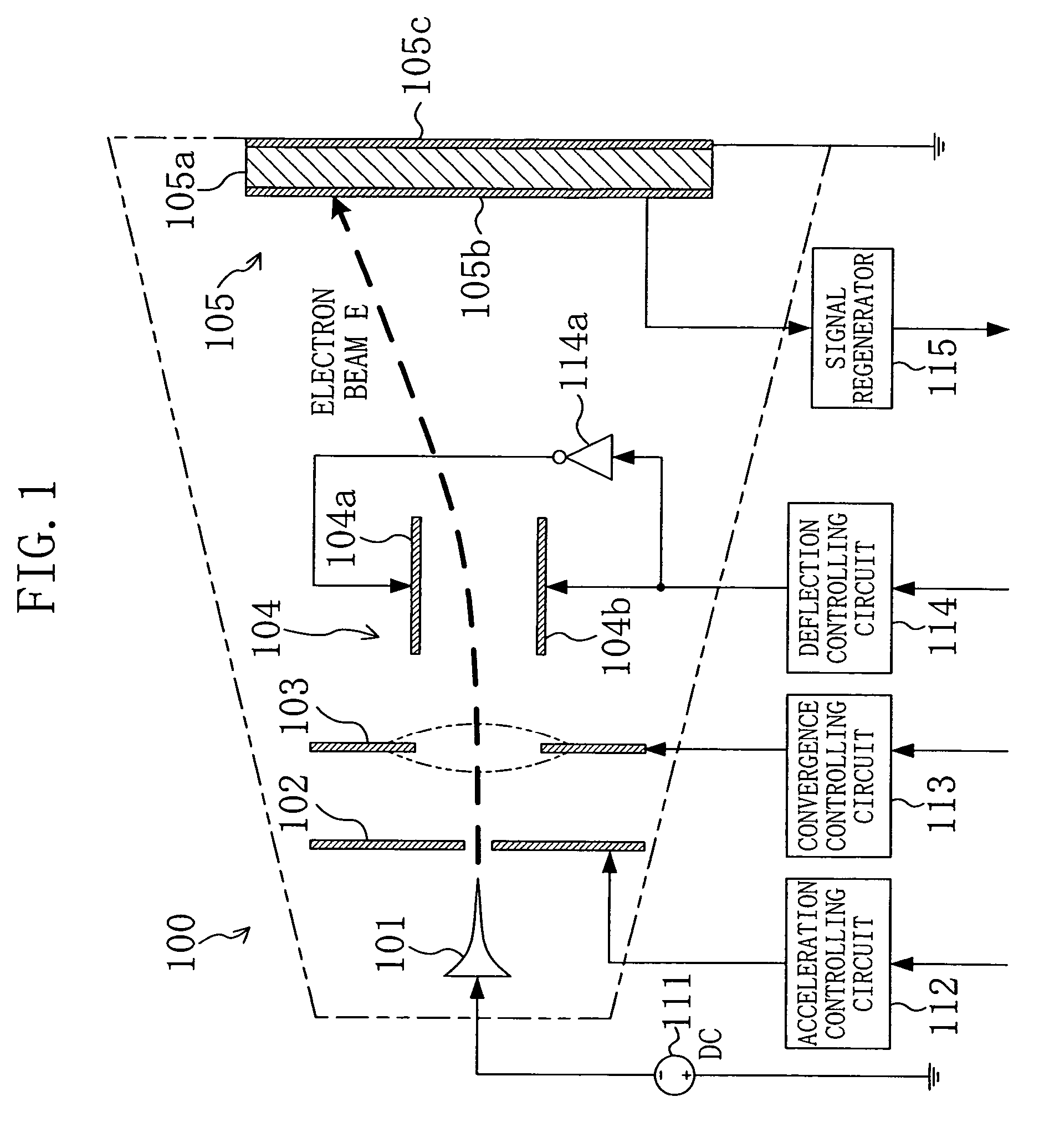

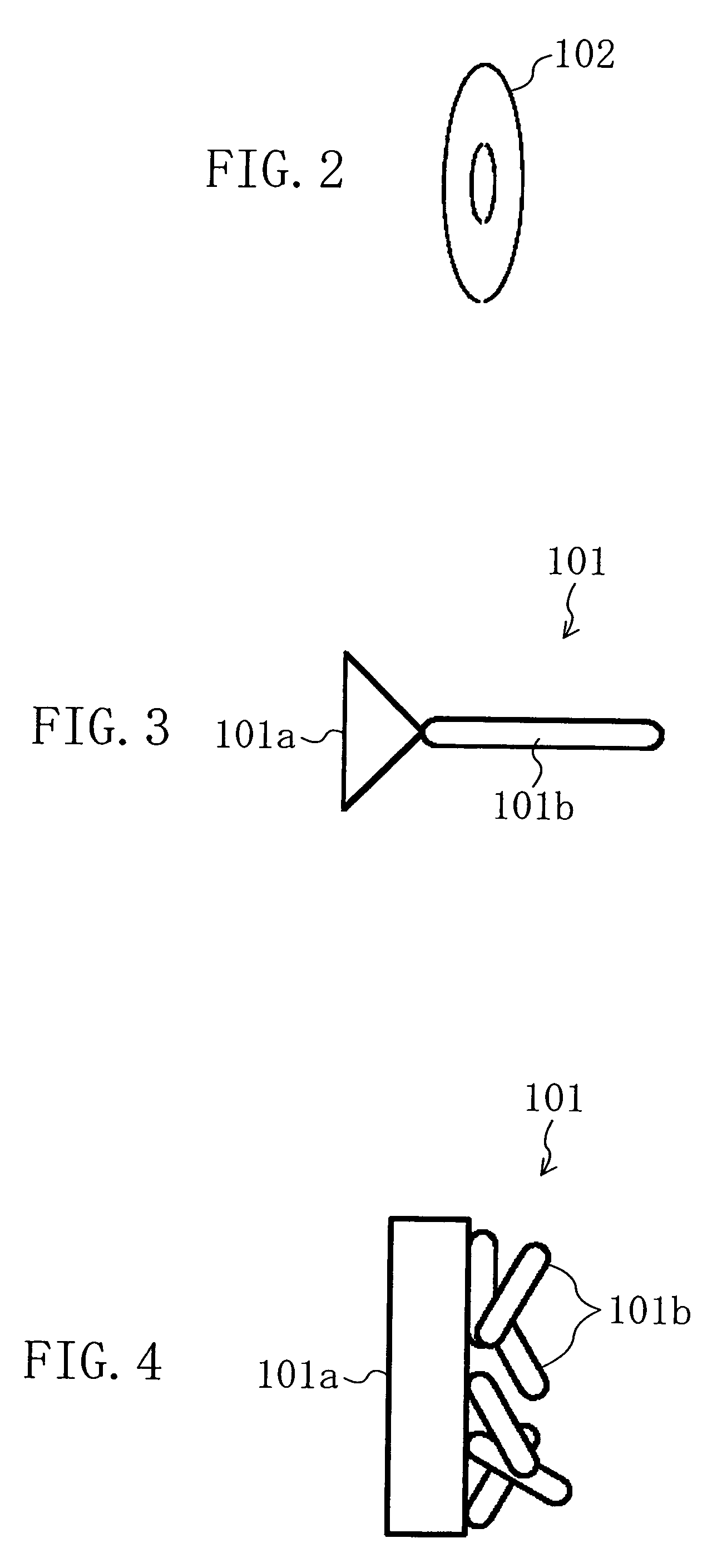

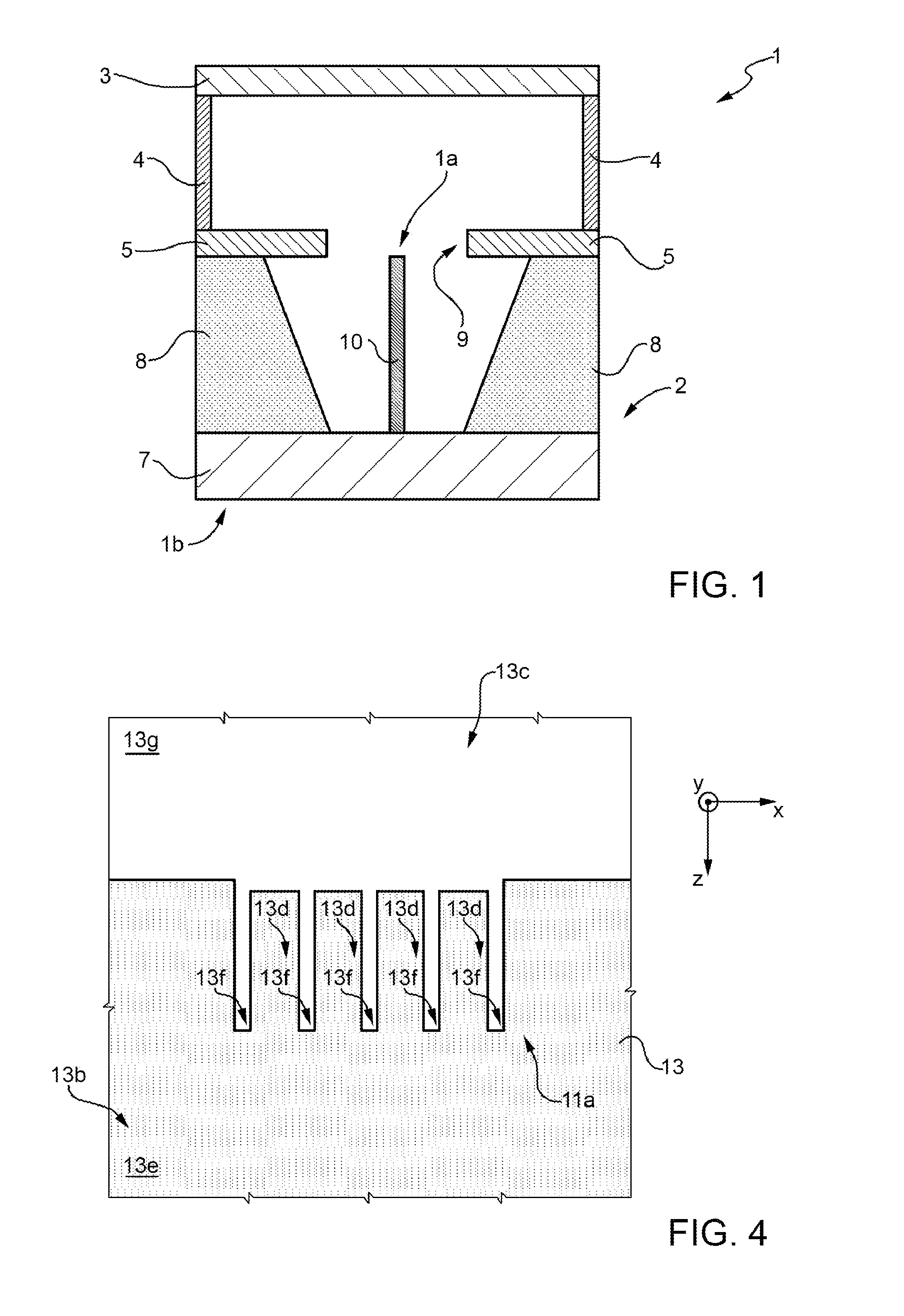

To greatly increase the storage density of a storage apparatus, an electron beam E emitted from a cold cathode 101 is accelerated by an accelerating electrode 102, caused to converge by a convergence electrode 103, deflected by a deflection electrode 104 and applied to a minute region of a storage film 105. The storage film 105 includes, for example, a phase change film 105a. The film is rapidly heated and cooled to change into an amorphous state upon irradiation with an electron beam E with high energy, while being gradually cooled to change into a crystallized state upon irradiation with an electron beam E with approximately intermediate energy, thereby storing data. Upon irradiation with an electron beam E with low energy, the potential difference between a detection electrode 105b and an anode 105c is detected depending on the state, i.e., the amorphous or crystallized state, thereby reading stored data.

Owner:PANASONIC CORP

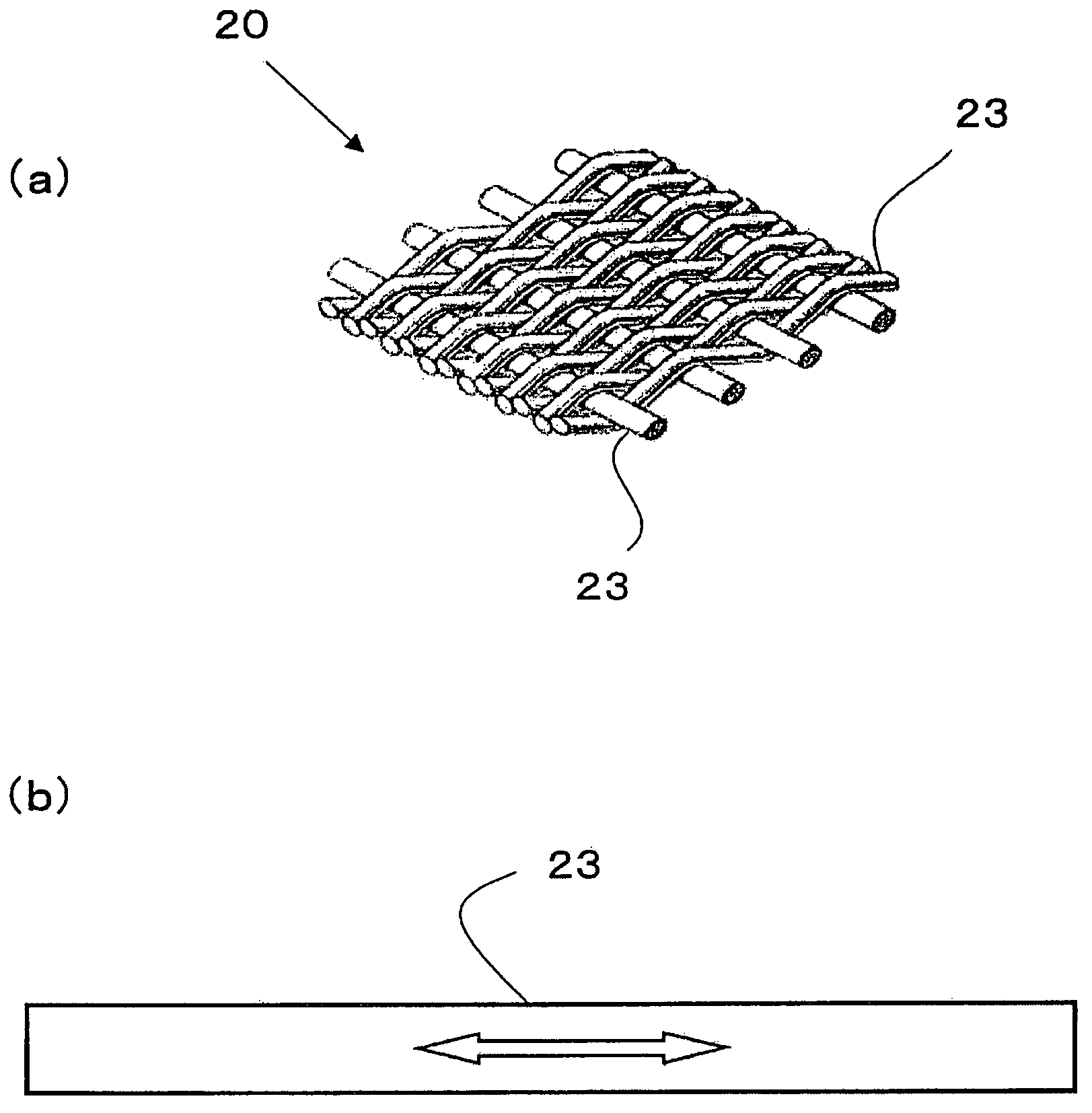

Energy conversion device and production method therefor

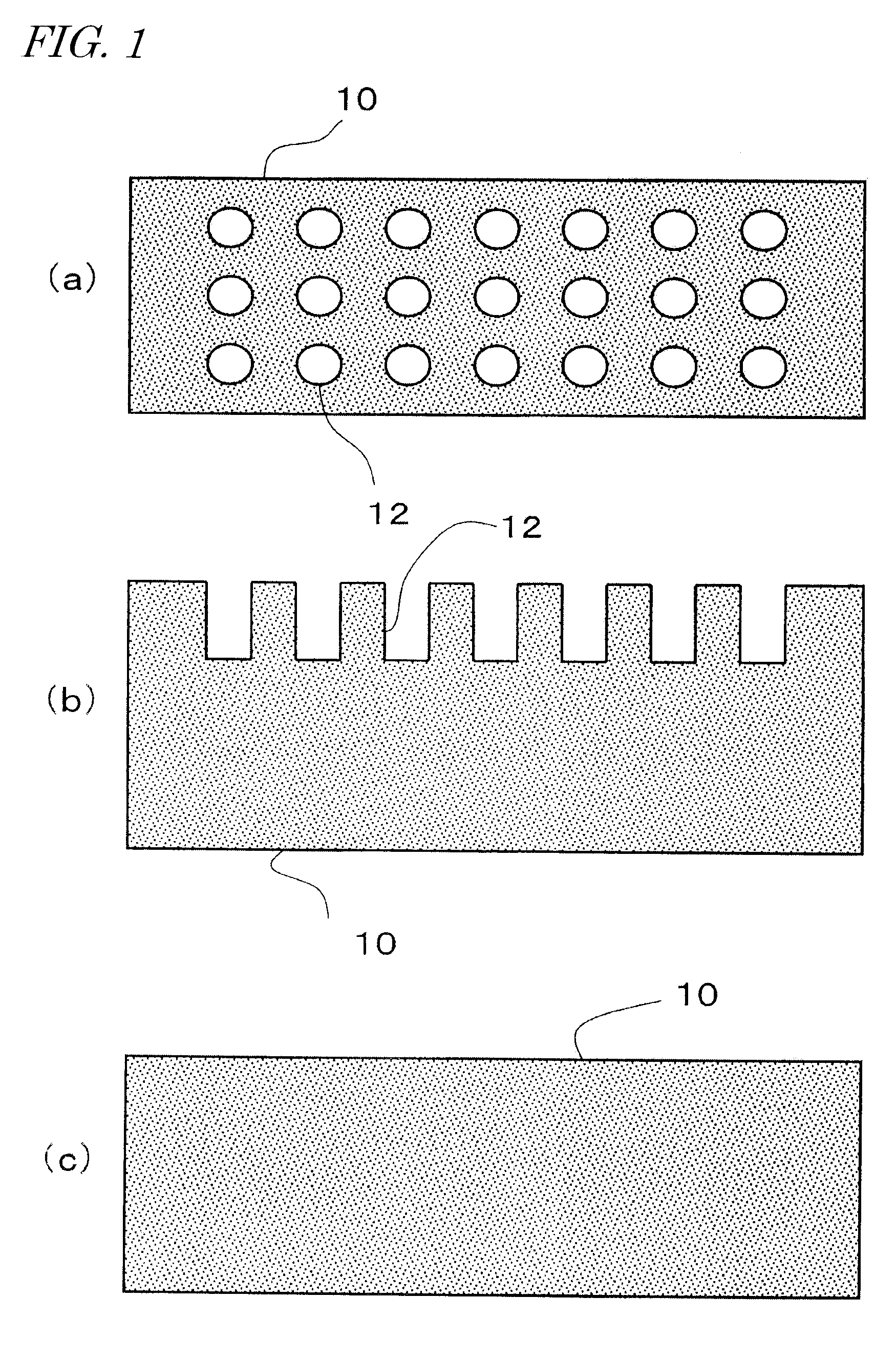

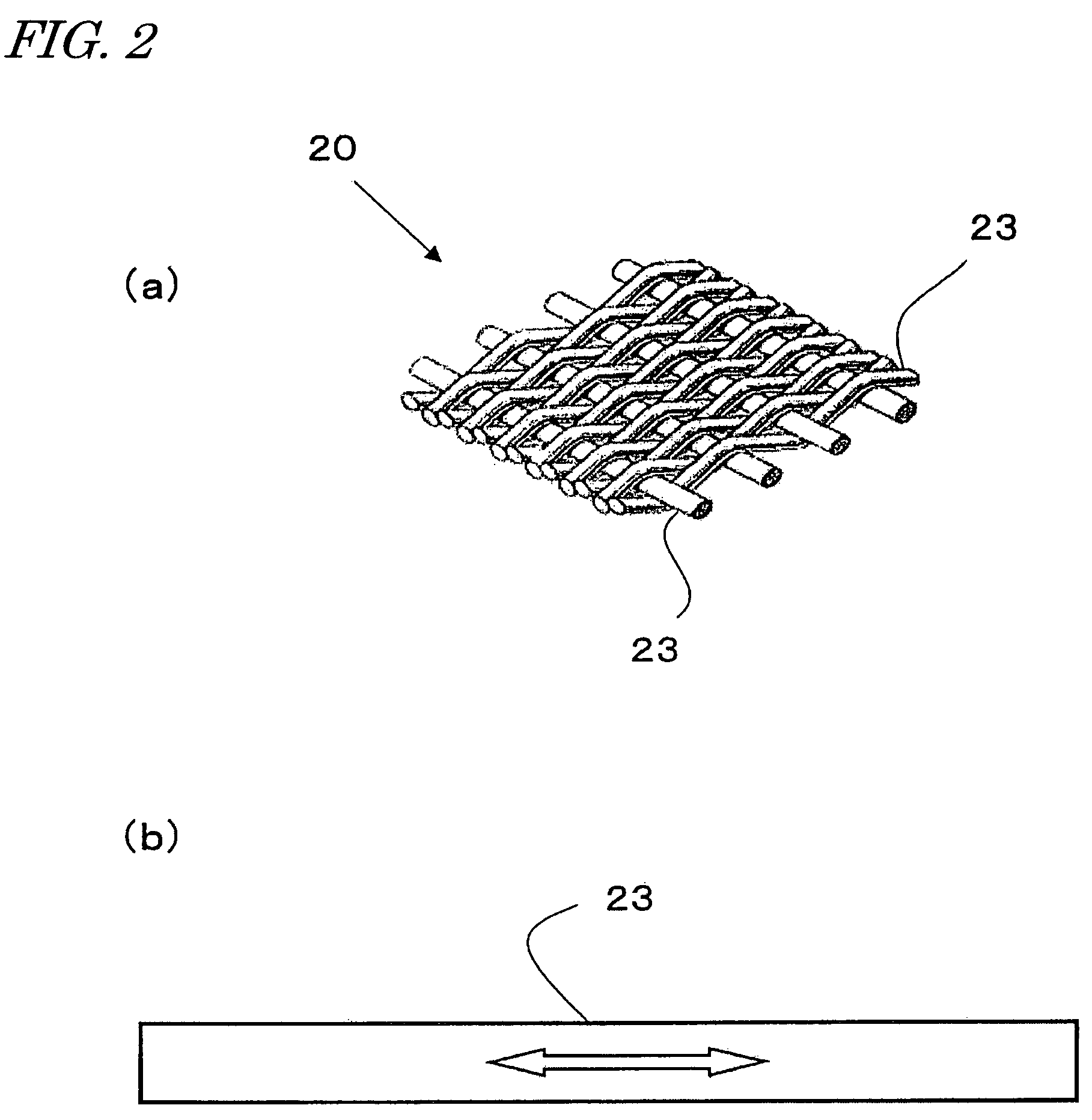

InactiveUS20060132014A1High light efficiencyRaise the ratioControl electrodesCigar manufactureInfraredEngineering

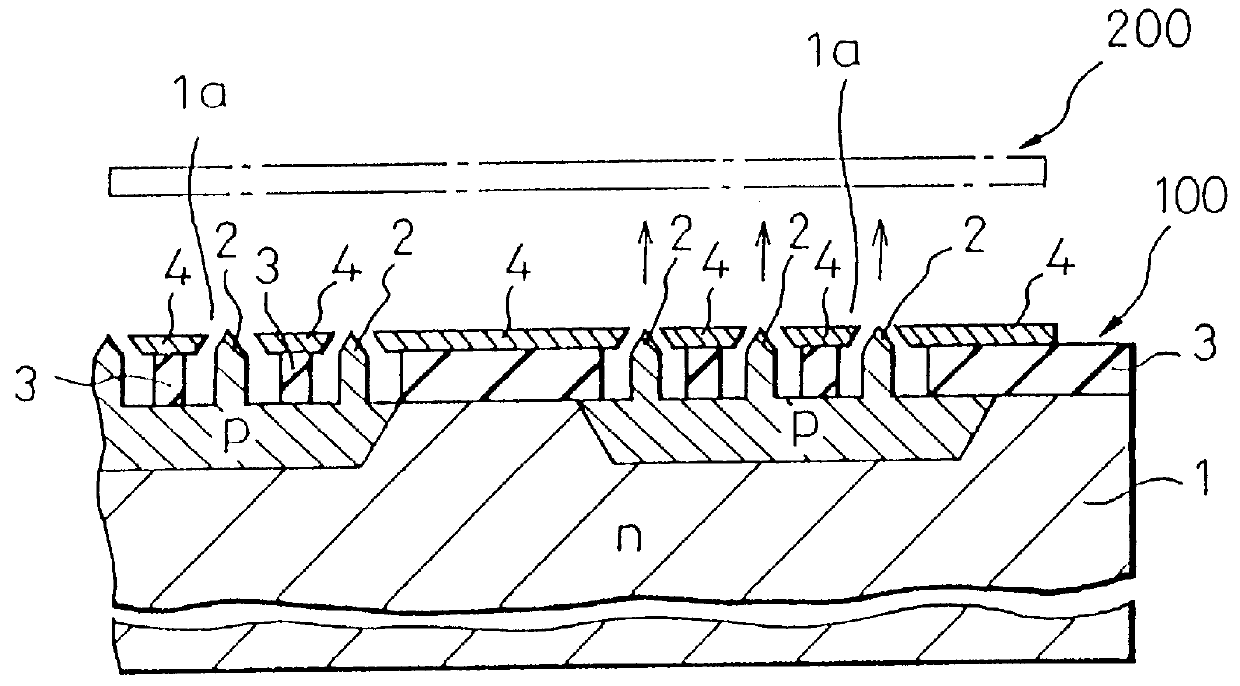

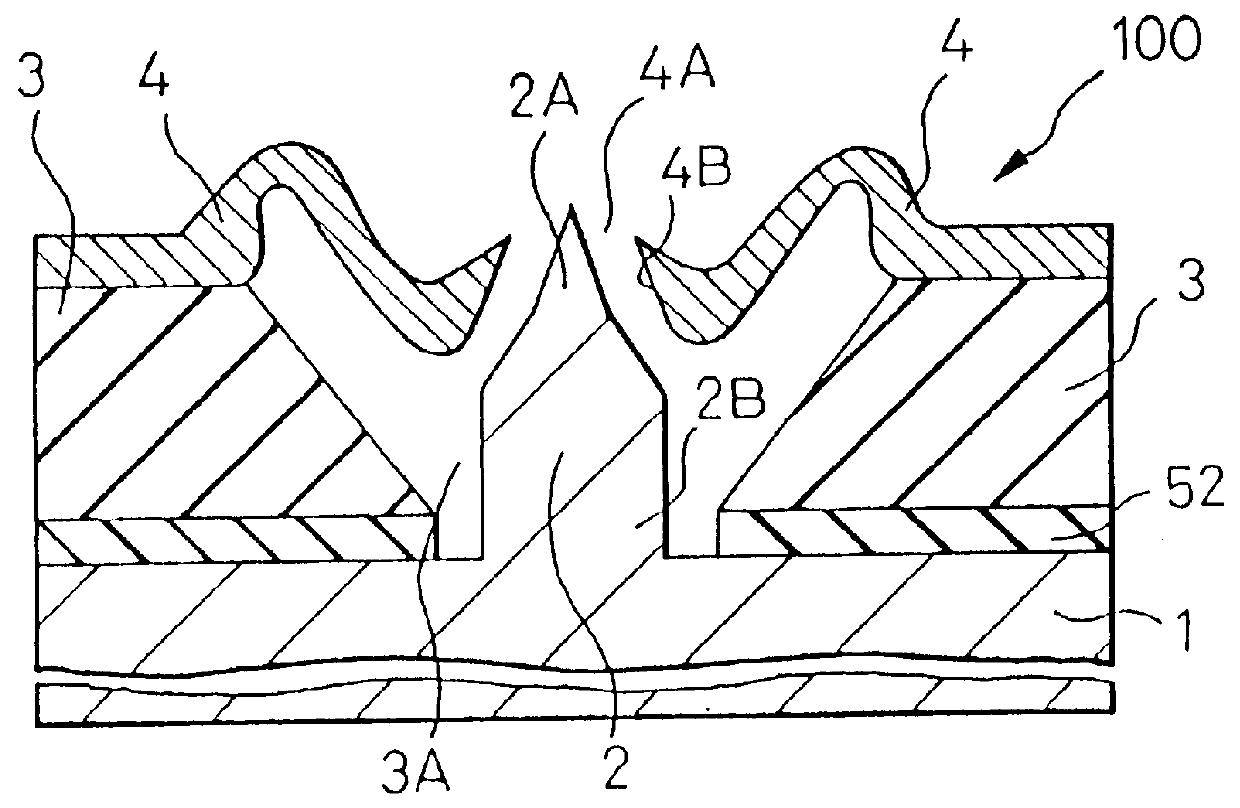

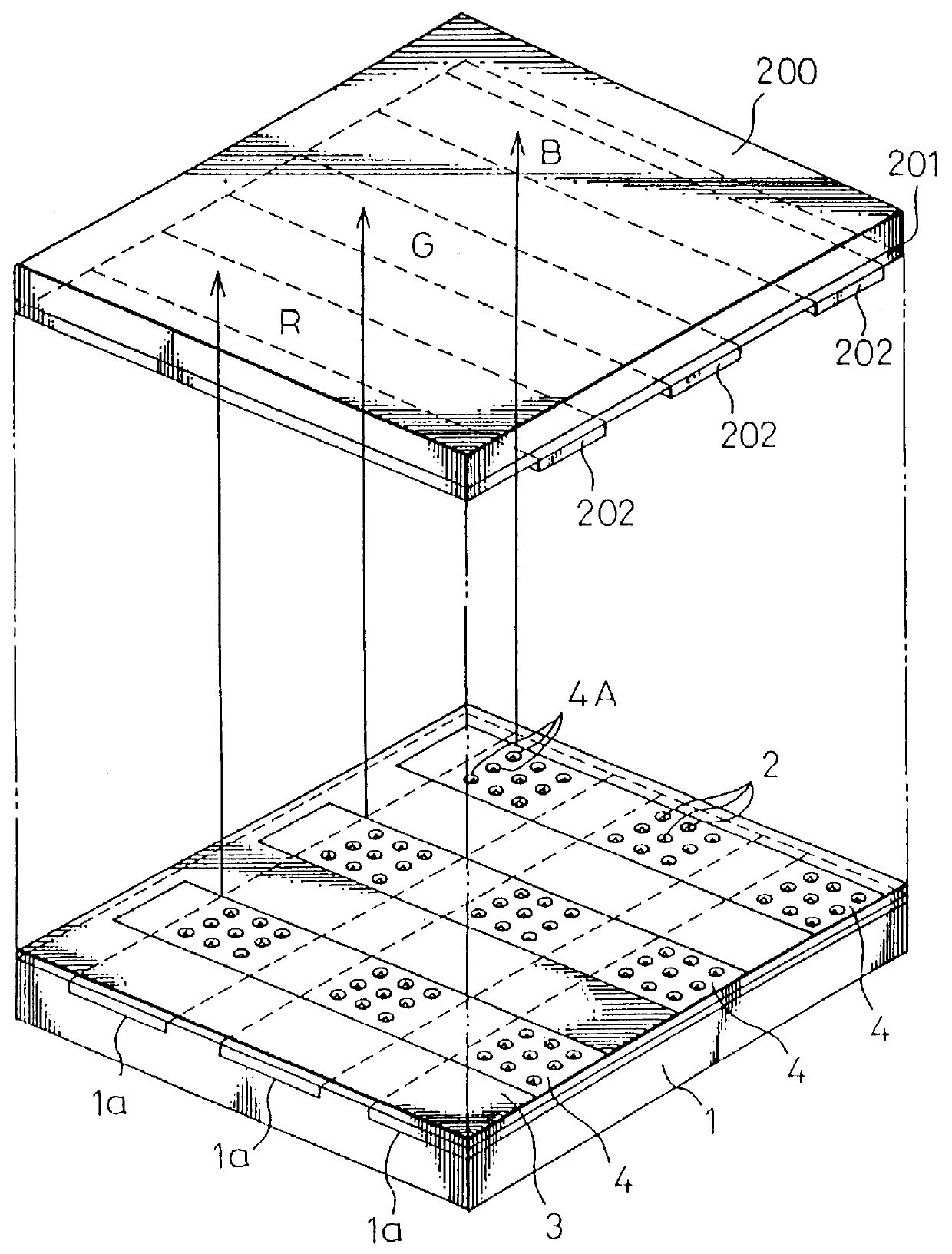

An energy converter according to the present invention includes a heat source (radiator 1), which receives externally applied energy and raises its temperature, thereby emitting electromagnetic radiations, and a radiation cut portion (mesh 2) for cutting down infrared radiations, of which the wavelengths are longer than a predetermined wavelength. The mesh 2 is a woven or knitted mesh of metal wires. The openings of the woven or knitted mesh have an aperture size that is smaller than the predetermined wavelength.

Owner:PANASONIC CORP

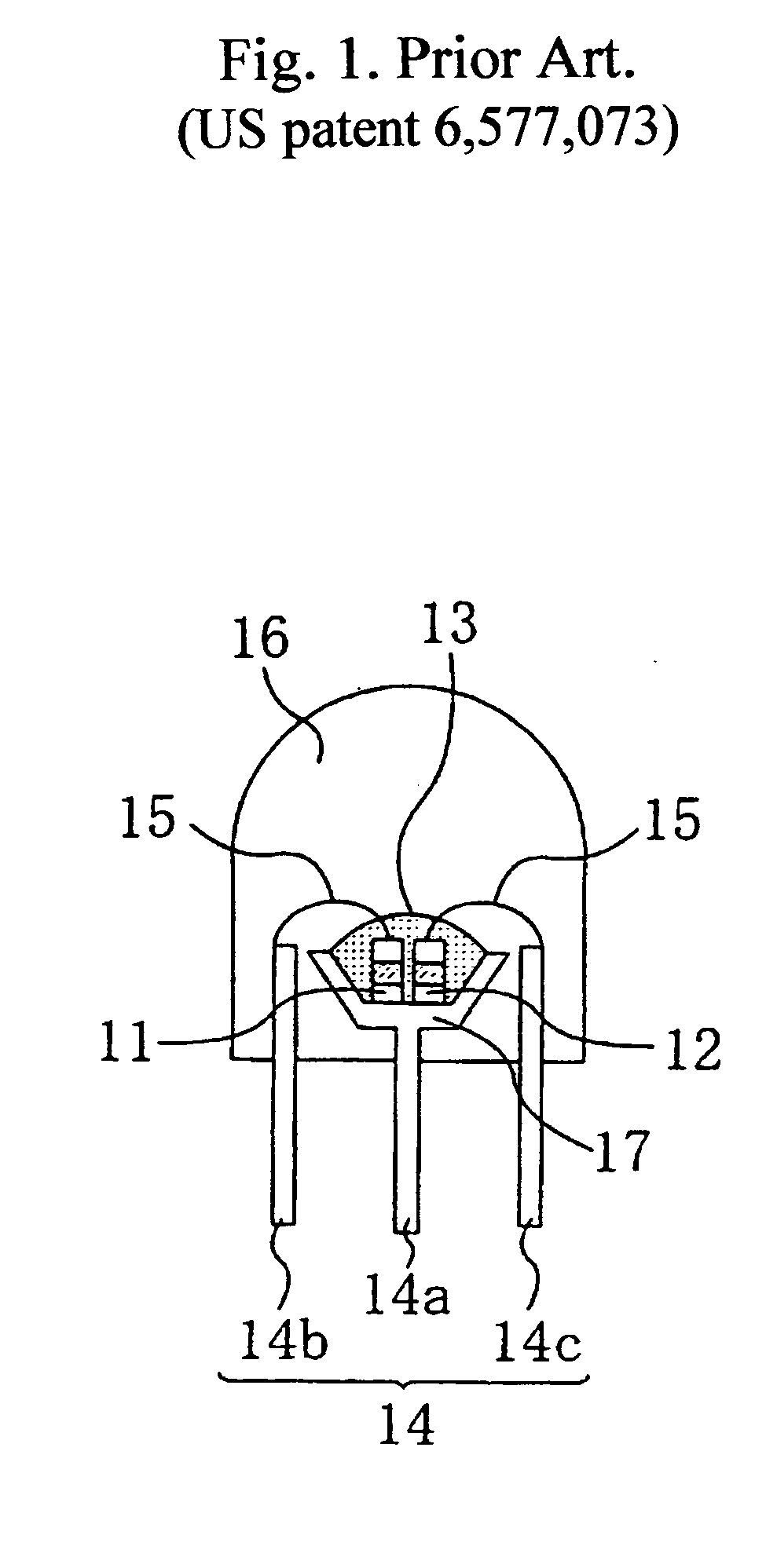

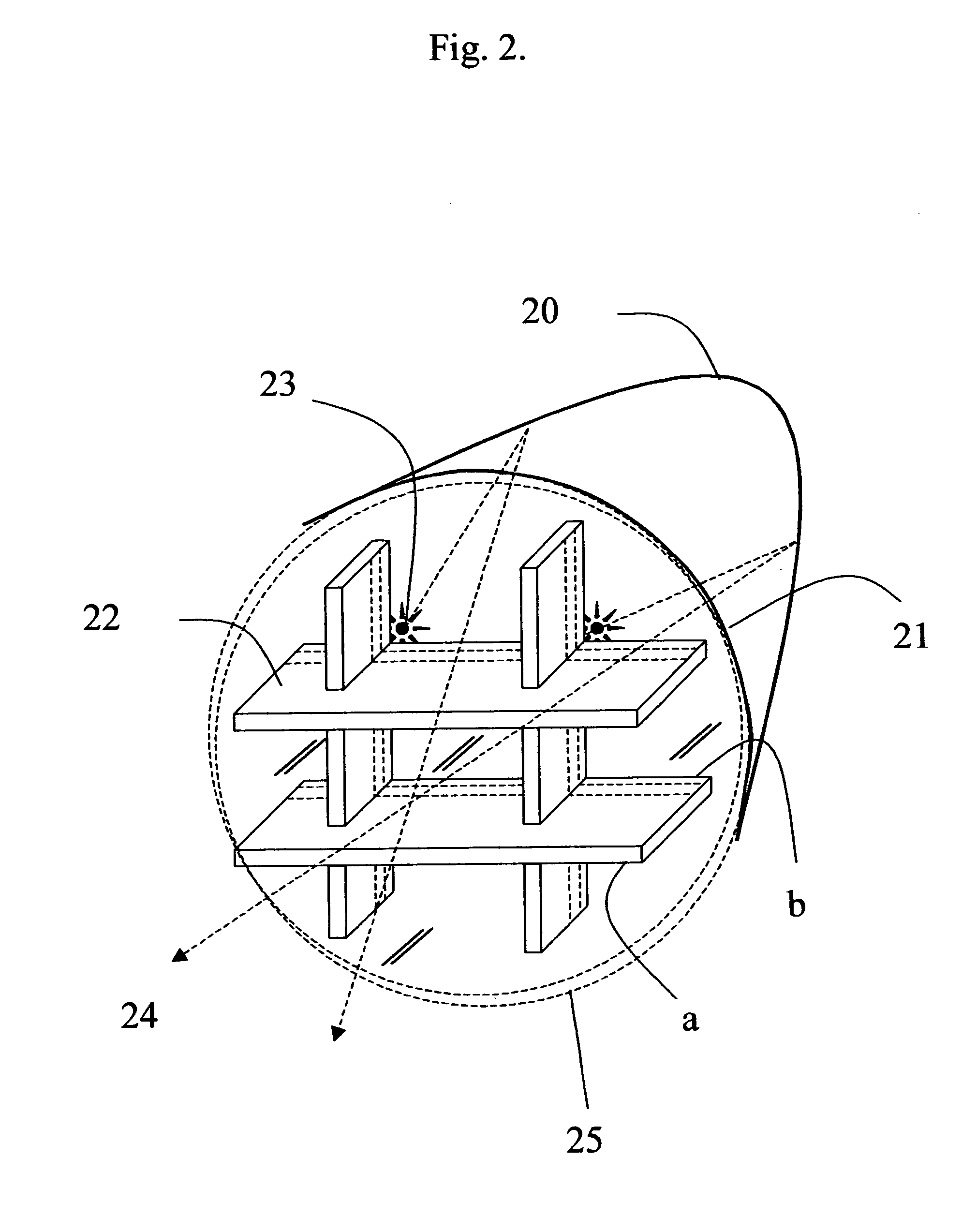

Lamp with metal grid radiator for heat dissipation

InactiveUS20050200262A1Increase light intensityRemove heatControl electrodesLighting heating/cooling arrangementsPolymer compositesLight emitting device

A metal grid is placed in the open end of a cup-shaped light bulb as a radiator to dissipate the heat generated from the light emitting device. One or more light emitting devices can be placed on the inner side surface of the metal grid, and the light emitted from the light emitting devices is reflected by the inner surface of the cup and transmitted through the windows in the metal grid. The horizontal plates of the metal grid and the vertical walls of the grid can be insulated from each other to serve as electrodes for the light emitting device. The cup can be back-filled with glass or other transparent polymer composite to prevent dust from entering the cup. Alternatively, a single light emitting device is place near the bottom of the cup

Owner:WU JIAHN CHANG

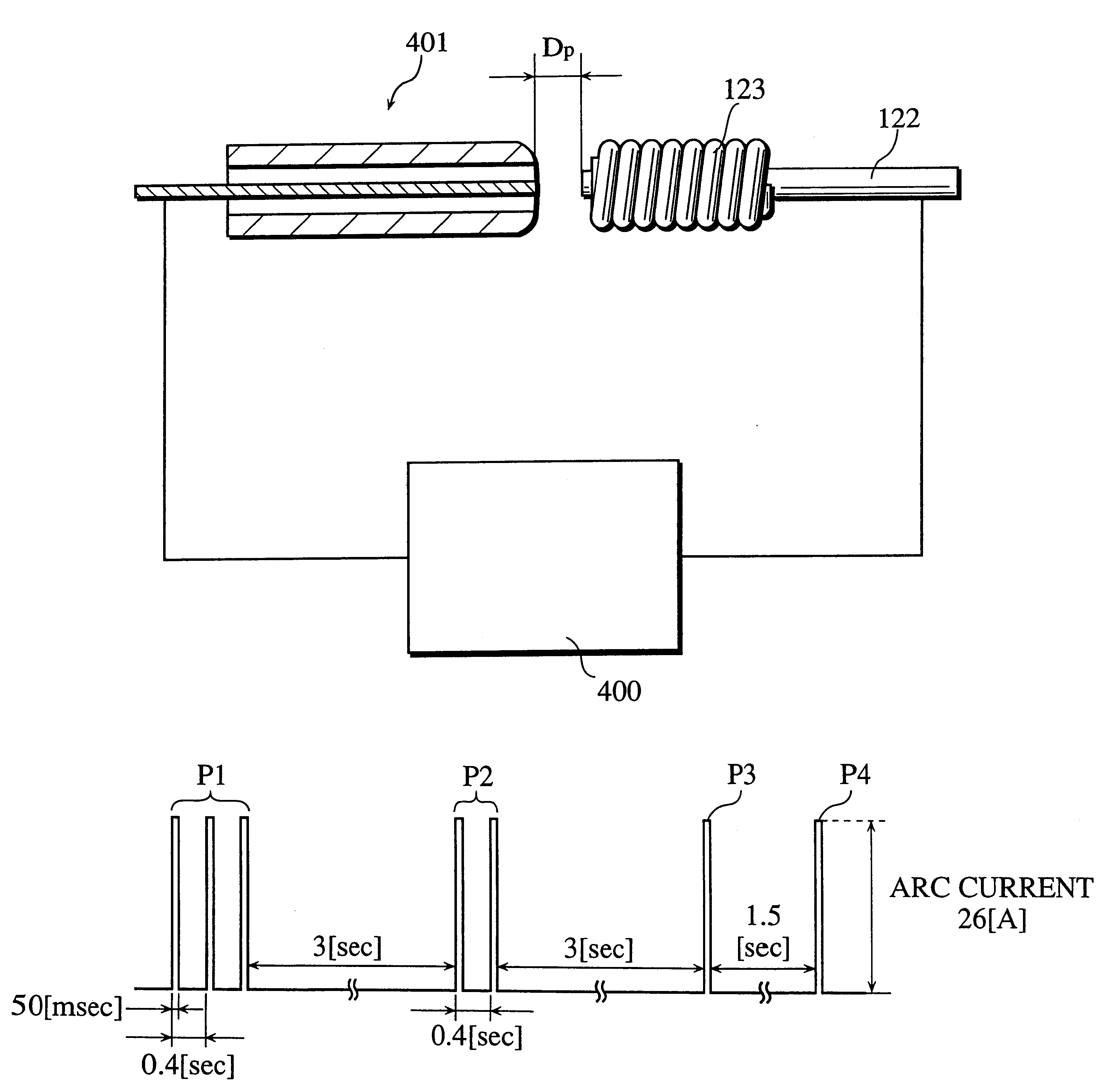

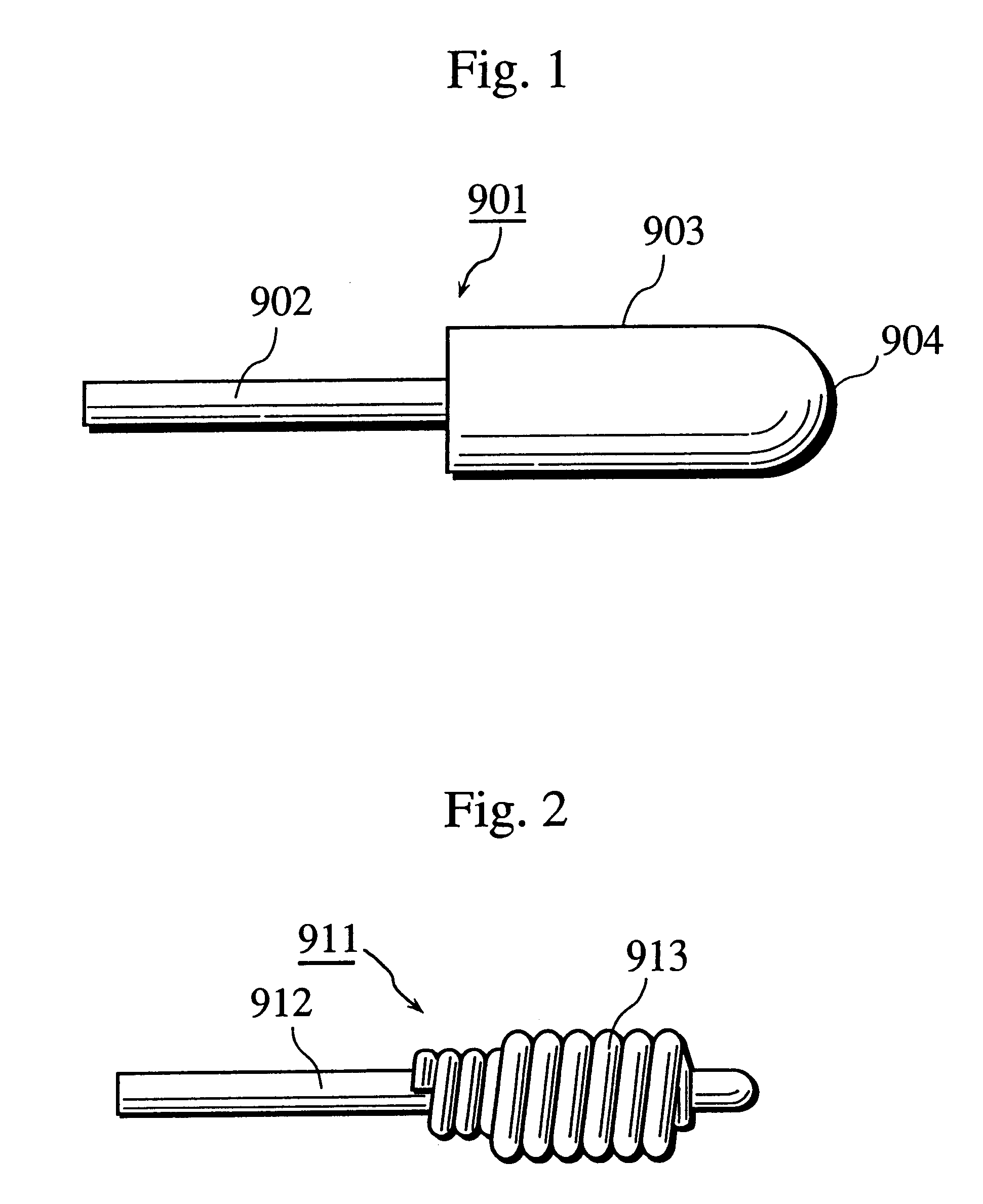

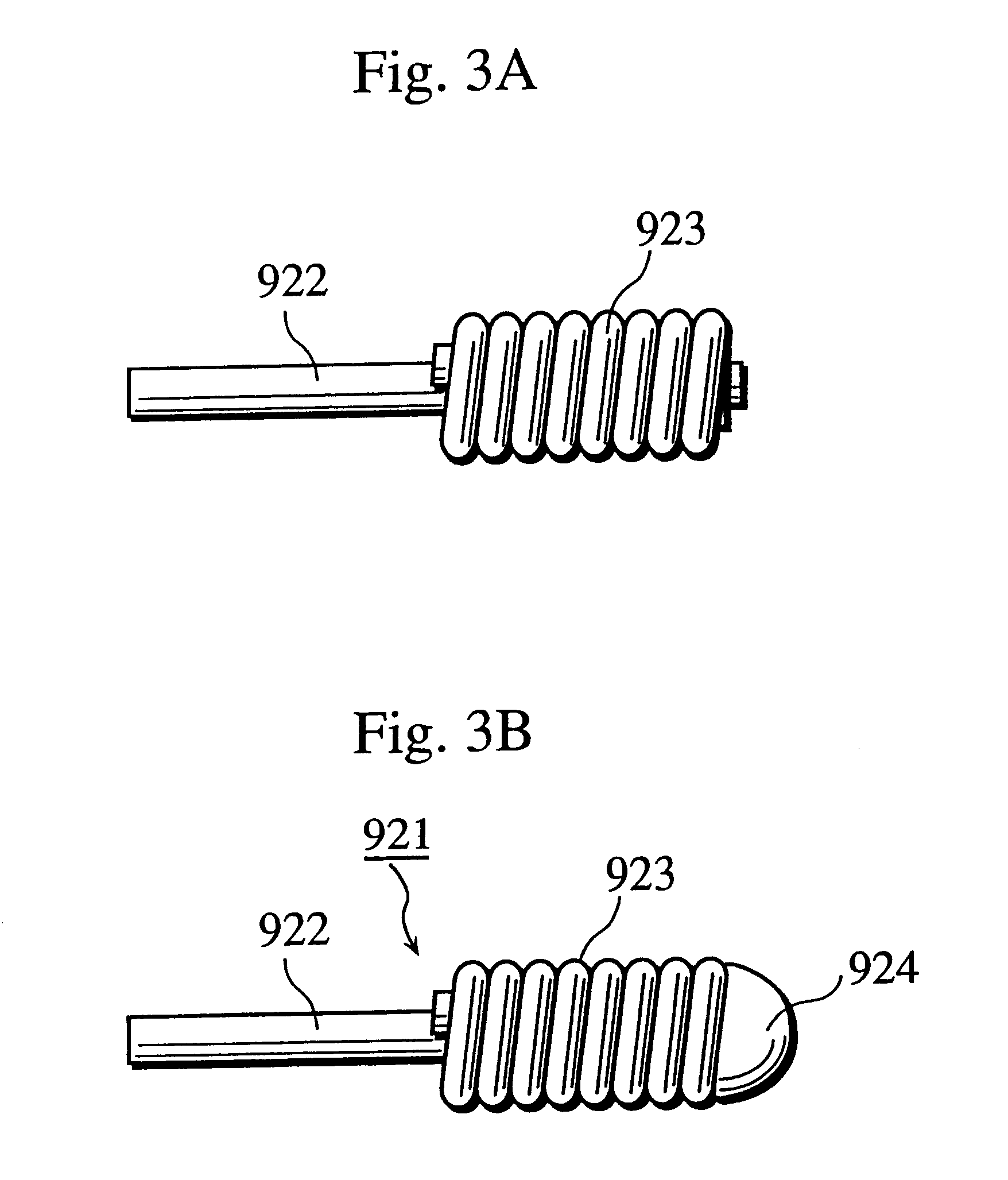

Method of forming spherical electrode surface for high intensity discharge lamp

InactiveUS6705914B2Suppress mutationControl electrodesNon-electron-emitting control electrodesOptoelectronicsHigh intensity

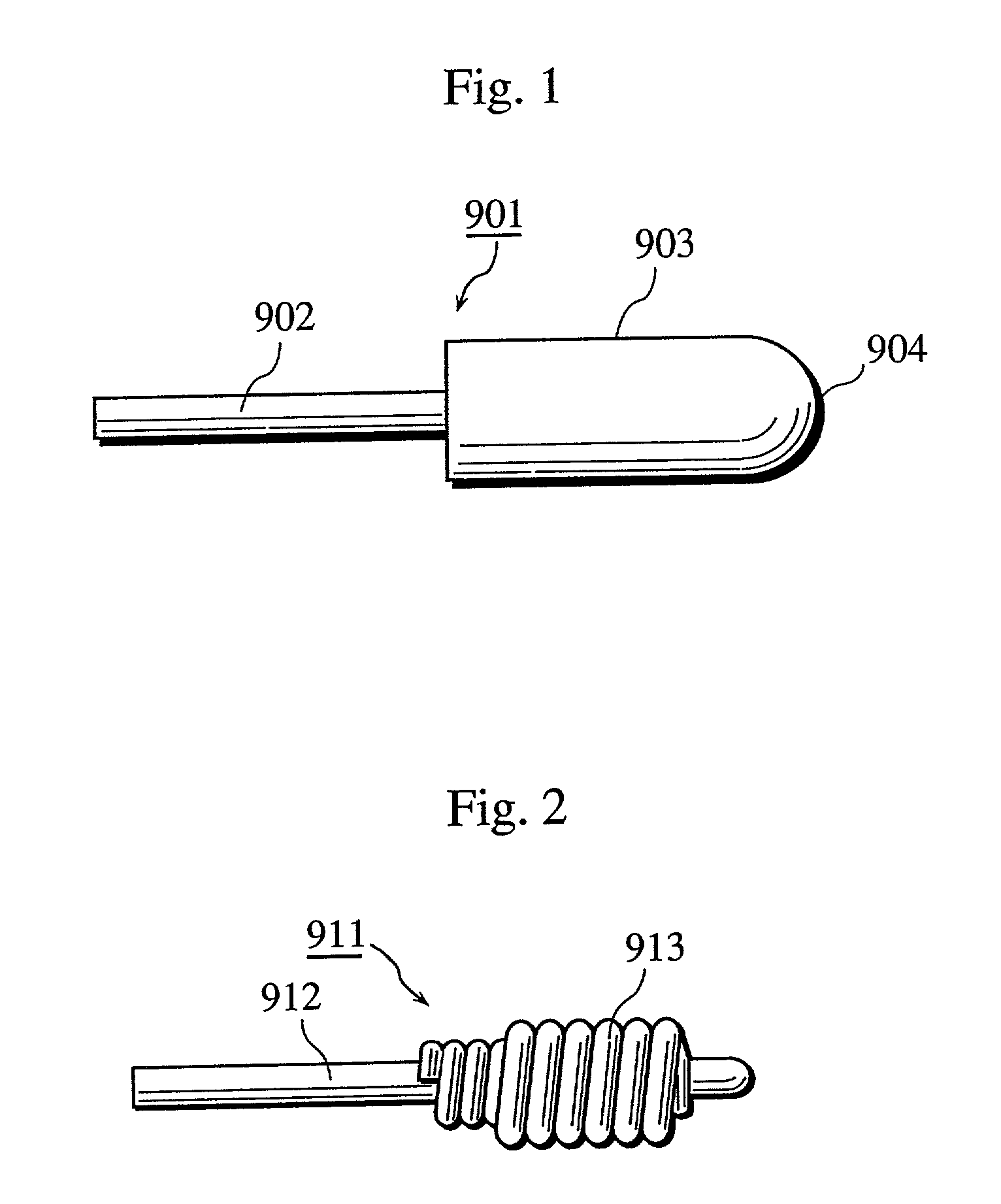

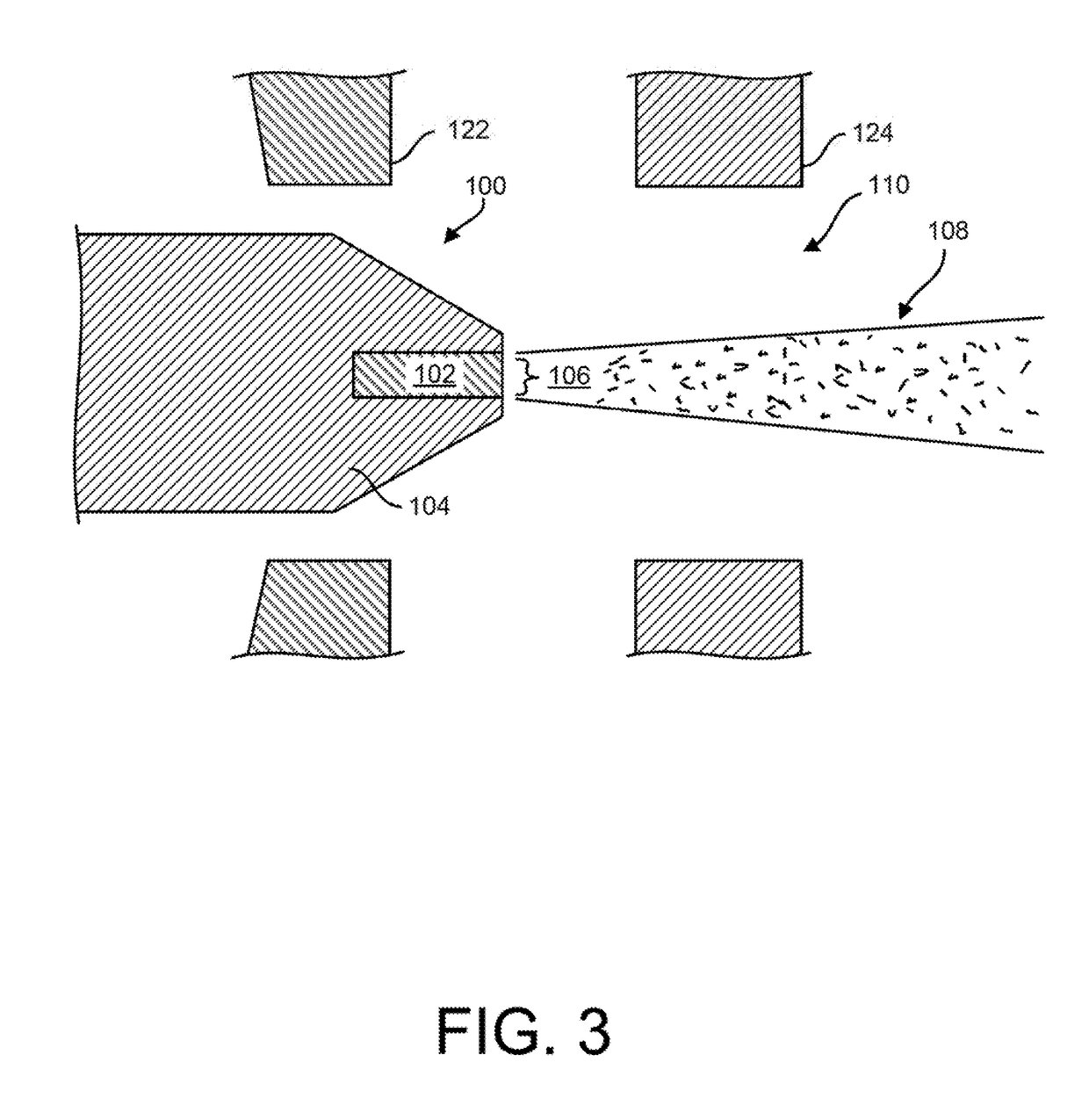

A high pressure discharge lamp which achieves a long life of at least 3000 hours and in which variations in lamp characteristics are suppressed is disclosed. In the high pressure discharge lamp of the present invention, during manufacturing of an electrode, a covering member 123 having a coil shape and being made of refractory metal is applied on a discharge side end of an electrode rod 122 made of refractory metal so as to cover a circumference of the electrode rod 122 in a vicinity of the discharge side end. The discharge side end 124 on which the covering member 123 is applied is fused into a semi-sphere by intermittently heat fusing the discharge side end according, for instance, to arc discharge or laser irradiation.

Owner:PANASONIC CORP

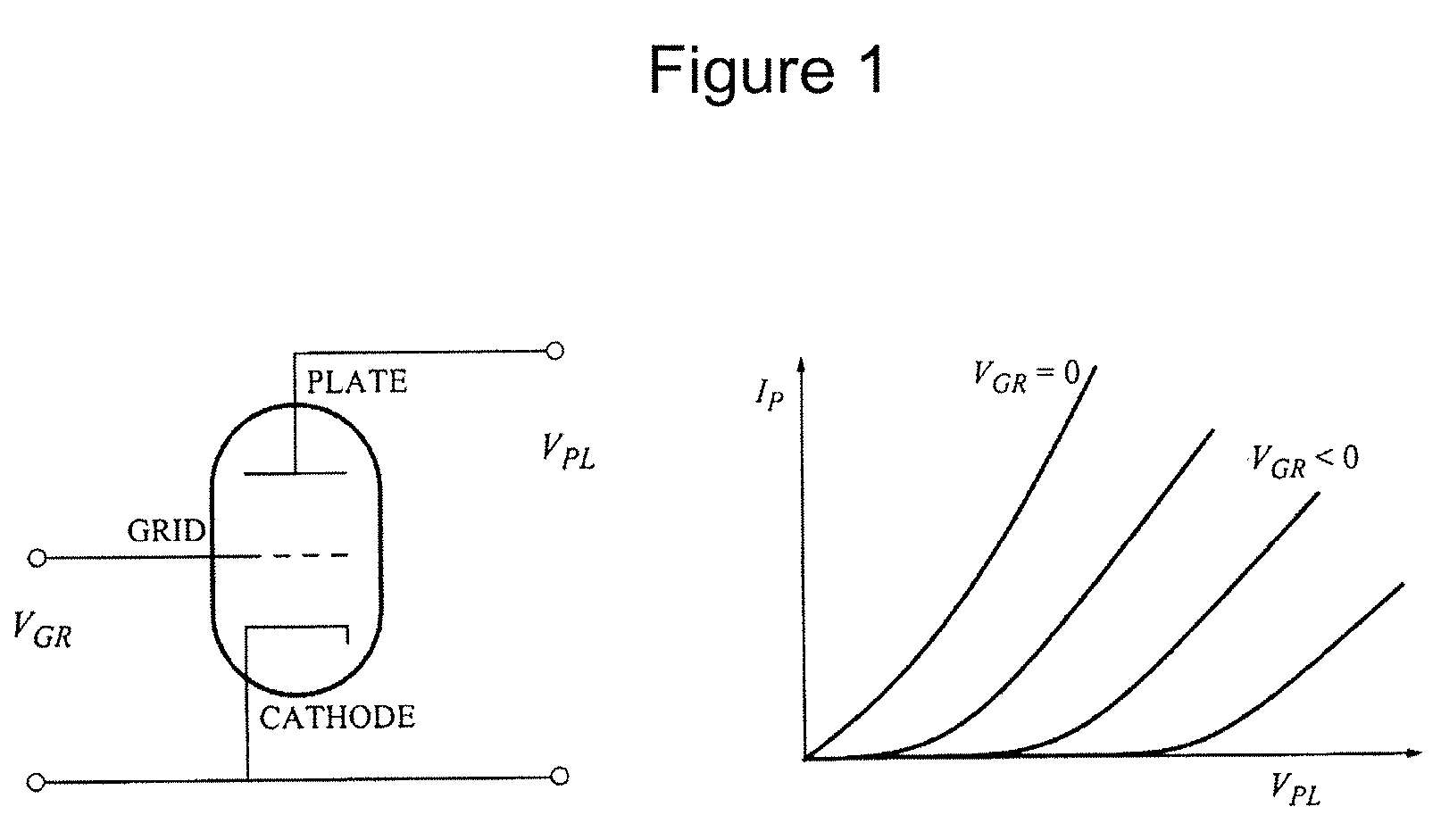

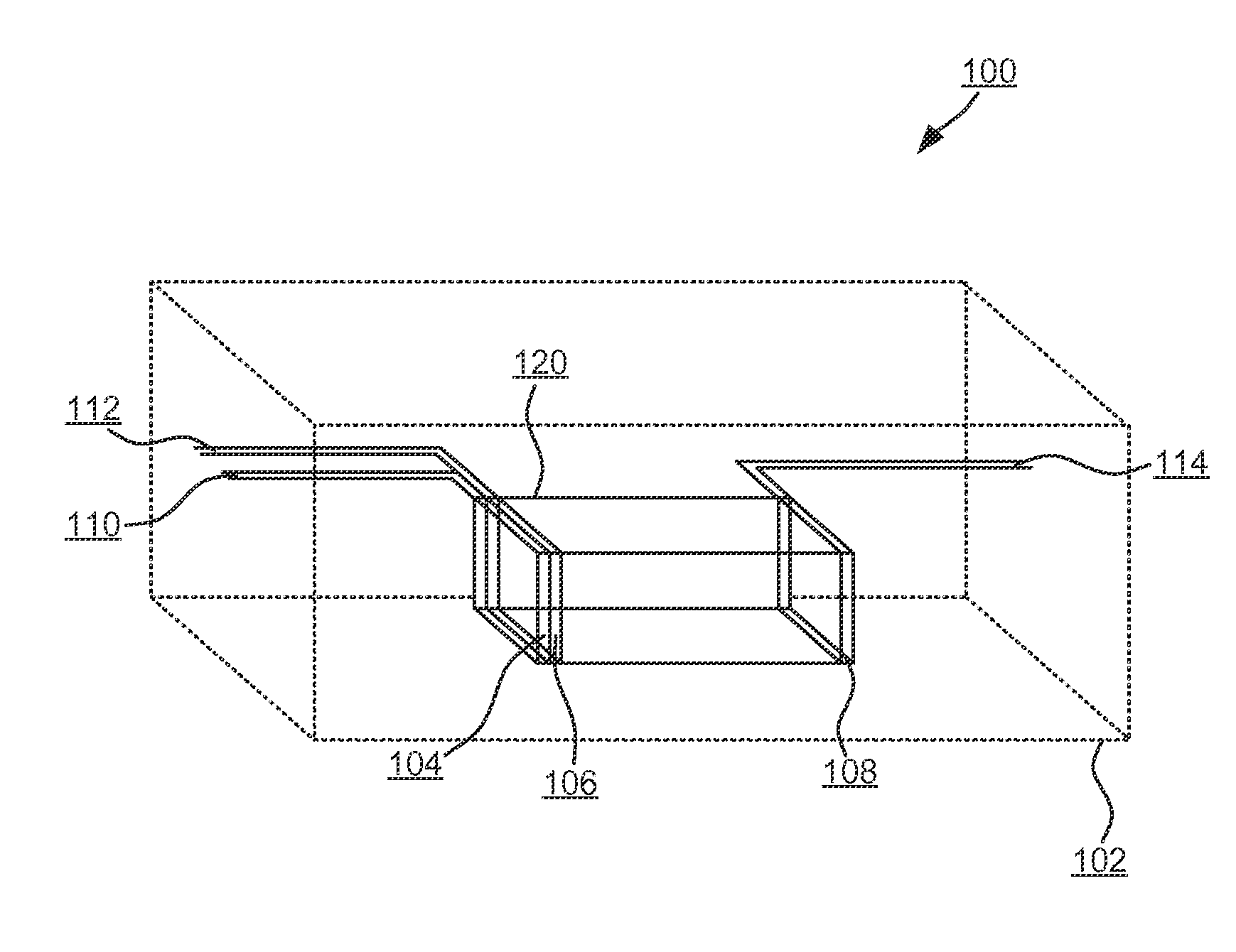

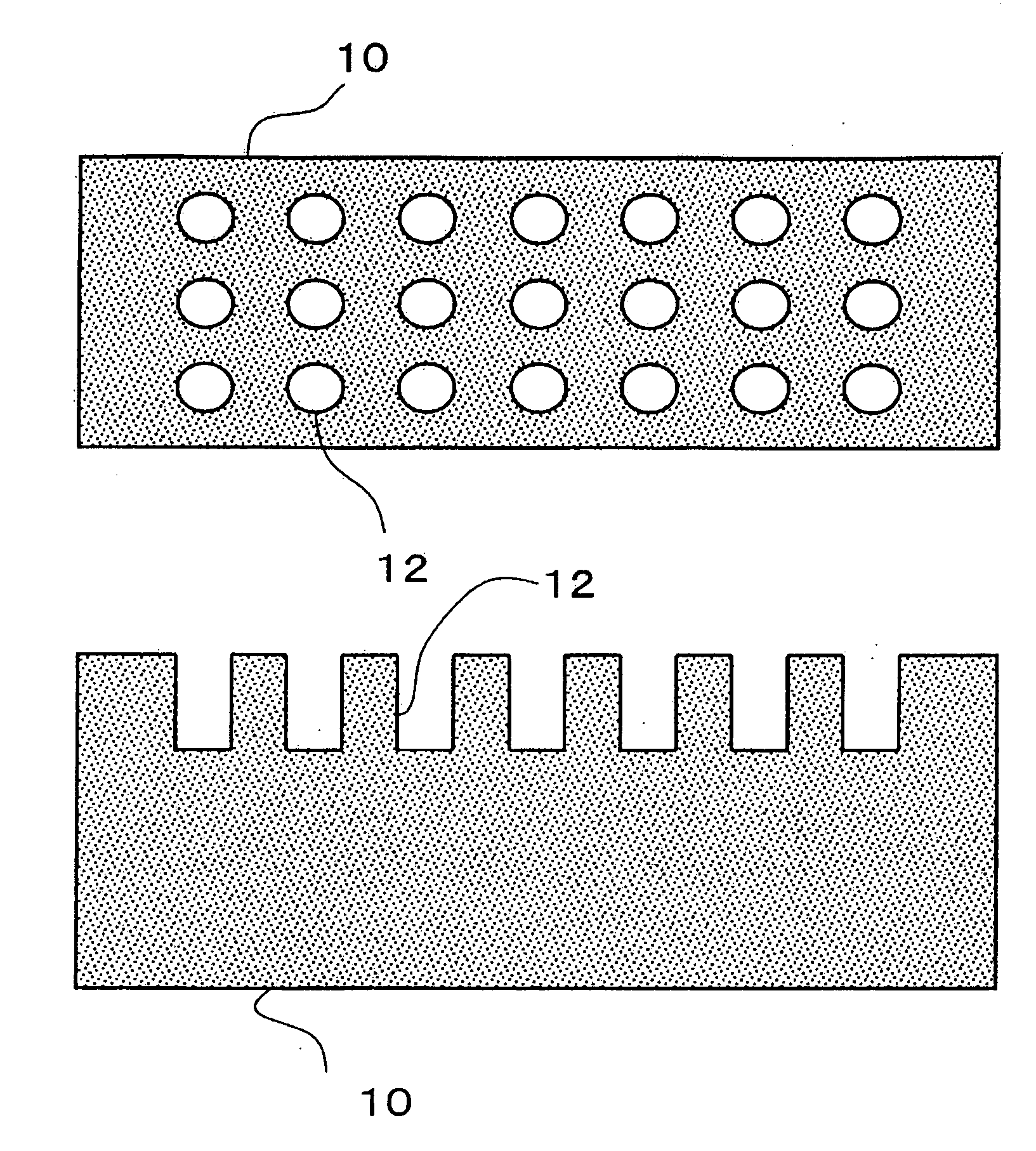

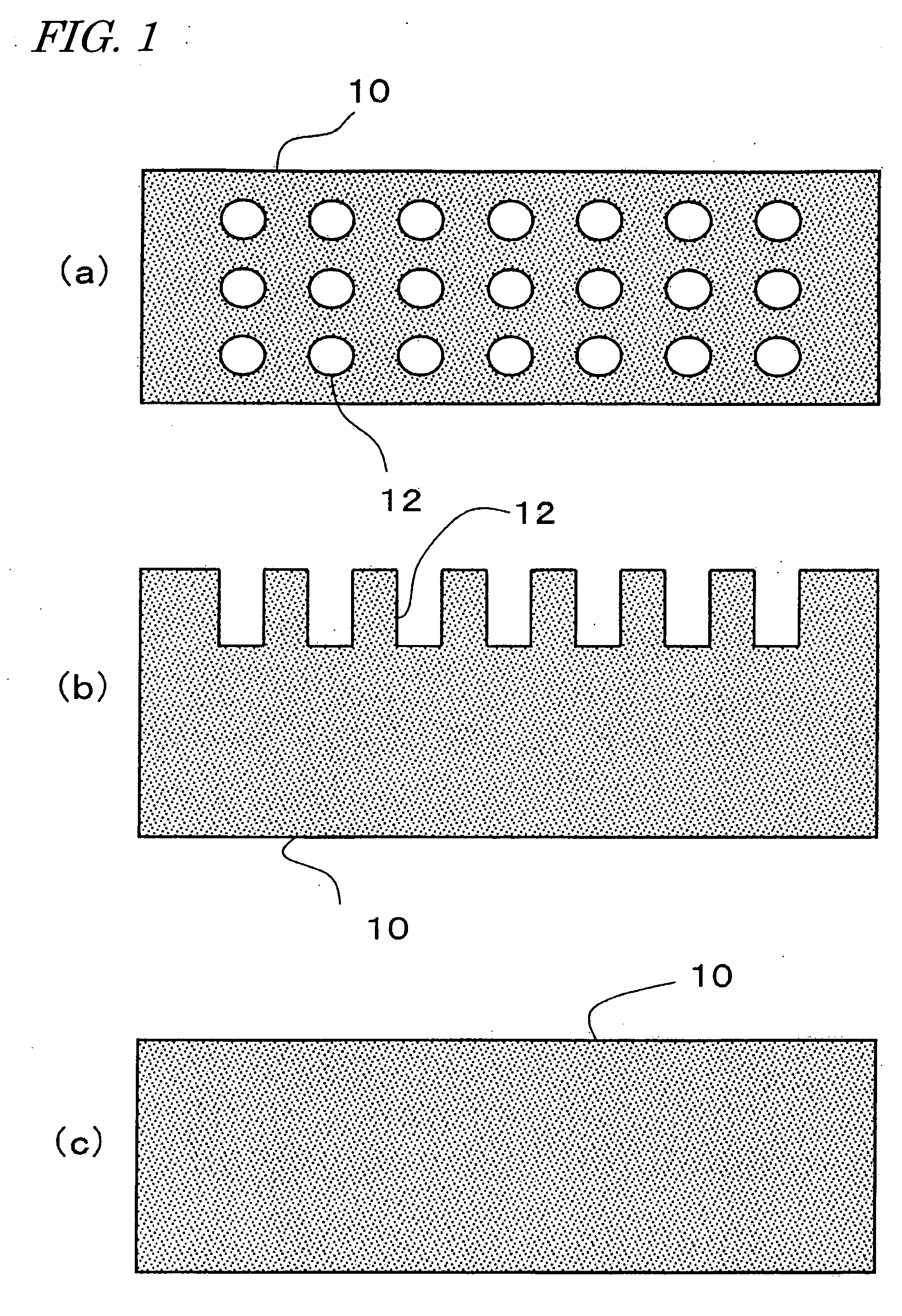

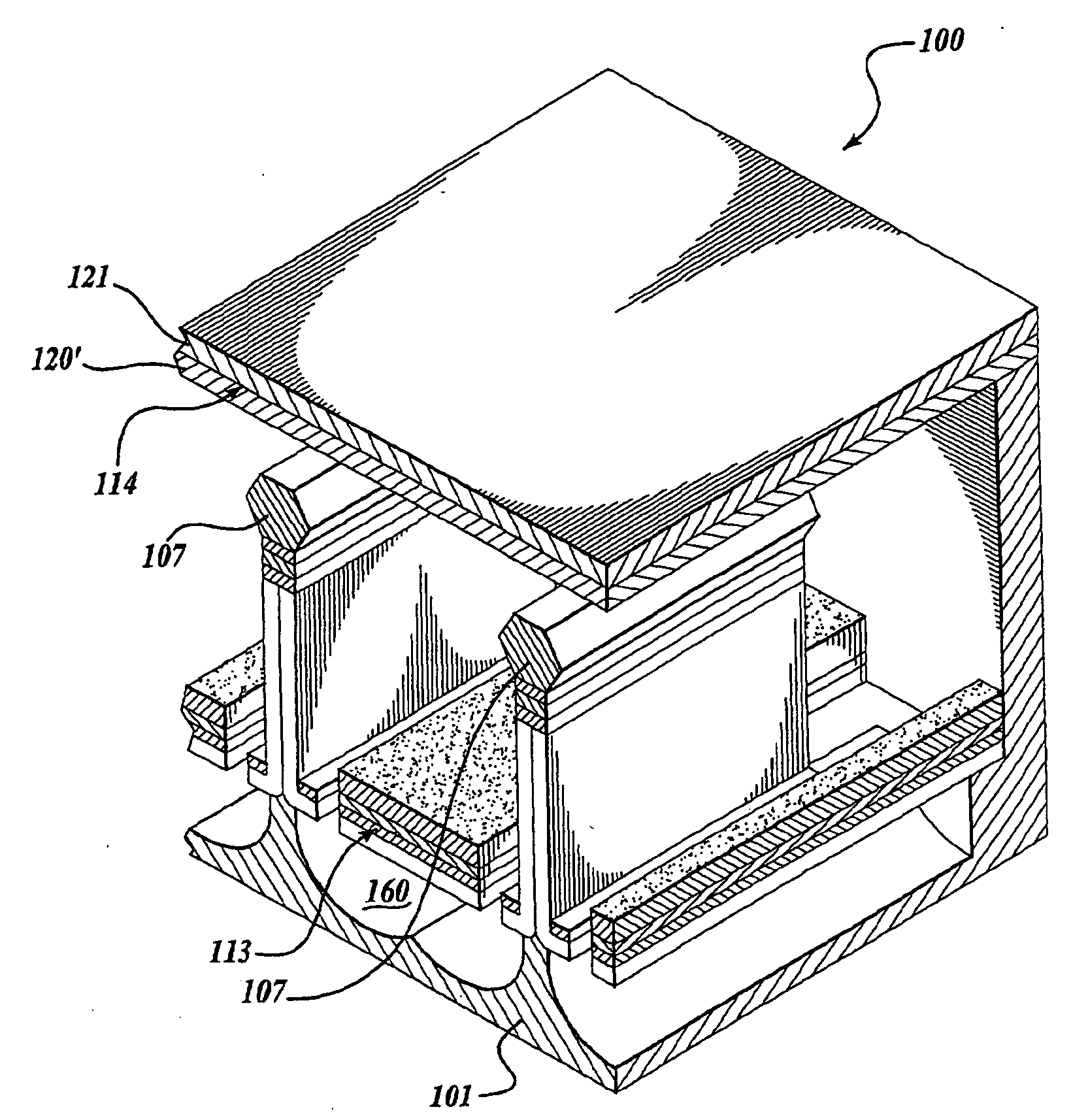

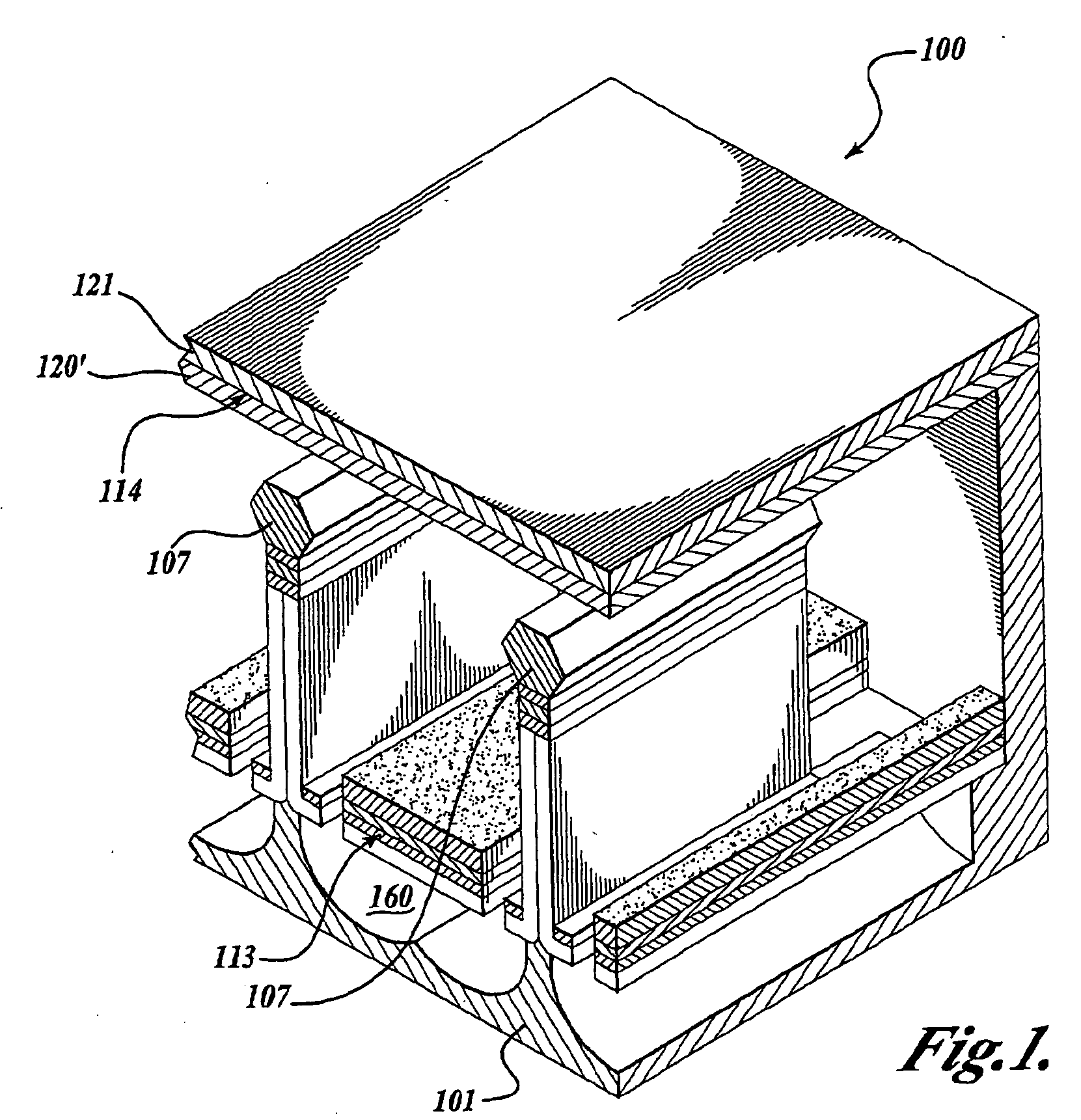

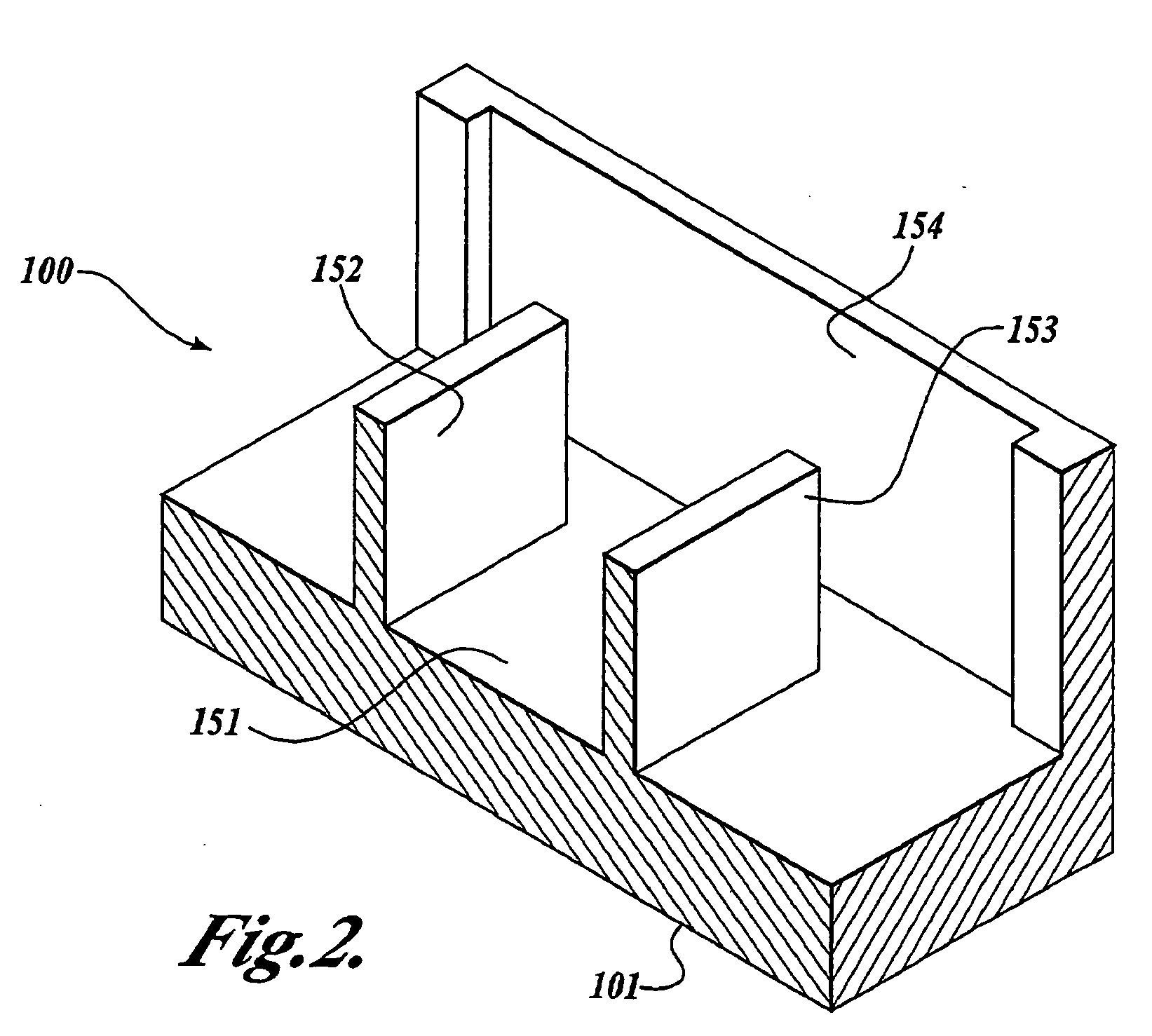

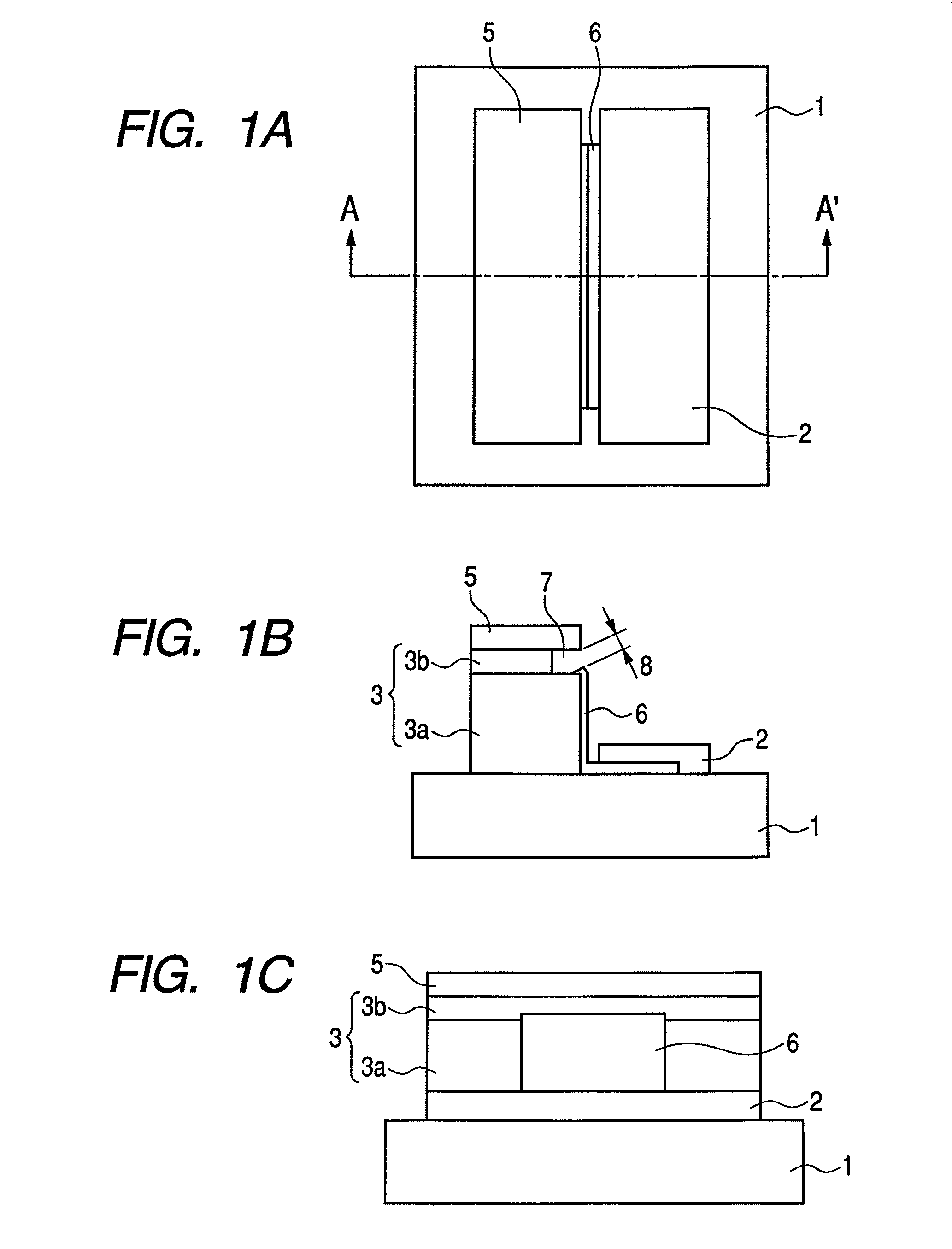

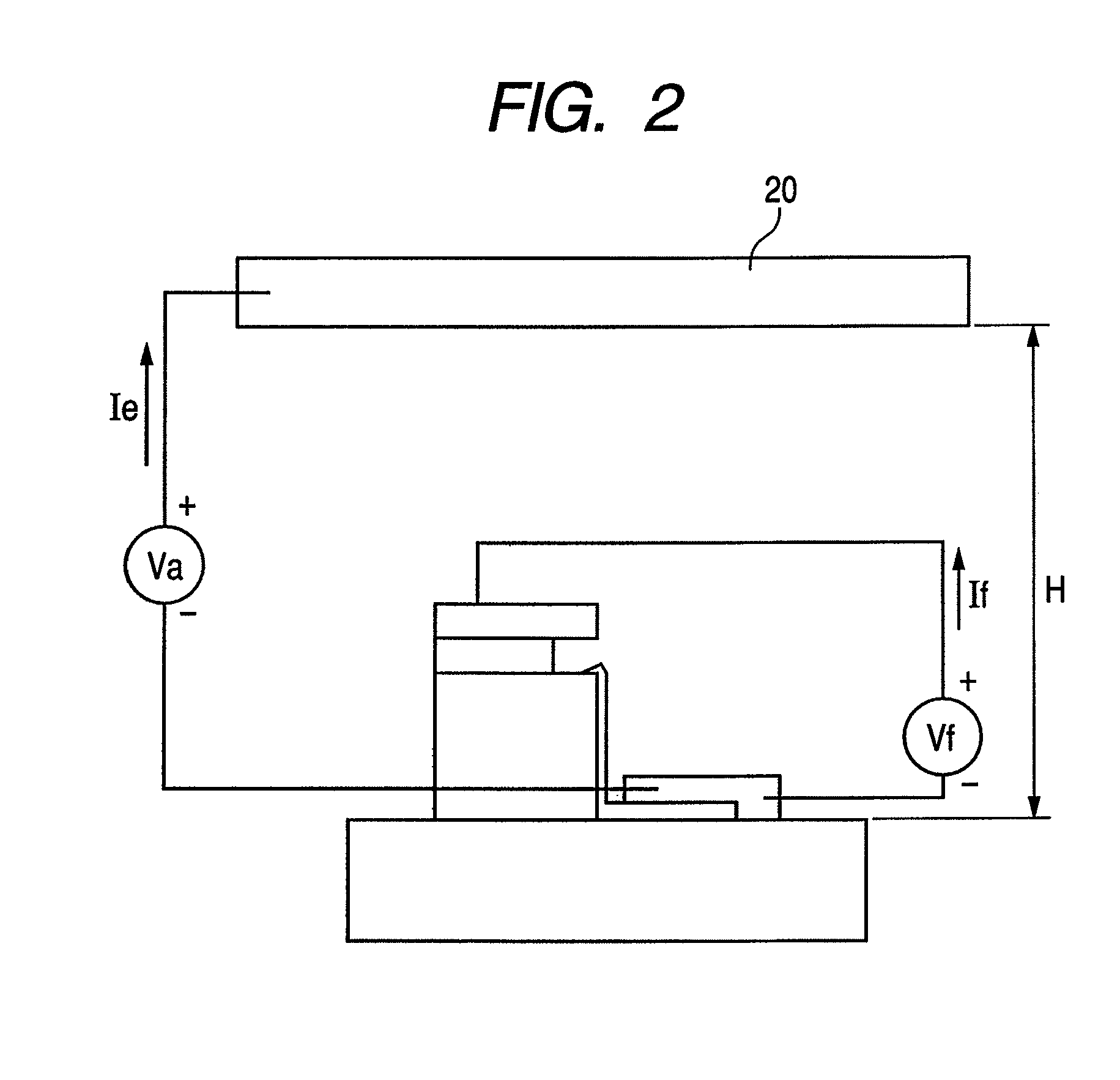

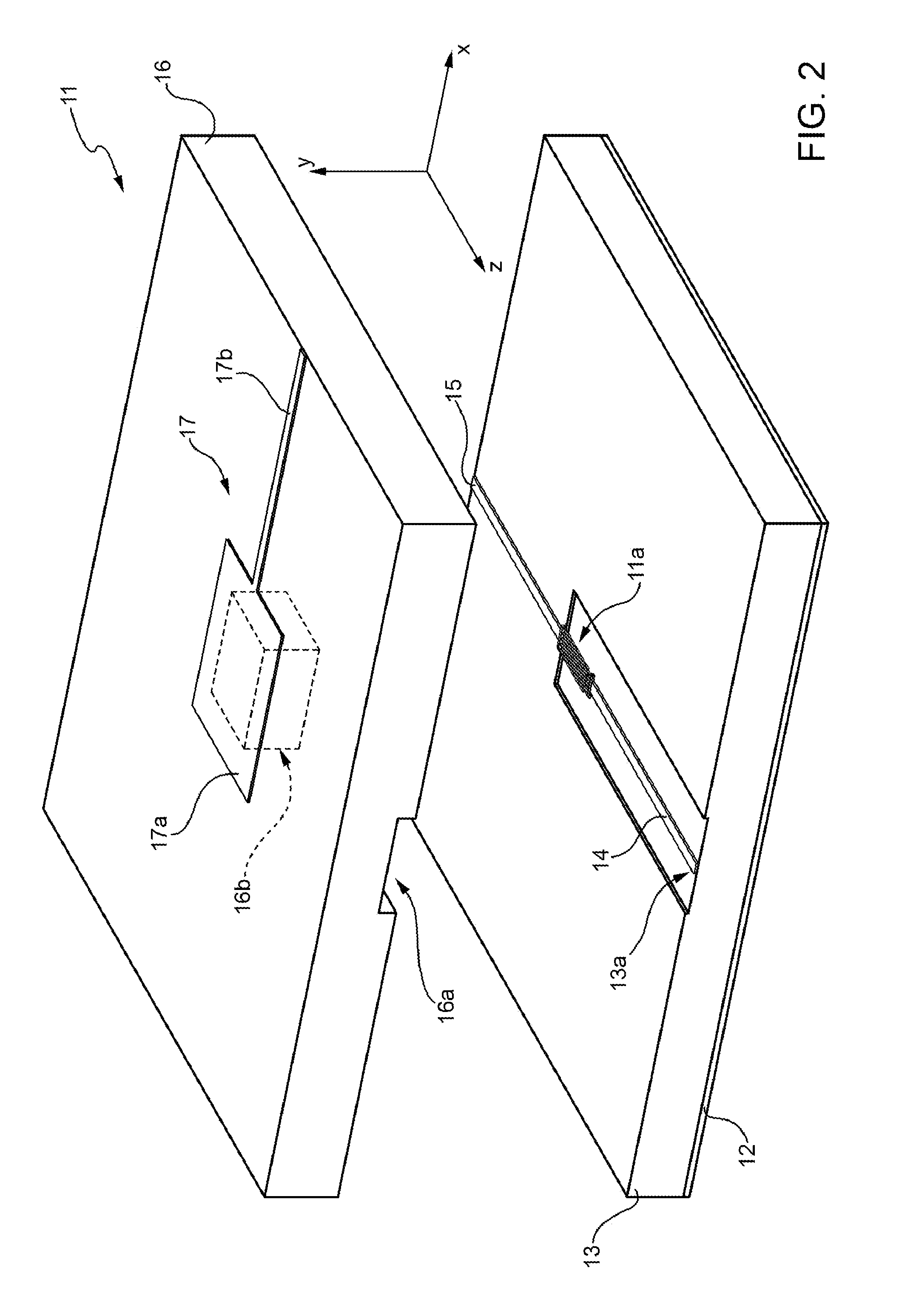

Solid state vacuum devices and method for making the same

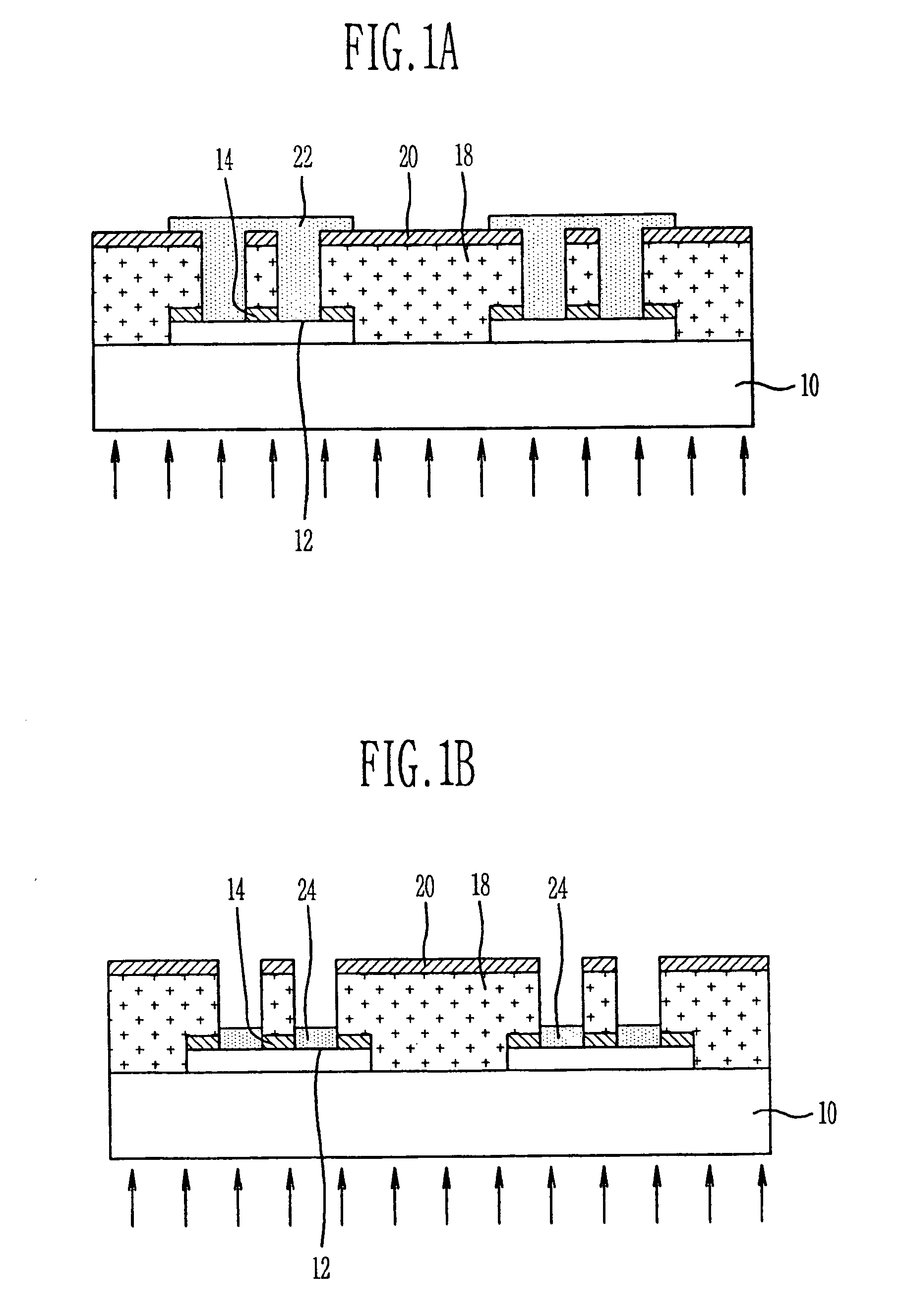

InactiveUS20060125368A1Control electrodesDischarge tube luminescnet screensEngineeringVoltage control

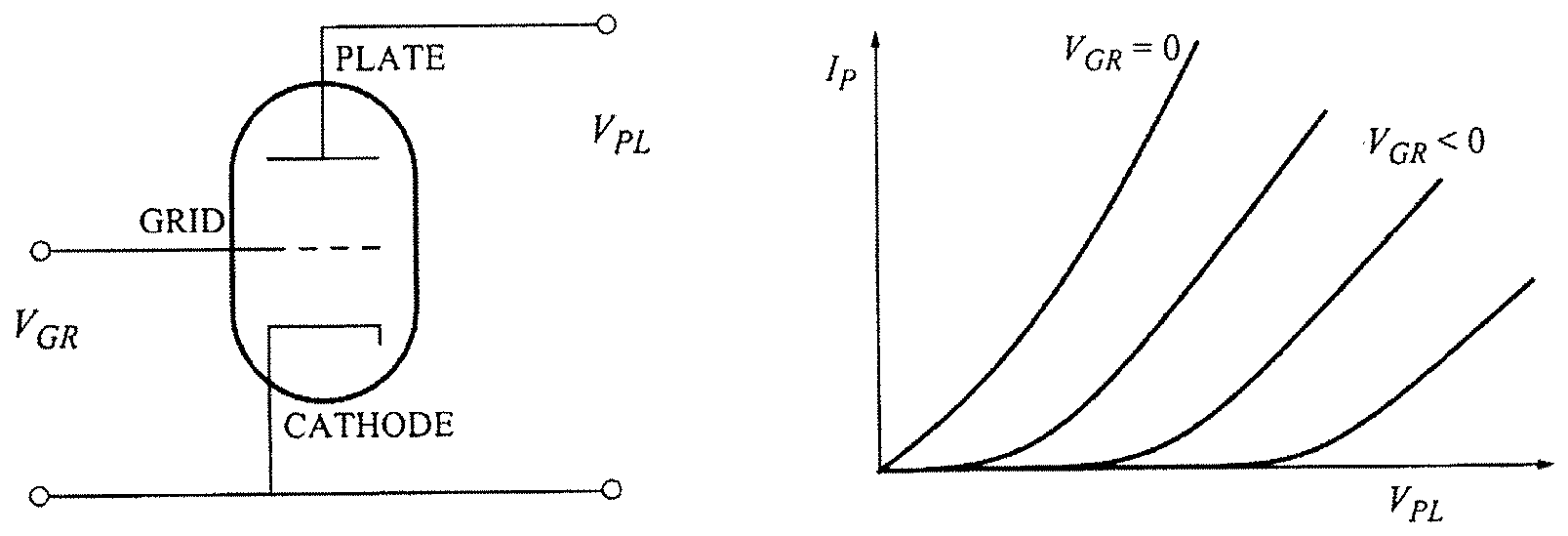

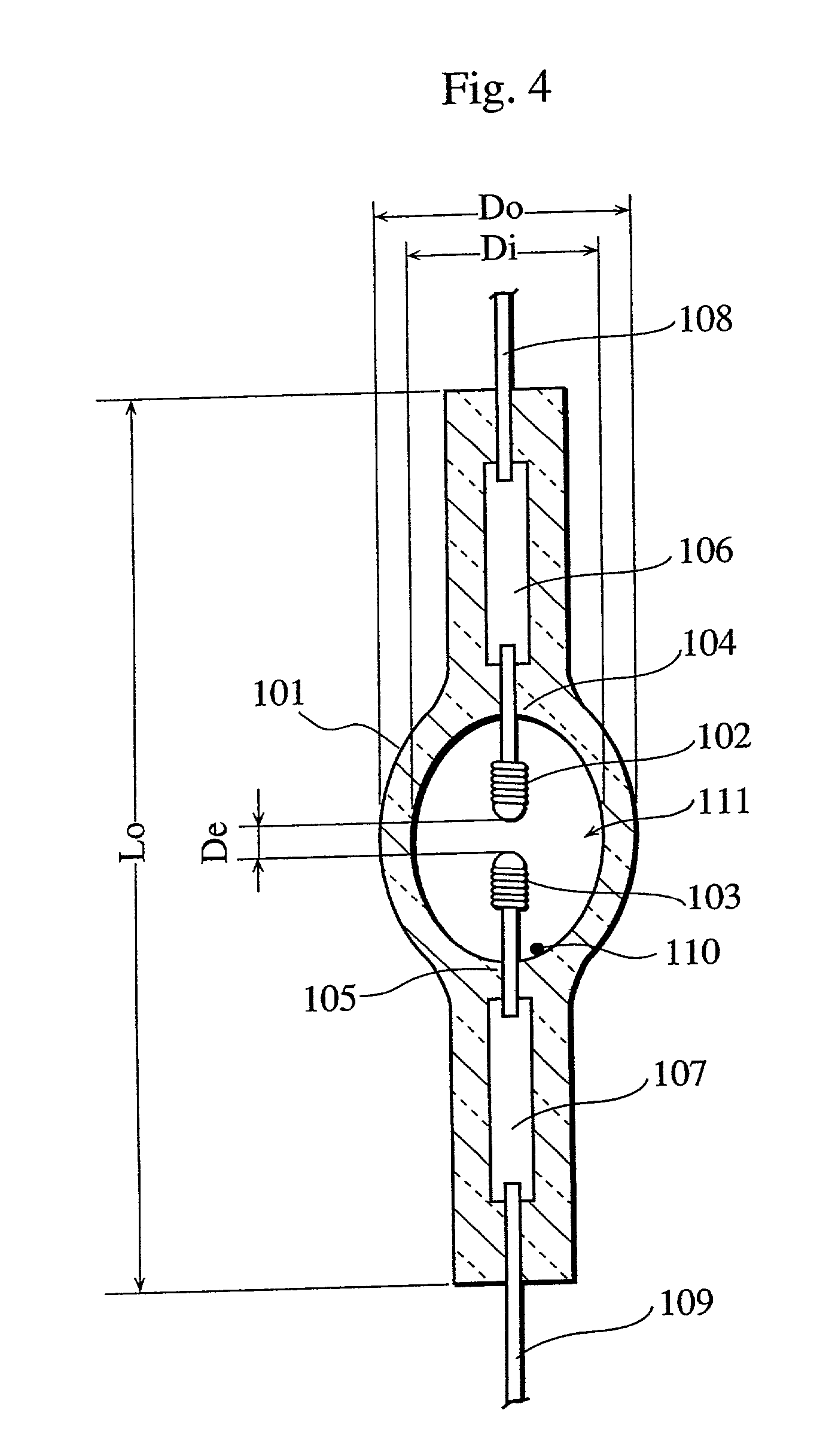

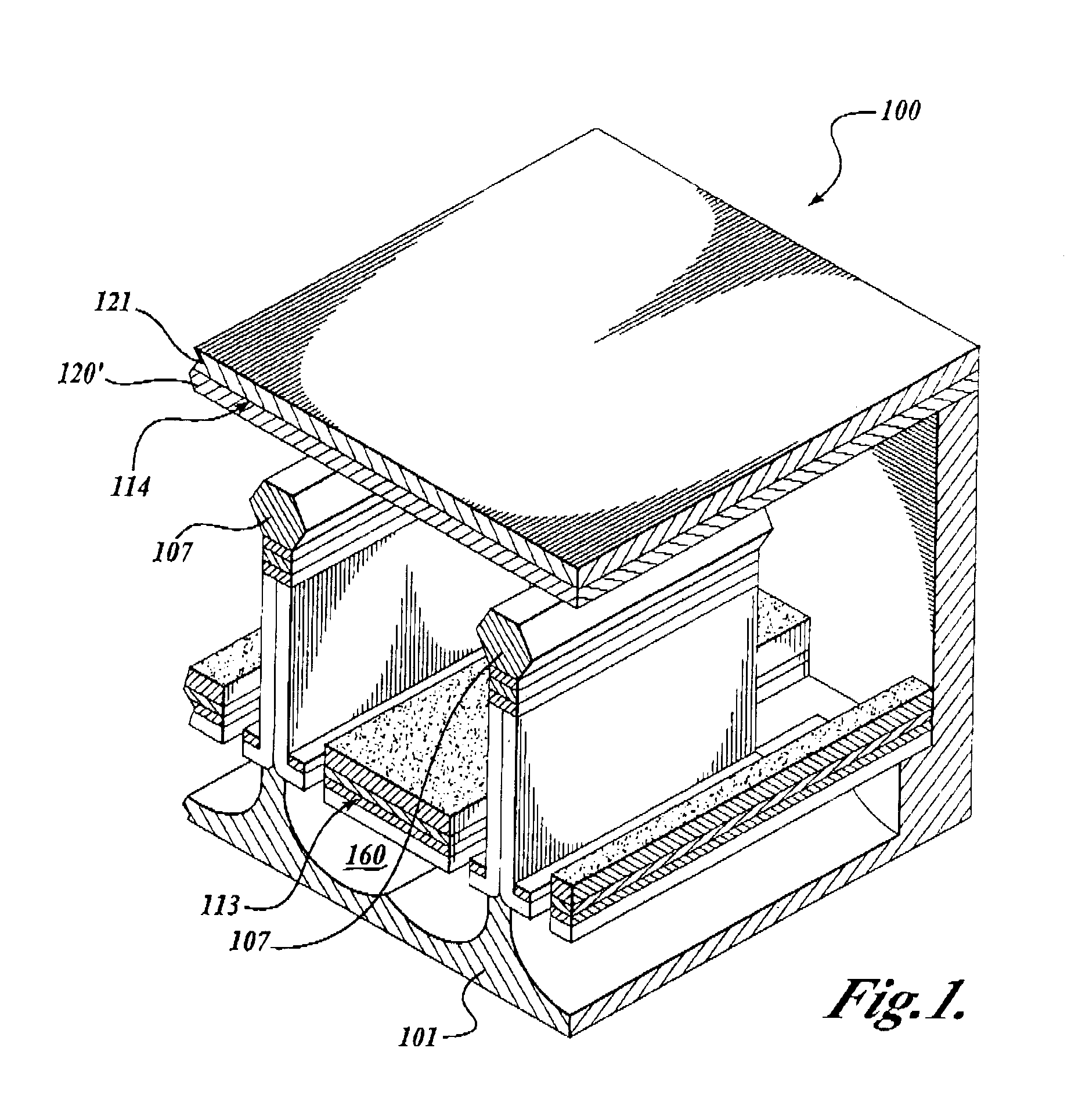

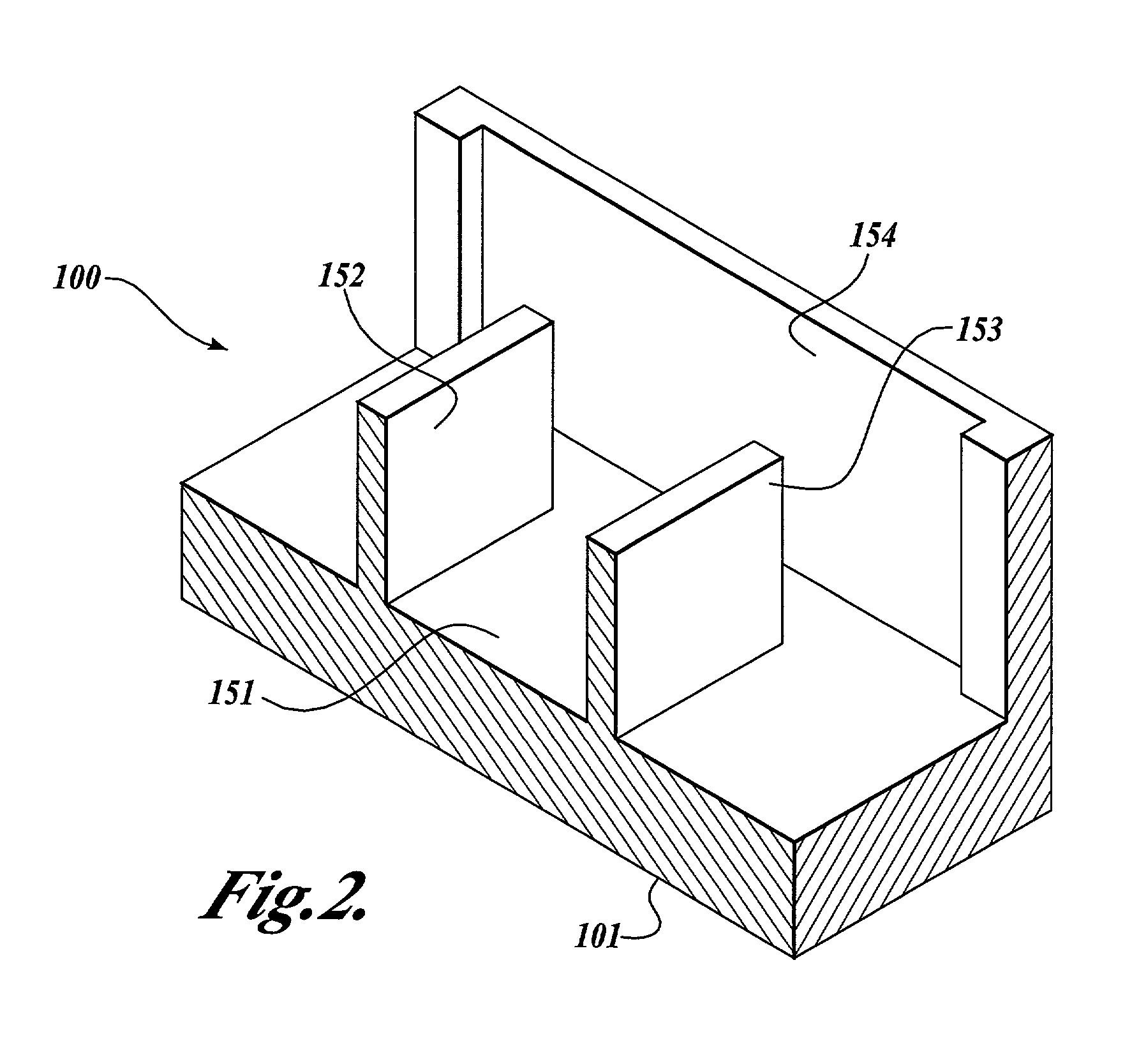

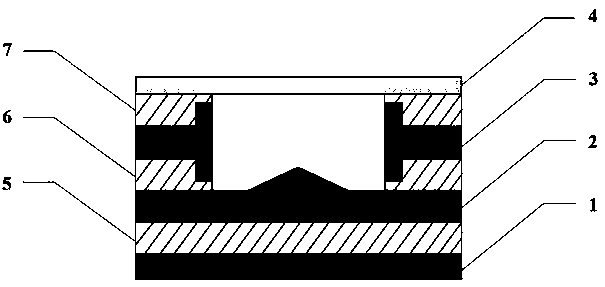

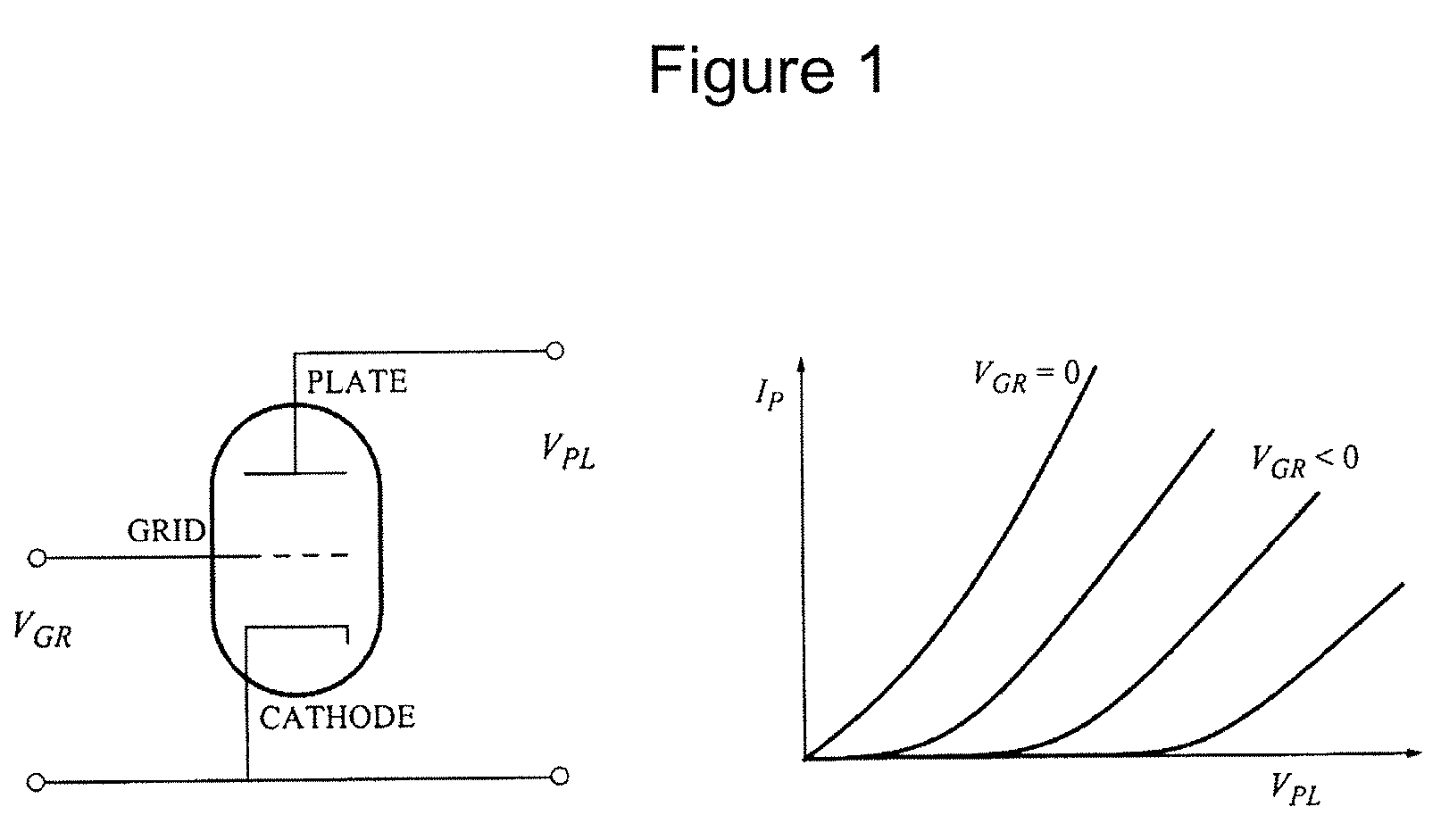

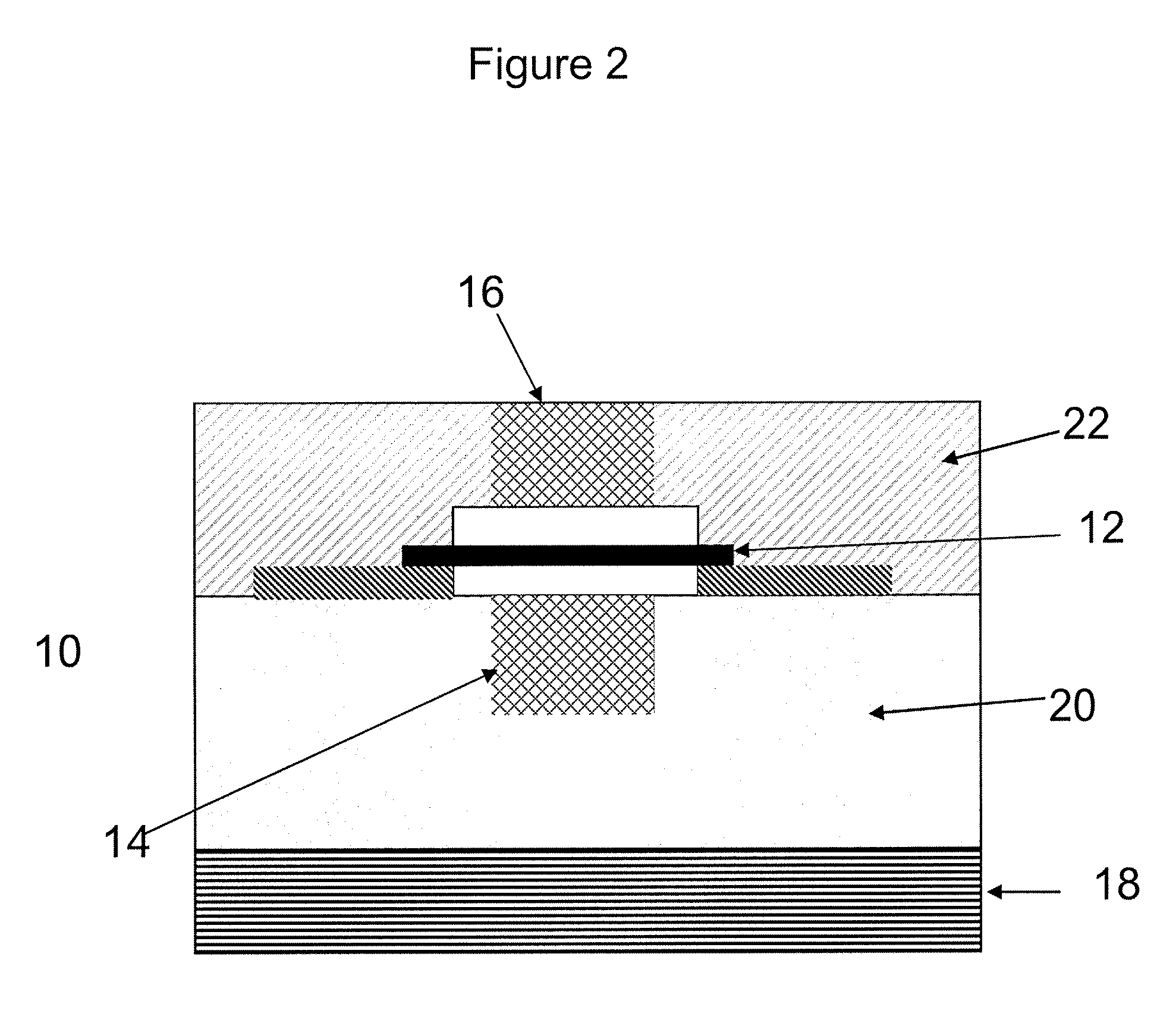

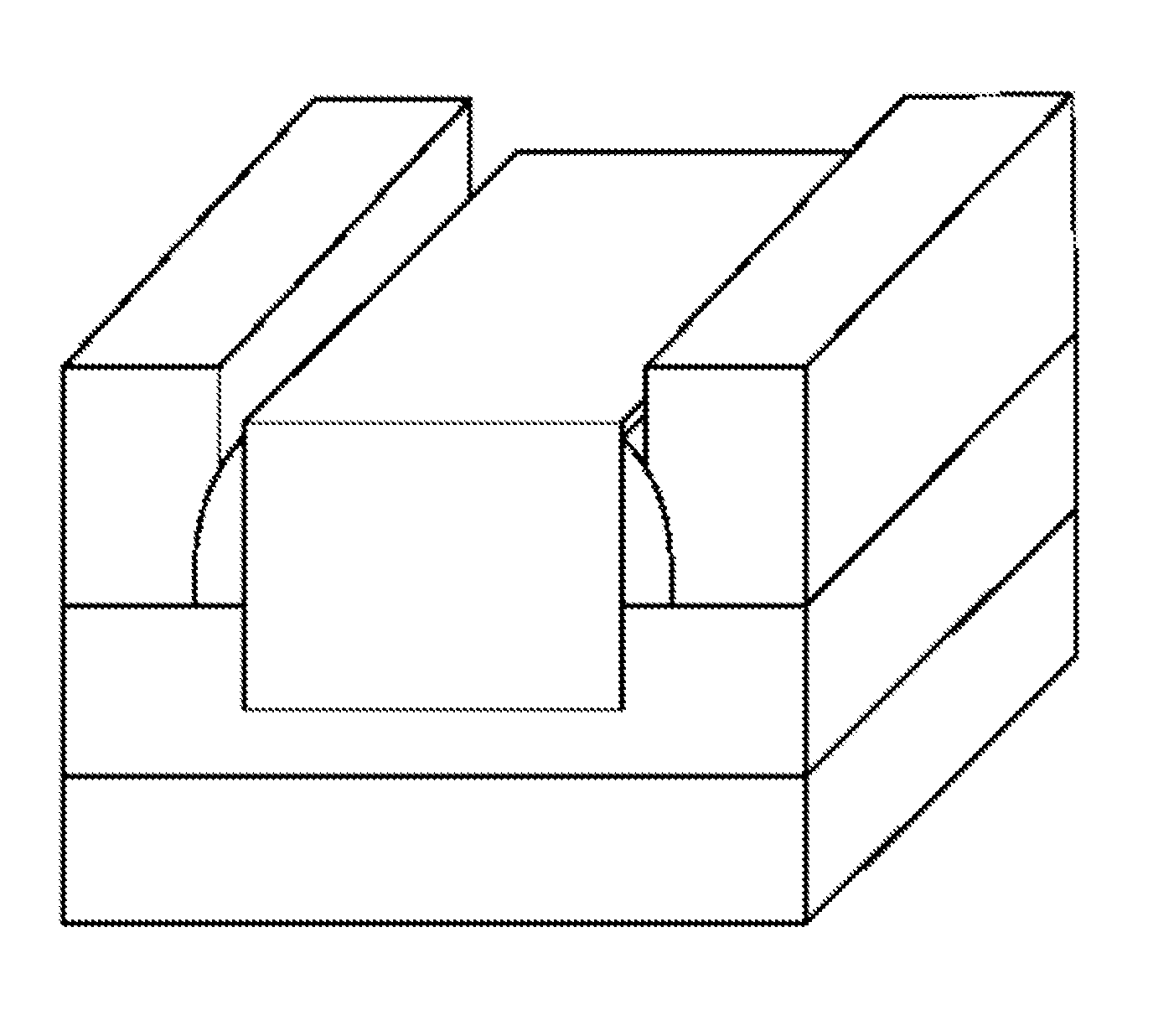

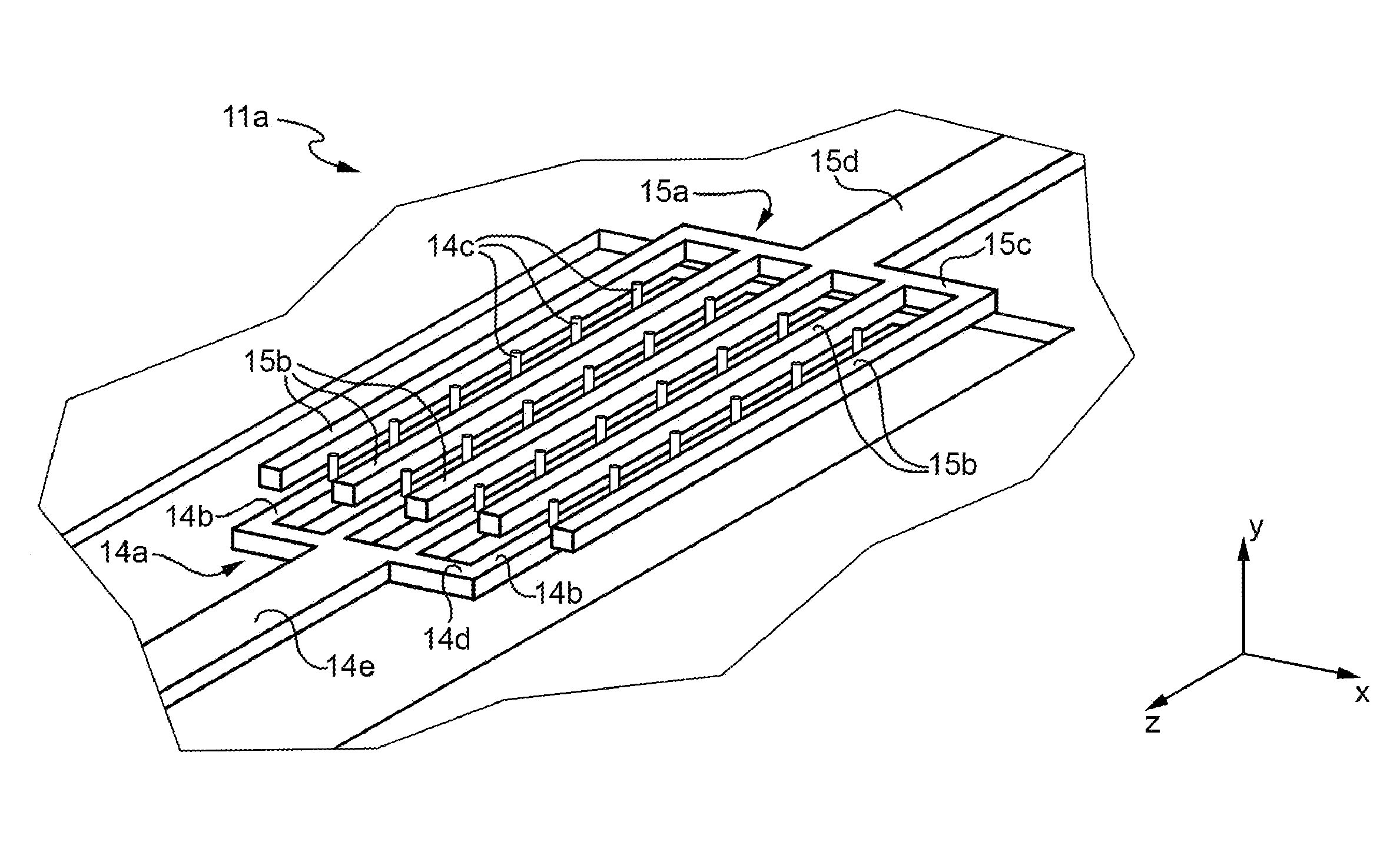

A solid-state vacuum device (SSVD) and method for making the same. In one embodiment, the SSVD forms a triode device comprising a substrate having a cavity formed therein. The SSVD further comprises cathode positioned near the opening of the cavity, wherein the cathode spans over the cavity in the form of a bridge that creates an air gap between the cathode and substrate. In addition, the SSVD further comprises an anode and a grid that is positioned between the anode and cathode. Upon applying heat to the cathode, electrons are released from the cathode, passed through the grid, and received by the anode. In response to receiving the electrons, the anode produces a current. The current received by the anode is controlled by a voltage applied to the grid. Other embodiments of the present invention provide diode, tetrode, pentode, and other higher order device configurations.

Owner:HWU RUEY JEN +1

Electrode for a high pressure discharge lamp, high pressure discharge lamp, and method of manufacturing therefor

InactiveUS20010030498A1Suppress mutationControl electrodesElectroluminescent light sourcesOptoelectronicsHigh pressure

A high pressure discharge lamp which achieves a long life of at least 3000 hours and in which variations in lamp characteristics are suppressed is disclosed. In the high pressure discharge lamp of the present invention, during manufacturing of an electrode, a covering member 123 having a coil shape and being made of refractory metal is applied on a discharge side end of an electrode rod 122 made of refractory metal so as to cover a circumference of the electrode rod 122 in a vicinity of the discharge side end. The discharge side end 124 on which the covering member 123 is applied is fused into a semi-sphere by intermittently heat fusing the discharge side end according, for instance, to arc discharge or laser irradiation.

Owner:PANASONIC CORP

Solid state vacuum devices and method for making the same

A solid-state vacuum device (SSVD) and method for making the same. In one embodiment, the SSVD forms a triode device comprising a substrate having a cavity formed therein. The SSVD further comprises cathode positioned near the opening of the cavity, wherein the cathode spans over the cavity in the form of a bridge that creates an air gap between the cathode and substrate. In addition, the SSVD further comprises an anode and a grid that is positioned between the anode and cathode. Upon applying heat to the cathode, electrons are released from the cathode, passed through the grid, and received by the anode. In response to receiving the electrons, the anode produces a current. The current received by the anode is controlled by a voltage applied to the grid. Other embodiments of the present invention provide diode, tetrode, pentode, and other higher order device configurations.

Owner:INNOSYS

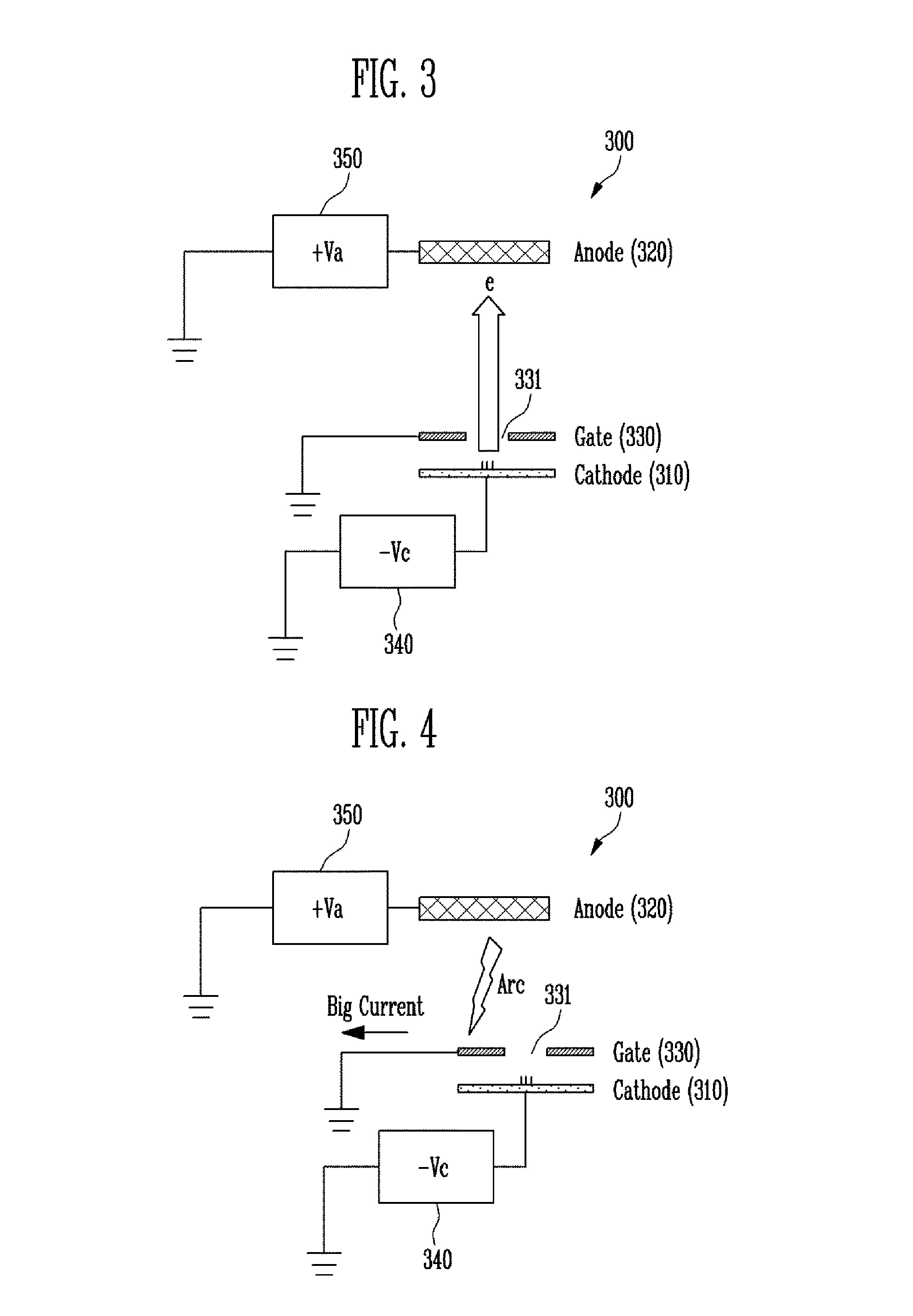

Field emission device

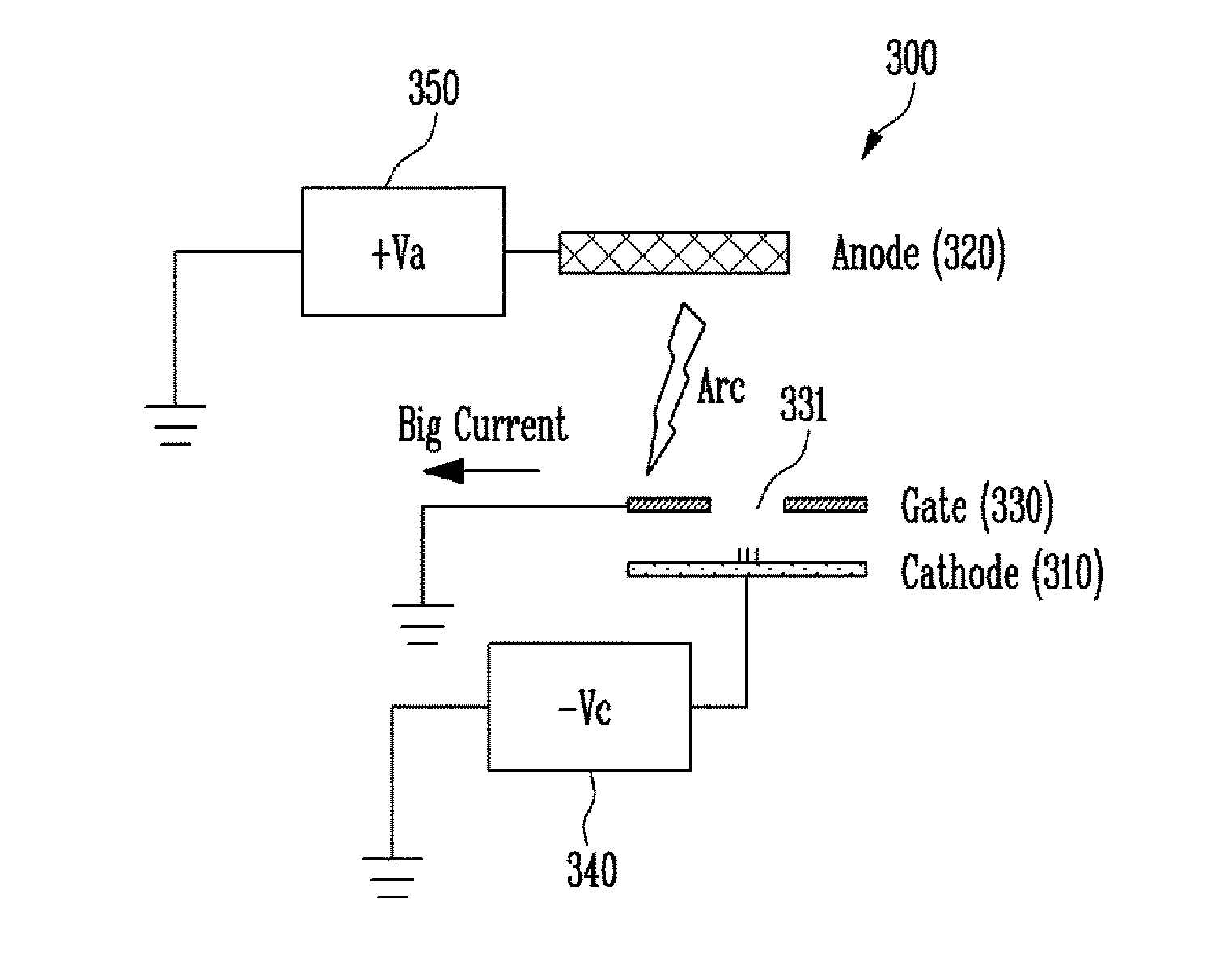

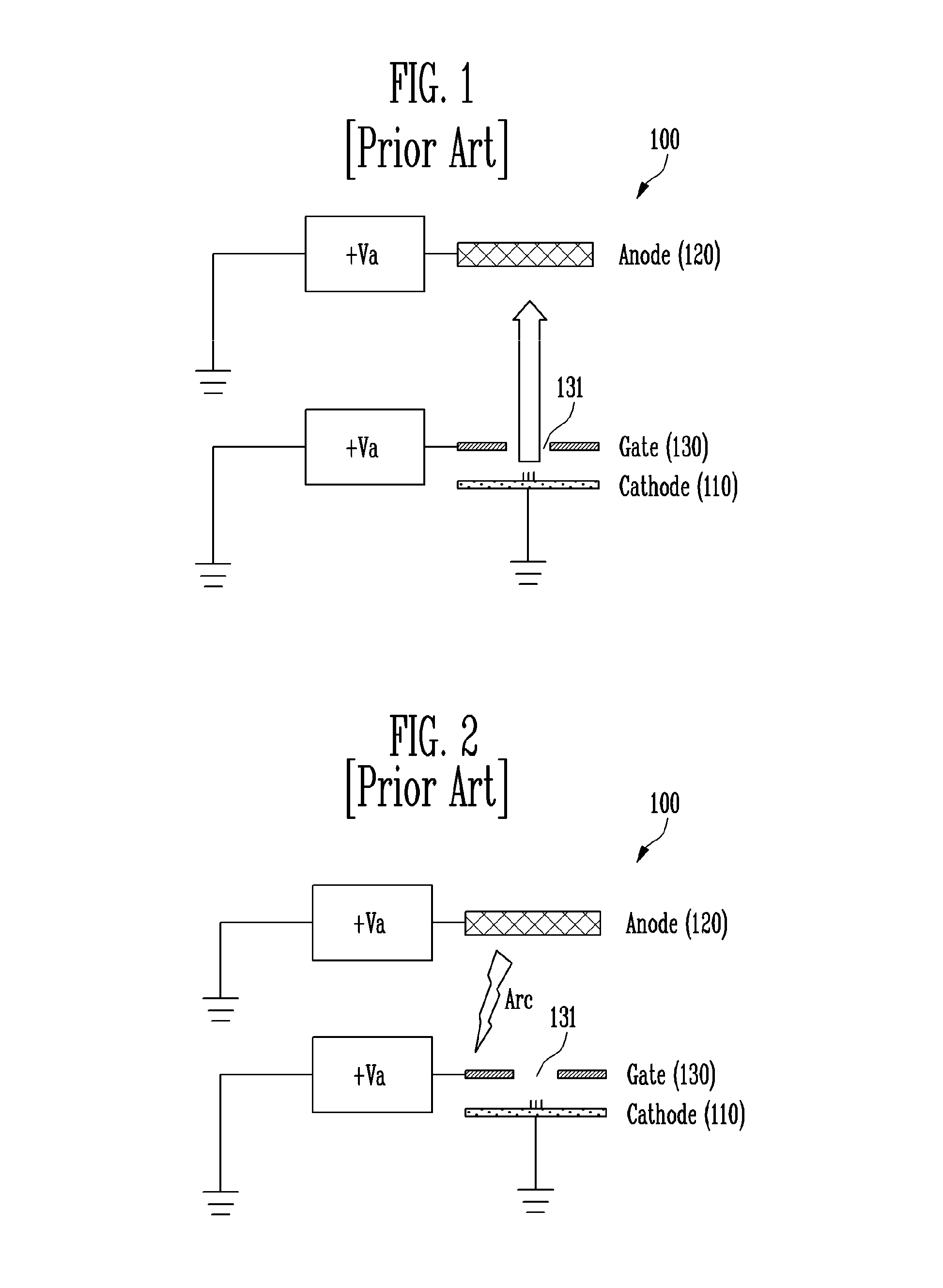

ActiveUS20160148776A1Electrode and associated part arrangementsAlternating current plasma display panelsField emission deviceNegative power

Provided herein is a field emission device. The field emission device includes a cathode which is connected to a negative power supply and emits electrons, an anode which is connected to a positive power supply and includes a target material receiving the electrons emitted from the cathode, and a ground electrode which is formed to face the anode and has an opening through which the electrons emitted from the cathode pass. The ground electrode is grounded so that when an arc discharge occurs due to high voltage operation of the anode, electric charge produced by the arc discharge is emitted to a ground.

Owner:ELECTRONICS & TELECOMM RES INST

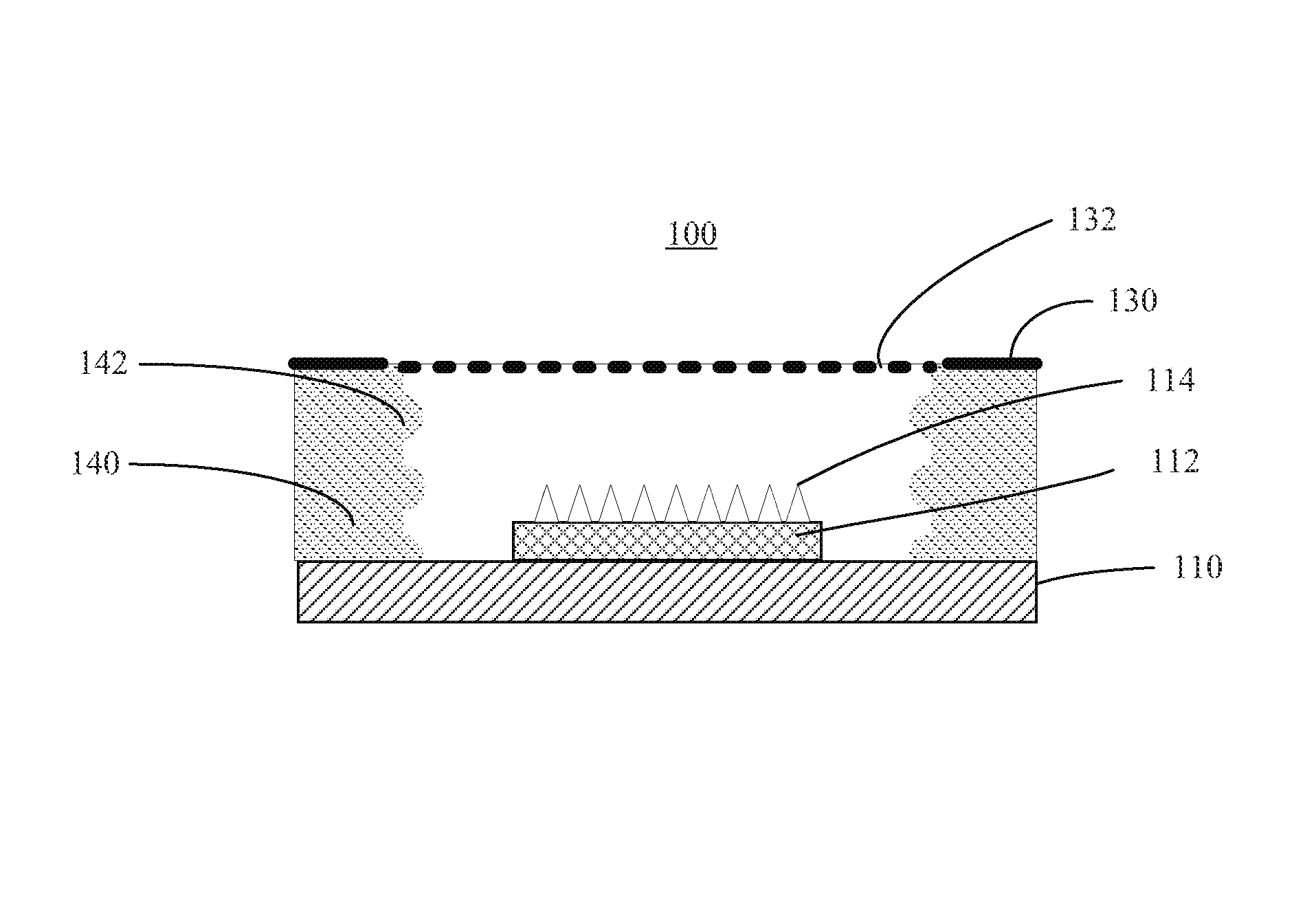

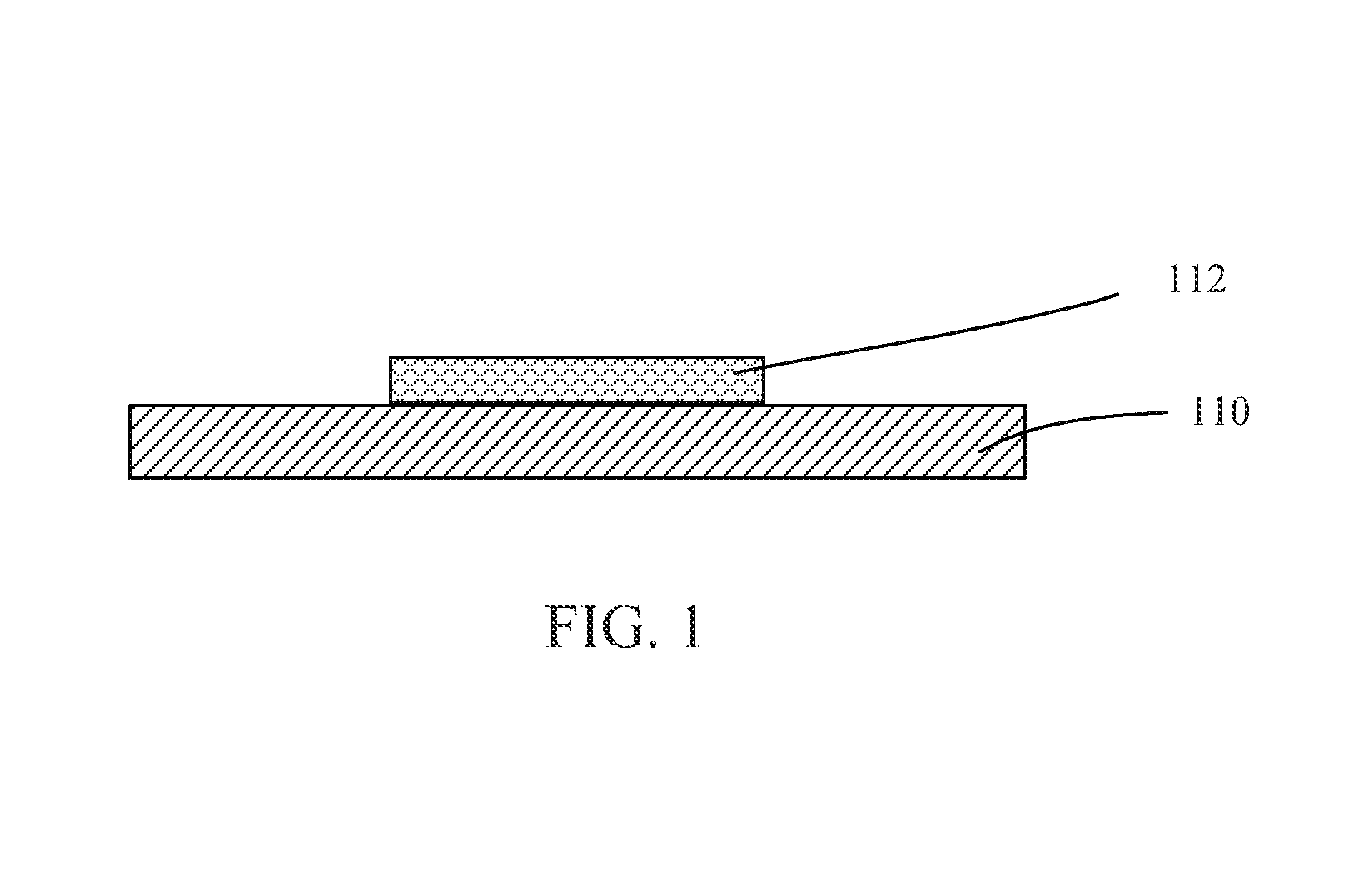

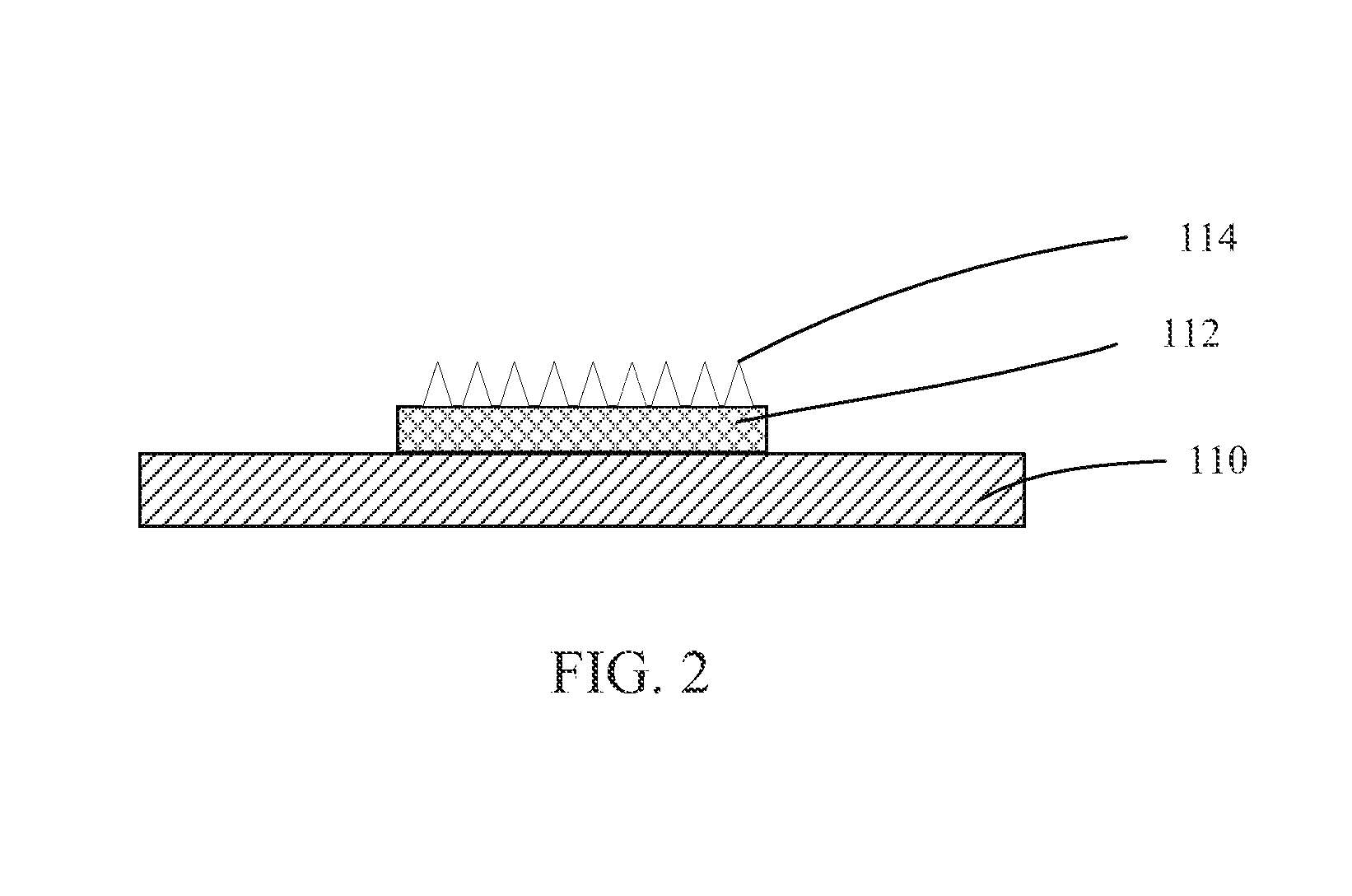

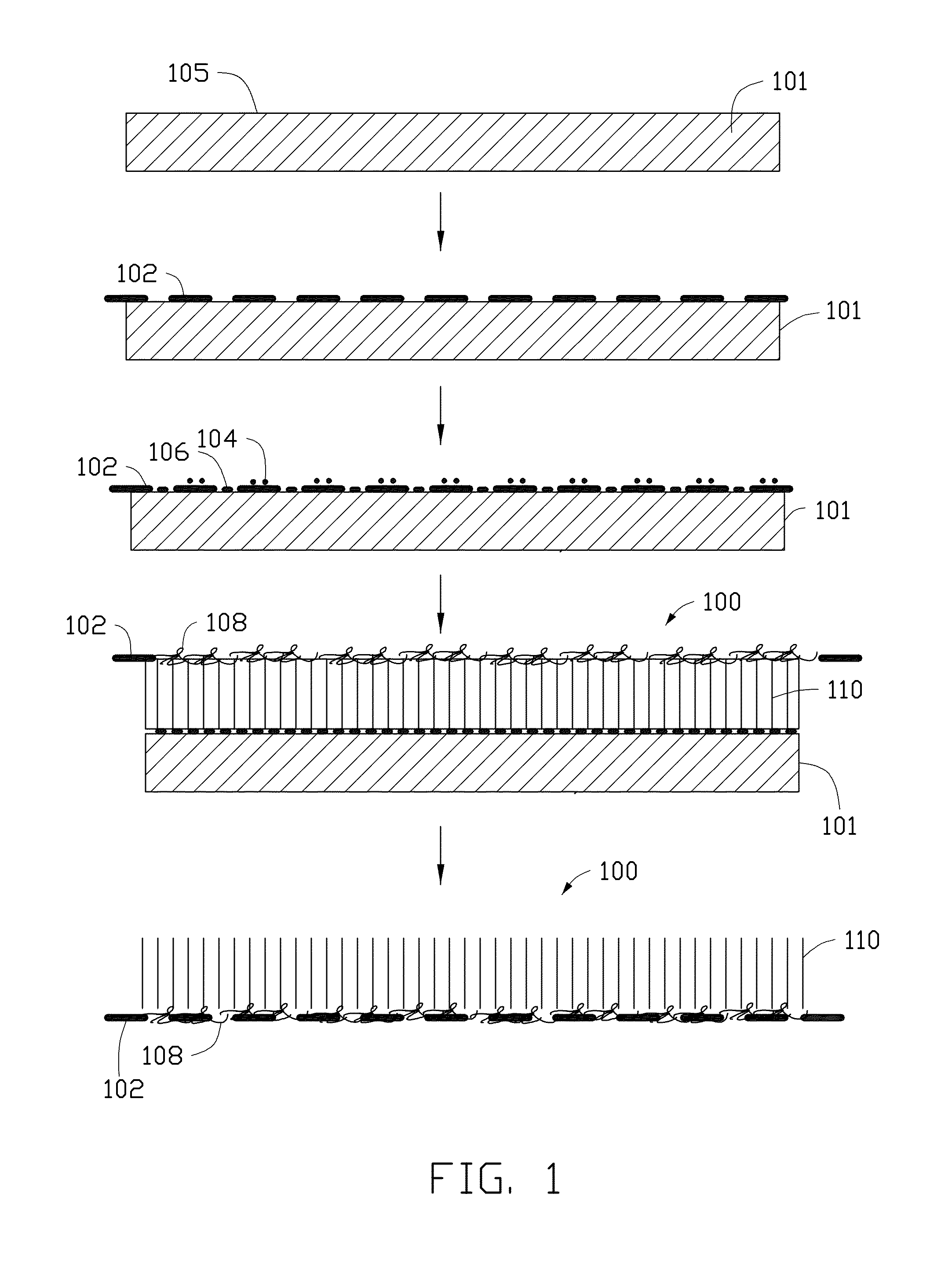

Field electron emission source

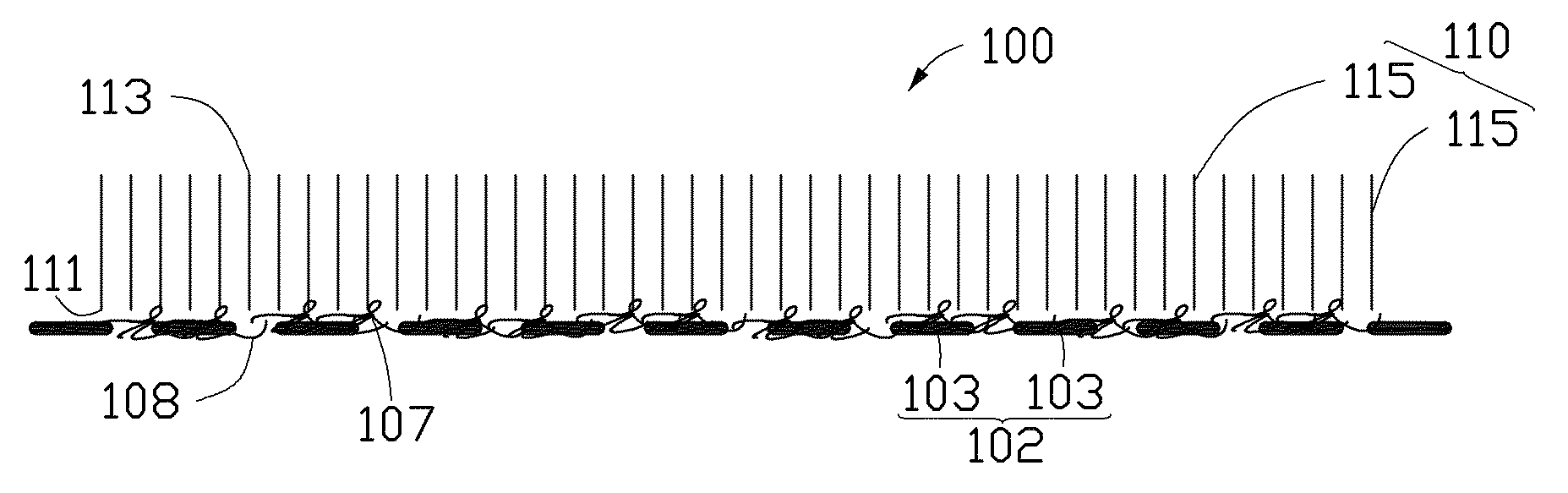

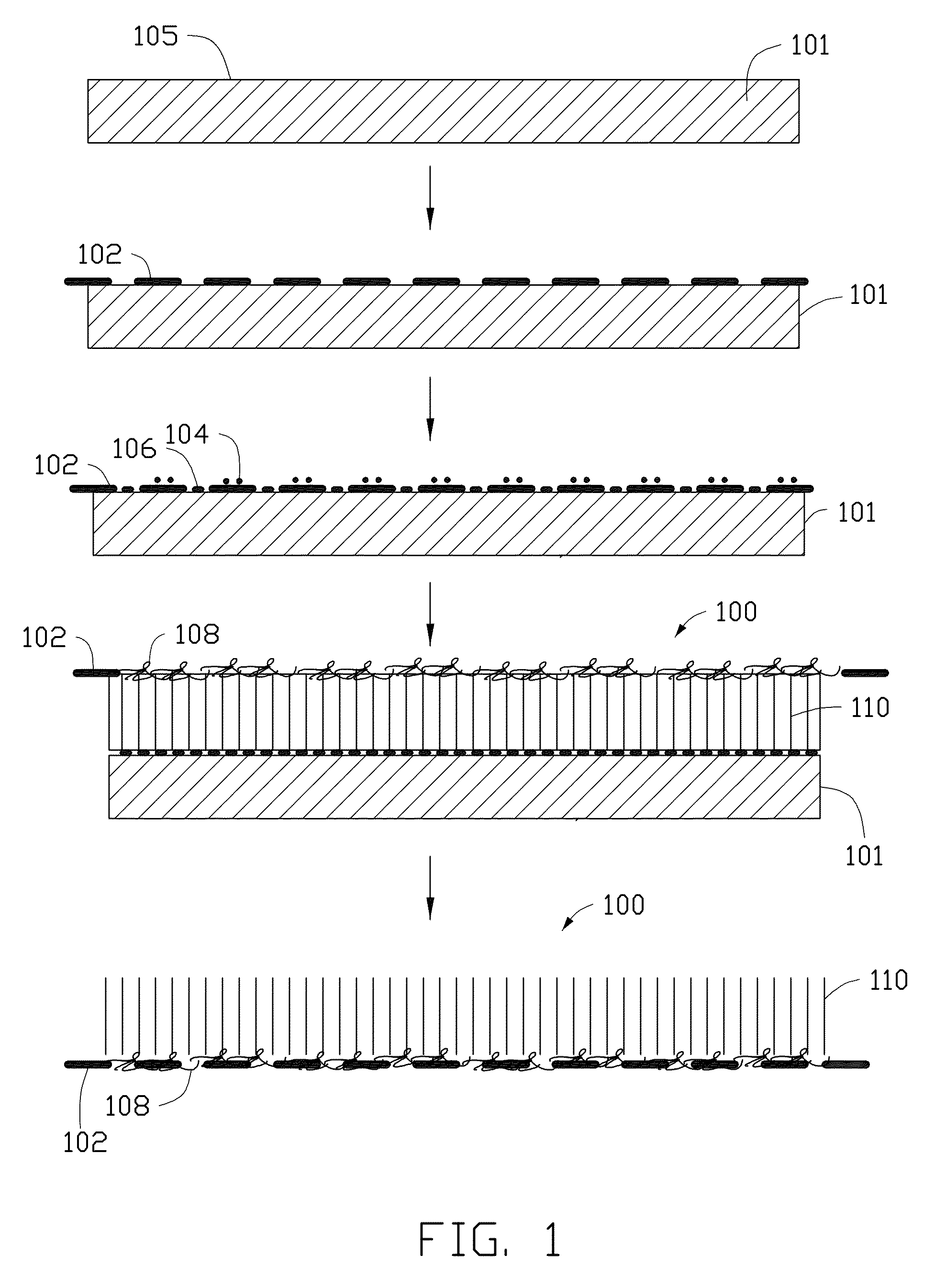

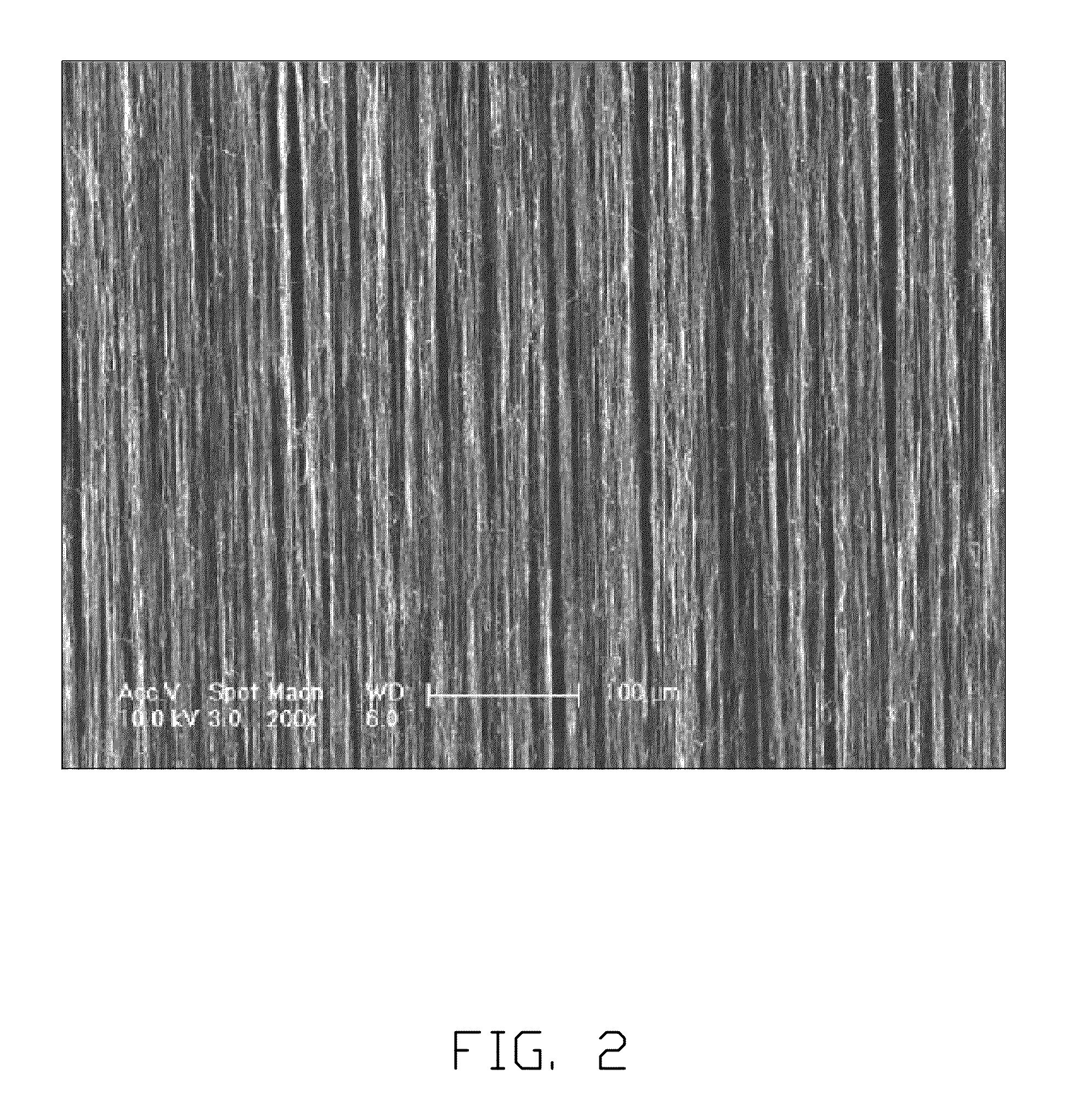

ActiveUS8350459B2Reduced stabilityWide applicationTube/lamp screens manufactureControl electrodesField electron emissionHigh electron

A method for manufacturing a field electron emission source includes: providing an insulating substrate; patterning a cathode layer on at least one portion of the insulating substrate; forming a number of emitters on the cathode layer; coating a photoresist layer on the insulating substrate, the cathode layer and the emitters; exposing predetermined portions of the photoresist layer to radiation, wherein the exposed portions are corresponding to the emitters; forming a mesh structure on the photoresist layer; and removing the exposed portions of photoresist layer. The method can be easily performed and the achieved the field electron emission source has a high electron emission efficiency.

Owner:TSINGHUA UNIV +1

Cathode

ActiveUS7864925B2High electron emissionExtended service lifeControl electrodesX-ray tube electrodesField electron emissionHigh electron

A cathode has a cathode head in which is arranged a surface emitter is arranged that emits electrons upon the application of a heating voltage. At least one electrically conductive barrier plate that is galvanically separated from the surface emitter extends up to the surface emitter. This cathode has a longer lifespan, a high electron emission and a good blocking capability.

Owner:SIEMENS HEALTHCARE GMBH

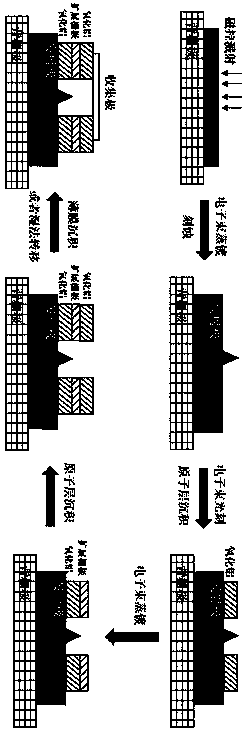

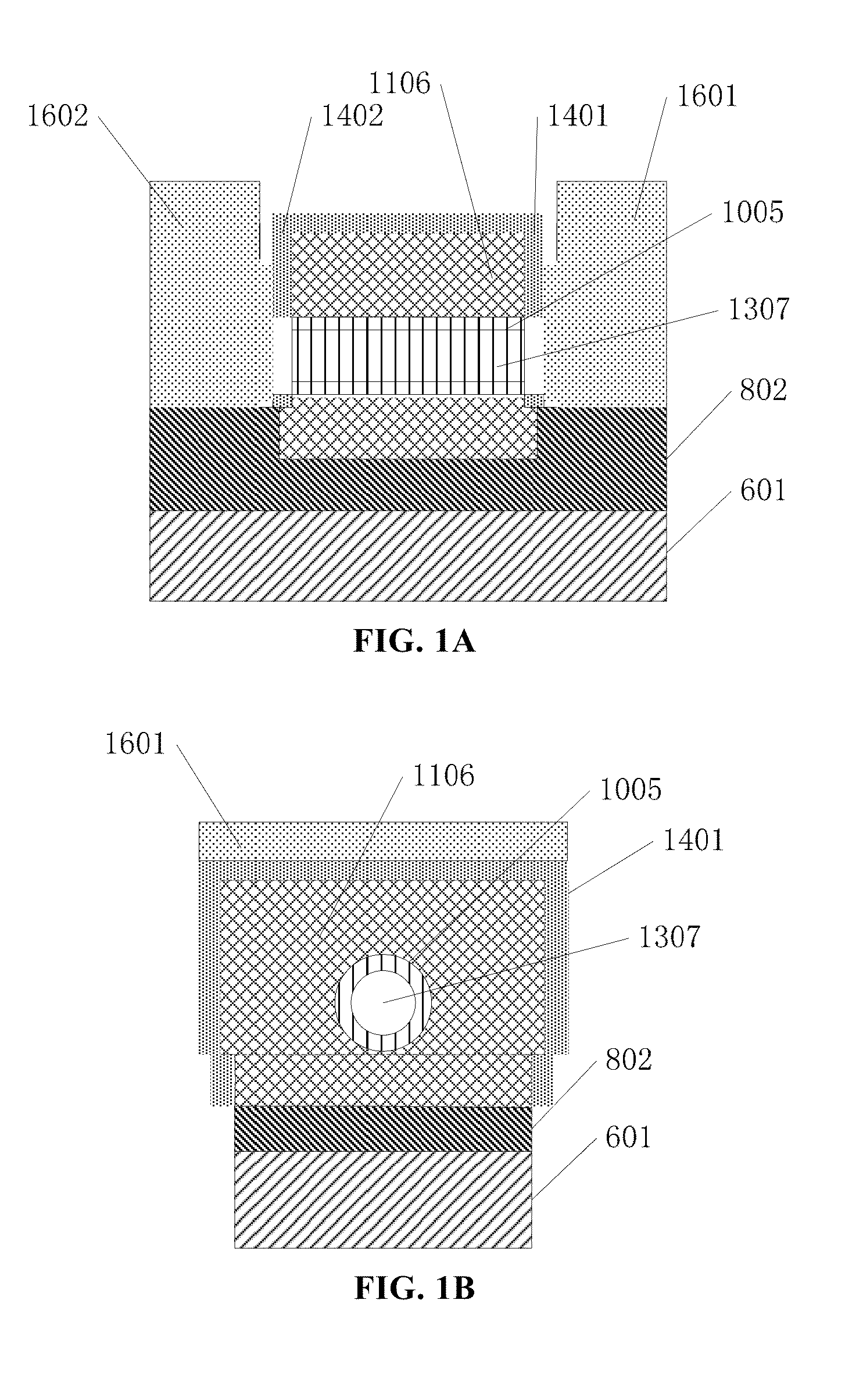

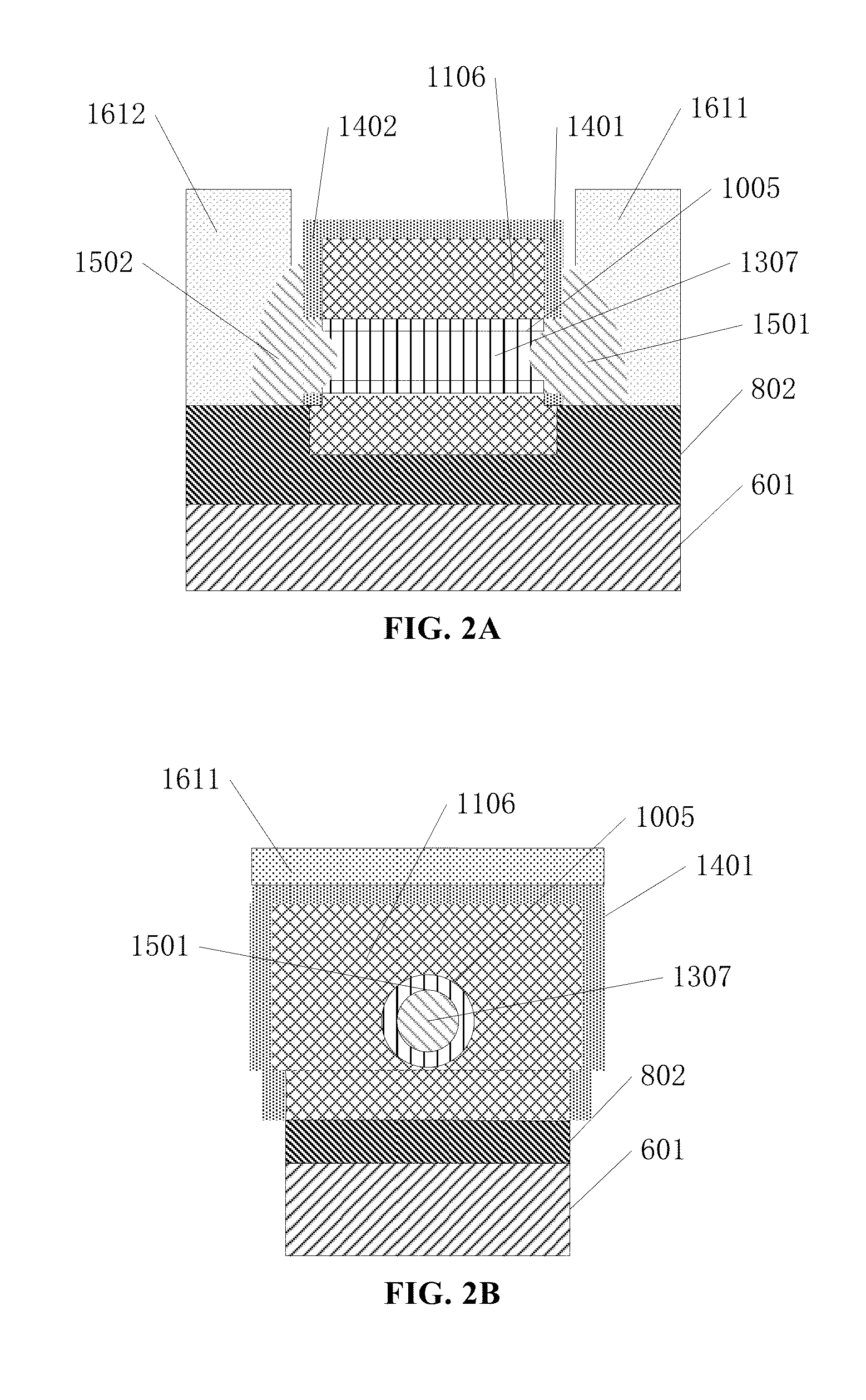

Vertical type nano gap vacuum transistor with extended gate structure and preparation method thereof

InactiveCN110310873AEnhanced surface electric field strengthImprove emission efficiencyNon-electron-emitting anodesNon-emitting electrodes manufactureElectricityElectronic systems

The invention discloses a vertical type nano gap vacuum transistor with an extended gate structure and a preparation method thereof. The vertical type nano gap vacuum transistor includes an emitter, acollector, a gate and an oxide insulating layer, and the nano gap refers to distances between the collector and the emitter and between the gate and the emitter in a sub-100 nm scale. The vertical type nano gap vacuum transistor is advantaged in that dimensions of vacuum devices are compressed to the sub-100 nm scale, device processing requirements are similar to traditional semiconductor processes, a problem that traditional electric vacuum devices require complex machining and assembling is ameliorated, more importantly, and the possibility of realizing miniaturization and integration of vacuum components, integrated circuits and vacuum electronic systems in the future is provided.

Owner:SOUTHEAST UNIV

Information storage apparatus storing and reading information by irradiating a storage medium with electron beam

InactiveUS7471542B2Inhibition of attachmentReduced stabilityRead-only memoriesRecord information storageHigh energyPotential difference

To greatly increase the storage density of a storage apparatus, an electron beam E emitted from a cold cathode 101 is accelerated by an accelerating electrode 102, caused to converge by a convergence electrode 103, deflected by a deflection electrode 104 and applied to a minute region of a storage film 105. The storage film 105 includes, for example, a phase change film 105a. The film is rapidly heated and cooled to change into an amorphous state upon irradiation with an electron beam E with high energy, while being gradually cooled to change into a crystallized state upon irradiation with an electron beam E with approximately intermediate energy, thereby storing data. Upon irradiation with an electron beam E with low energy, the potential difference between a detection electrode 105b and an anode 105c is detected depending on the state, i.e., the amorphous or crystallized state, thereby reading stored data.

Owner:PANASONIC CORP

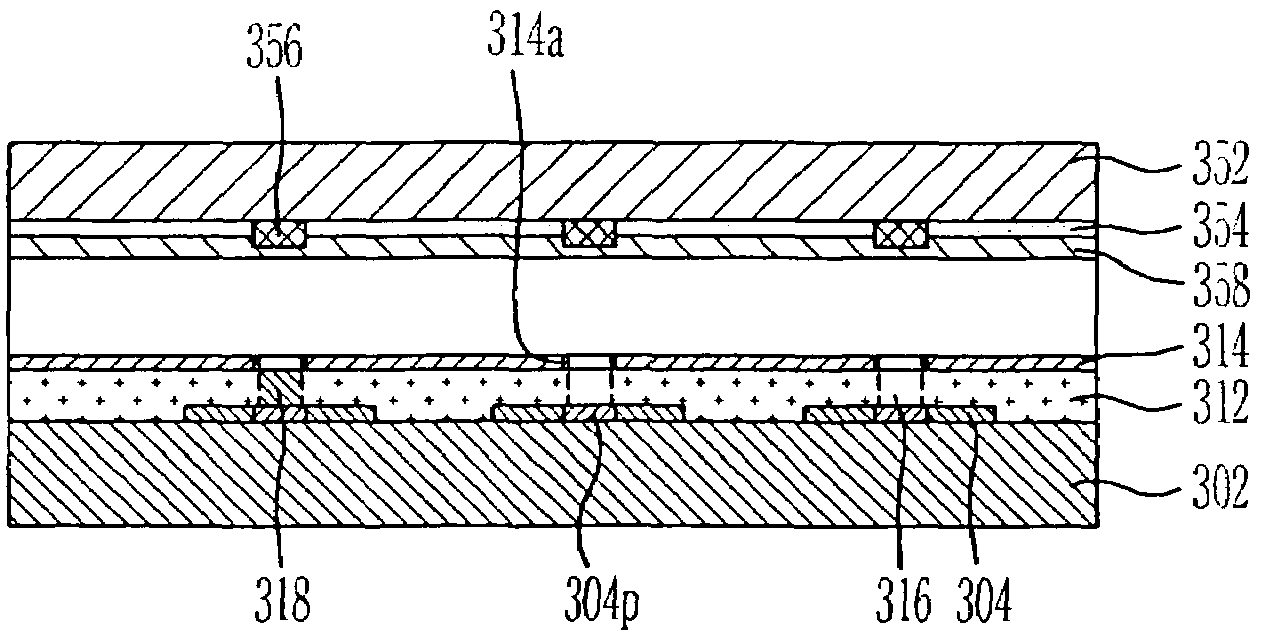

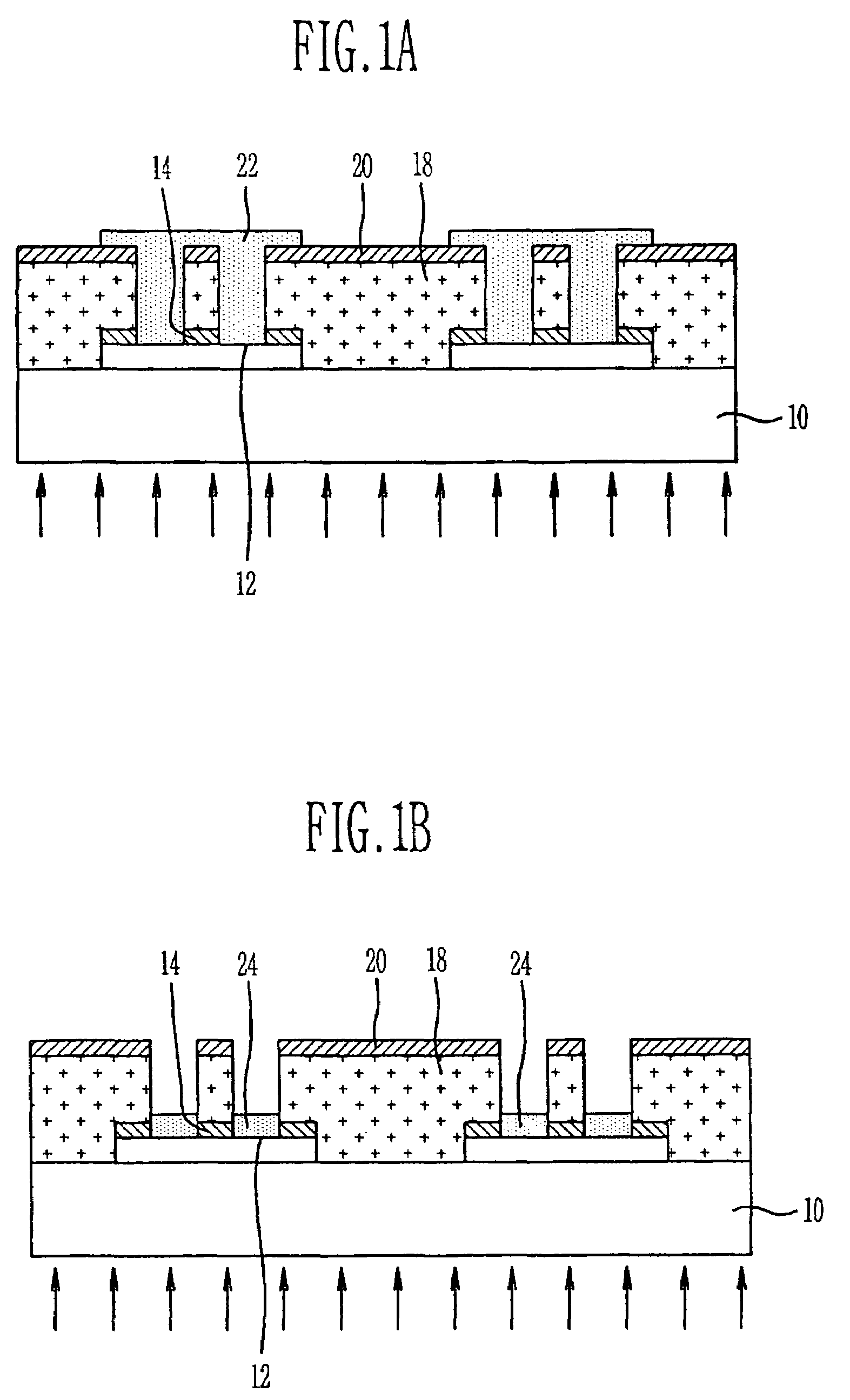

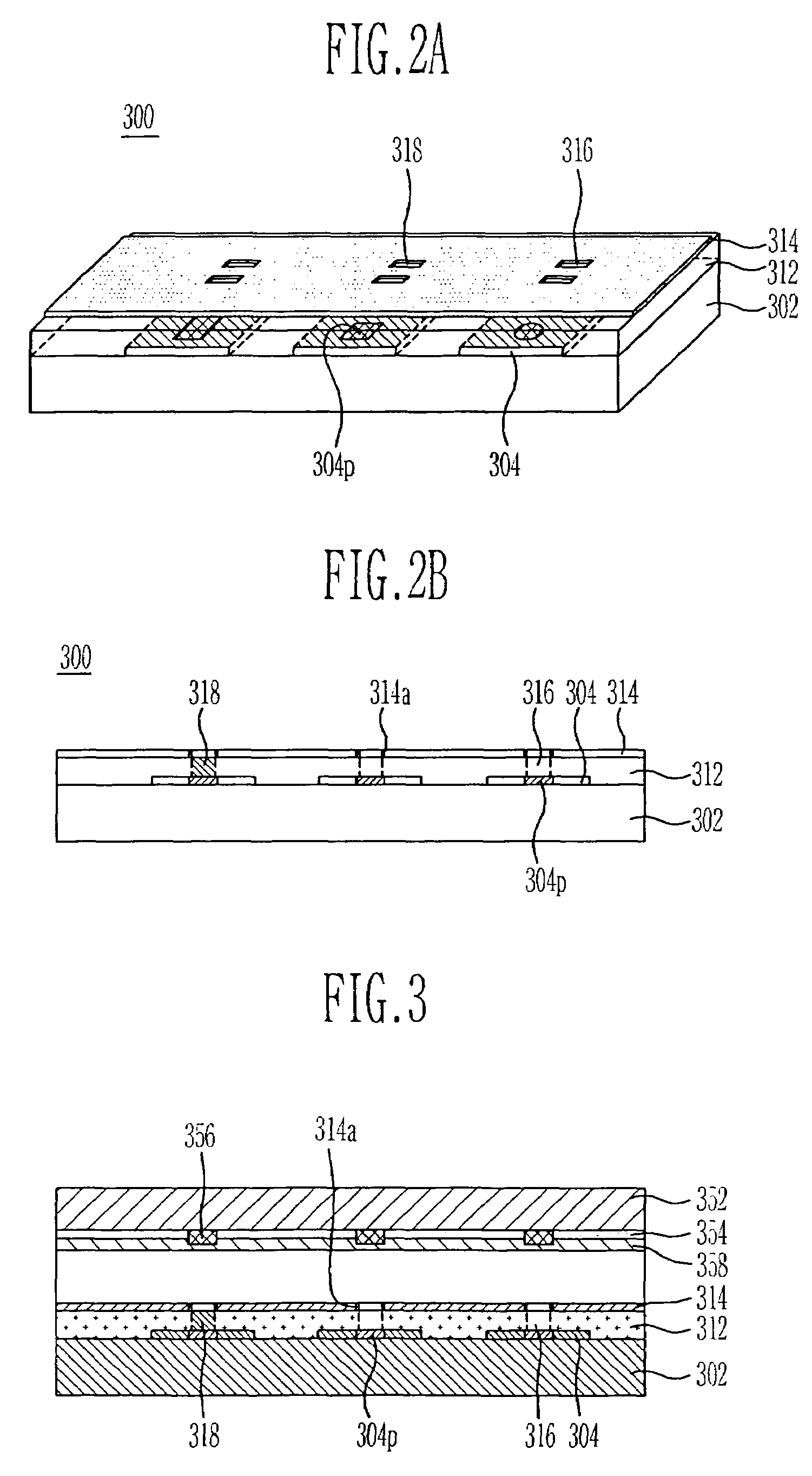

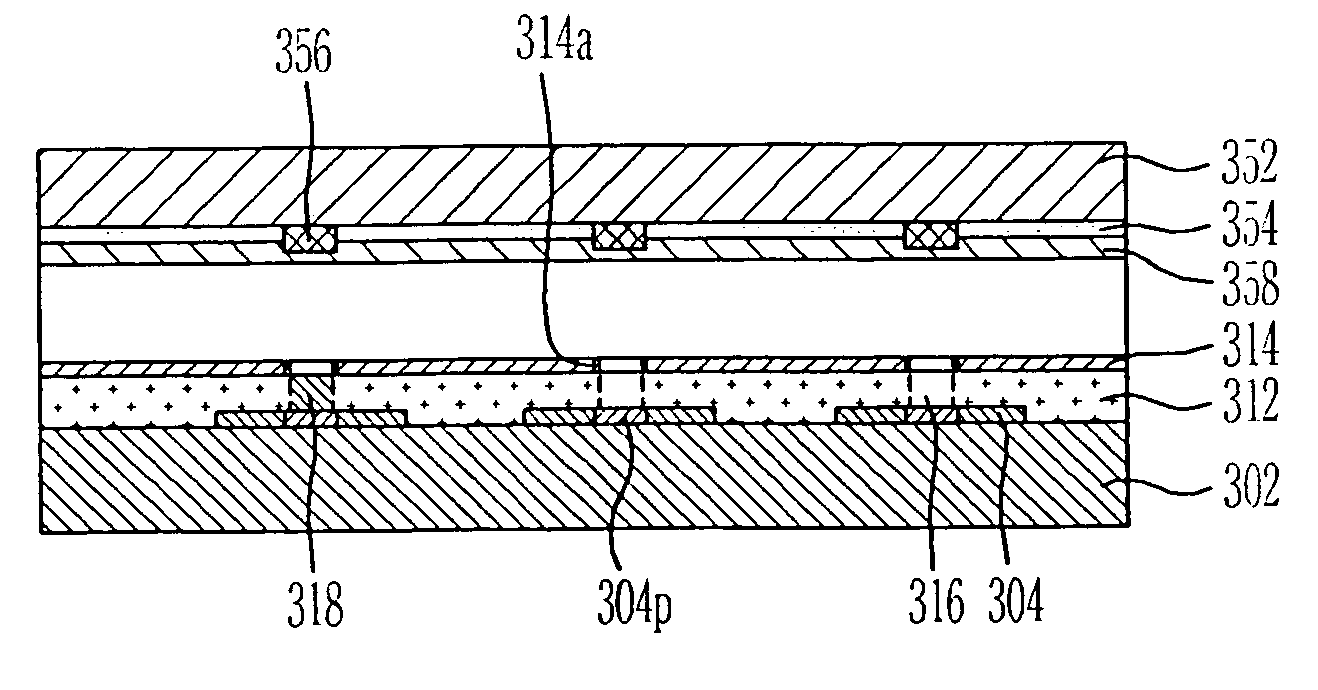

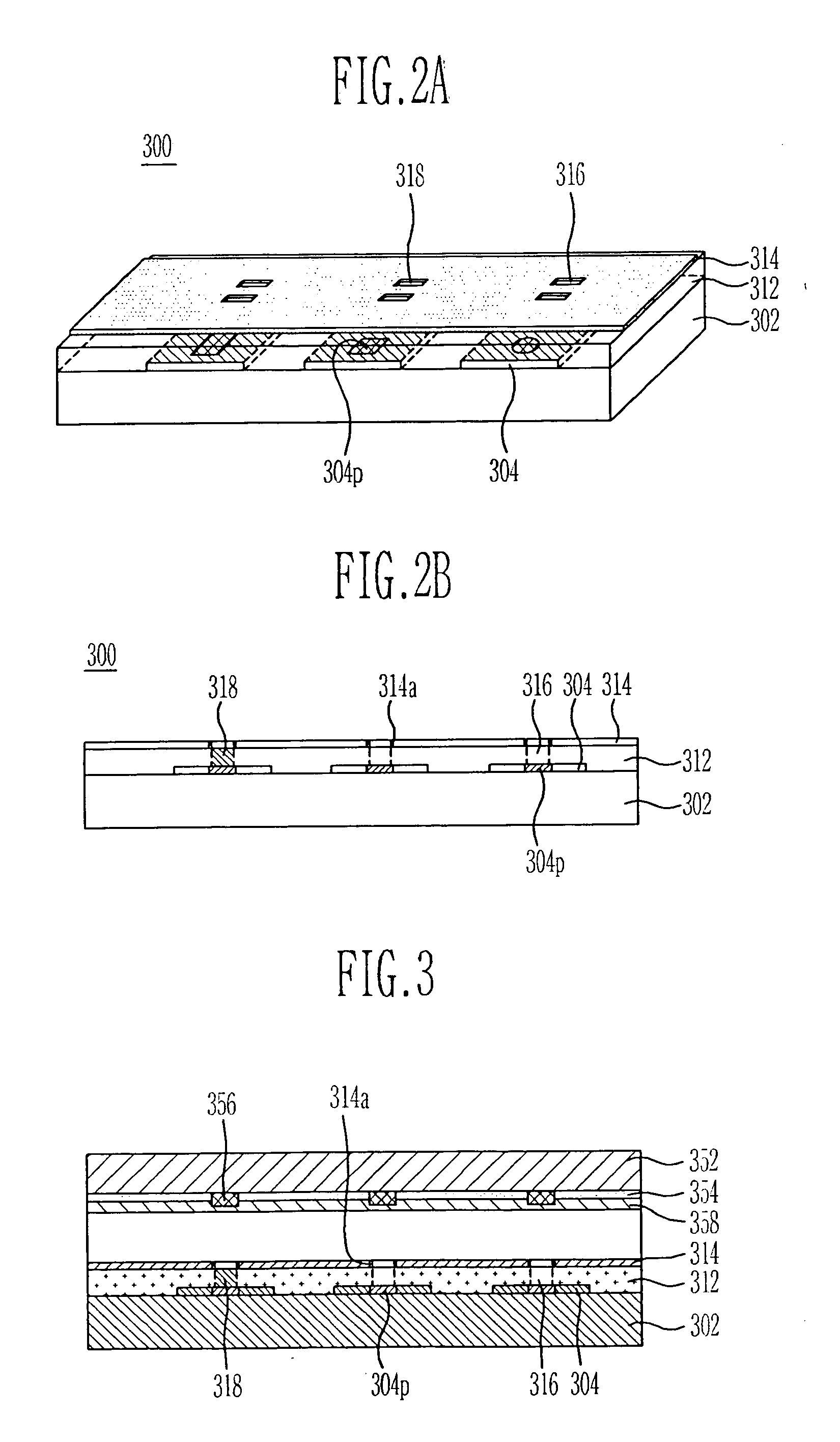

Electron emission device with decreased electrode resistance and fabrication method and electron emission display

InactiveUS7586251B2Lower electrode resistanceControl electrodesThermionic cathodesFluorescenceDisplay device

An electron emission device includes: a substrate; first and second electrodes insulated from each other and having a predetermined shape on the substrate, at least one of the first and second electrodes being formed with a fine mesh pattern; and an electron emission region formed on the substrate and connected to one of the first and second electrodes. Furthermore, an electron emission display includes: first and second substrate arranged opposite to each other; first and second electrodes insulated from each other and having a predetermined shape on the first substrate, at least one of the first and second electrodes being formed with a fine mesh pattern; an electron emission region formed on the first substrate and connected to one of the first and second electrodes; and an image displaying portion including an anode electrode and a fluorescent layer arranged on the second substrate.

Owner:SAMSUNG SDI CO LTD

Electron emission device and fabrication method and electron emission display

InactiveUS20060055311A1Lower electrode resistanceControl electrodesThermionic cathodesDisplay deviceElectron

An electron emission device includes: a substrate; first and second electrodes insulated from each other and having a predetermined shape on the substrate, at least one of the first and second electrodes being formed with a fine mesh pattern; and an electron emission region formed on the substrate and connected to one of the first and second electrodes. Furthermore, an electron emission display includes: first and second substrate arranged opposite to each other; first and second electrodes insulated from each other and having a predetermined shape on the first substrate, at least one of the first and second electrodes being formed with a fine mesh pattern; an electron emission region formed on the first substrate and connected to one of the first and second electrodes; and an image displaying portion including an anode electrode and a fluorescent layer arranged on the second substrate.

Owner:SAMSUNG SDI CO LTD

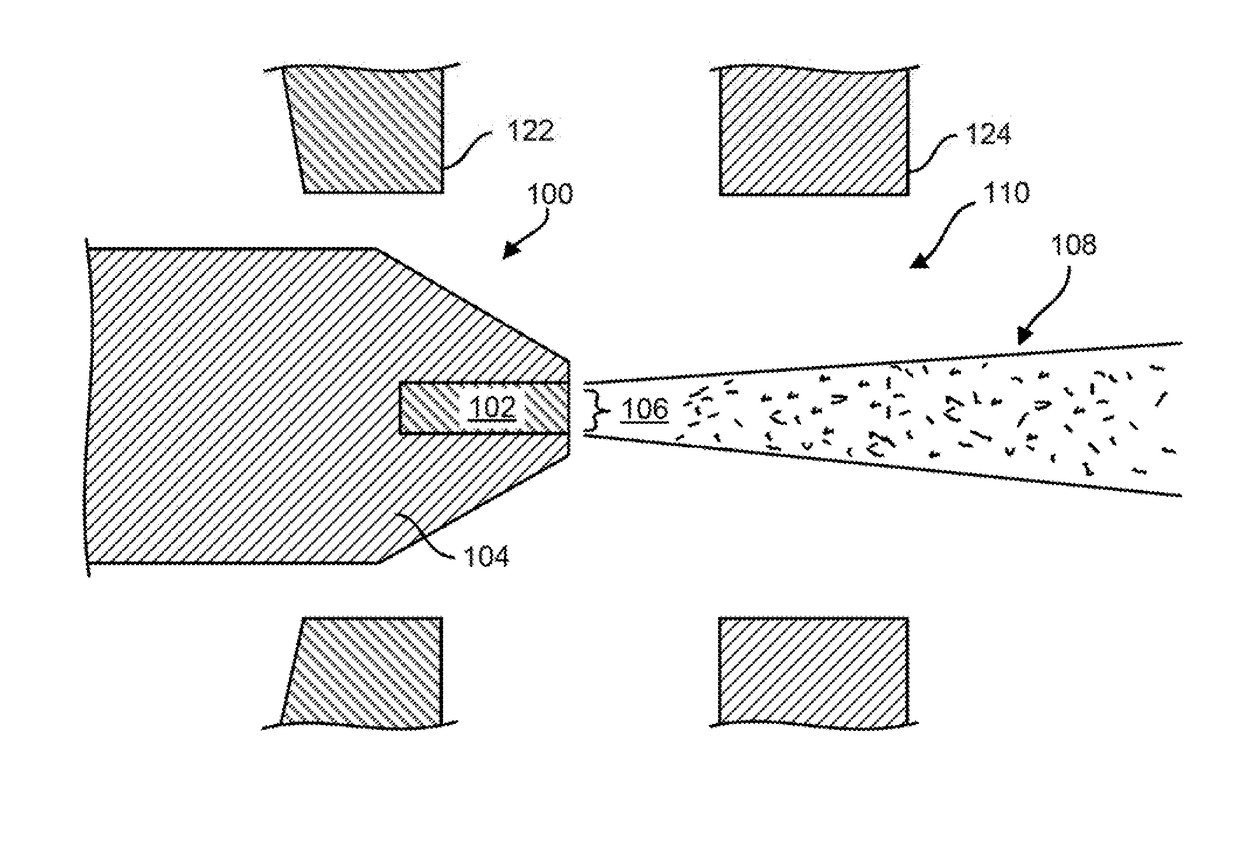

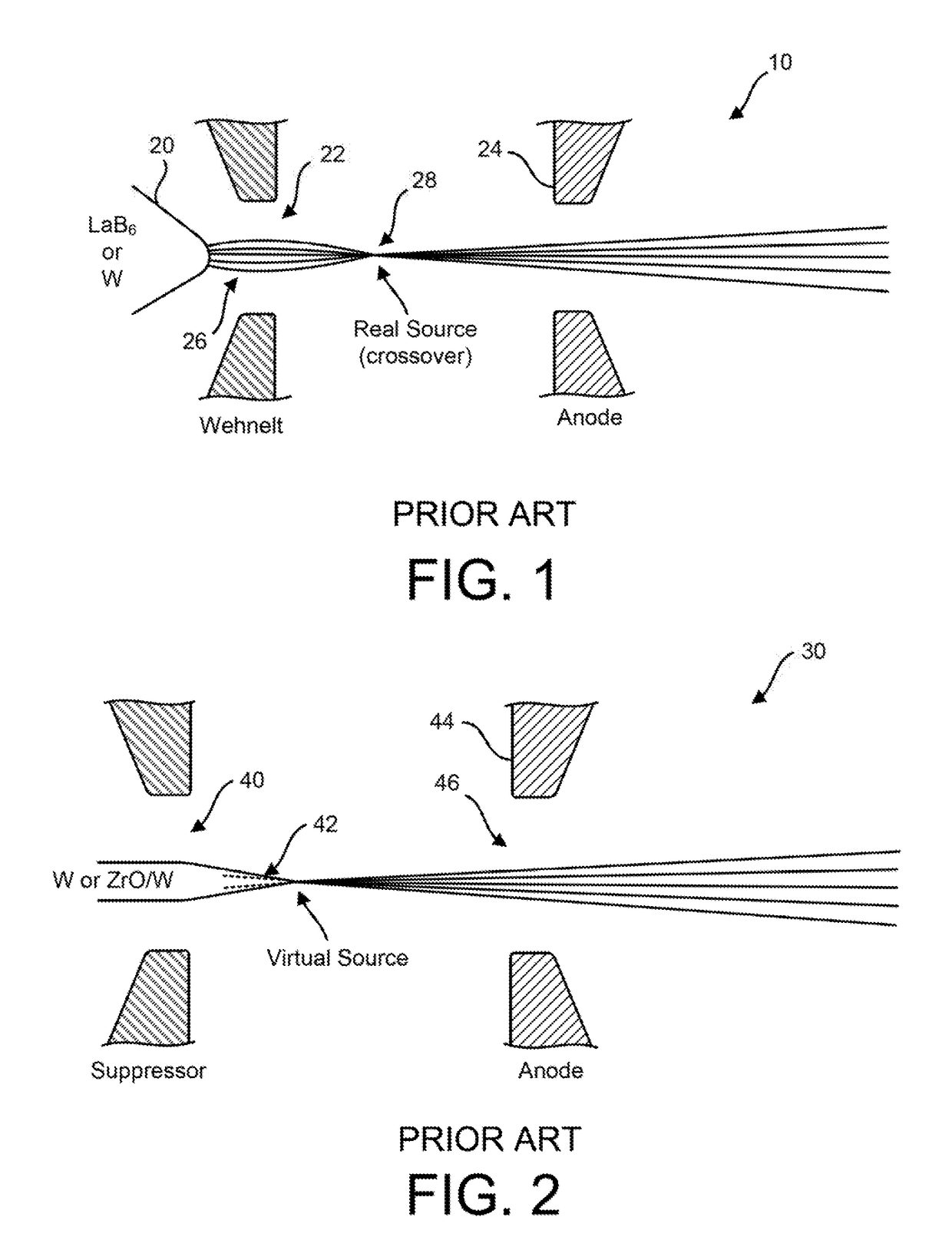

Electron emitter source

An electron emitter that consists of: a low work function material including Lanthanum hexaboride or Iridium Cerium that acts as an emitter, a cylinder base made of high work function material that has a cone shape where the low work function material is embedded in the high work function material but is exposed at end of the cone and the combined structure is heated and biased to a negative voltage relative to an anode, an anode electrode that has positive bias relative to the emitter, and a wehnelt electrode with an aperture where the cylindrical base protrudes through the wehnelt aperture so the end of the cone containing the emissive area is placed between the wehnelt and the anode.

Owner:OREGON PHYSICS +1

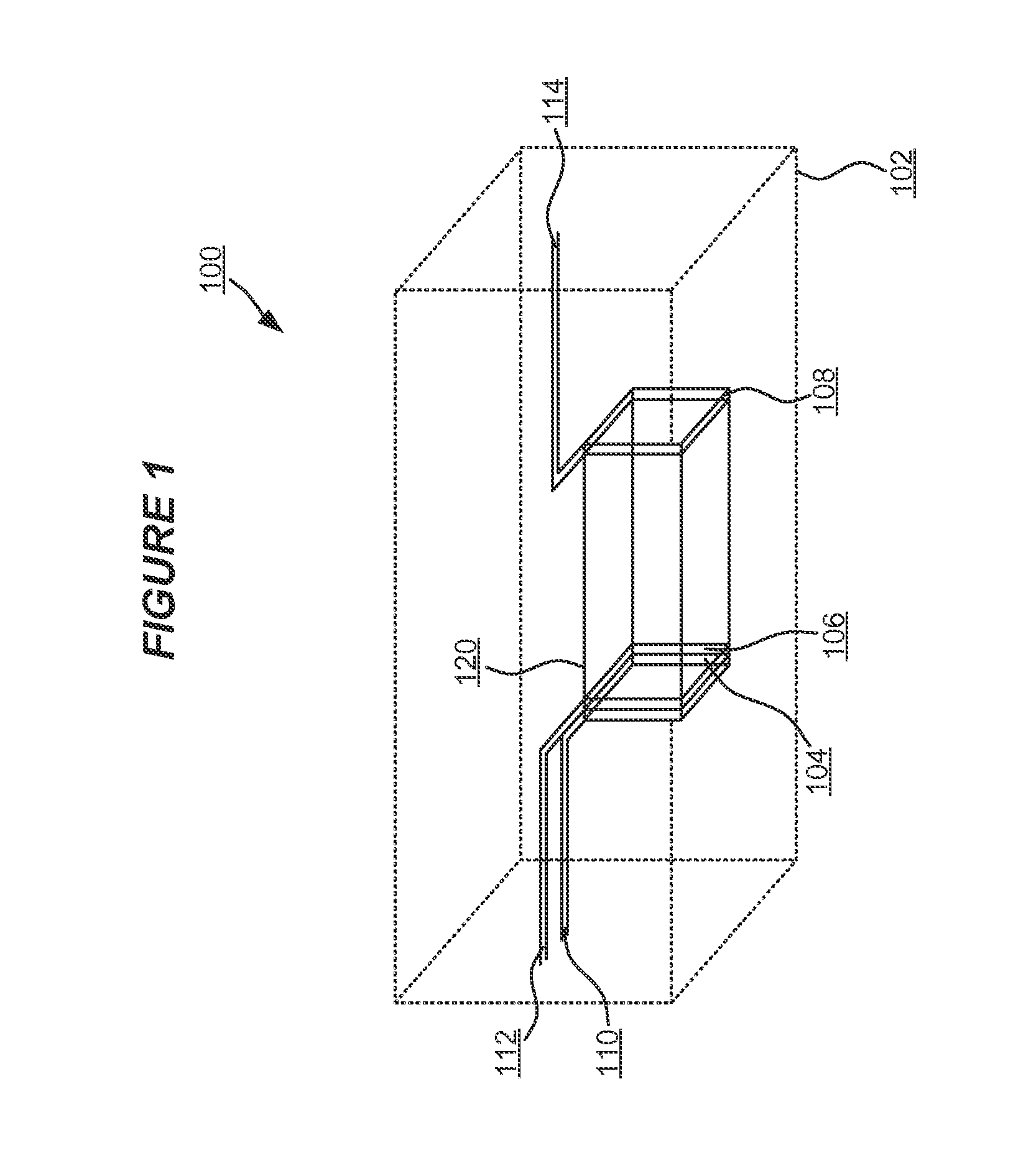

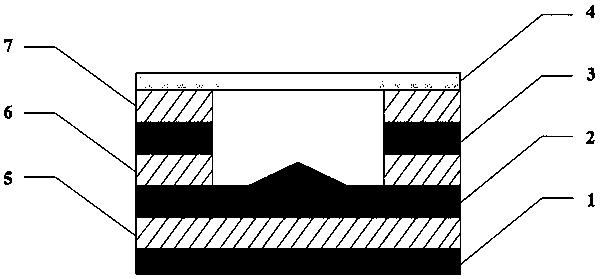

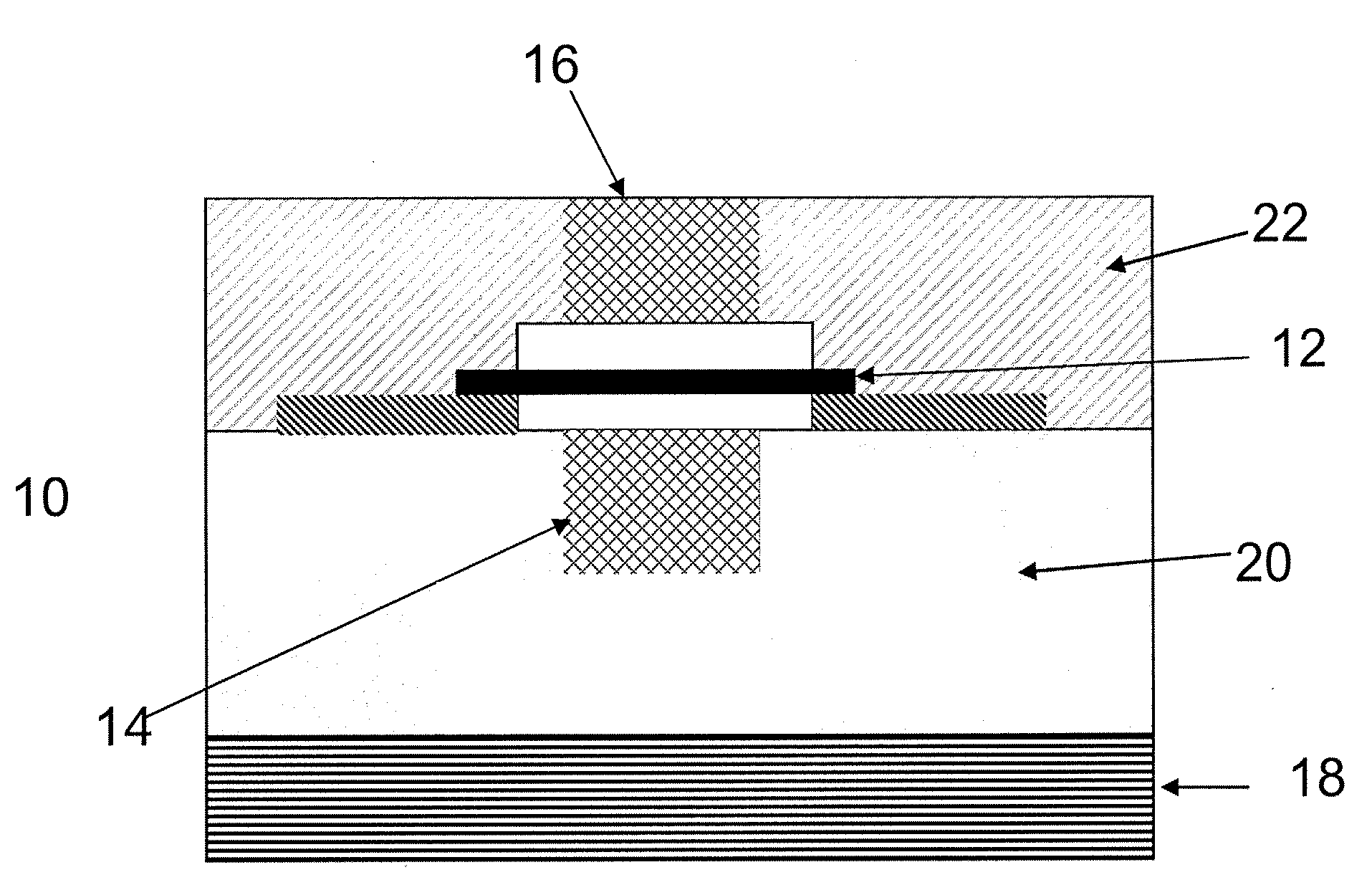

Semiconductor device and related manufacturing method

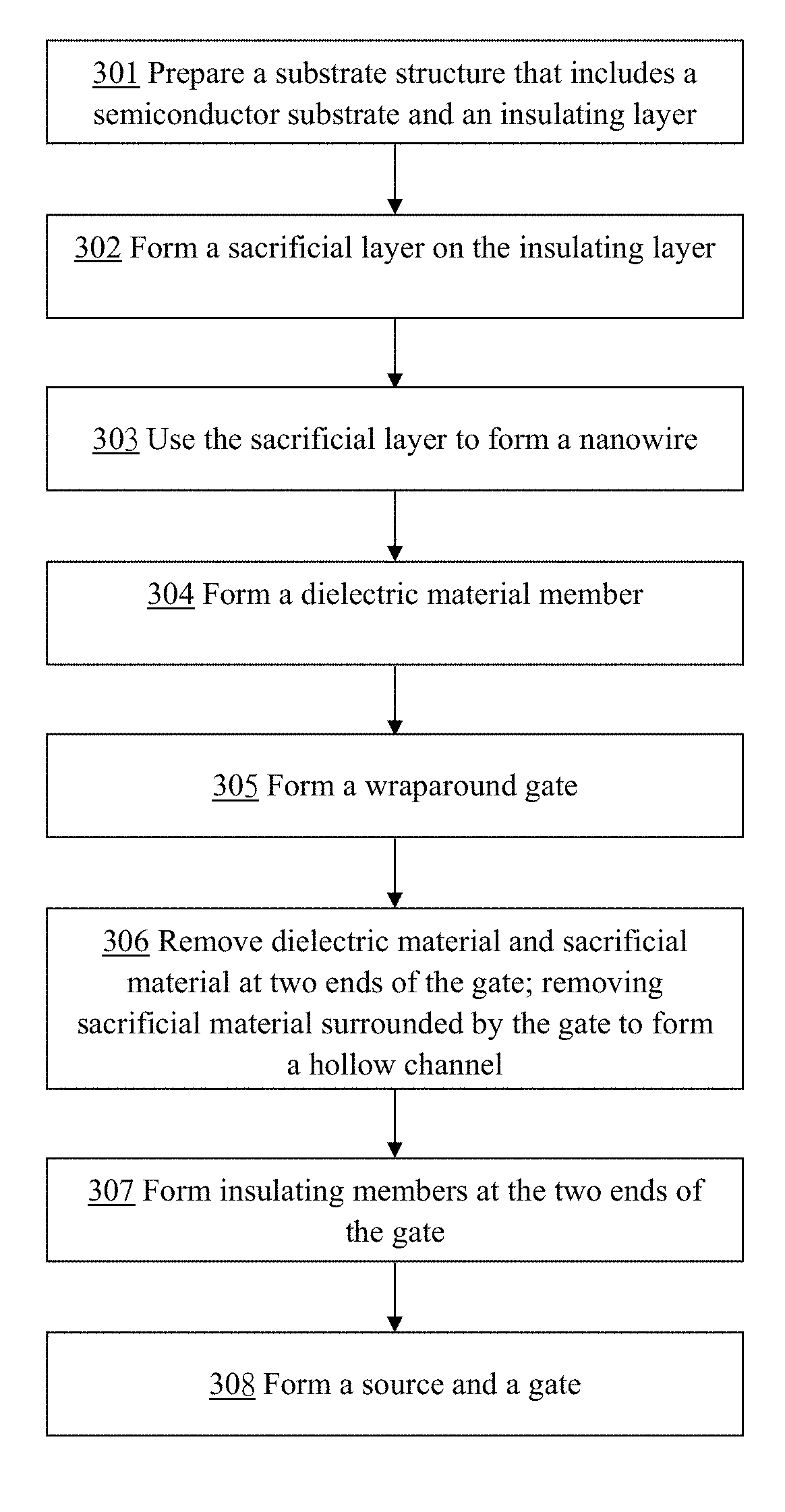

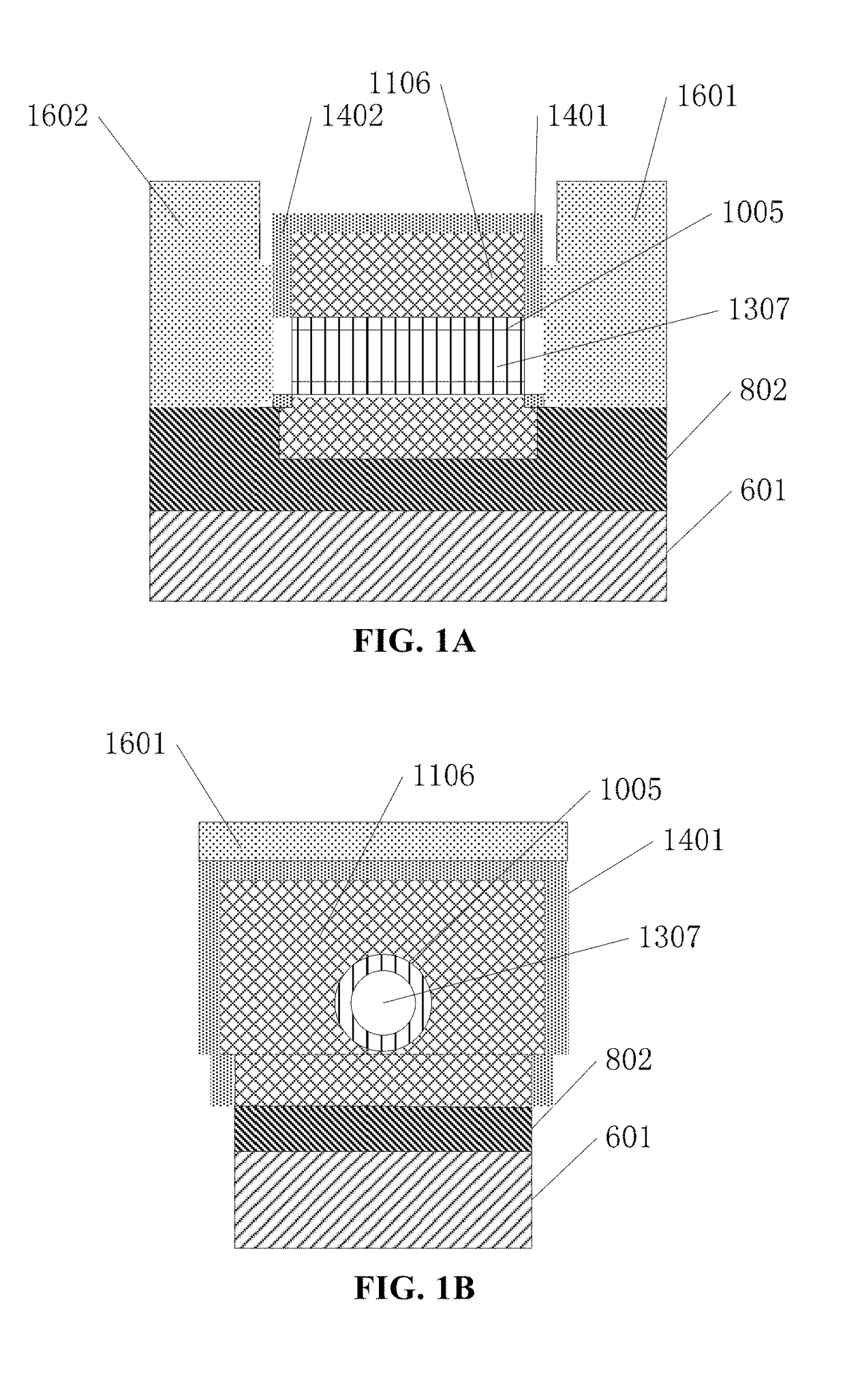

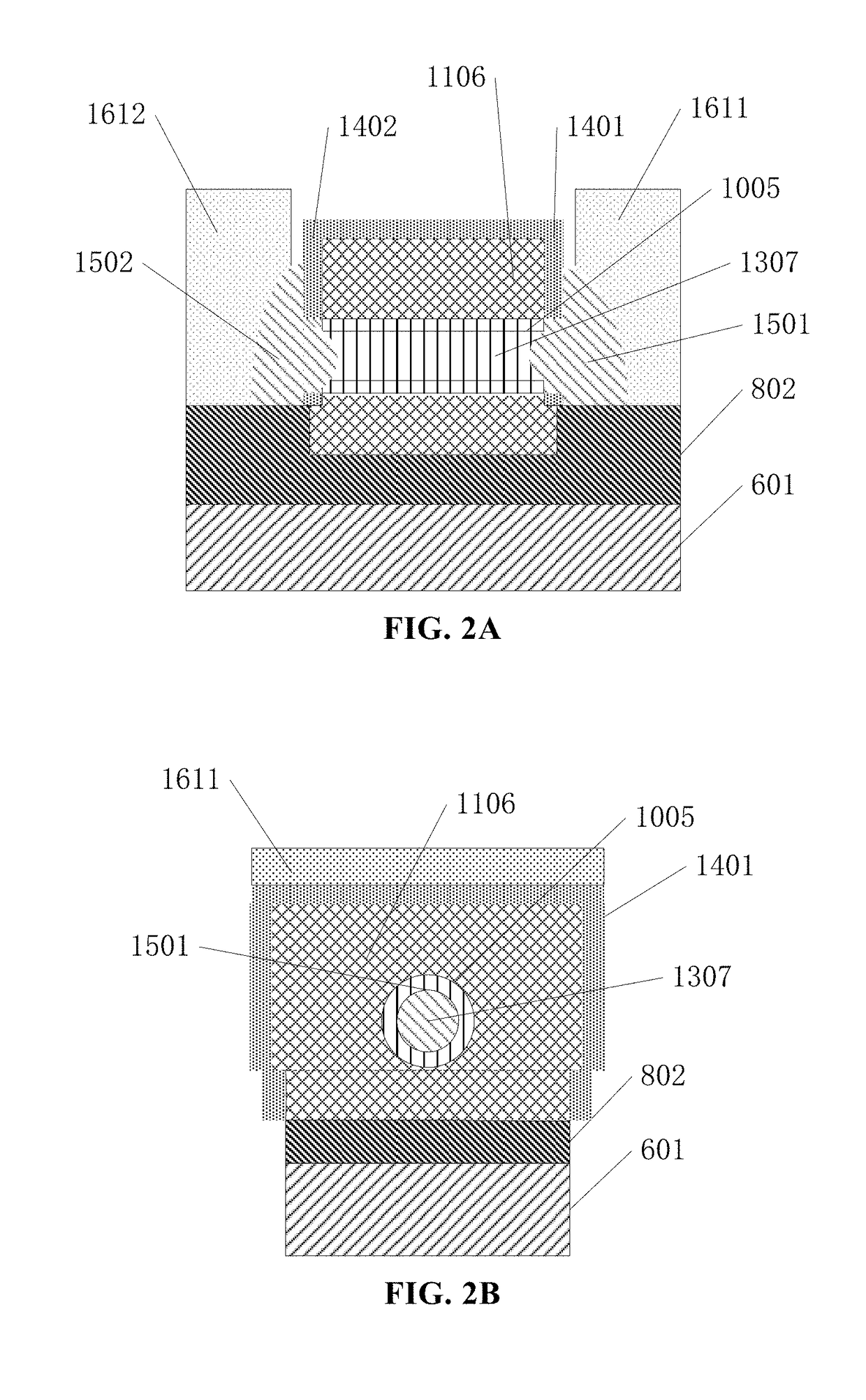

ActiveUS9715987B2Effective controlEnergy be utilizedVessels or leading-in conductors manufactureTube/lamp vessels exhaustionEngineeringSemiconductor

A semiconductor device may include the following elements: a semiconductor substrate, an insulator positioned on the substrate, a source electrode positioned on the insulator, a drain electrode positioned on the insulator, a gate electrode positioned between the source electrode and the drain electrode, a hollow channel surrounded by the gate electrode and positioned between the source electrode and the drain electrode, a dielectric member positioned between the hollow channel and the gate electrode, a first insulating member positioned between the gate electrode and the source electrode, and a second insulating member positioned between the gate electrode and the drain electrode.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Cathode device having smaller opening

A cathode device comprising a plurality of emitter tips having conical tip end portions to emit electrons therefrom. A gate electrode layer has an opening through which the tip end portion of each of the emitter tips is exposed. The diameter of the opening in the gate electrode layer is made smaller than that of the portion of the emitter tip at the juncture thereof with the substrate. In the fabrication of the cathode device, an oxide layer is formed at least on the surface of the formed emitter tip to sharpen the latter. By removing the oxide layer, an inner circumferential wall of the opening of the gate electrode layer is formed on the outside of the conical tip end portion of the emitter tip and extends approximately in parallel to the conical tip end portion of the emitter tip.

Owner:FUJITSU LTD

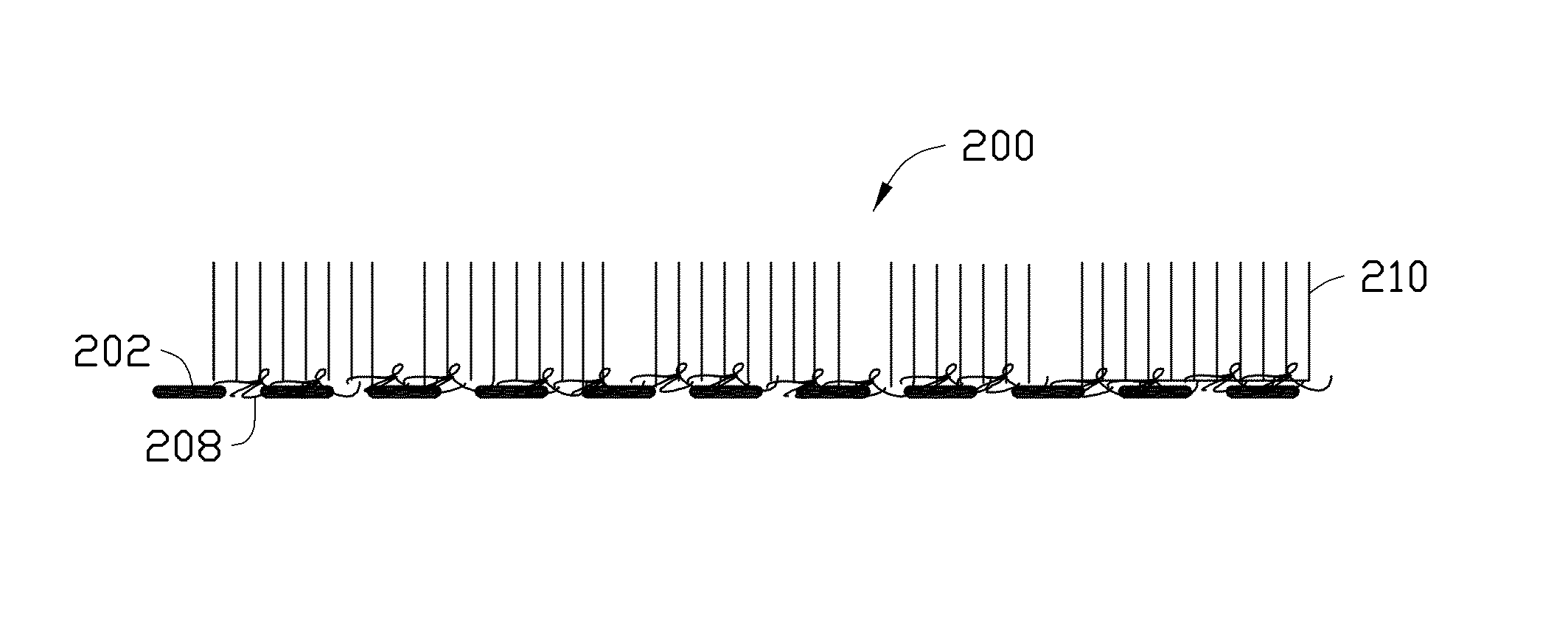

Triodes using nanofabric articles and methods of making the same

Vacuum microelectronic devices with carbon nanotube films, layers, ribbons and fabrics are provided. The present invention discloses microelectronic vacuum devices including triode structures that include three-terminals (an emitter, a grid and an anode), and also higher-order devices such as tetrodes and pentodes, all of which use carbon nanotubes to form various components of the devices. In certain embodiments, patterned portions of nanotube fabric may be used as grid / gate components, conductive traces, etc. Nanotube fabrics may be suspended or conformally disposed. In certain embodiments, methods for stiffening a nanotube fabric layer are used. Various methods for applying, selectively removing (e.g. etching), suspending, and stiffening vertically- and horizontally-disposed nanotube fabrics are disclosed, as are CMOS-compatible fabrication methods. In certain embodiments, nanotube fabric triodes provide high-speed, small-scale, low-power devices that can be employed in radiation-intensive applications.

Owner:NANTERO

Semiconductor device and related manufacturing method

ActiveUS20150279607A1Effective controlEnergy be utilizedControl electrodesVessels or leading-in conductors manufactureEngineeringSemiconductor

A semiconductor device may include the following elements: a semiconductor substrate, an insulator positioned on the substrate, a source electrode positioned on the insulator, a drain electrode positioned on the insulator, a gate electrode positioned between the source electrode and the drain electrode, a hallow channel surrounded by the gate electrode and positioned between the source electrode and the drain electrode, a dielectric member positioned between the hollow channel and the gate electrode, a first insulating member positioned between the gate electrode and the source electrode, and a second insulating member positioned between the gate electrode and the drain electrode.

Owner:SEMICON MFG INT (SHANGHAI) CORP

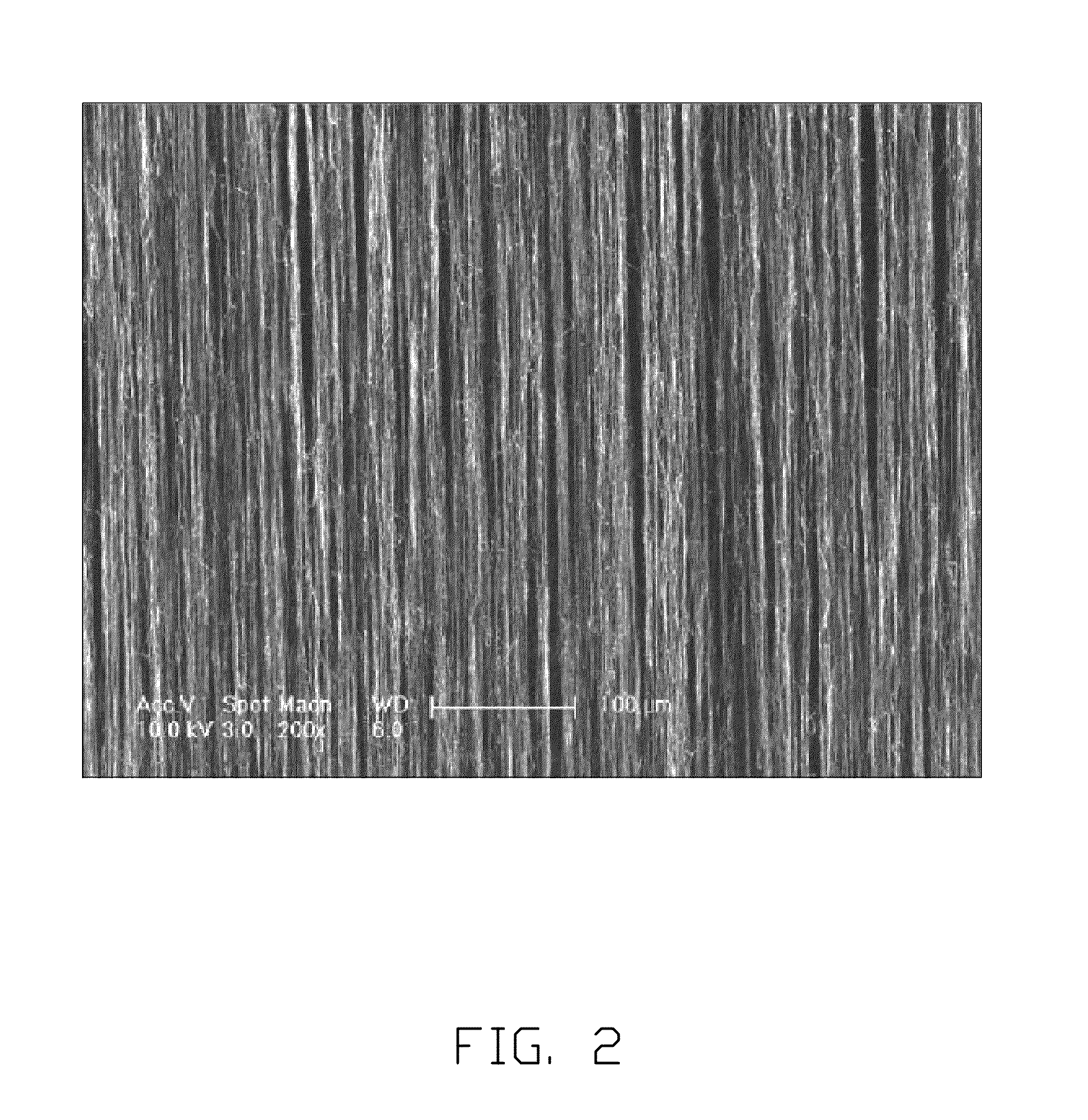

Field emission device

The present disclosure relates to a field emission device. The field emission device includes a carbon nanotube structure and two electrodes electrically connected with the carbon nanotube structure. The carbon nanotube structure includes a carbon nanotube array, a carbon nanotube layer located on one side of the carbon nanotube array, and a carbon nanotube cluster between the carbon nanotube array and the carbon nanotube layer. The carbon nanotube array includes a number of first carbon nanotubes that are parallel with each other. The carbon nanotube layer includes a number of second carbon nanotubes. The carbon nanotube cluster includes a plurality of third carbon nanotubes that are entangled around both the plurality of first carbon nanotubes and the plurality of second carbon nanotubes.

Owner:TSINGHUA UNIV +1

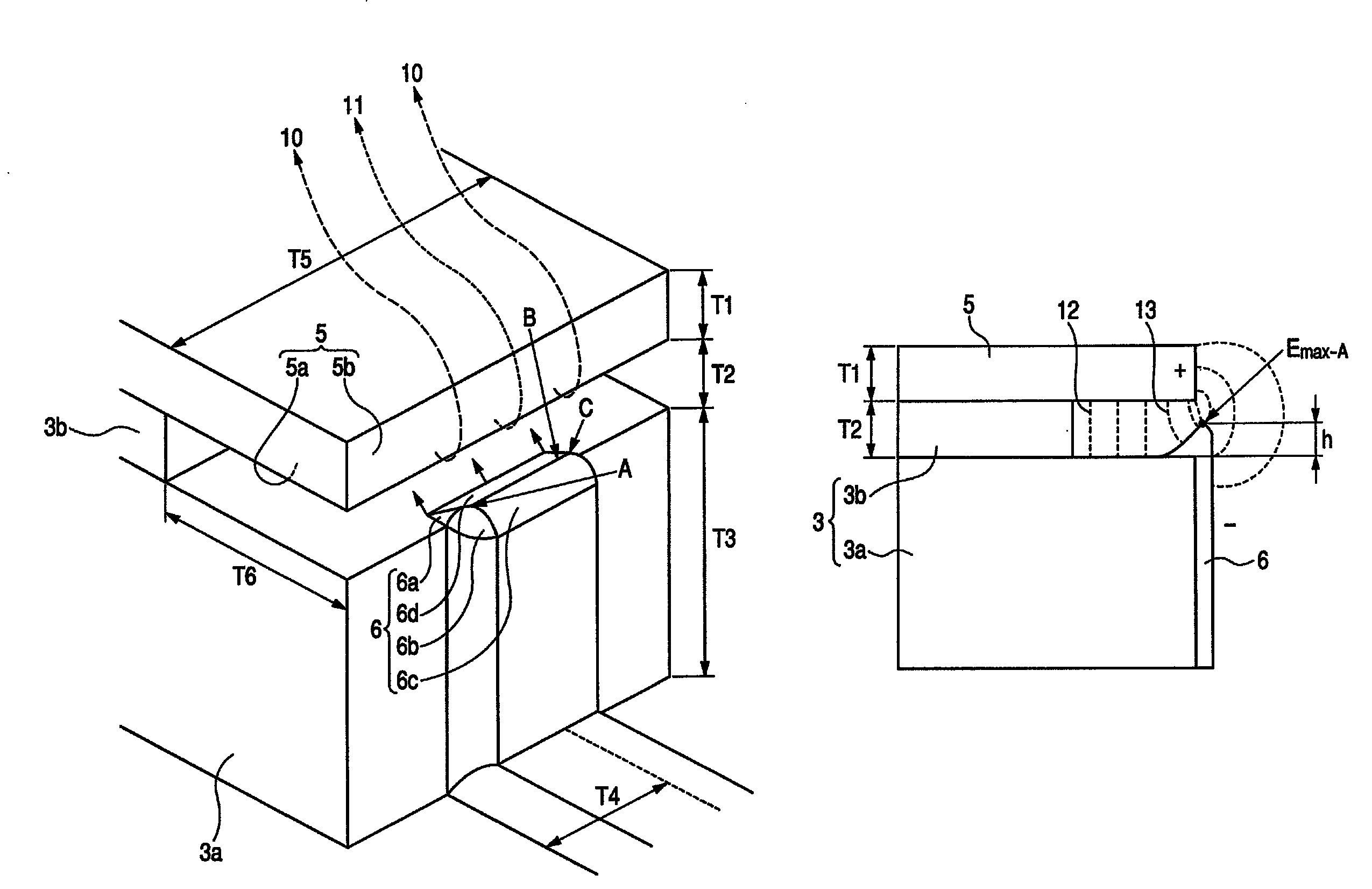

Electron beam apparatus and image display apparatus using the same

InactiveUS7884533B2Simple structureHigh electron-emitting efficiencyDischarge tube luminescnet screensCathode ray tubes/electron beam tubesHigh electronElectron

The present invention provides an electron beam apparatus provided with an electron-emitting device which has a simple structure, shows high electron-emitting efficiency and stably works. This electron beam apparatus has an insulating member and a gate formed on a substrate, a recess portion formed in the insulating member, a protruding portion that protrudes from an edge of the recess portion toward the gate and is provided on an end part of a cathode opposing to the gate, which is arranged on the side face of the insulating member; and makes an electric field converge on an end part in the width direction of the protruding portion to make an electron emitted therefrom.

Owner:CANON KK

Energy converter and method of making the same

InactiveUS7487781B2High light efficiencySolution to short lifeControl electrodesCigar manufactureEngineeringElectromagnetic radiation

An energy converter according to the present invention includes a heat source (radiator 1), which receives externally applied energy and raises its temperature, thereby emitting electromagnetic radiations, and a radiation cut portion (mesh 2) for cutting down infrared radiations, of which the wavelengths are longer than a predetermined wavelength. The mesh 2 is a woven or knitted mesh of metal wires. The openings of the woven or knitted mesh have an aperture size that is smaller than the predetermined wavelength.

Owner:PANASONIC CORP

Field emission device having entangled carbon nanotubes between a carbon nanotube layer and carbon nanotube array

The present disclosure relates to a field emission device. The field emission device includes a carbon nanotube structure and two electrodes electrically connected with the carbon nanotube structure. The carbon nanotube structure includes a carbon nanotube array, a carbon nanotube layer located on one side of the carbon nanotube array, and a carbon nanotube cluster between the carbon nanotube array and the carbon nanotube layer. The carbon nanotube array includes a number of first carbon nanotubes that are parallel with each other. The carbon nanotube layer includes a number of second carbon nanotubes. The carbon nanotube cluster includes a plurality of third carbon nanotubes that are entangled around both the plurality of first carbon nanotubes and the plurality of second carbon nanotubes.

Owner:TSINGHUA UNIV +1

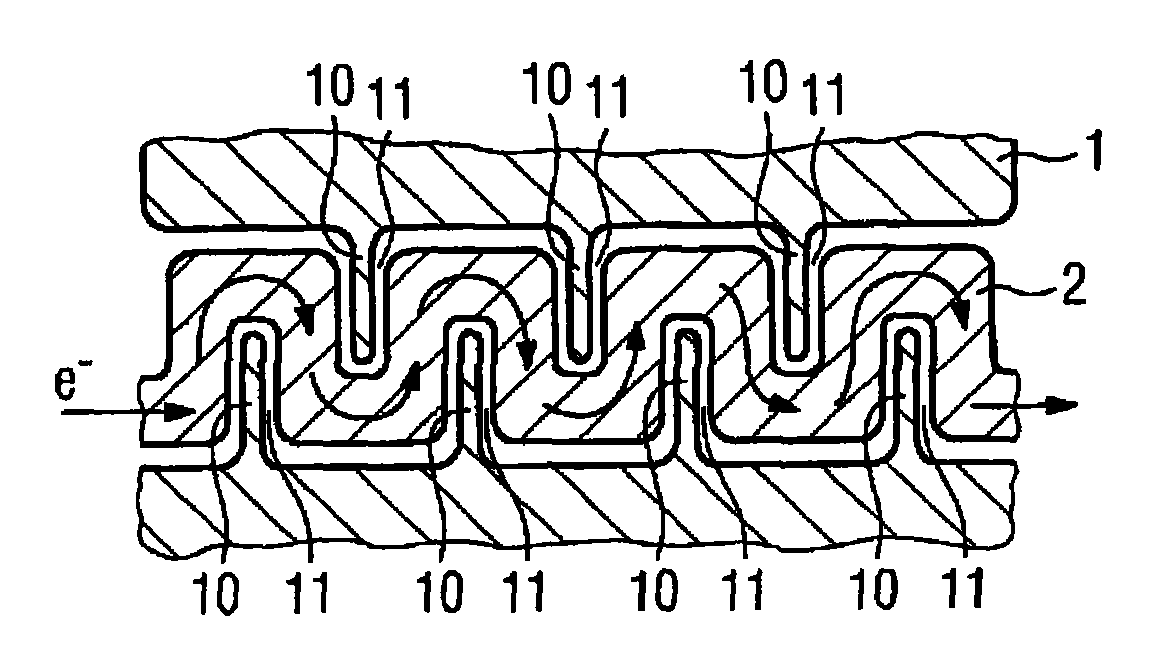

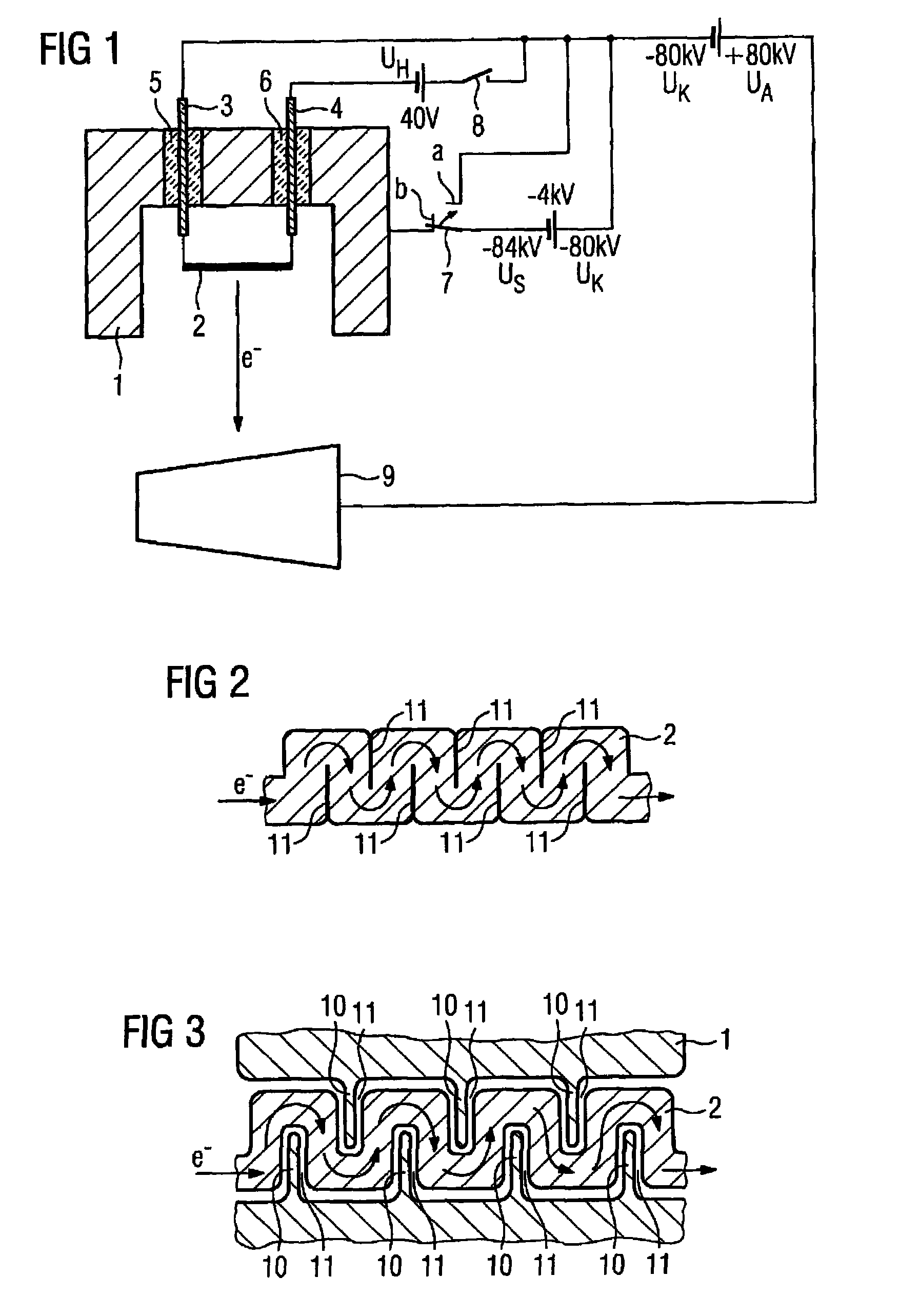

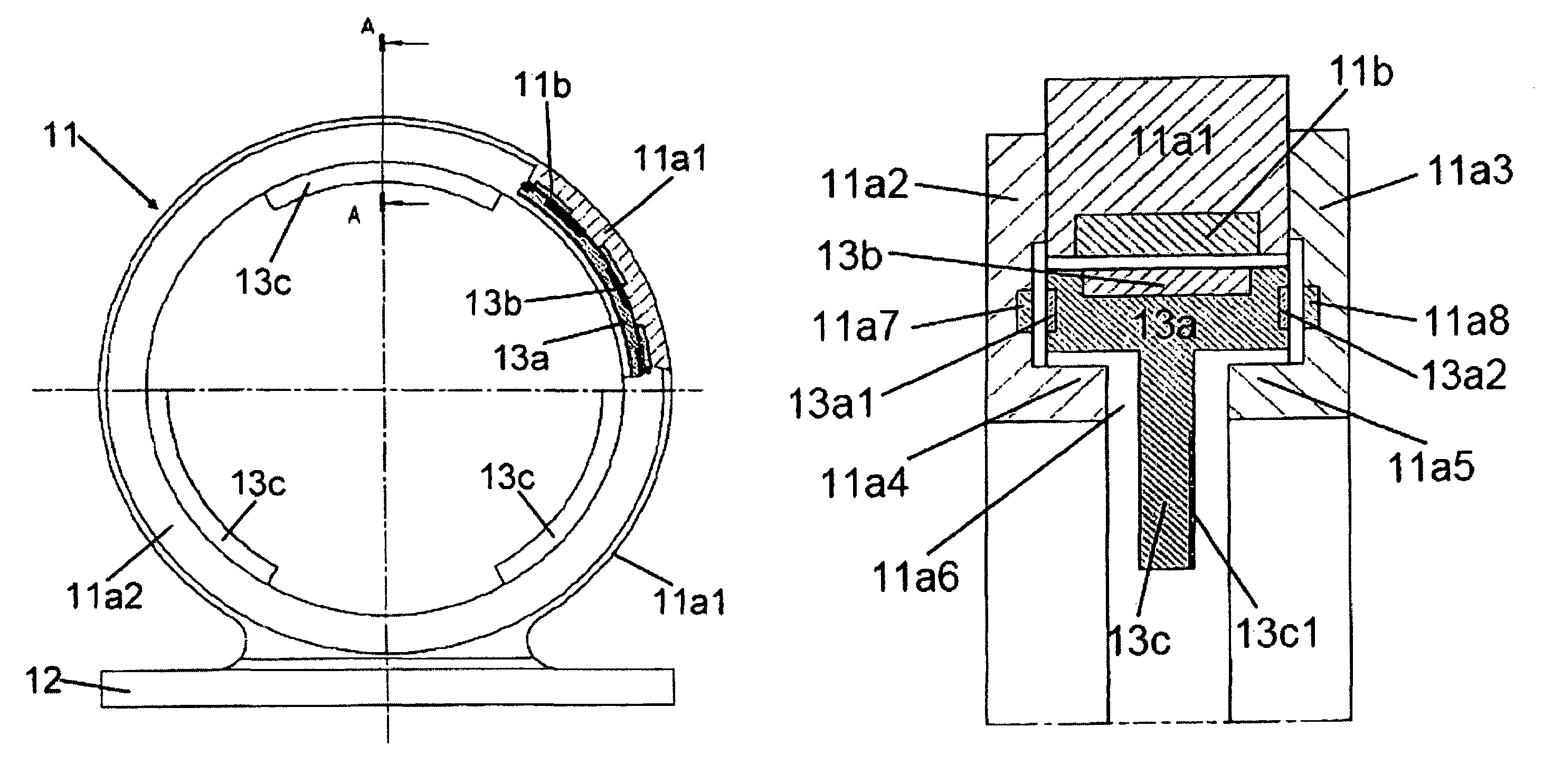

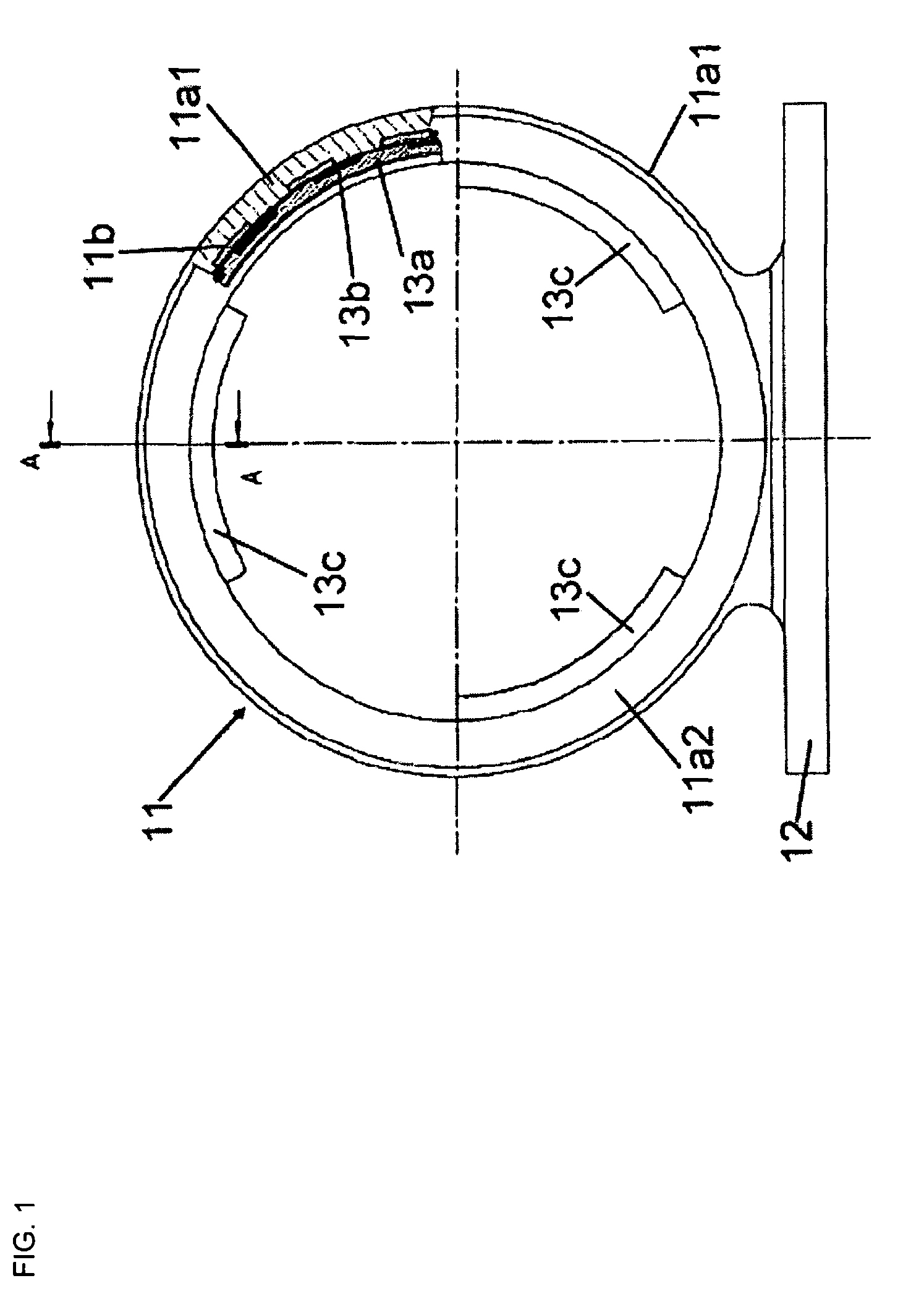

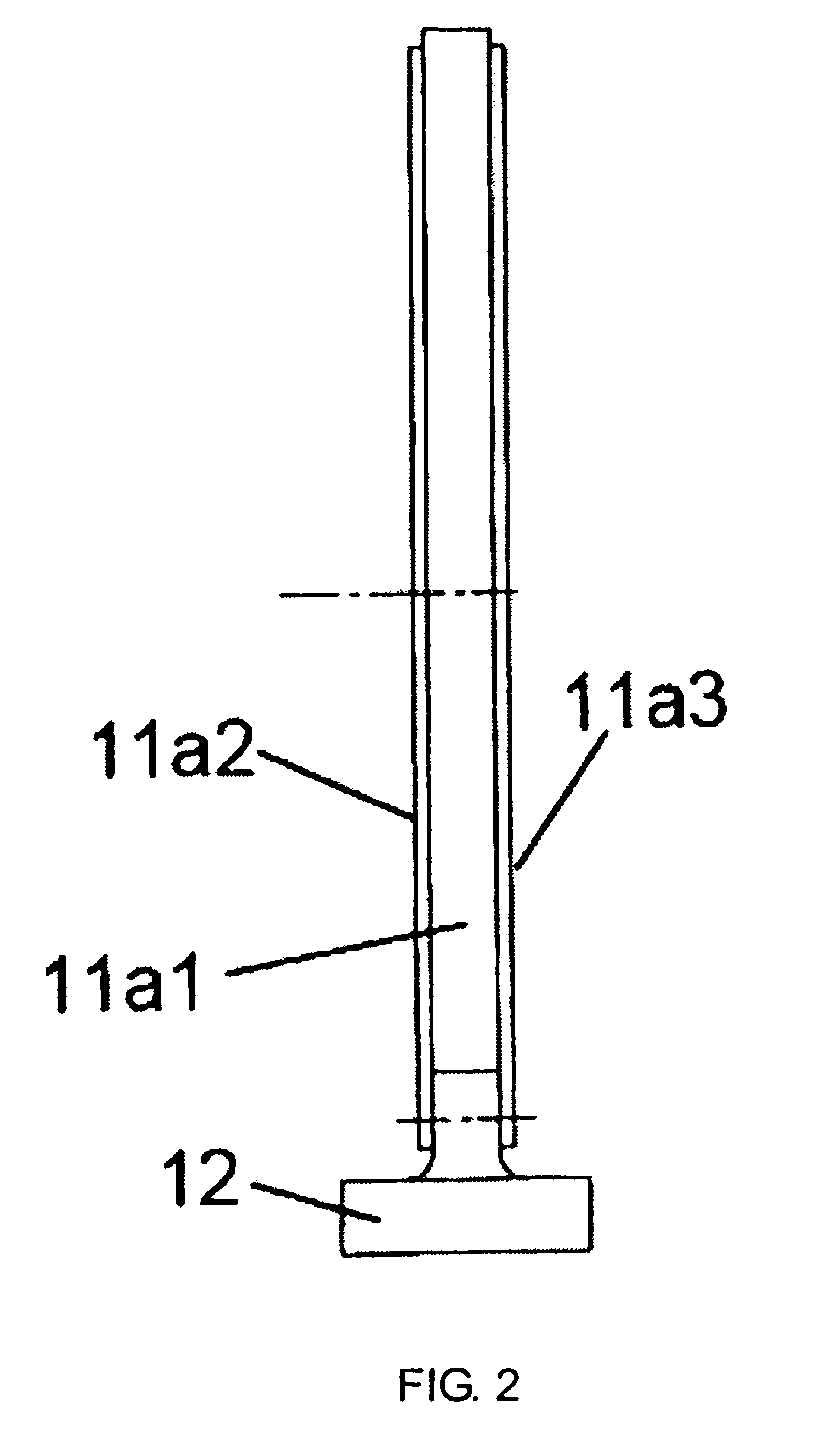

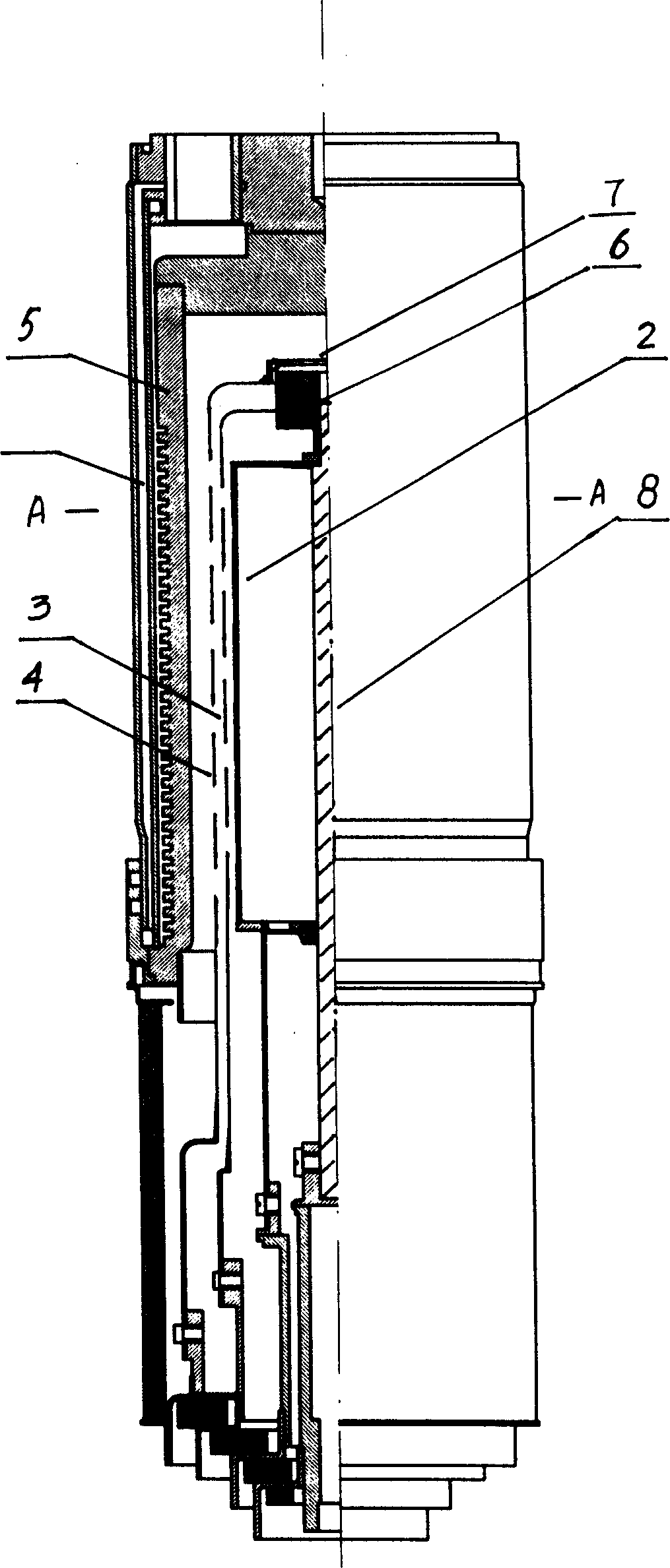

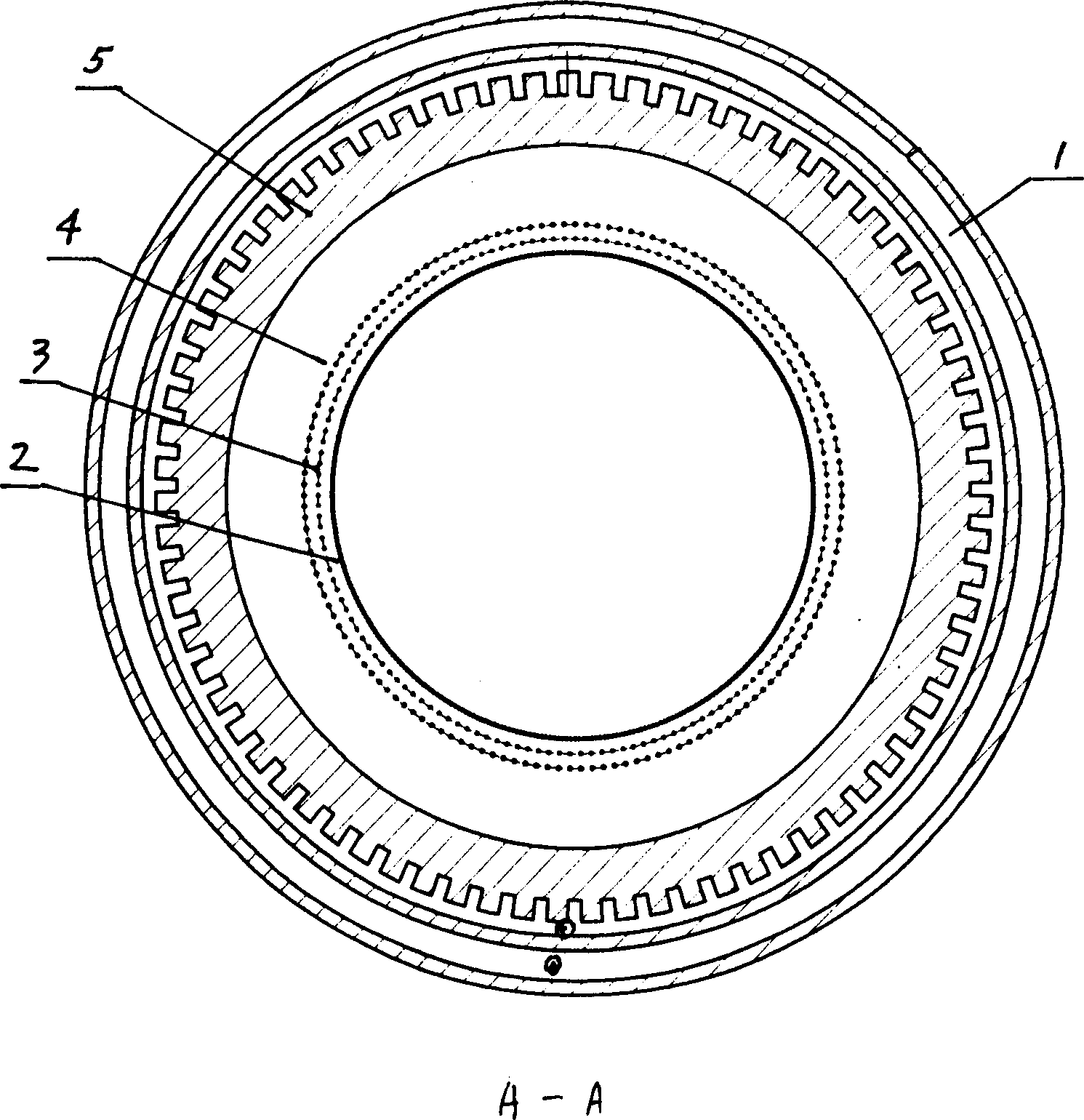

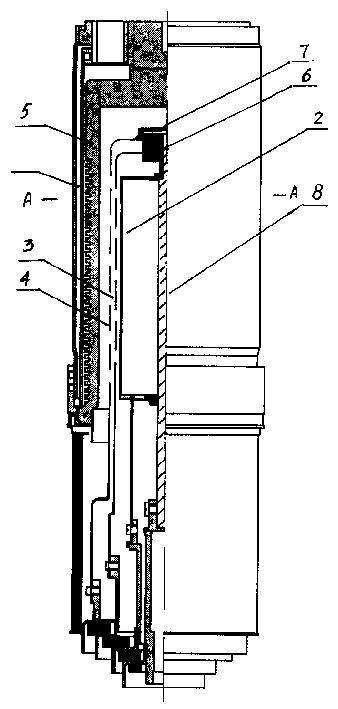

Chopper for a particle beam

ActiveUS8324590B2Operational securityHigh frequencyStability-of-path spectrometersControl electrodesParticle beamEngineering

A chopper for a particle beam comprises an annular guiding element and an element for controlling the intensity of the particle beam. The control element is supported on the guiding element so that at least one point under consideration on the control element can revolve along the circumference of the guiding element. Mounting along a circumference allows for accommodation of considerably higher disturbance torque than mounting on a rotational axle, using the same bearing force. Furthermore, it is possible to dispense with the entire rotational axle, and the control element can be designed, for example, as a ring. This brings about considerable weight savings as compared to chopper wheels according to the prior art, which accordingly enables higher circumferential speeds and therefore higher modulation frequencies for the particle beam, while at the same time increasing operational safety.

Owner:FORSCHUNGSZENTRUM JULICH GMBH

Large power quadrupole delectronic tube and its manufacturing method

InactiveCN1479343ASolve the defect of falling powder and ignitionReduce production conditionsTransit-time tubesNon-electron-emitting electrode materialsRadiation resistantTwo grid

The electron tube consists of cooling water jacket, cathode, first grid, second grid and anode. The improved first grid is made from pyrolytic graphite. The second grid is made from molybdenum filament welded in squirrel cage shape. With surface being sprayed by tungsten carbide, the molybdenum filament is sintered and plated by platinum. The upper parts of two grids are connected to ceramic ring at upper part of cathode. The first grid is made from graphite after dedicated procedure the first grid possesses higher capabilities of high temperature resistant and radiation resistant. The heat dissipation capability of the first grid made from graphite is 5 times of grid made from molybdenum filament so as to reduce size greatly.

Owner:卫军民 +1

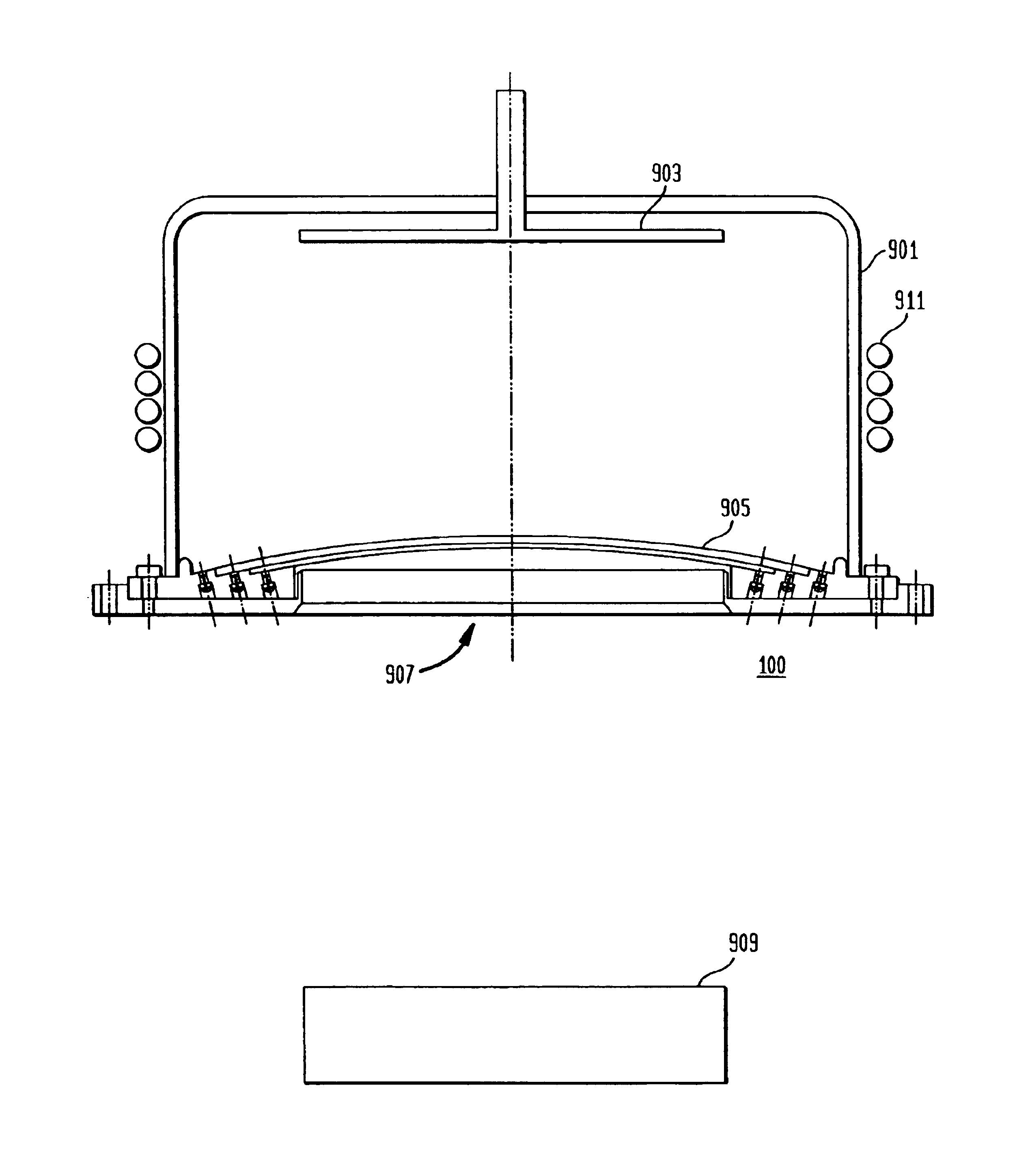

Charged particle beam extraction and formation apparatus

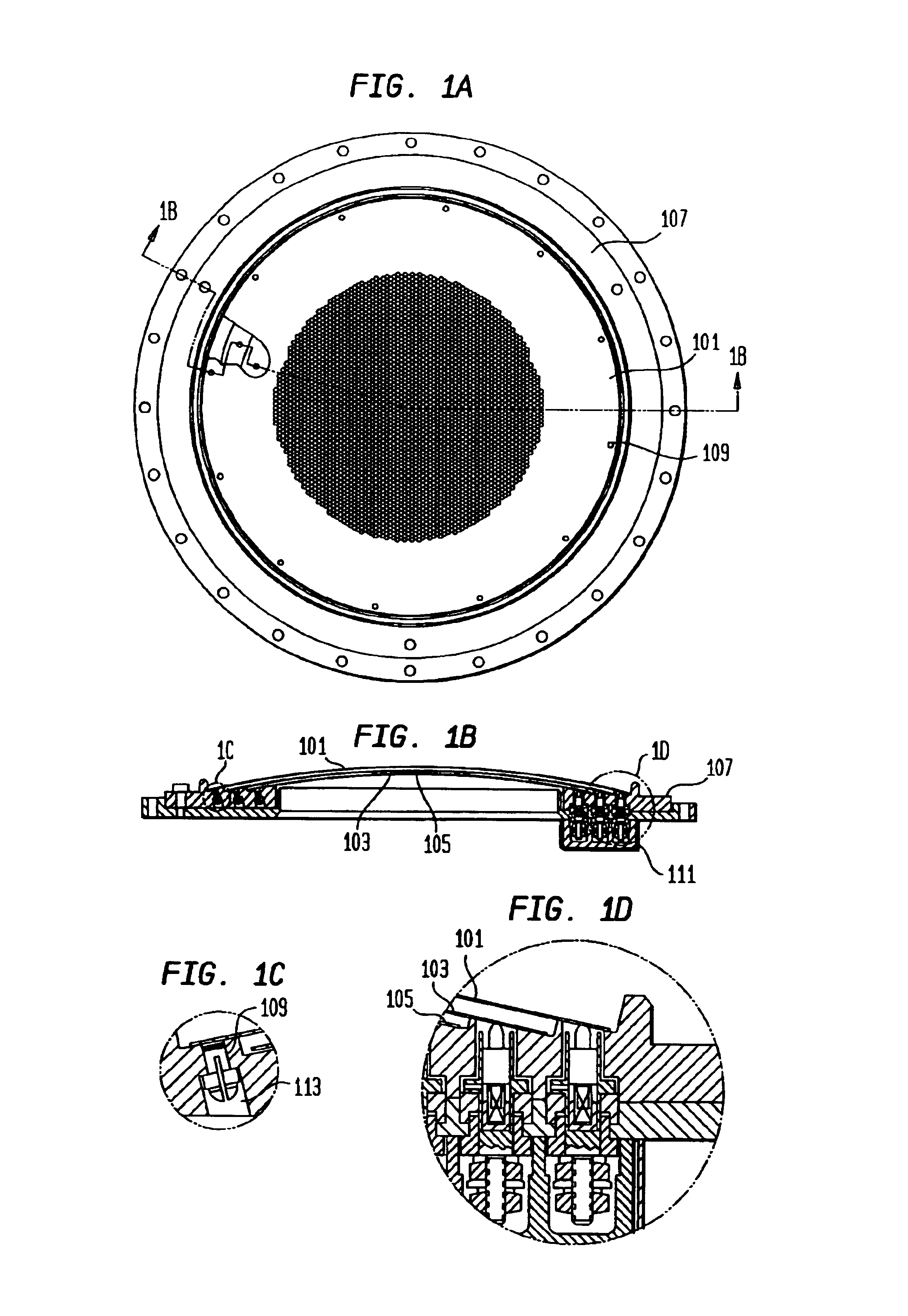

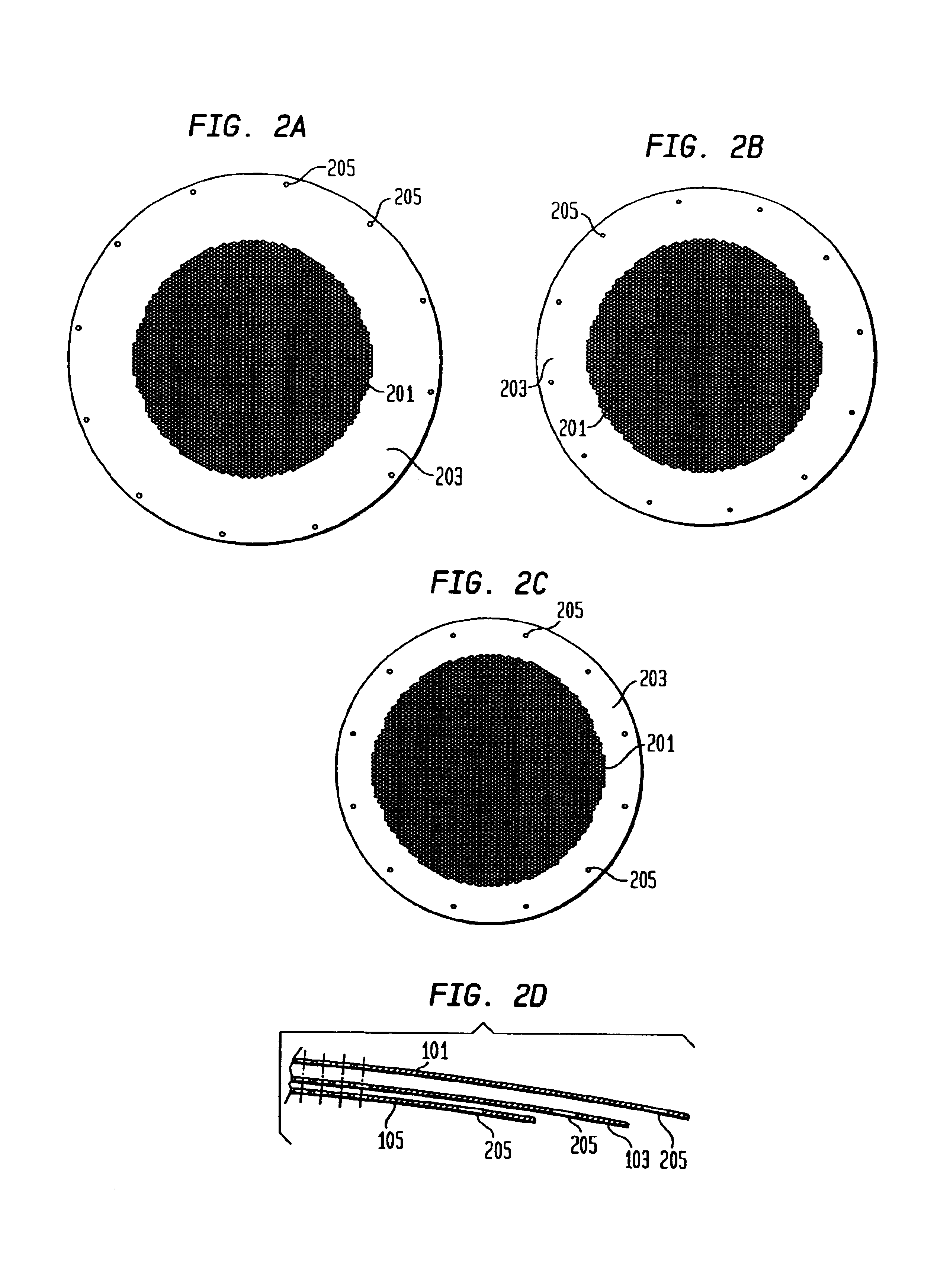

InactiveUS7005782B2Large caliberControl electrodesDischarge tube luminescnet screensThermal expansionSliding contact

A charged particle apparatus, with multiple electrically conducting semispheric grid electrodes, the grid electrodes mounted in a dielectric mounting ring, with hidden areas or regions to maintain electrical isolation between the grid electrodes as sputter deposits form on the grid electrodes and mounting ring. The grid electrodes are mounted to the mounting ring with slots and fastening pins that allow sliding thermal expansion and contraction between the grid electrodes and mounting ring while substantially maintaining alignment of grid openings and spacing between the grid electrodes. Asymmetric fastening pins facilitate the sliding thermal expansion while restraining the grid electrodes. Electrical contactors supply and maintain electrical potentials of the grid electrodes with spring loaded sliding contacts, without substantially affecting the thermal characteristics of the grid electrodes.

Owner:VEECO INSTR

Electron-emitting cold cathode device

InactiveUS20150022076A1Increase working frequencyMitigate such drawbackControl electrodesCold cathodesOhmic contactCold cathode

One or more embodiments of the invention concern a device comprising: a cathode that lies on a cathode plane and includes, in an active region one or more cathode straight-finger-shaped terminals with a main extension direction parallel to a first reference direction; for each cathode terminal, one or more electron emitters formed on, and in ohmic contact with, said cathode terminal; and a gate electrode that lies on a gate plane parallel to, and spaced apart from, said cathode plane, does not overlap the cathode and includes, in the active region, two or more gate straight-finger-shaped terminals with a main extension direction parallel to the first reference direction; wherein the gate terminals are interlaced with said cathode terminal(s).

Owner:SELEX ES

Popular searches

Bulk negative resistance effect devices Electric discharge lamps Tubes with electrostatic controls Cold cathode manufacture Optical articles Non-electron-emitting shielding screens Solid cathode details Organic semiconductor devices Manufacturing environment conditioning Electrode assembly manufacture

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com