Large power quadrupole delectronic tube and its manufacturing method

A production method and electron tube technology, which are applied to non-electron emission control electrodes, the manufacture of discharge tubes/lamps, transit time electron tubes, etc., can solve the problems of increasing grid heat consumption, reduce production conditions, and achieve good high-voltage performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

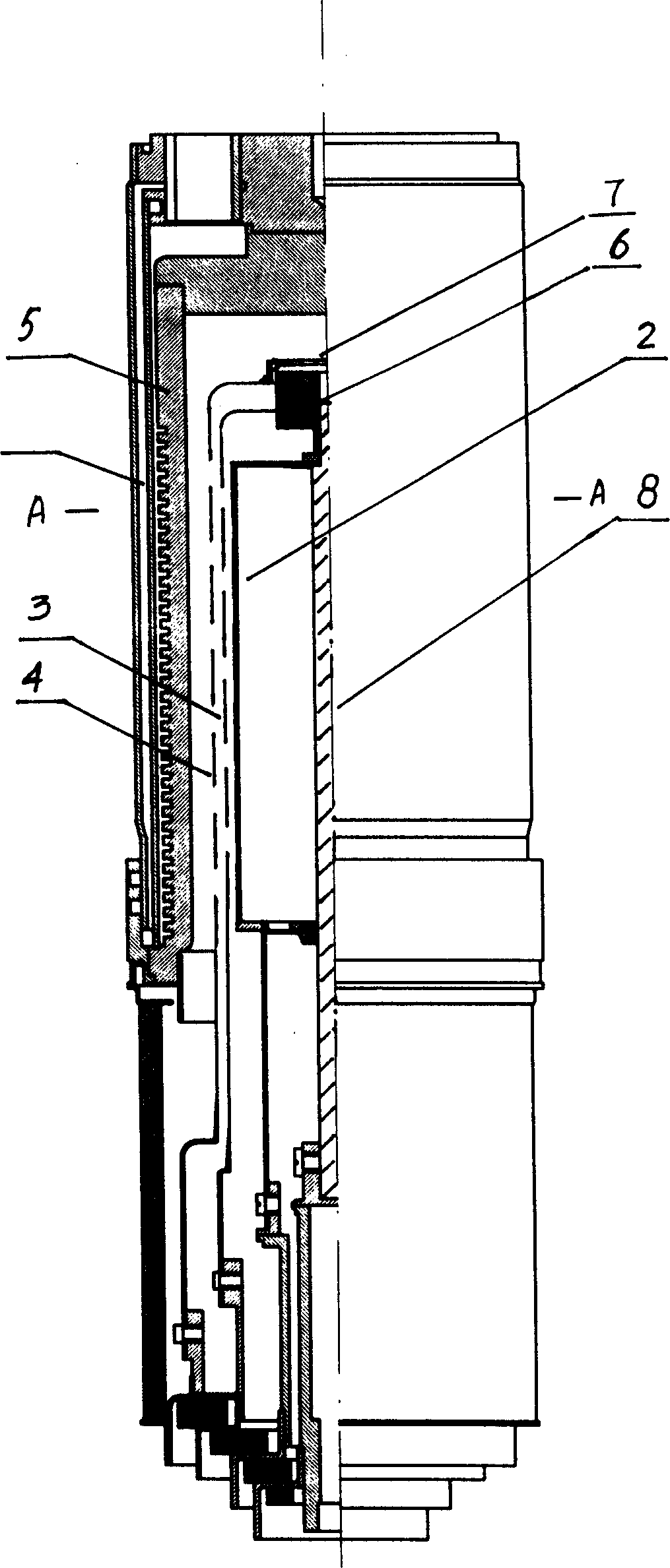

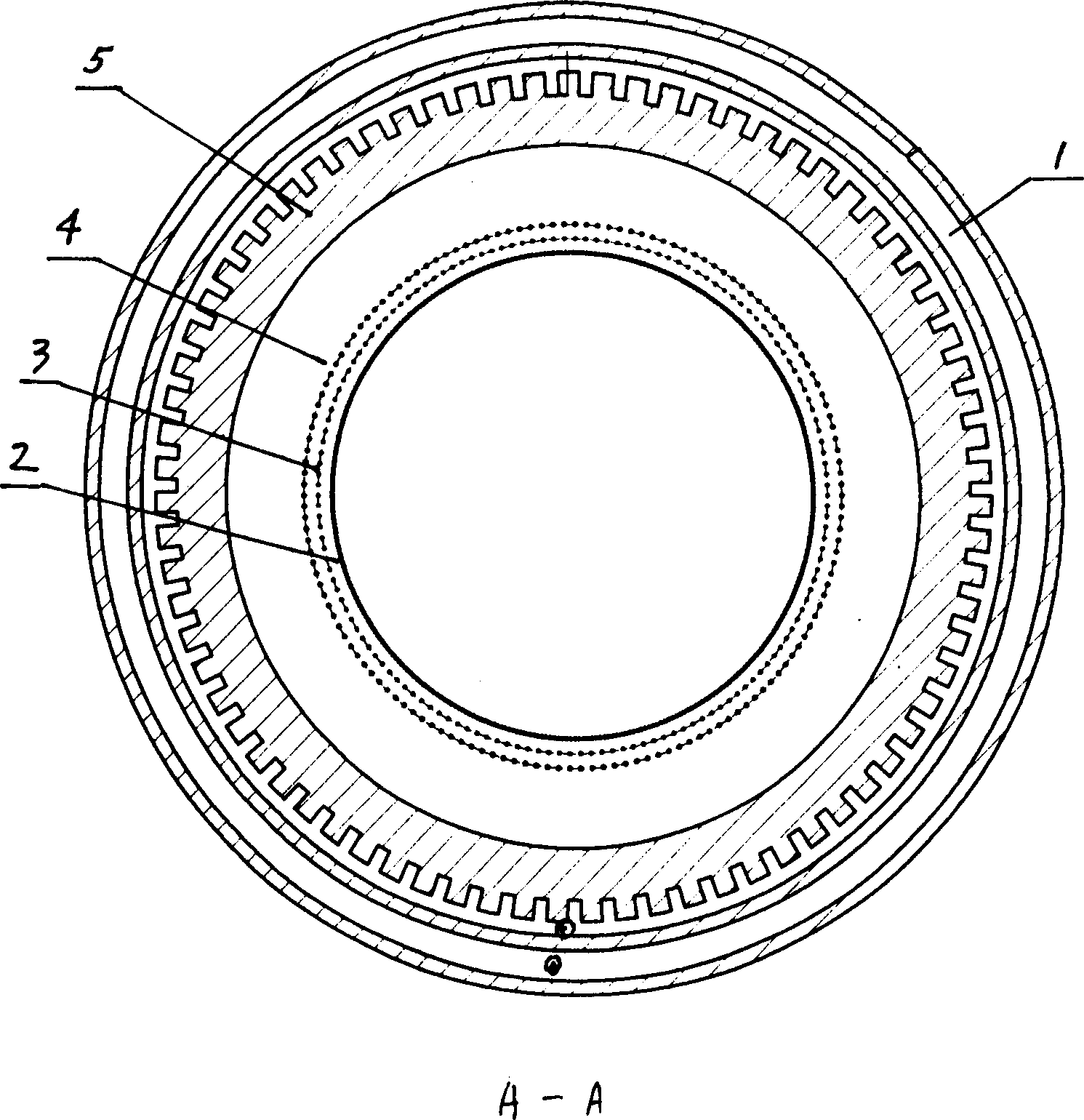

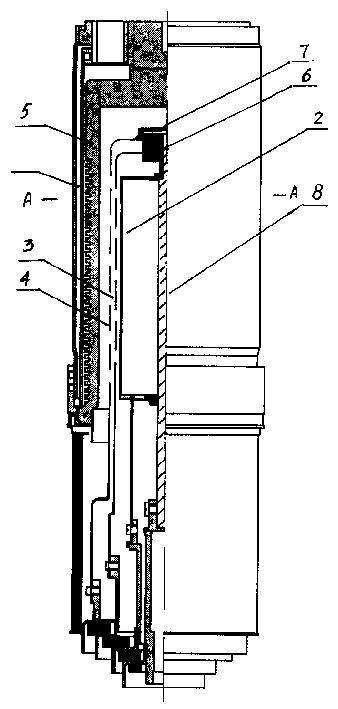

[0023] It can be seen from the figure that the basic structure of the present invention is basically the same as that of the existing high-power tetrode. A cooling water jacket 1 is provided on the periphery of the electron tube, and its cathode 2, first grid 3, second grid 4, and anode 5 are also arranged in a circular shape and concentrically. The improved first grid 3 and the second grid 4 are respectively made of two different materials, pyrolytic graphite and molybdenum wire-sprayed tungsten carbide plated with platinum. The first grid is made of pyrolytic graphite material which is stronger in high temperature resistance and heat dissipation than molybdenum metal, which can make the first grid resistant to high temperature radiation, not easy to deform, and has strong heat dissipation ability, making it difficult to Damage; the second grid made of molybdenum sprayed with tungsten carbide and then plated with platinum keeps the electron tube from falling powder under high...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com