Patents

Literature

56results about "Non-electron-emitting electrode materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

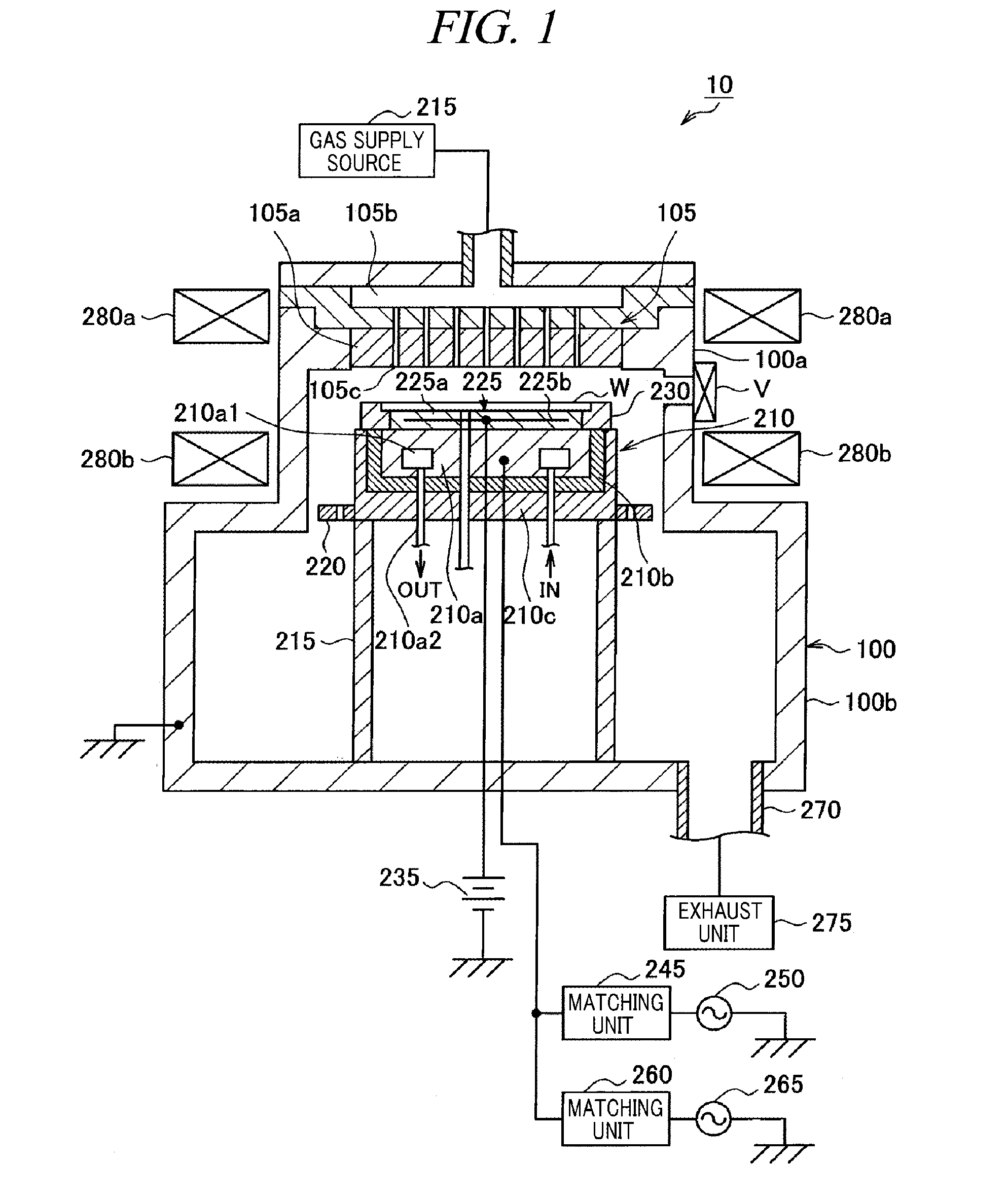

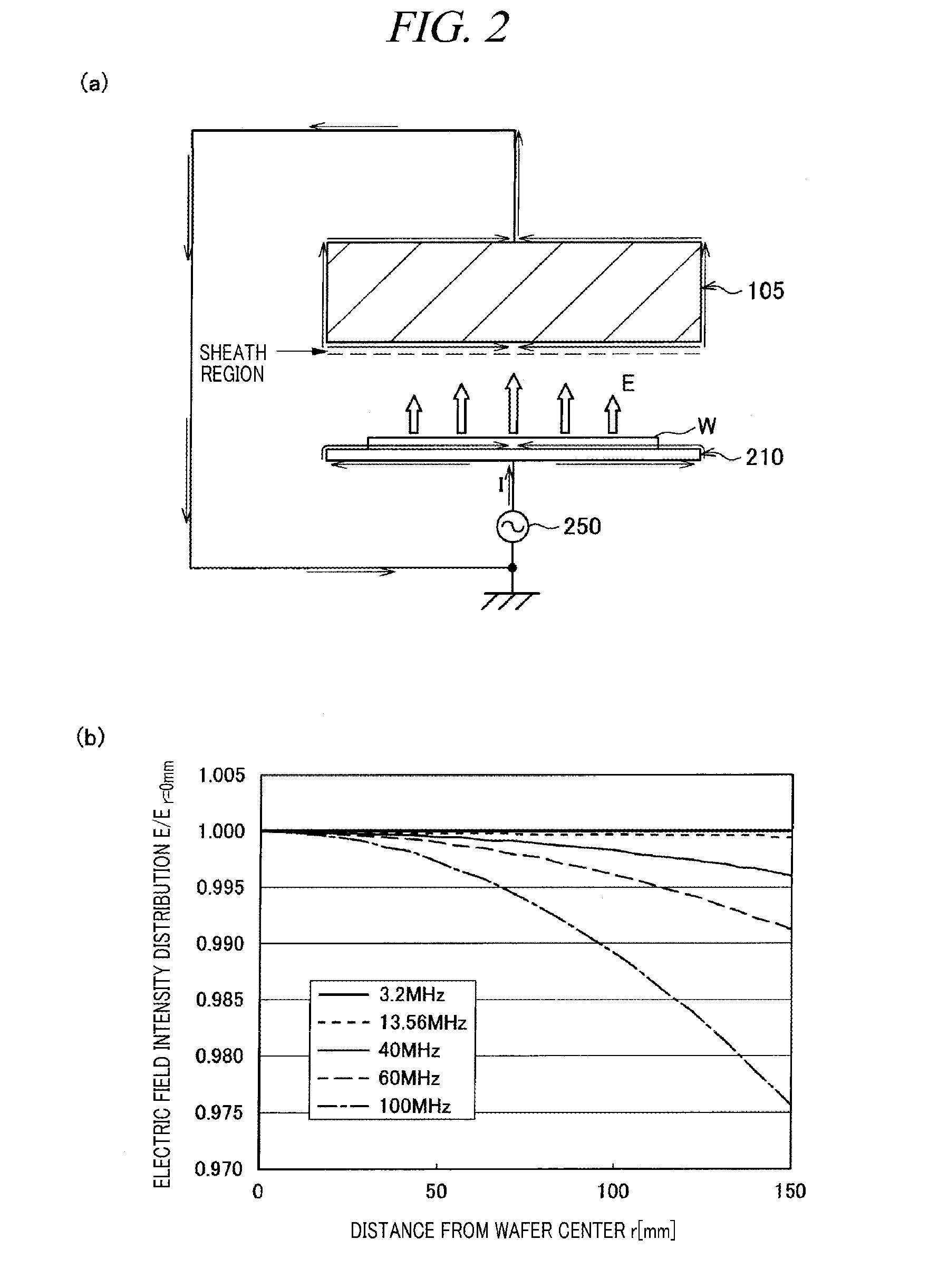

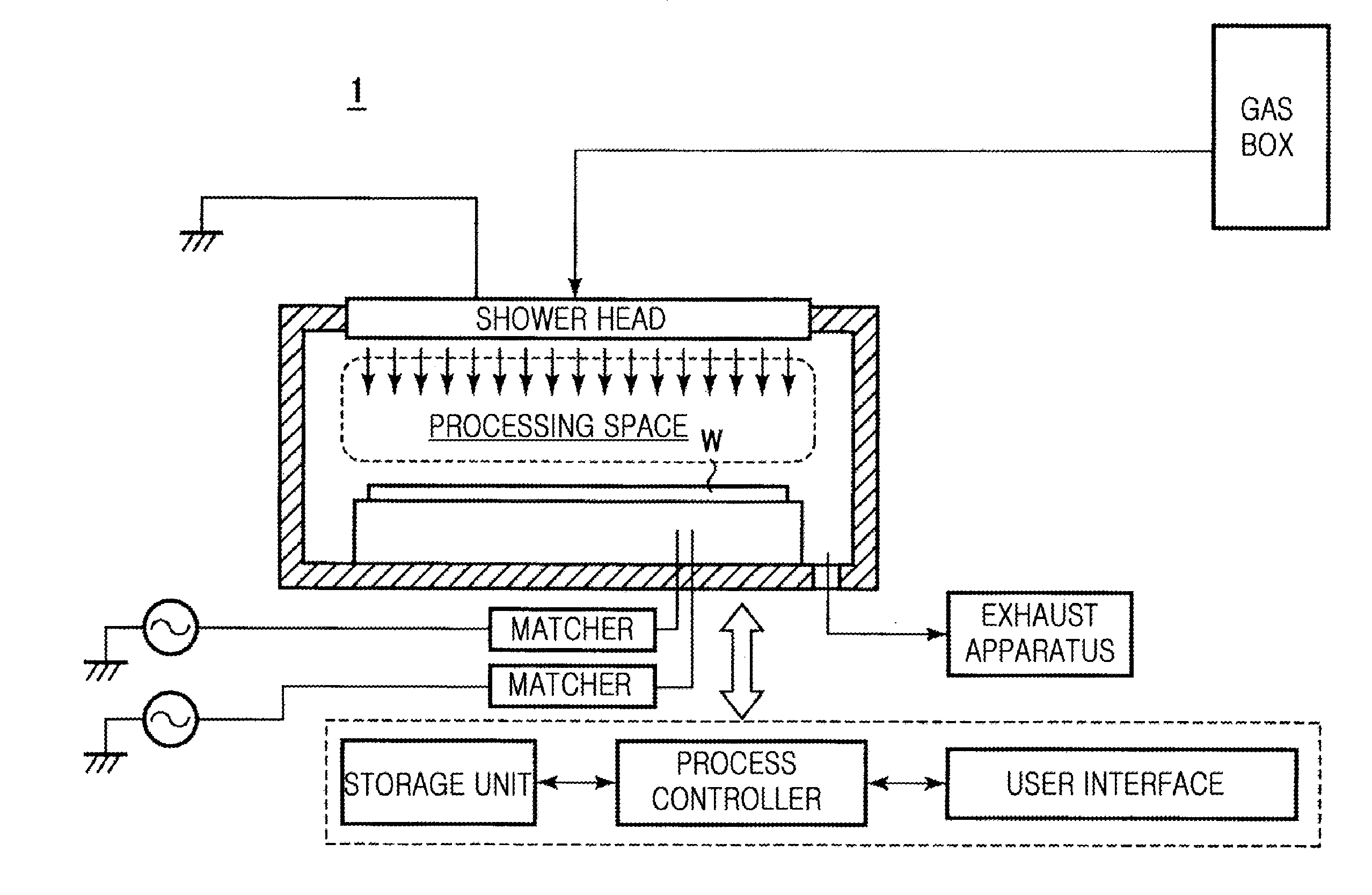

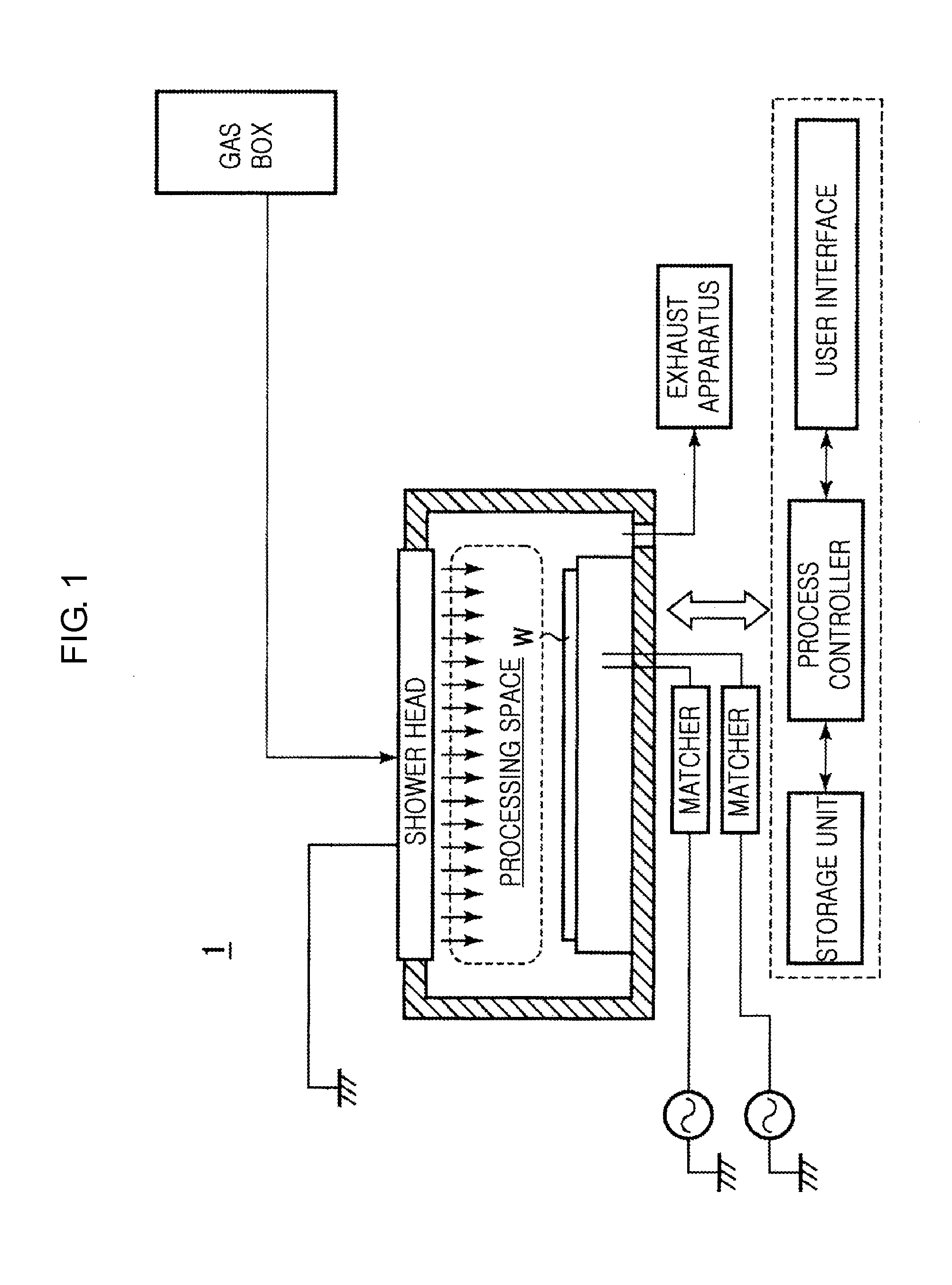

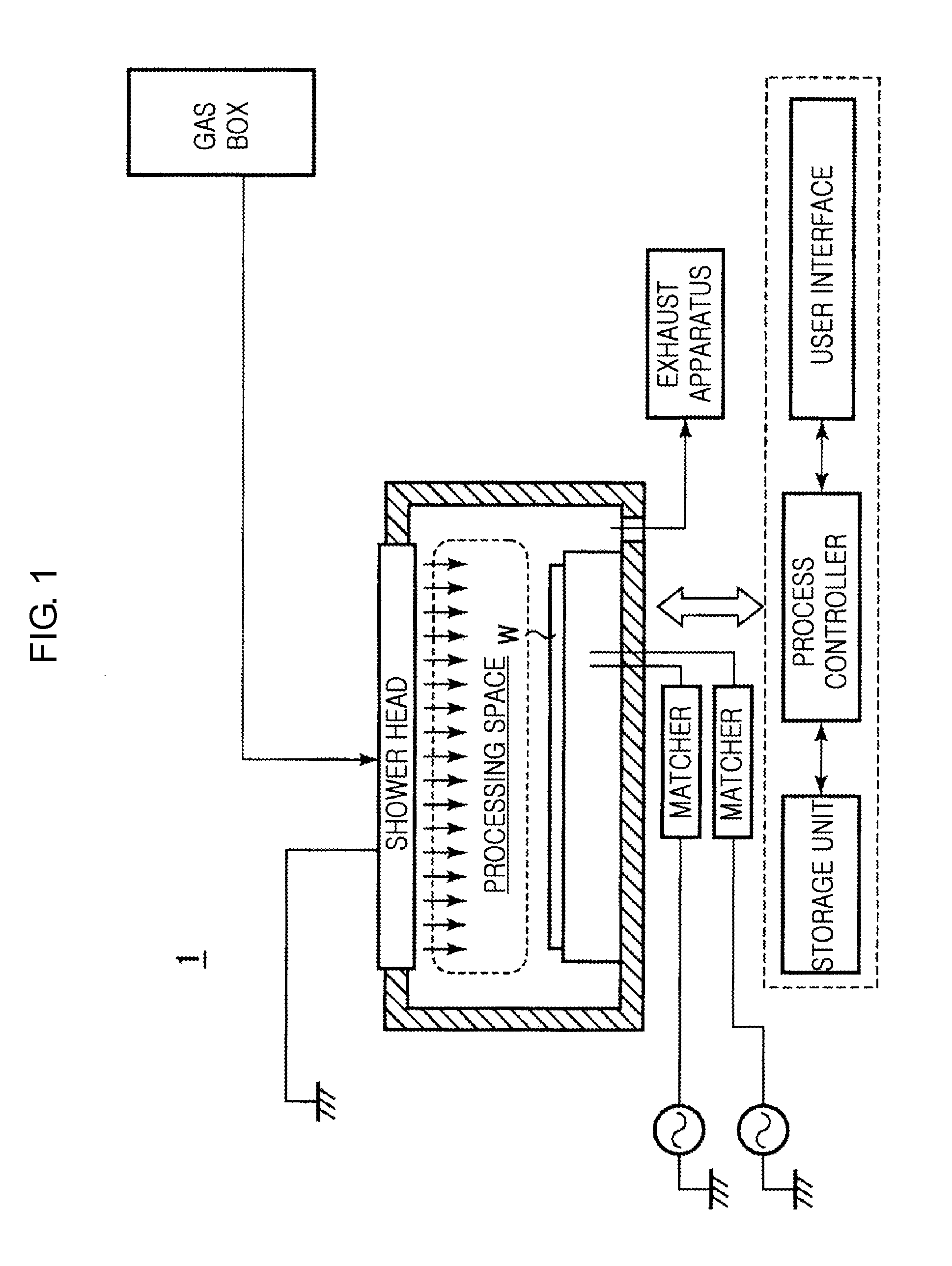

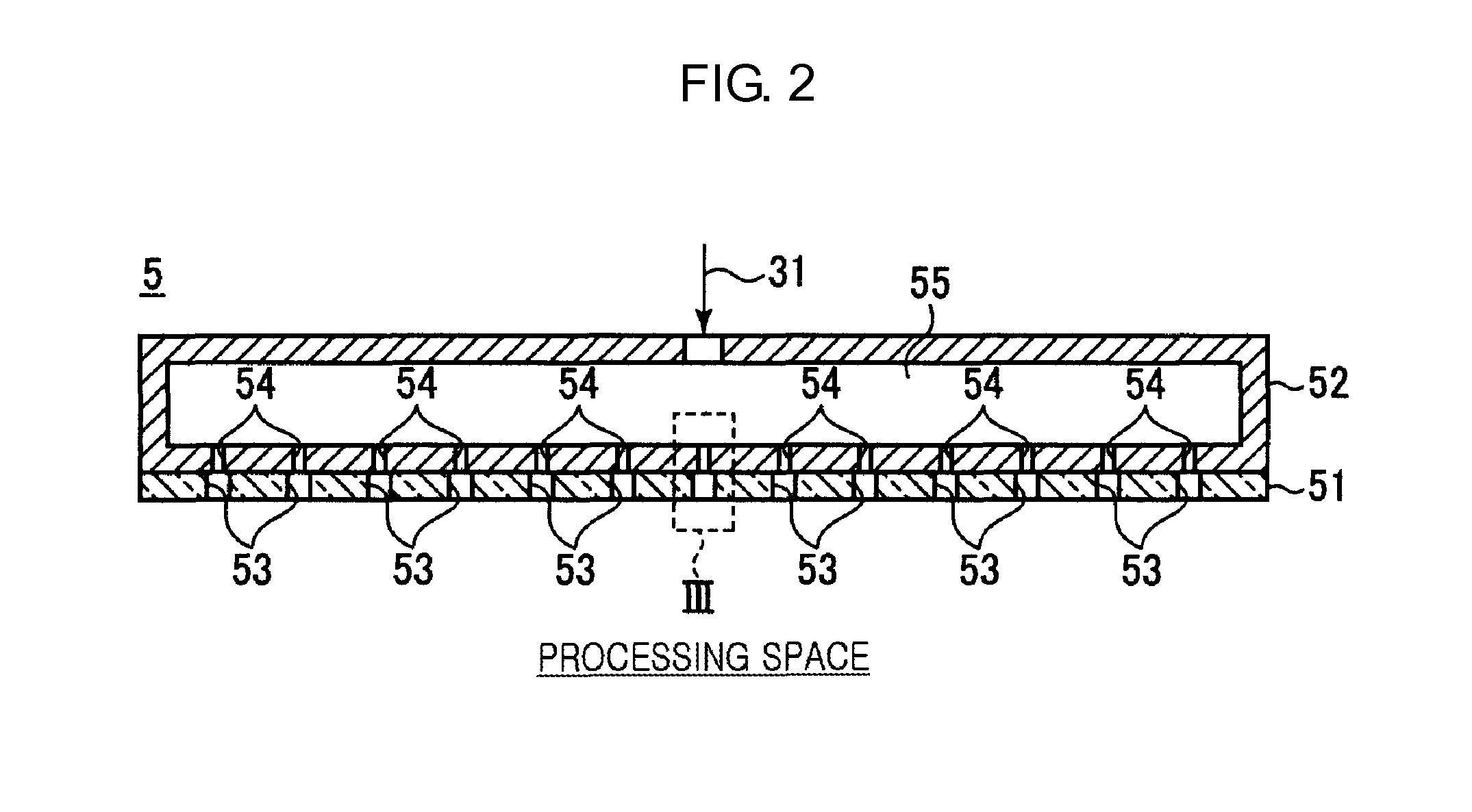

Upper electrode and plasma processing apparatus

ActiveUS20120206033A1Plasma uniformity can be improvedLamp incadescent bodiesThermionic cathodesParallel plateOptoelectronics

Owner:TOKYO ELECTRON LTD

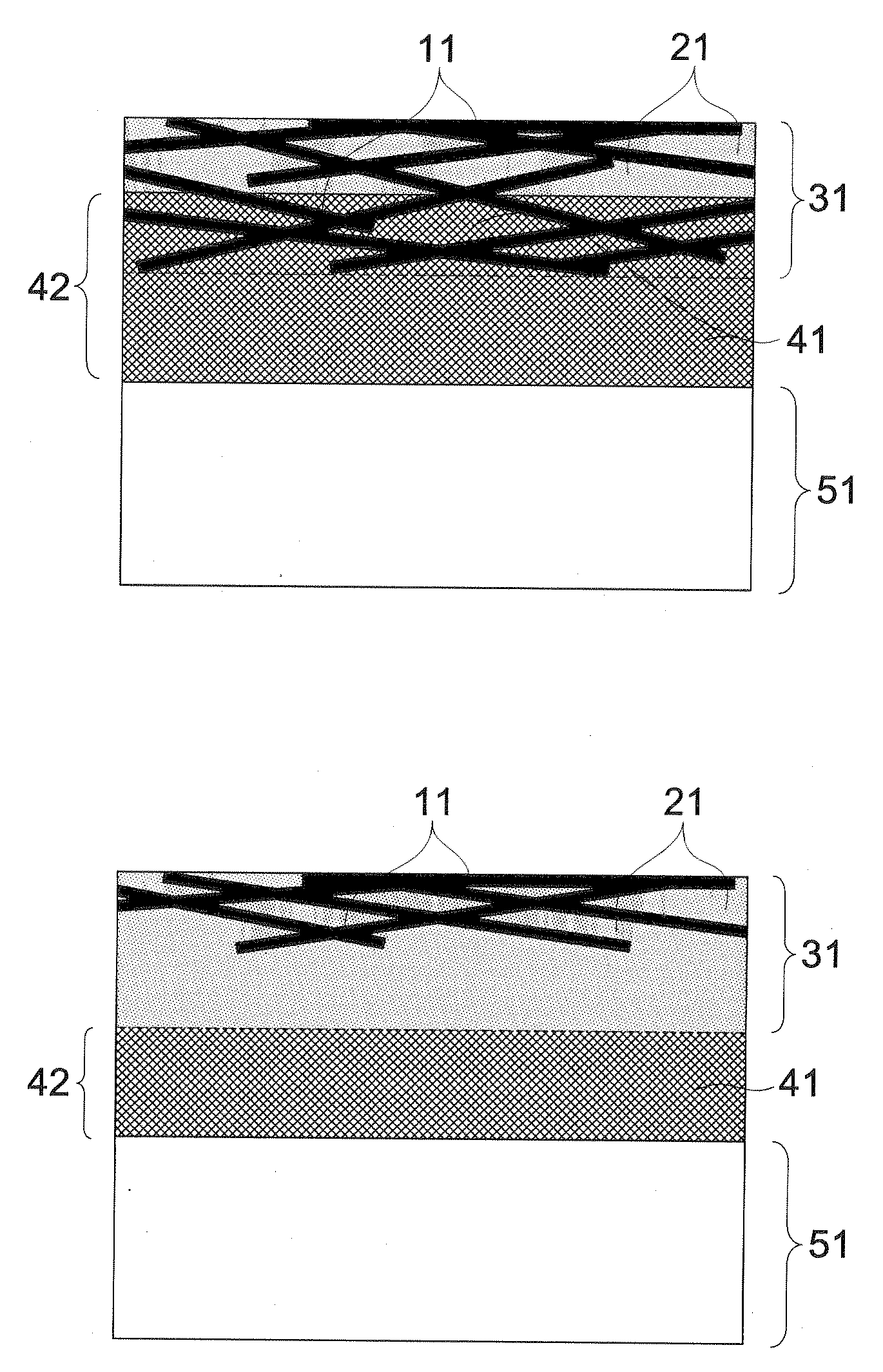

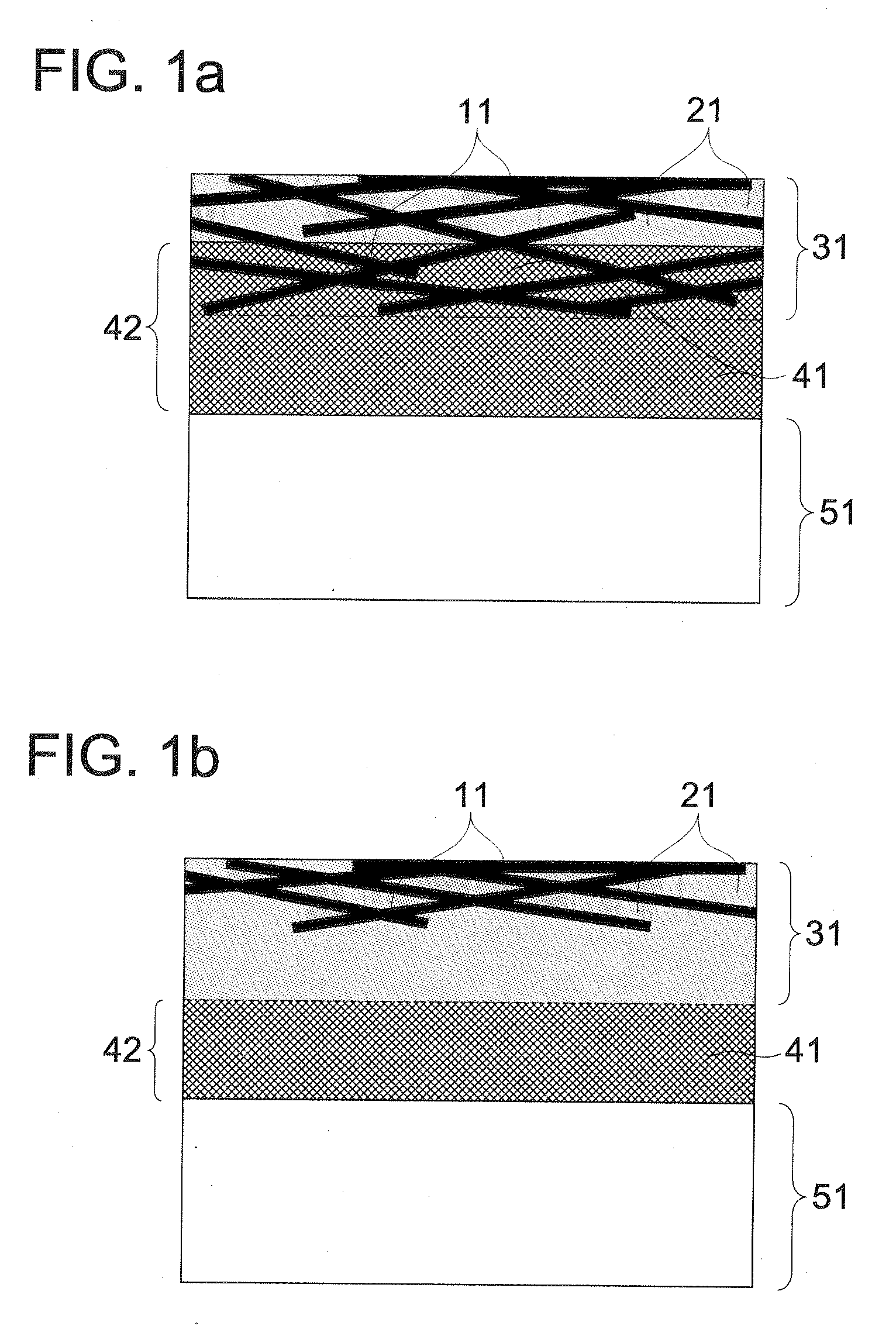

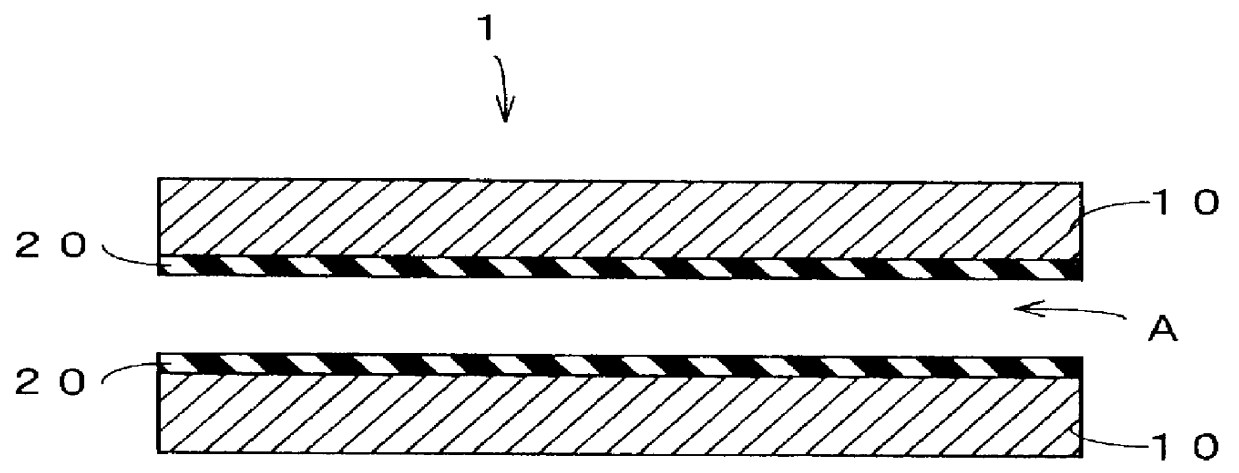

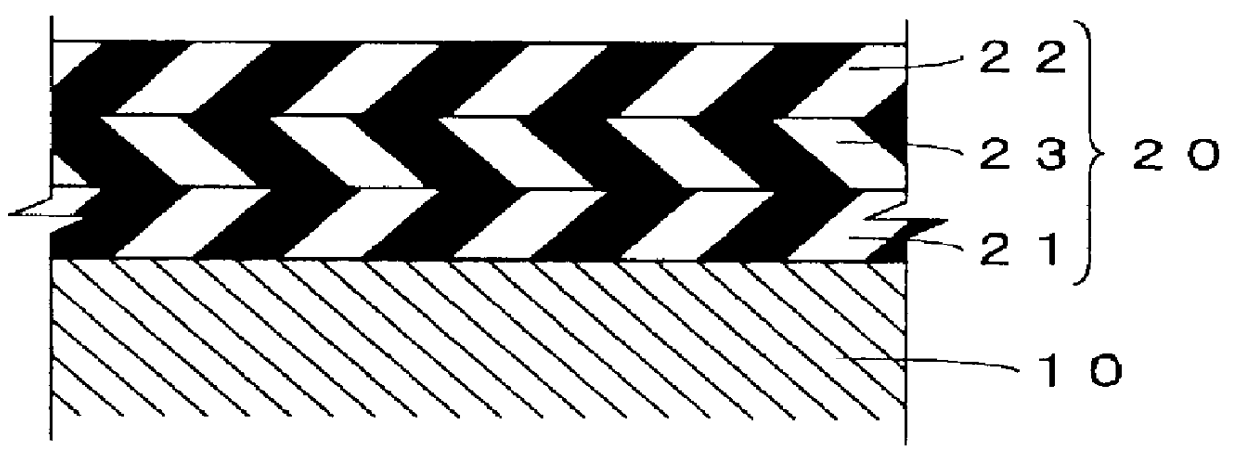

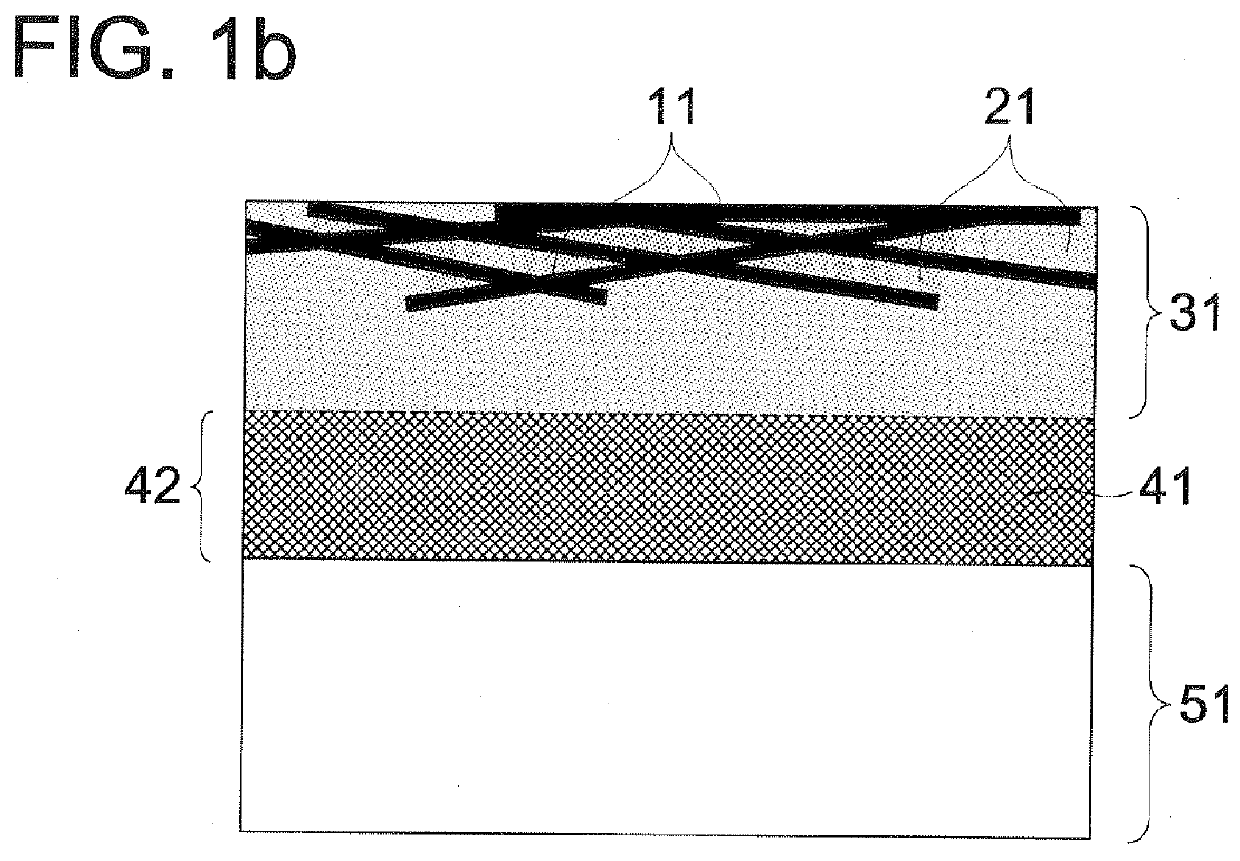

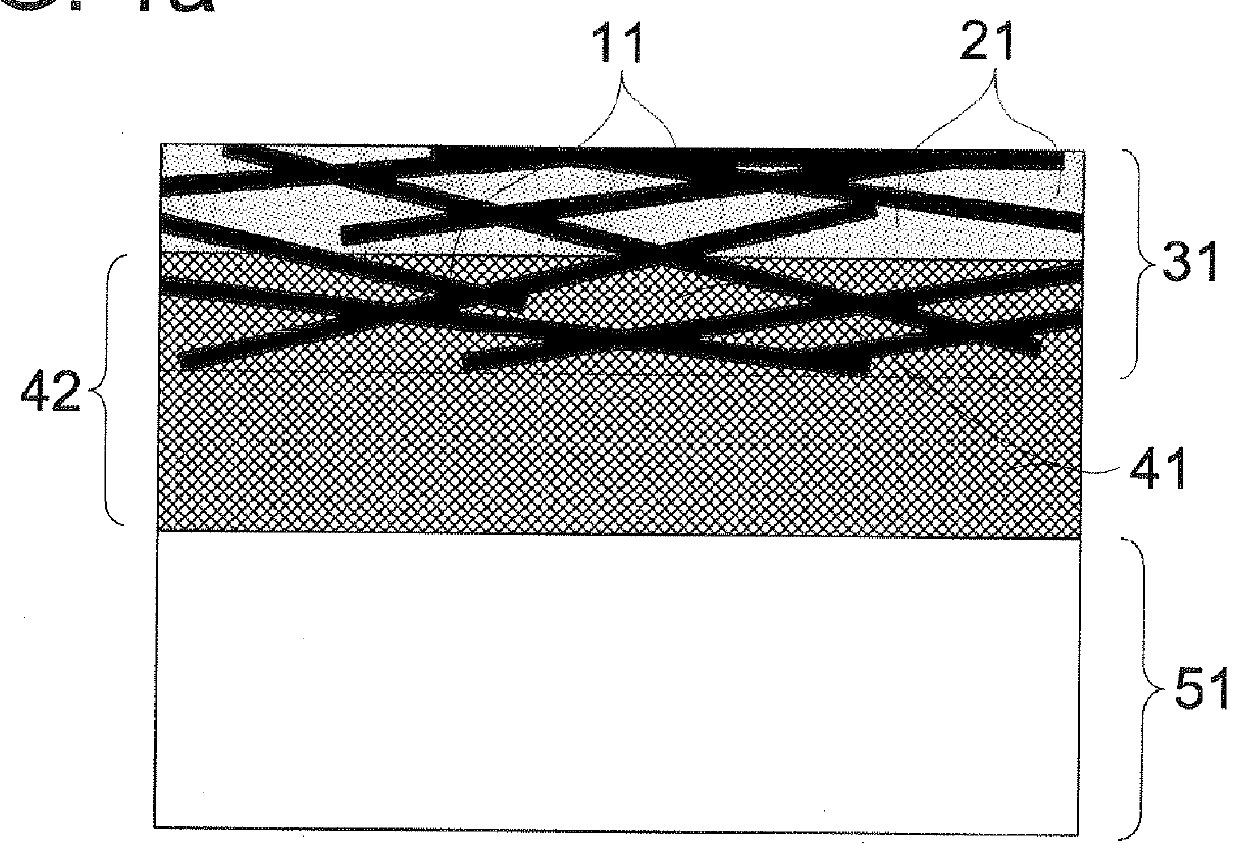

Transparent electrode and production method of same

ActiveUS20110018424A1Improve surface smoothnessIncrease flexibilityFinal product manufactureLamp incadescent bodiesFiberOptical transparency

Owner:RESONAC CORP

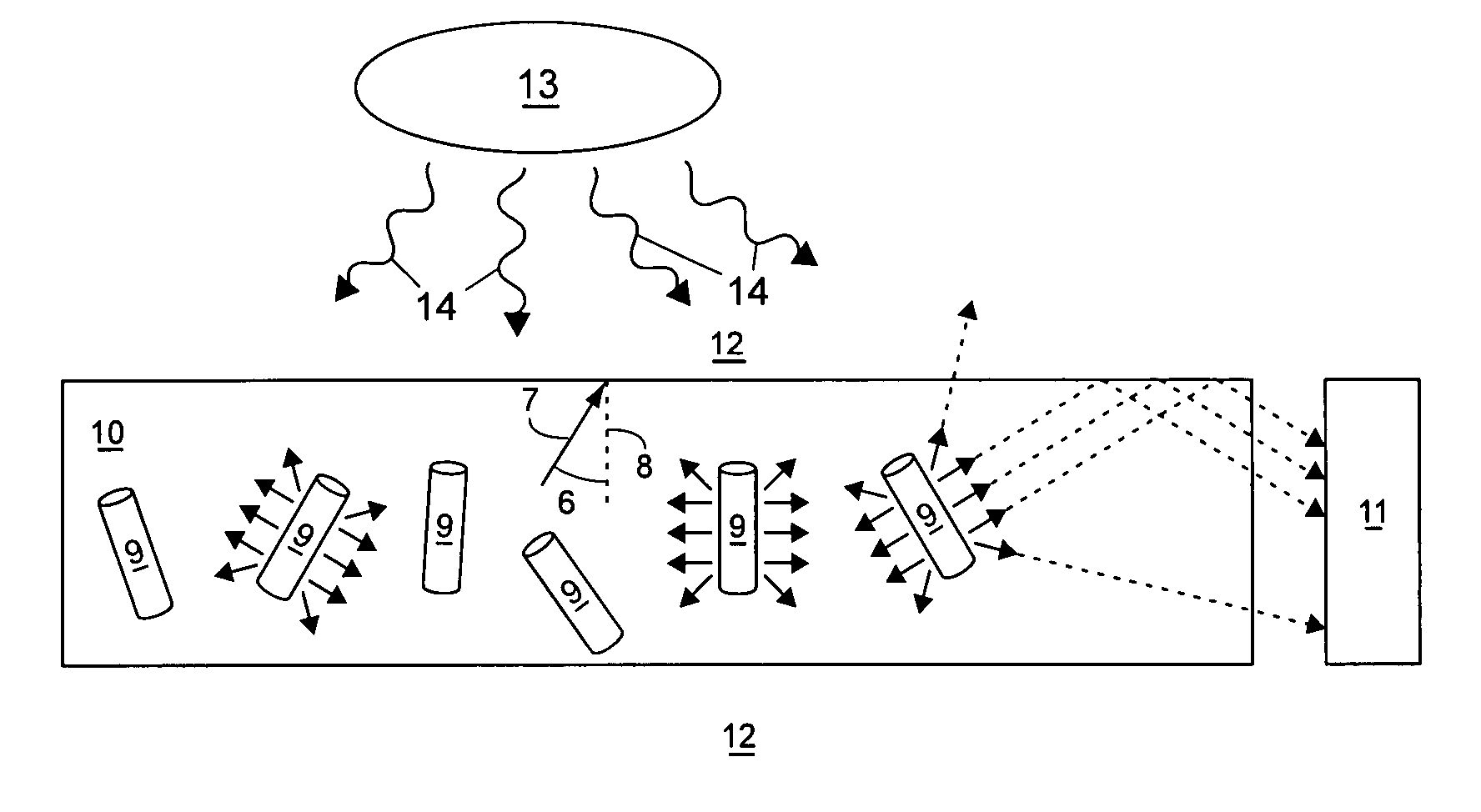

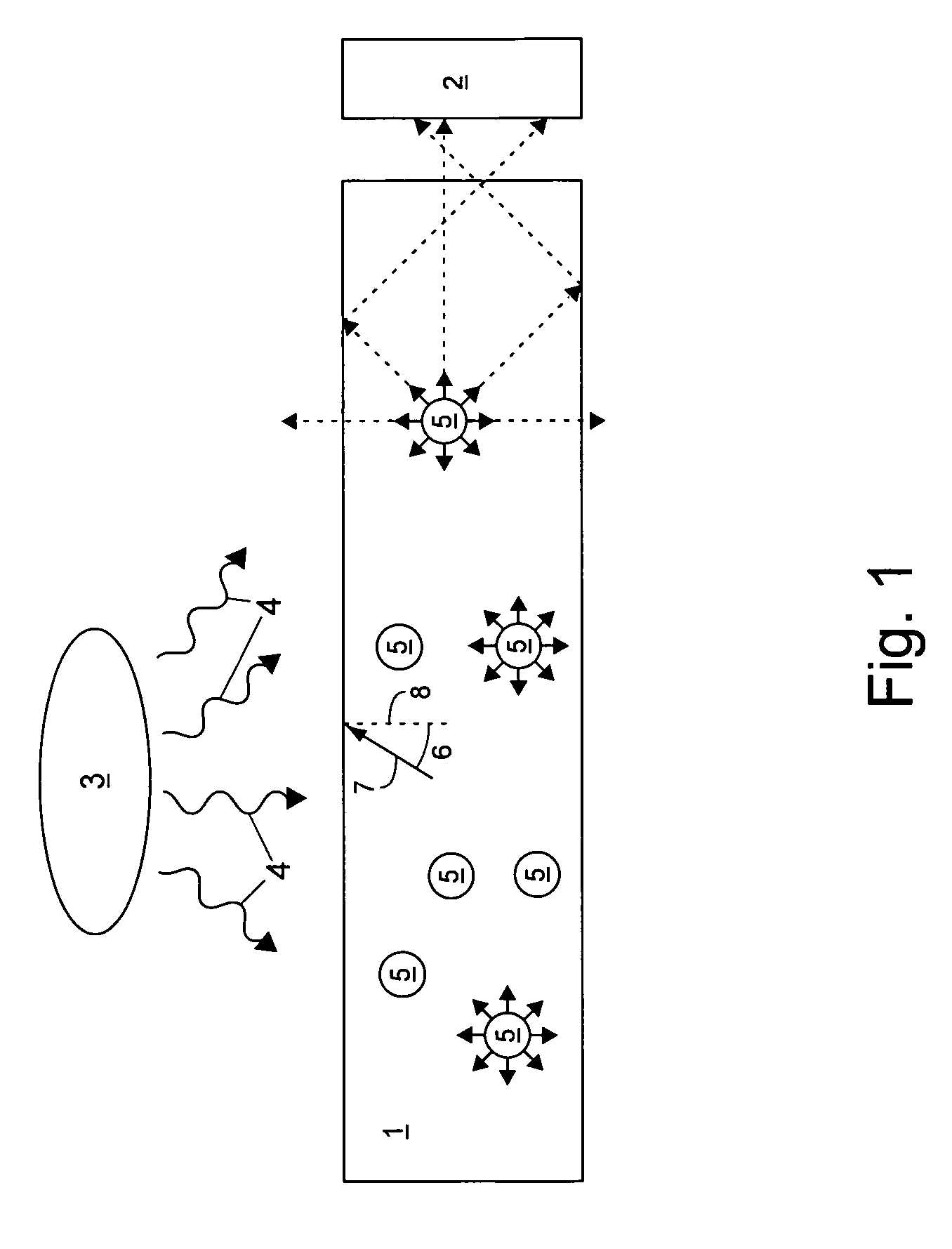

Nanocomposites

InactiveUS20070122101A1Increase percentageEfficiently waveguidedSolar heating energyMaterial nanotechnologyNanowireNanocrystal

This invention provides composite materials comprising nanostructures (e.g., nanowires, branched nanowires, nanotetrapods, nanocrystals, and nanoparticles). Methods and compositions for making such nanocomposites are also provided, as are articles comprising such composites. Waveguides and light concentrators comprising nanostructures (not necessarily as part of a nanocomposite) are additional features of the invention.

Owner:ONED MATERIAL INC

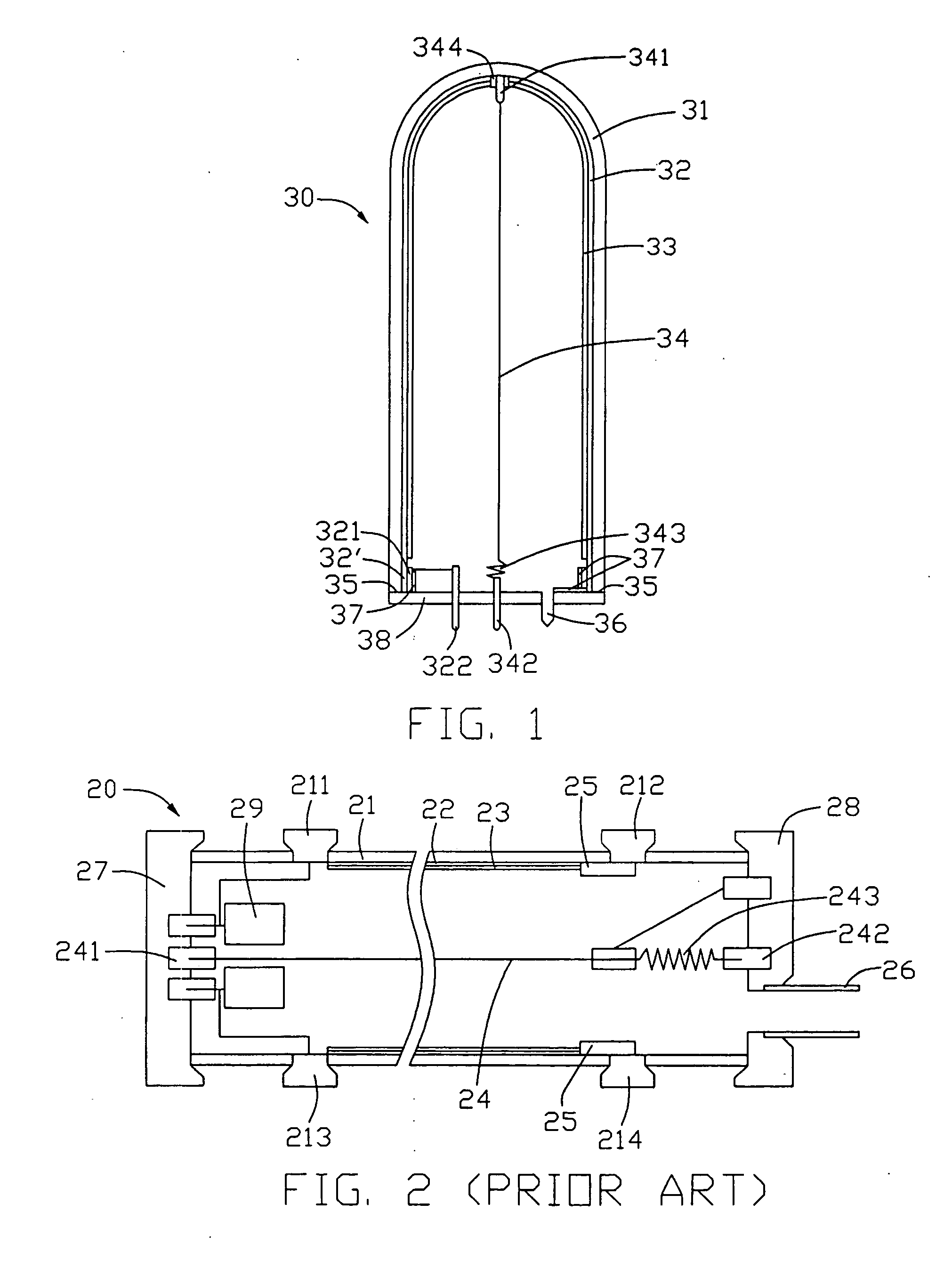

Discharge cell for ozone generator

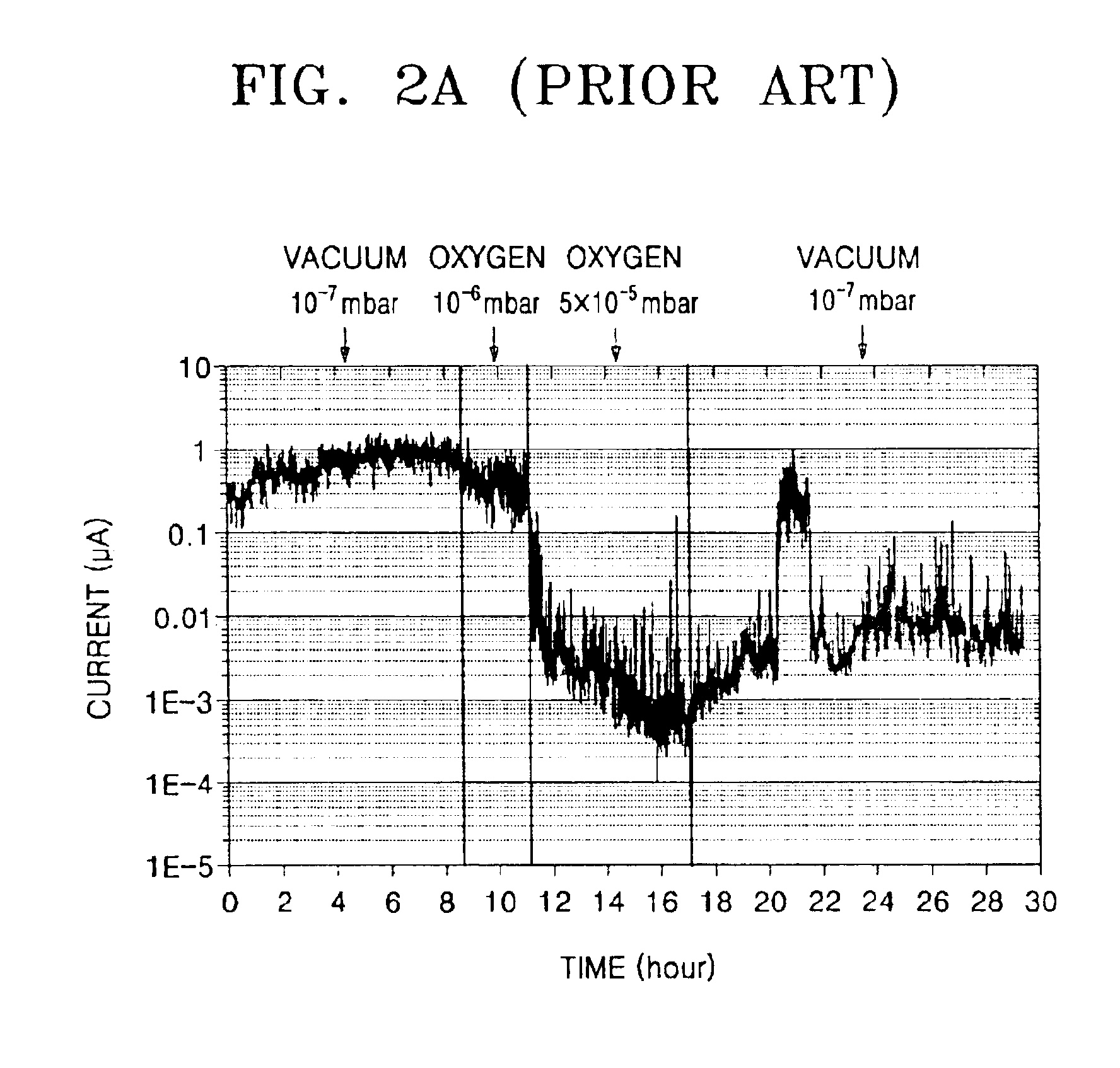

InactiveUS6046533AEffectively suppress the time-related reduction in the ozone concentrationAvoid impuritiesLamp incadescent bodiesThermionic cathodesOzone generatorElectricity

A discharge cell for use in an ozone generator is provided which can suppress a time-related reduction in ozone concentration without adding a catalytic gas such as nitrogen gas to oxygen gas as a raw material gas. The discharge cell includes a pair of electrodes disposed in an opposed spaced relation with a discharge space therebetween, and a dielectric layer of a three-layer structure consisting of three ceramic dielectric layers successively stacked on at least one of the electrodes, wherein a first dielectric layer of the dielectric layer contacting the one electrode contains no titanium dioxide, wherein a second dielectric layer of the dielectric layer exposed to the discharge space contains titanium dioxide in a metal element ratio of not lower than 10 wt %.

Owner:SUMITOMO PRECISION PROD CO LTD

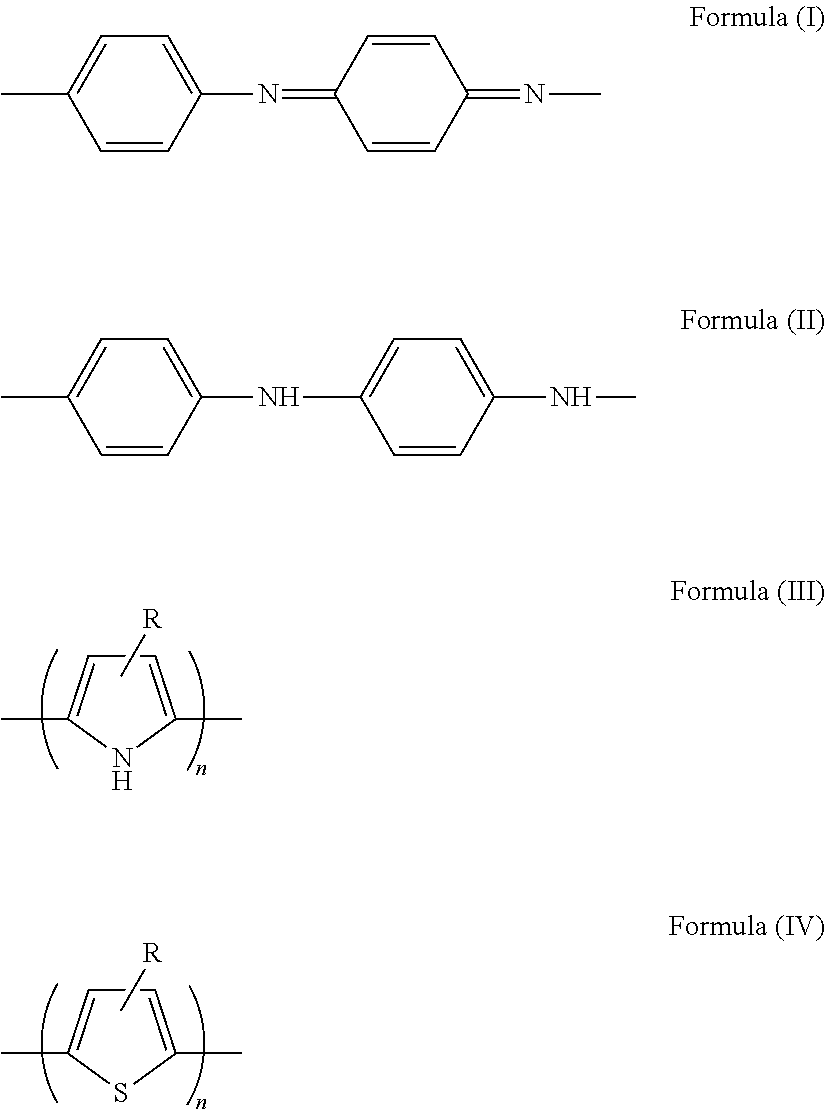

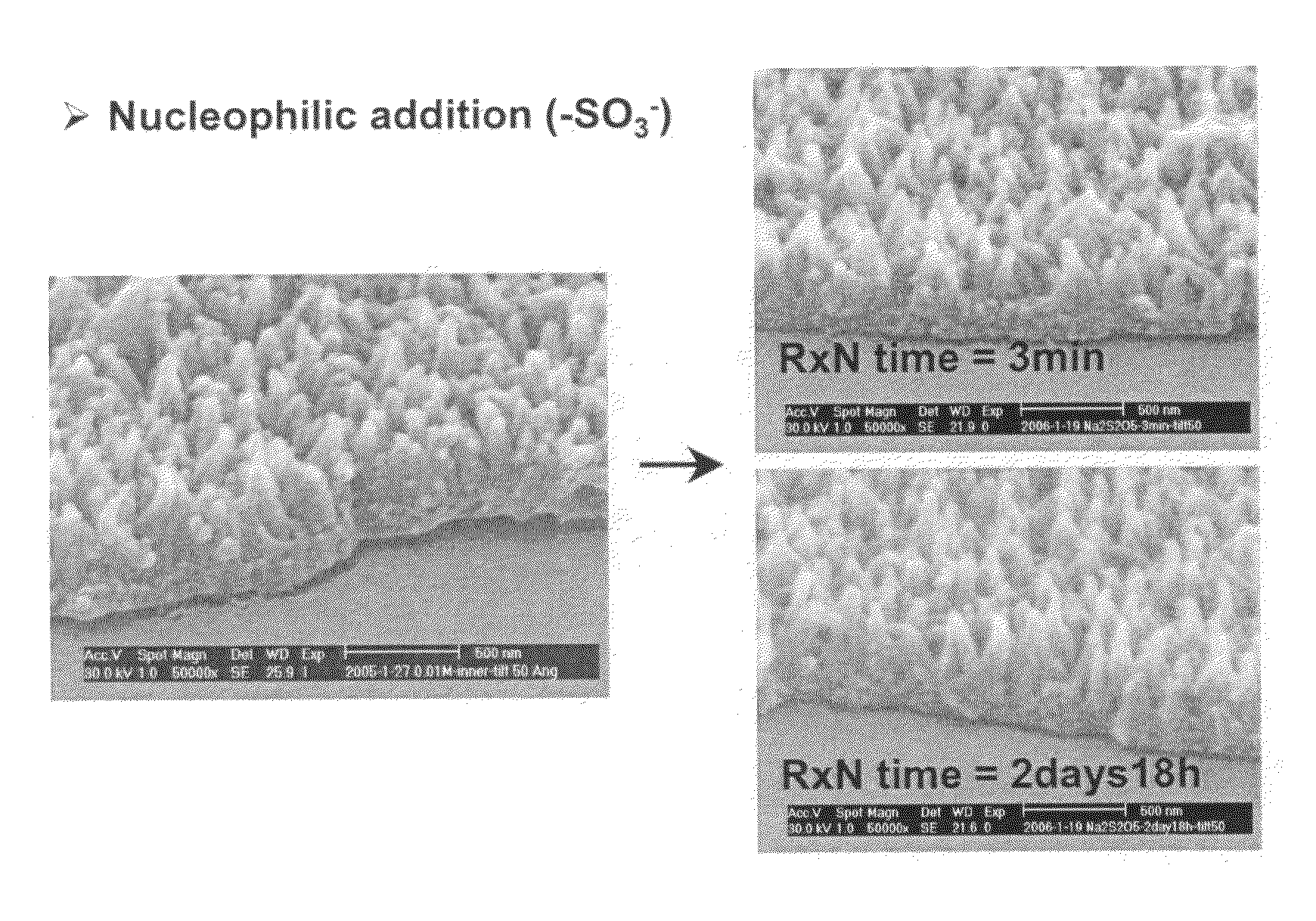

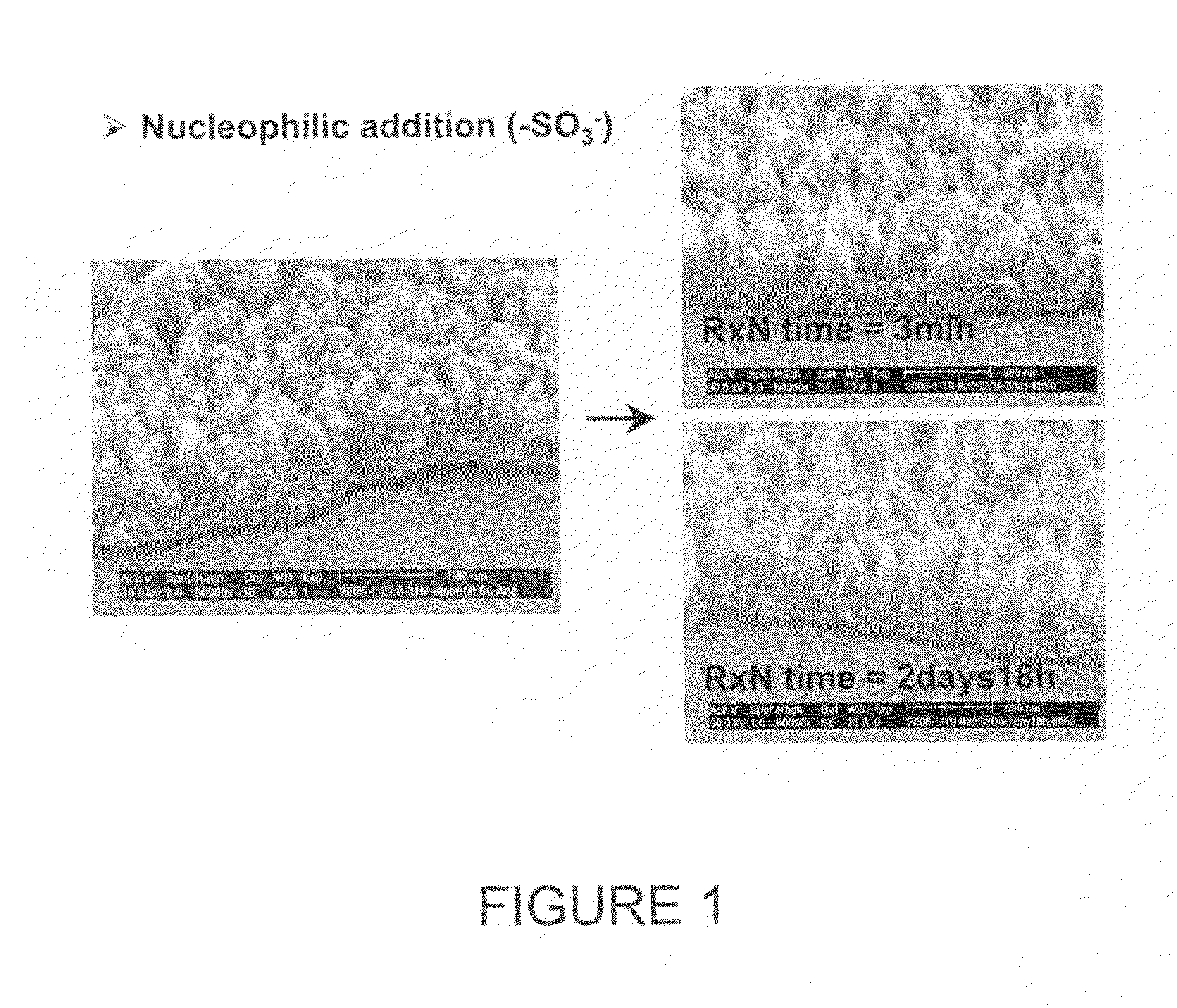

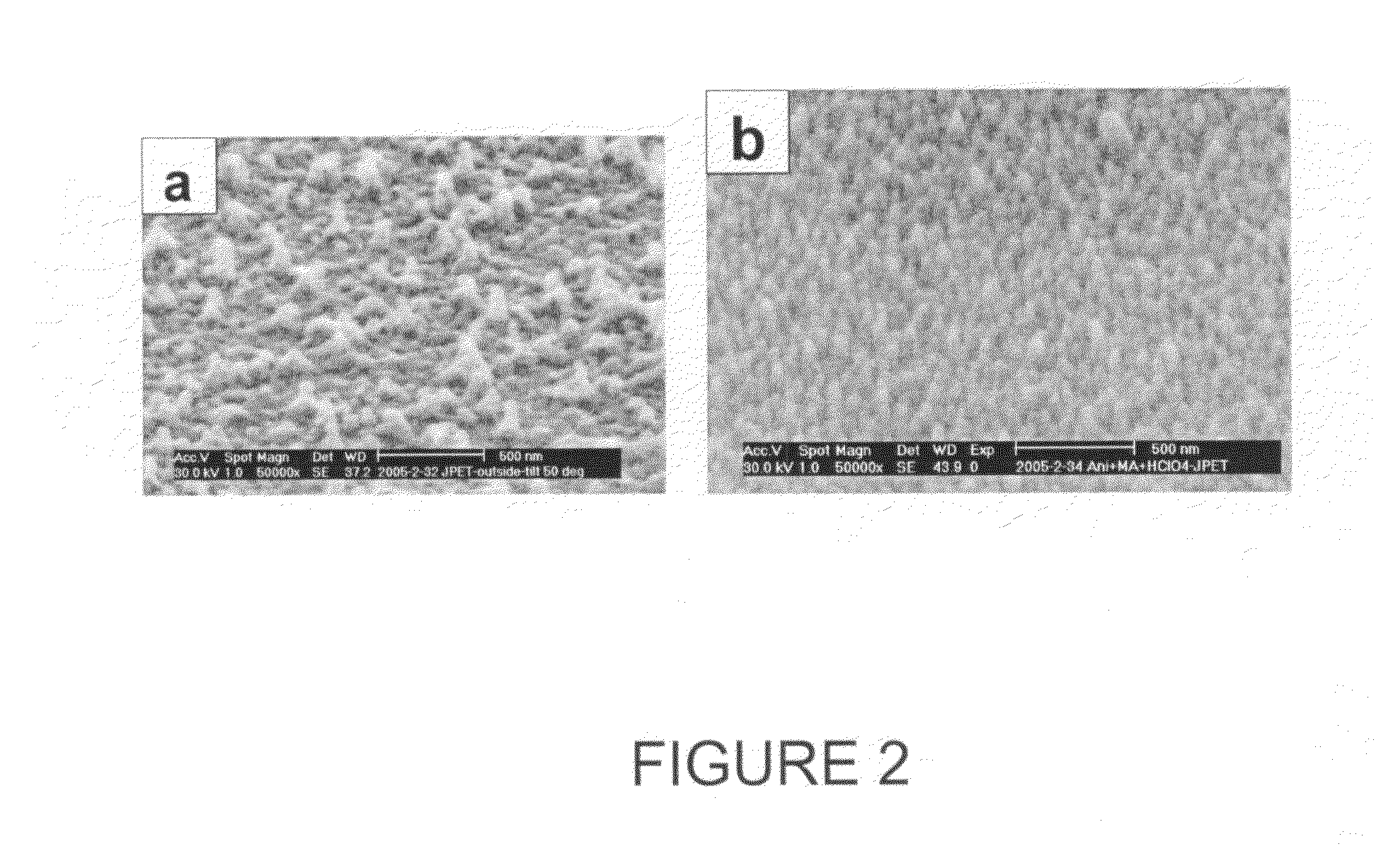

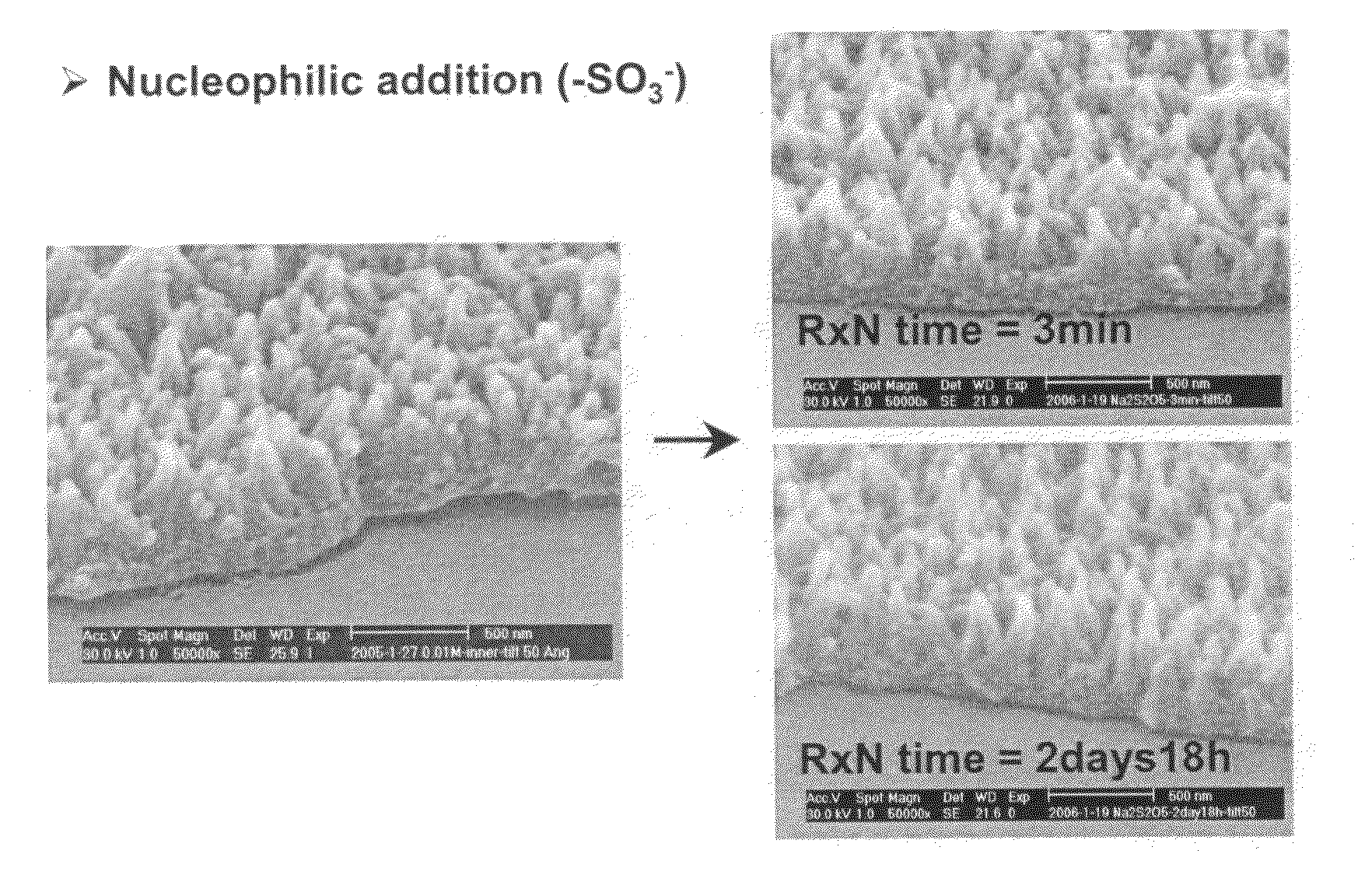

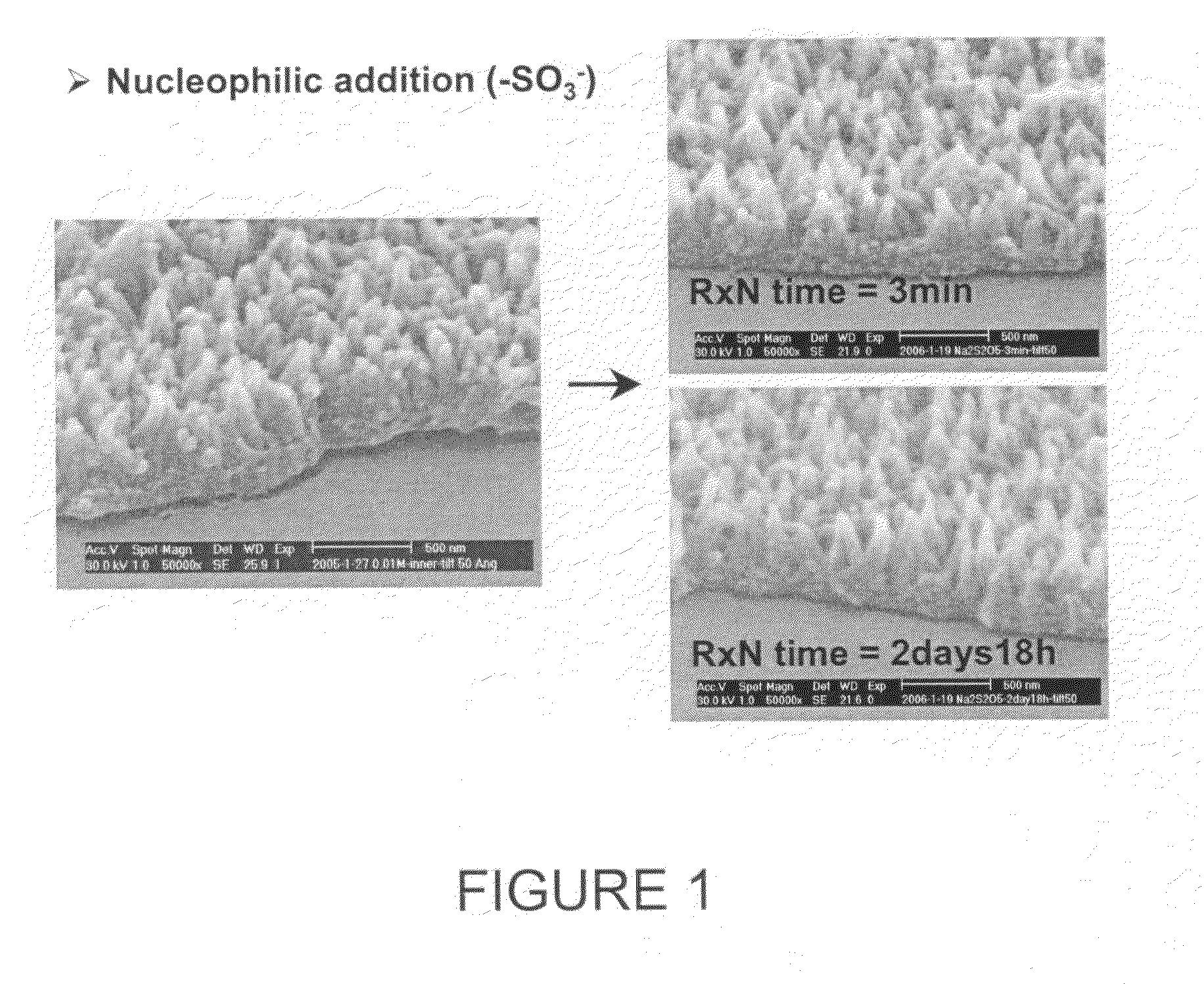

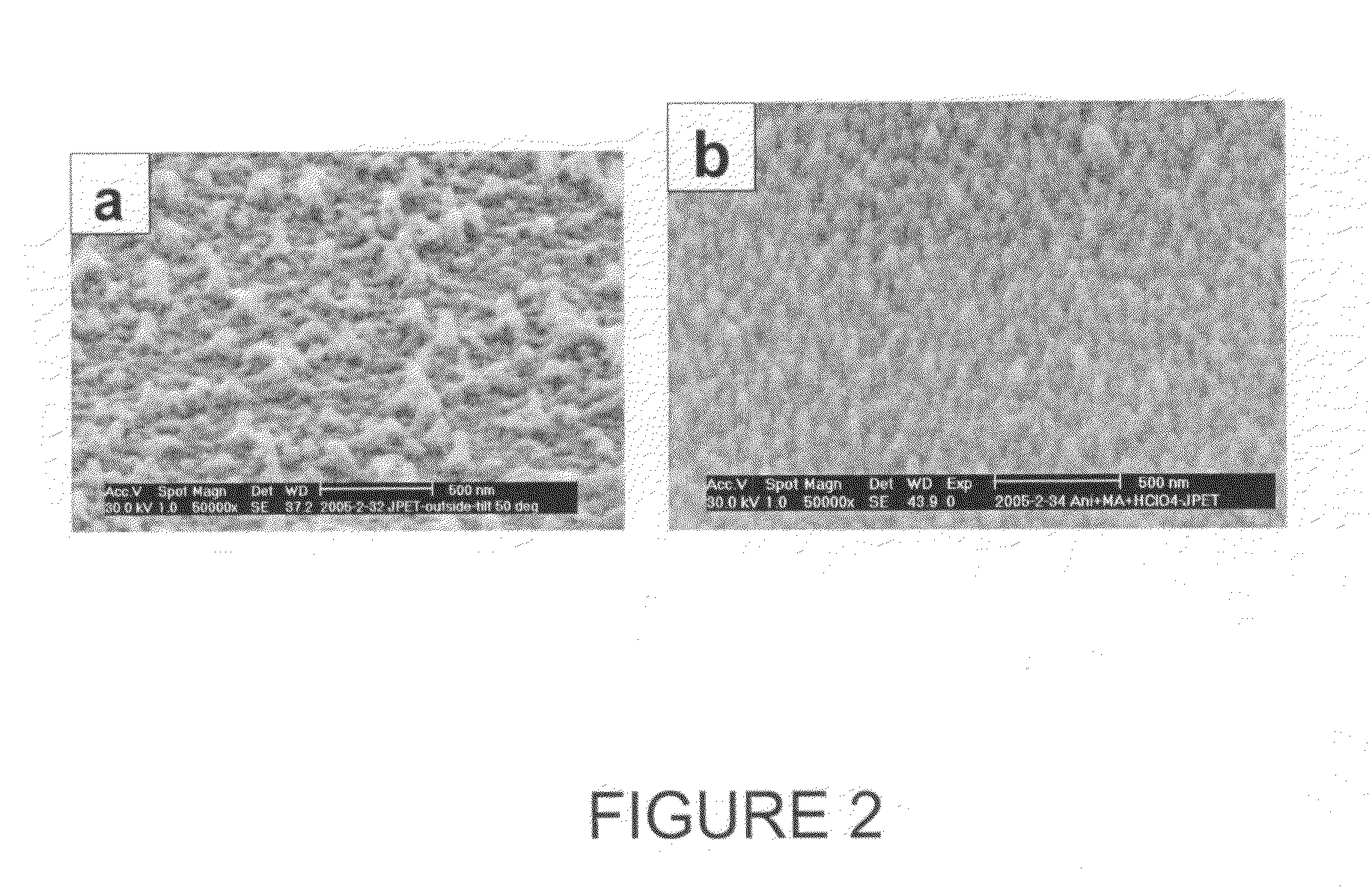

Aligned nanostructured polymers

Novel, simple methods are presented directed to the synthesis of aligned nanofibers of polyaniline and substituted derivatives on a substrate. The production of these fibers is achieved via various methods by controlling the concentration of aniline monomer or substituted aniline derivatives or an oxidant in the reaction medium and maintaining said concentration at a level much lower than conventional polyaniline synthesis methods. Methods are disclosed relating to the use of a permeable membrane to control the release of a monomer and / or oxidant as well as a bulk polymerization method.

Owner:THE OHIO STATE UNIV RES FOUND

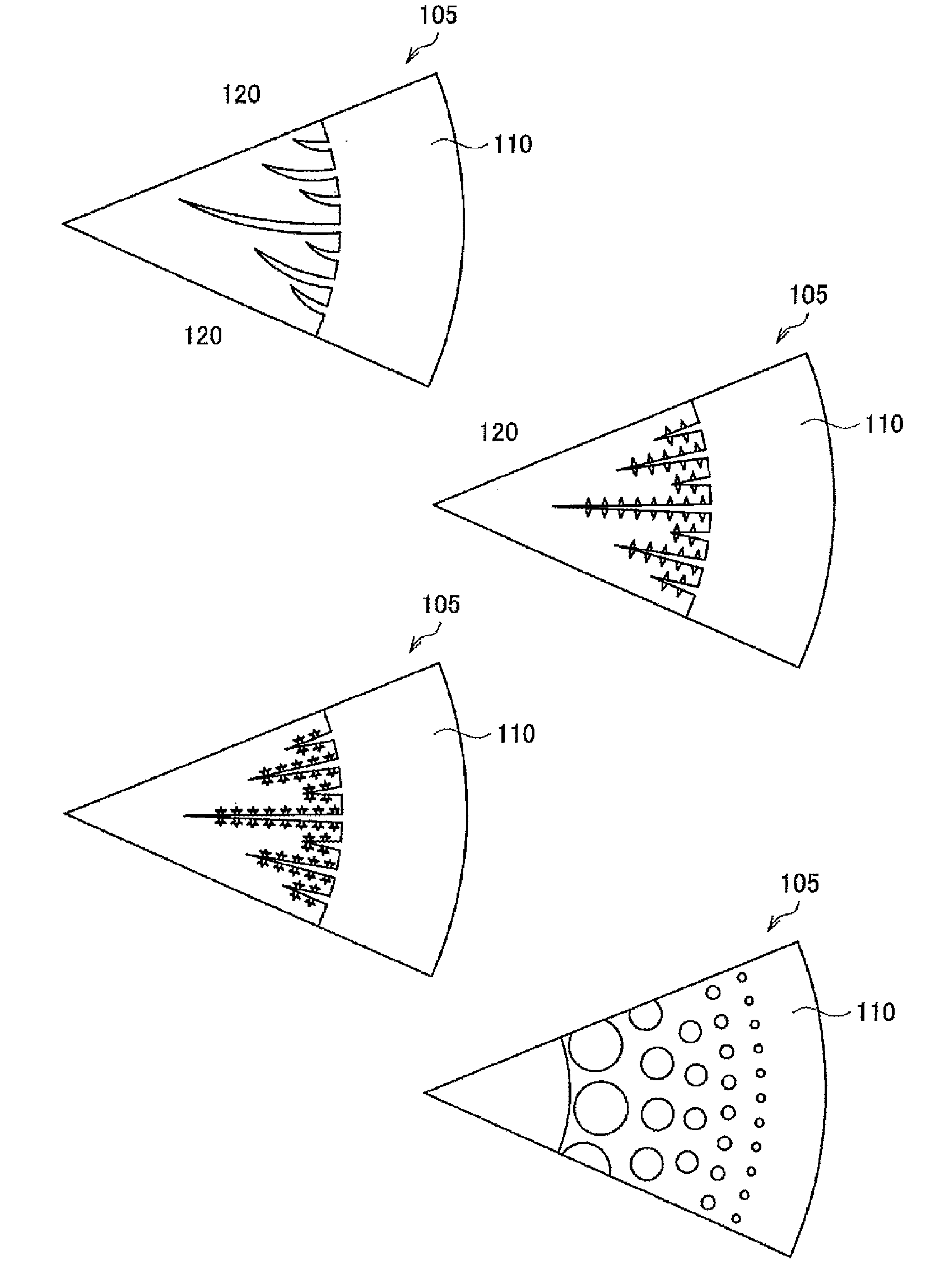

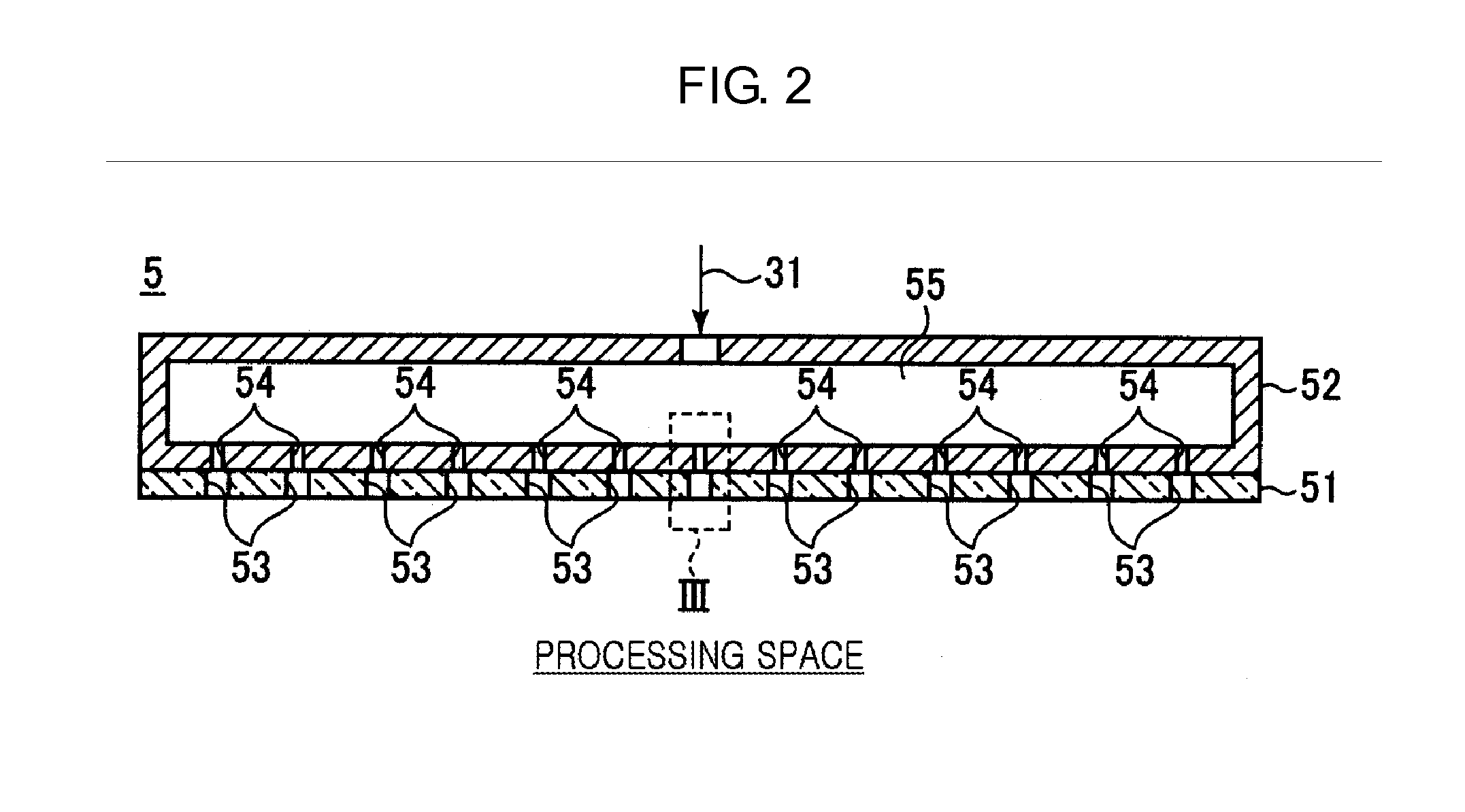

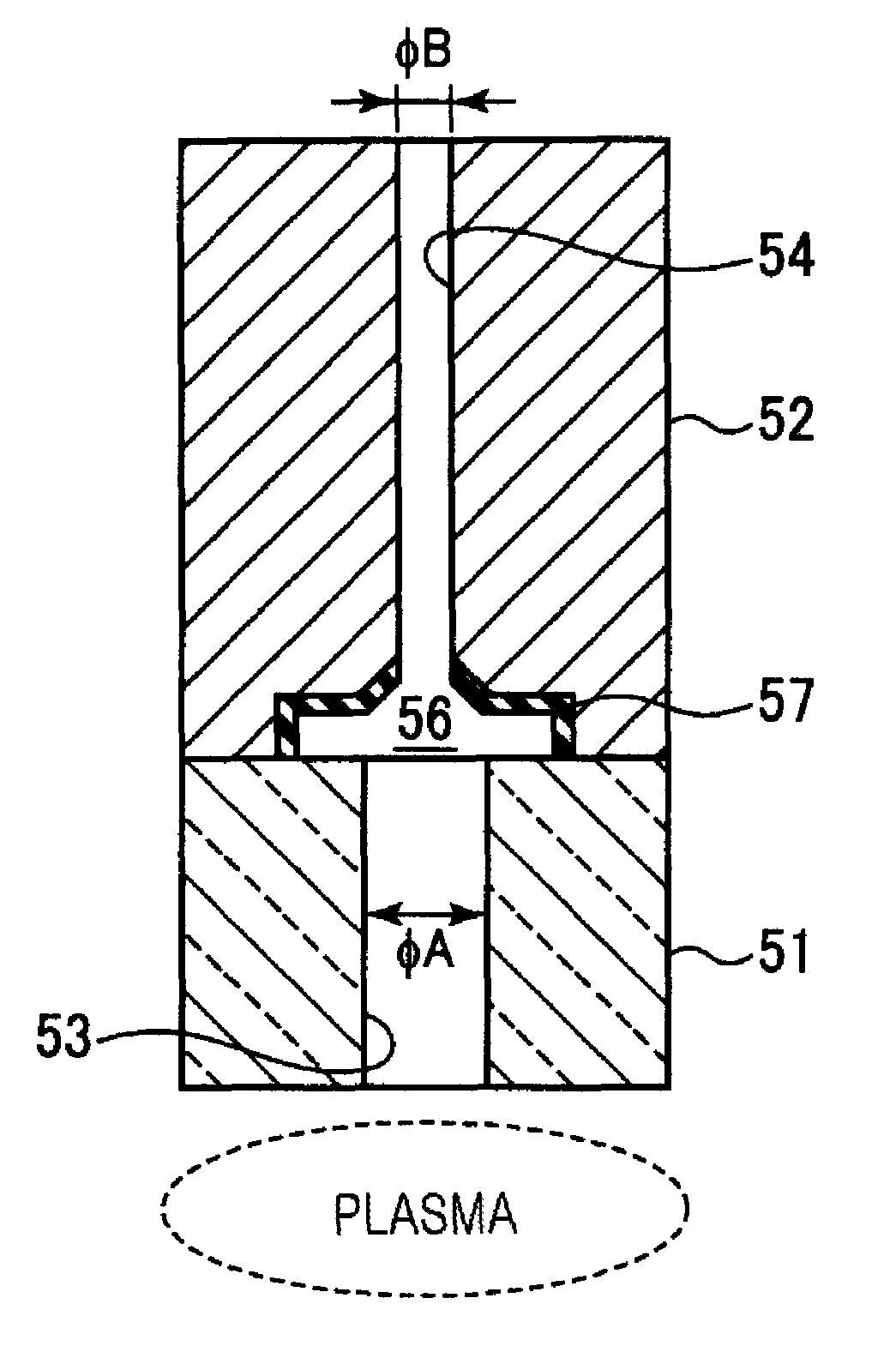

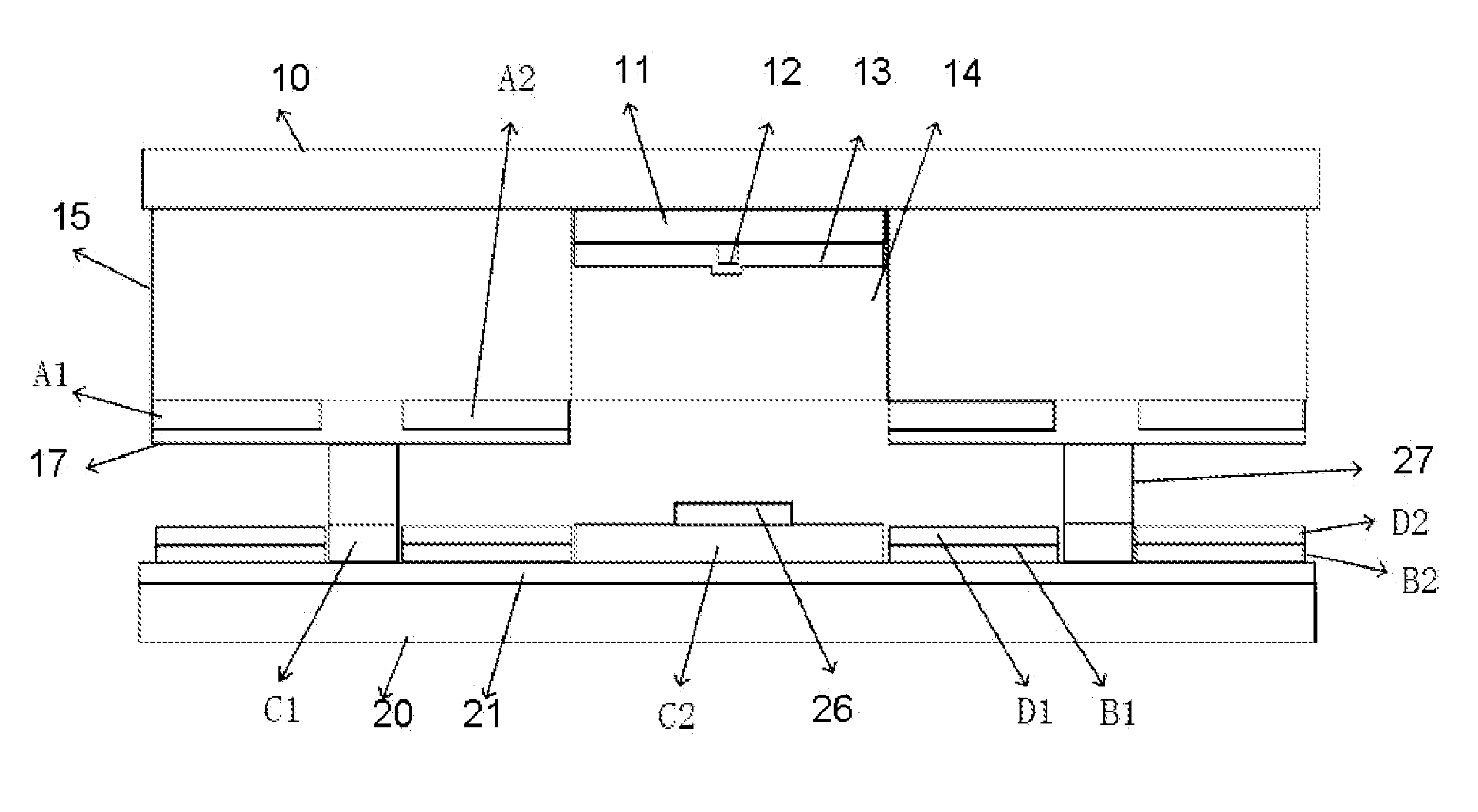

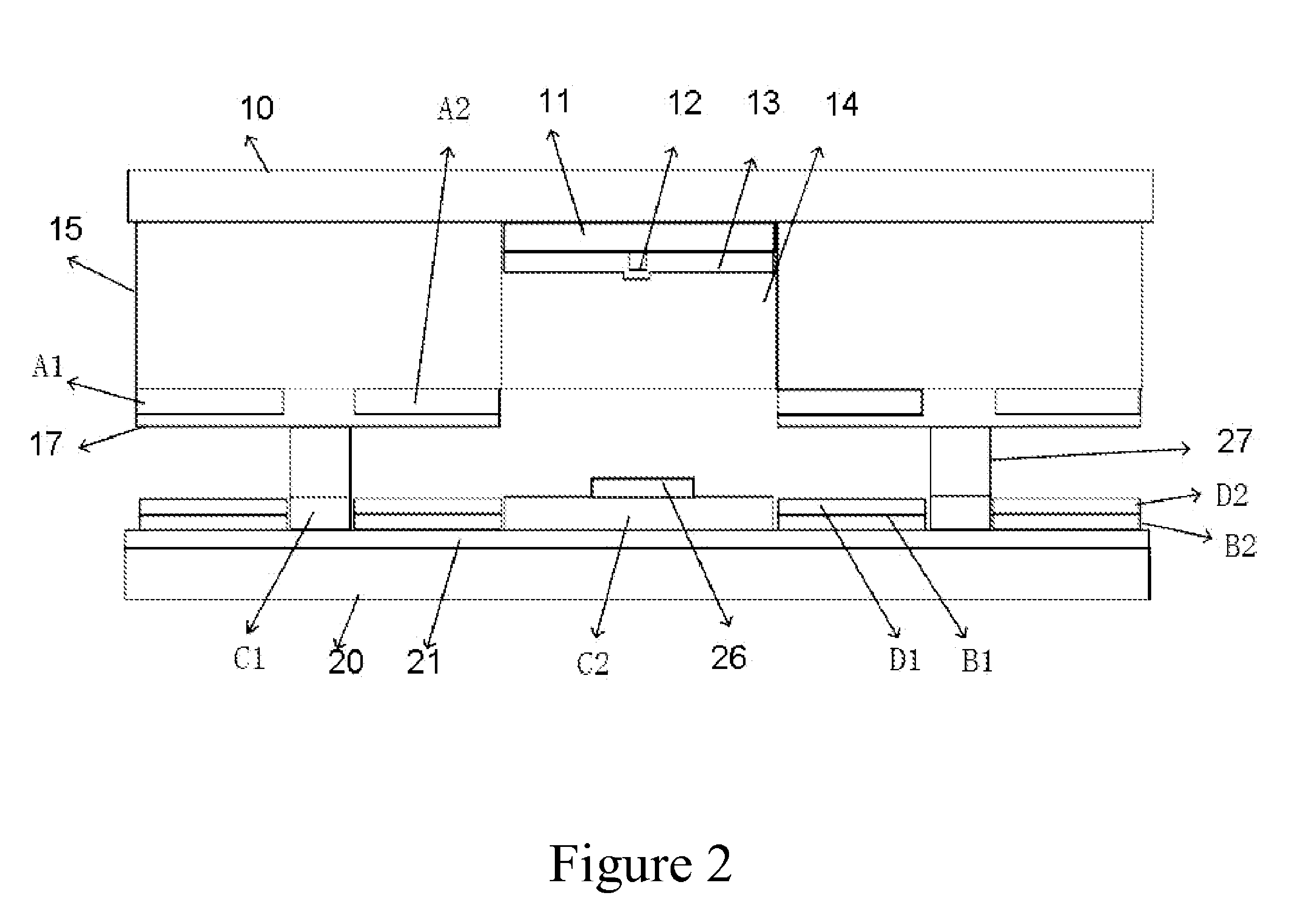

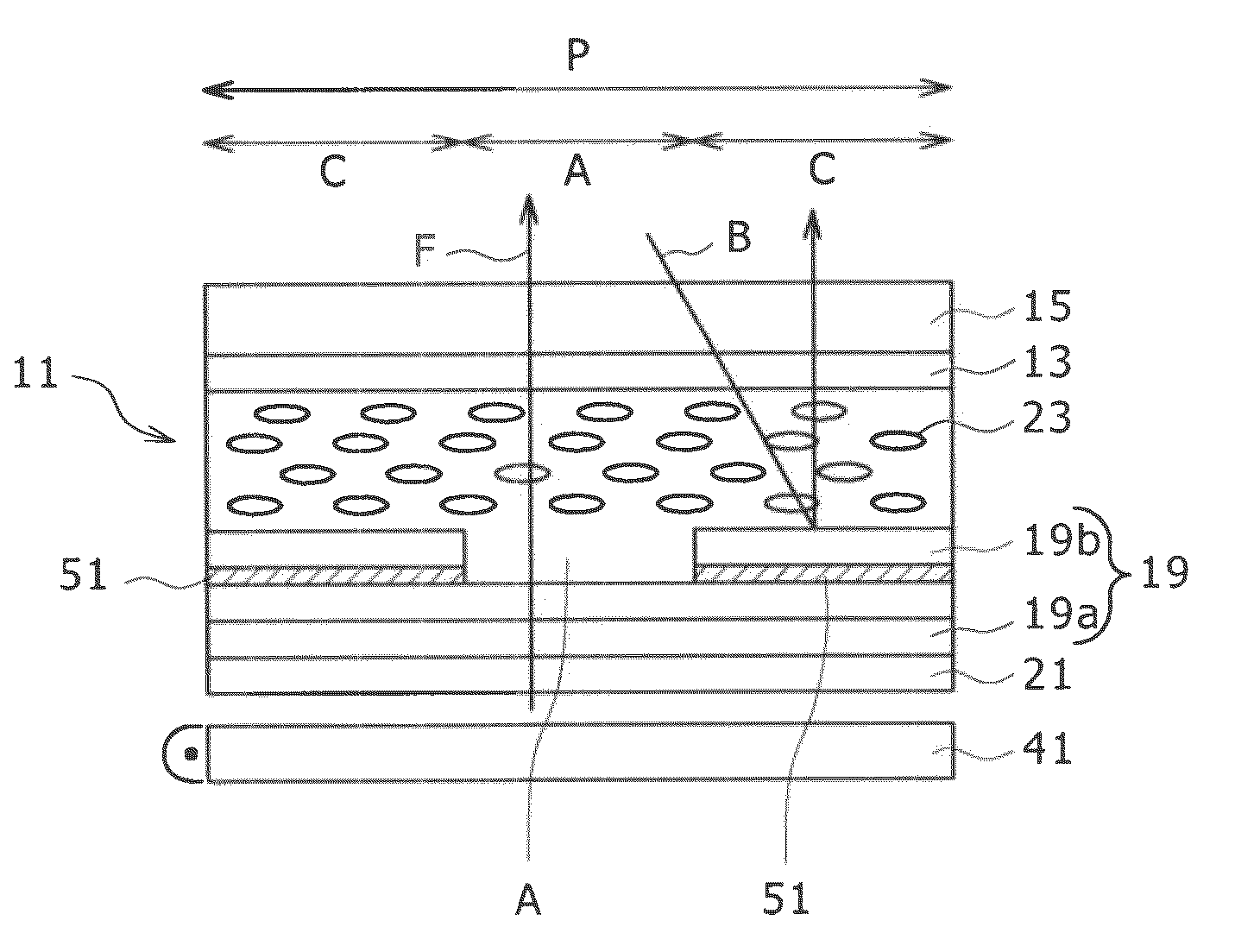

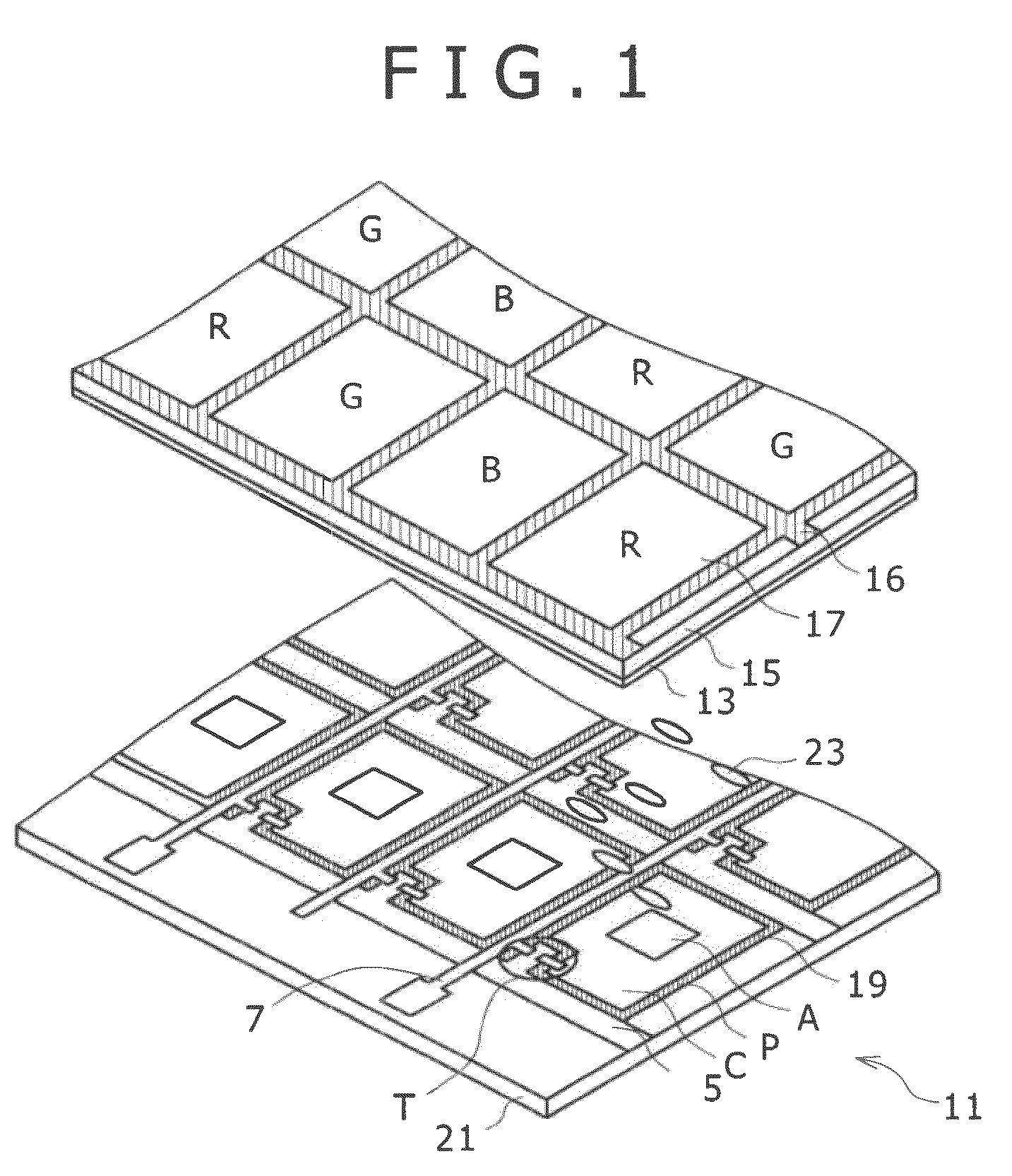

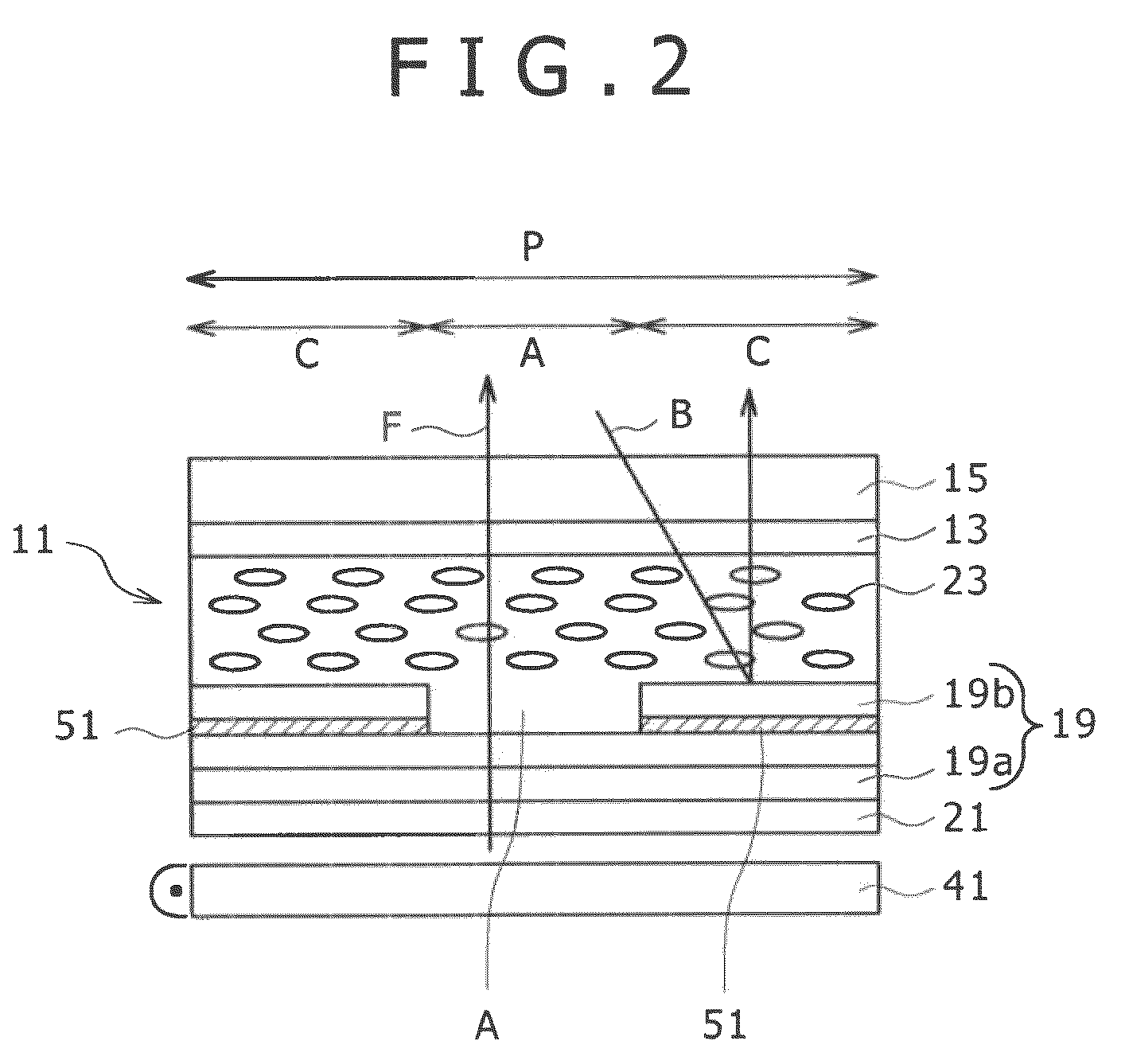

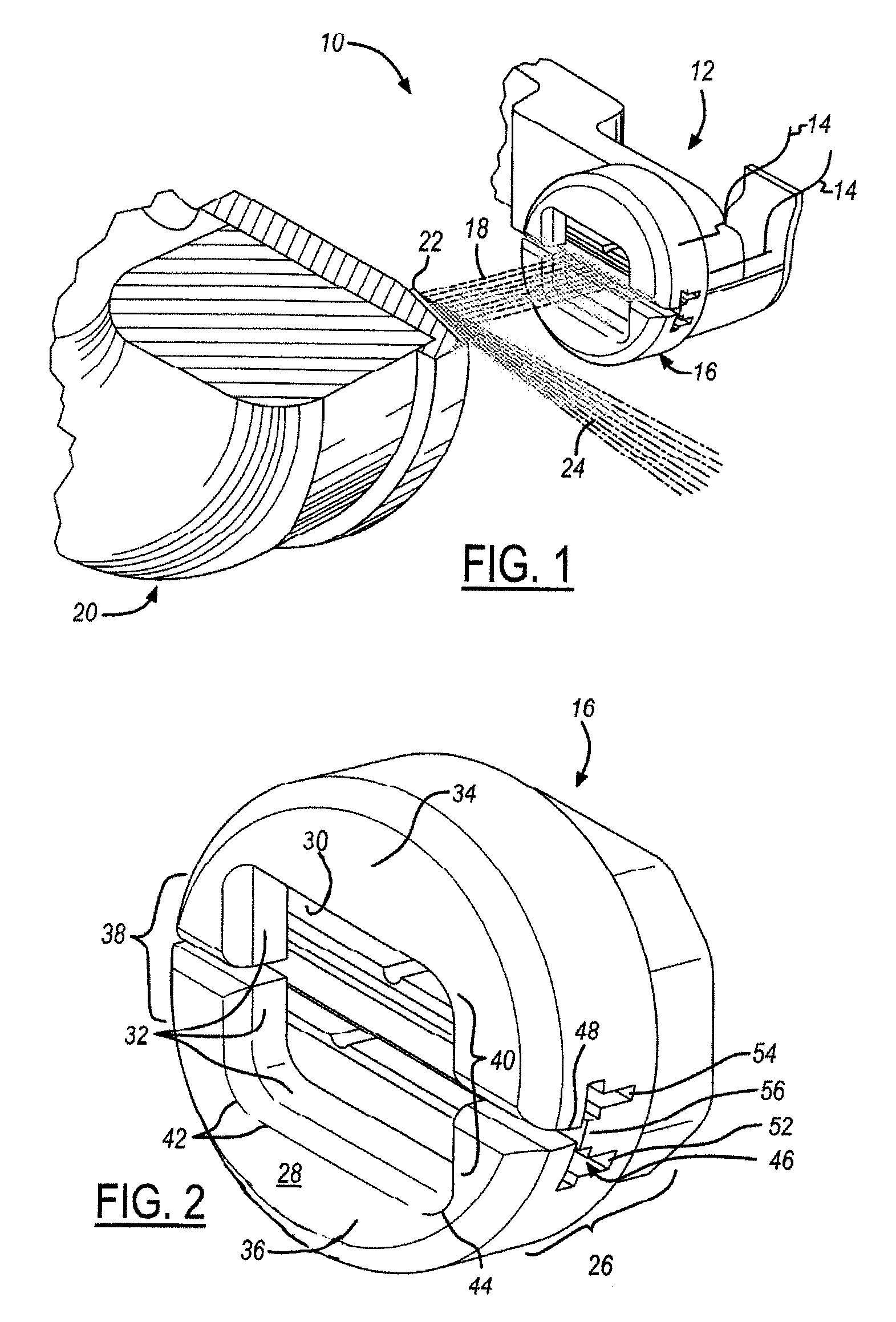

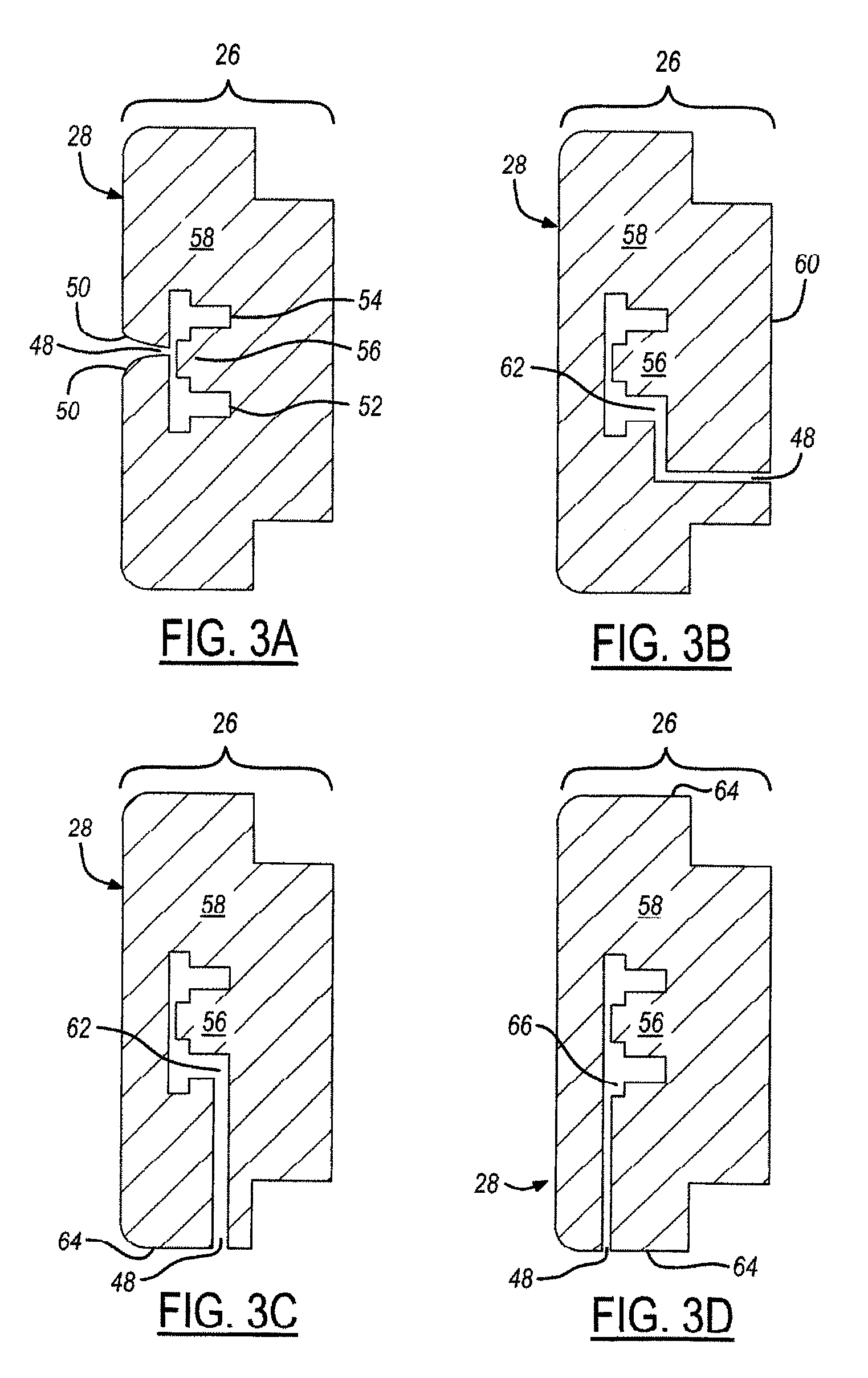

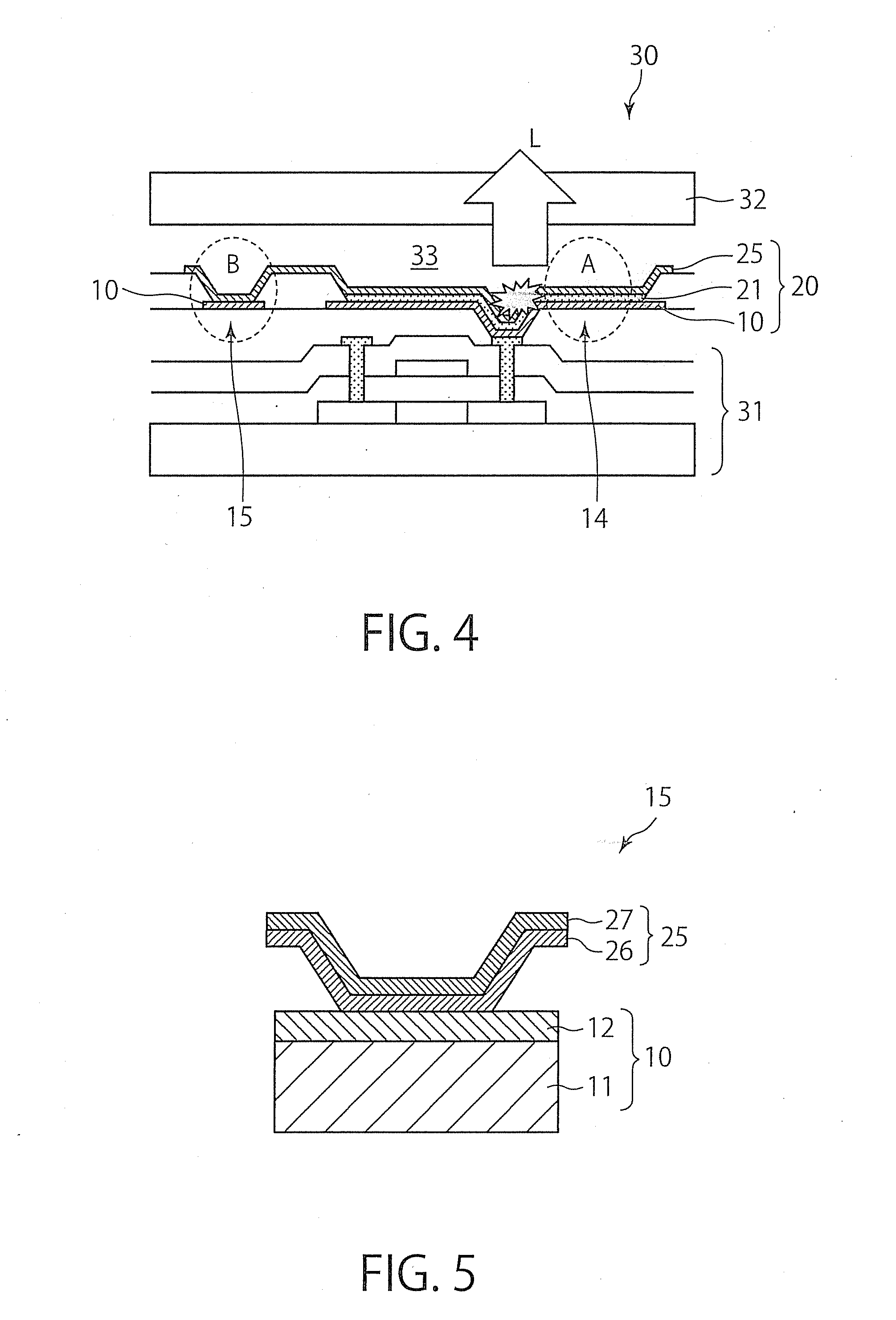

Electrode having gas discharge function and plasma processing apparatus

ActiveUS20120247673A1Not easy to changeLamp incadescent bodiesDecorative surface effectsEngineeringDegrees of freedom

An electrode having a gas discharge function, where the degree of freedom related to a maximum gas flow rate is abundant, an electrode cover member may be thinned, and a change of a gas behavior according to time is difficult to be generated in a processing chamber during gas introduction. The electrode includes: a base material having a plurality of gas holes; and an electrode cover member having a plurality of gas holes respectively corresponding to the plurality of gas holes of the base material in a one-to-one manner, fixed to the base material, and disposed facing a processing space in which the object is plasma-processed, wherein a gas hole diameter of the electrode cover member is larger than a gas hole diameter of the base material.

Owner:TOKYO ELECTRON LTD

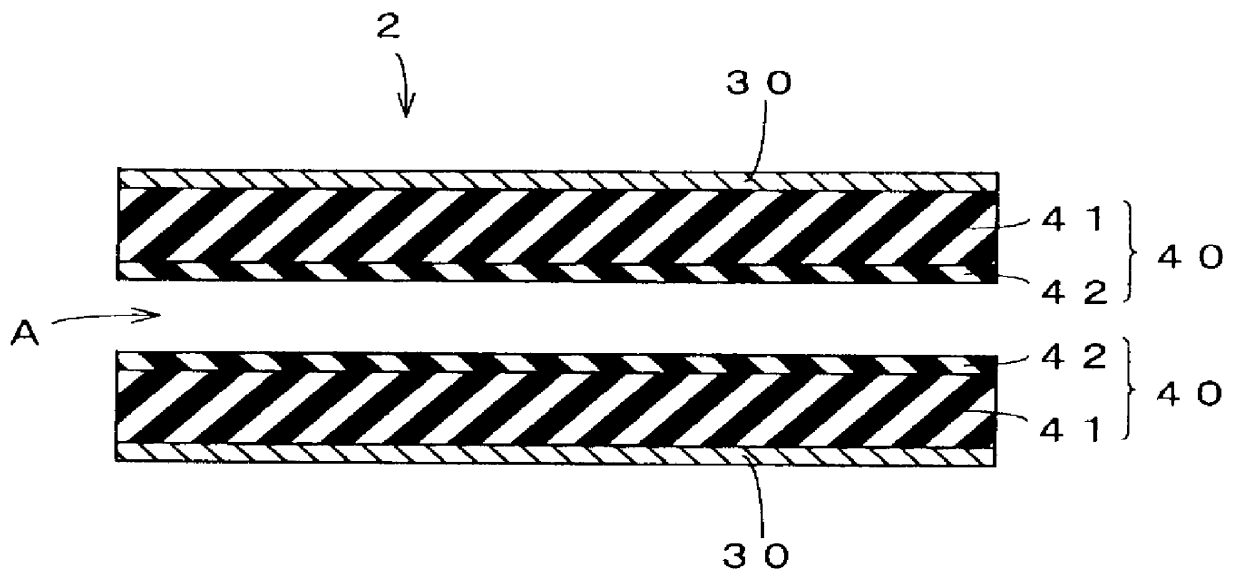

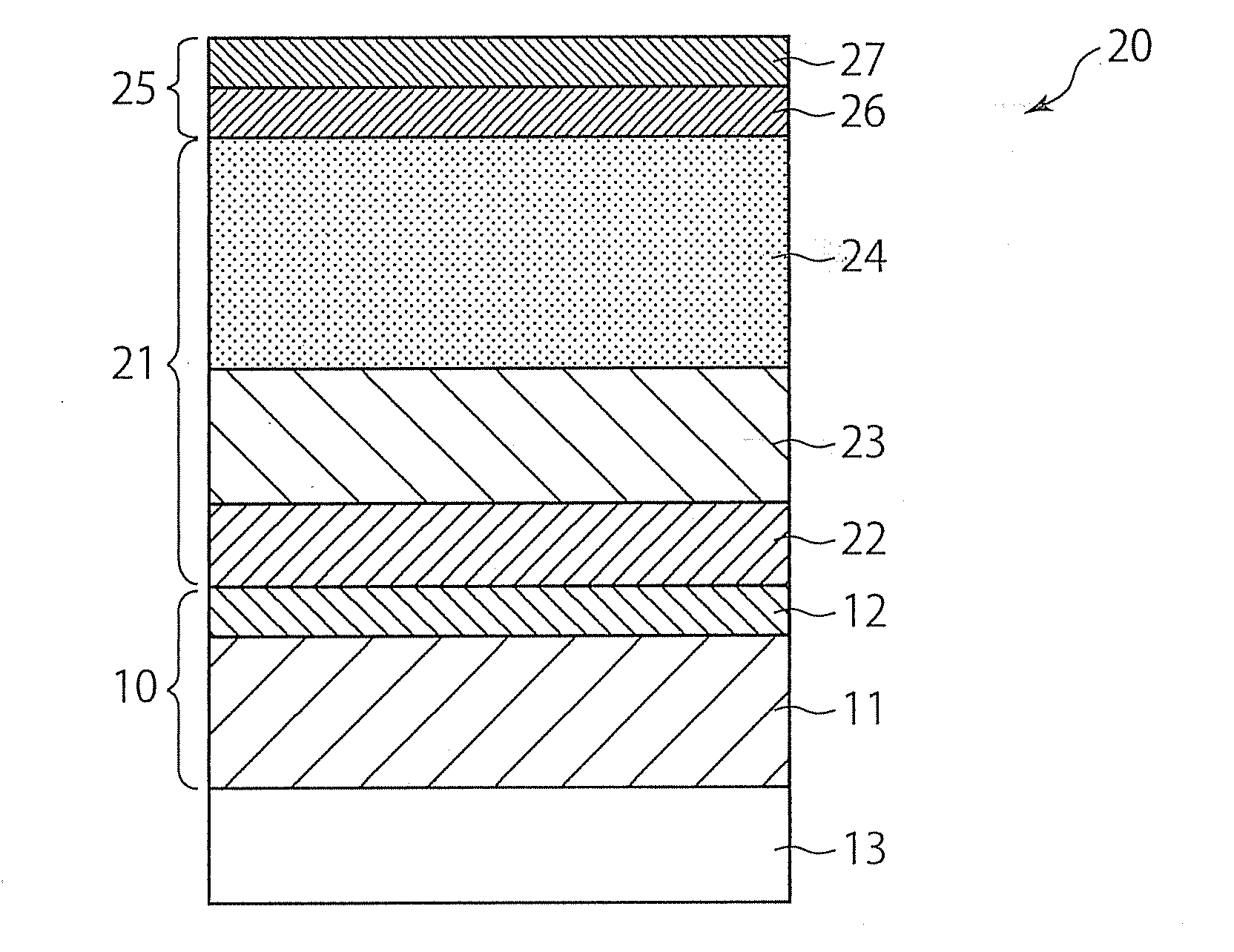

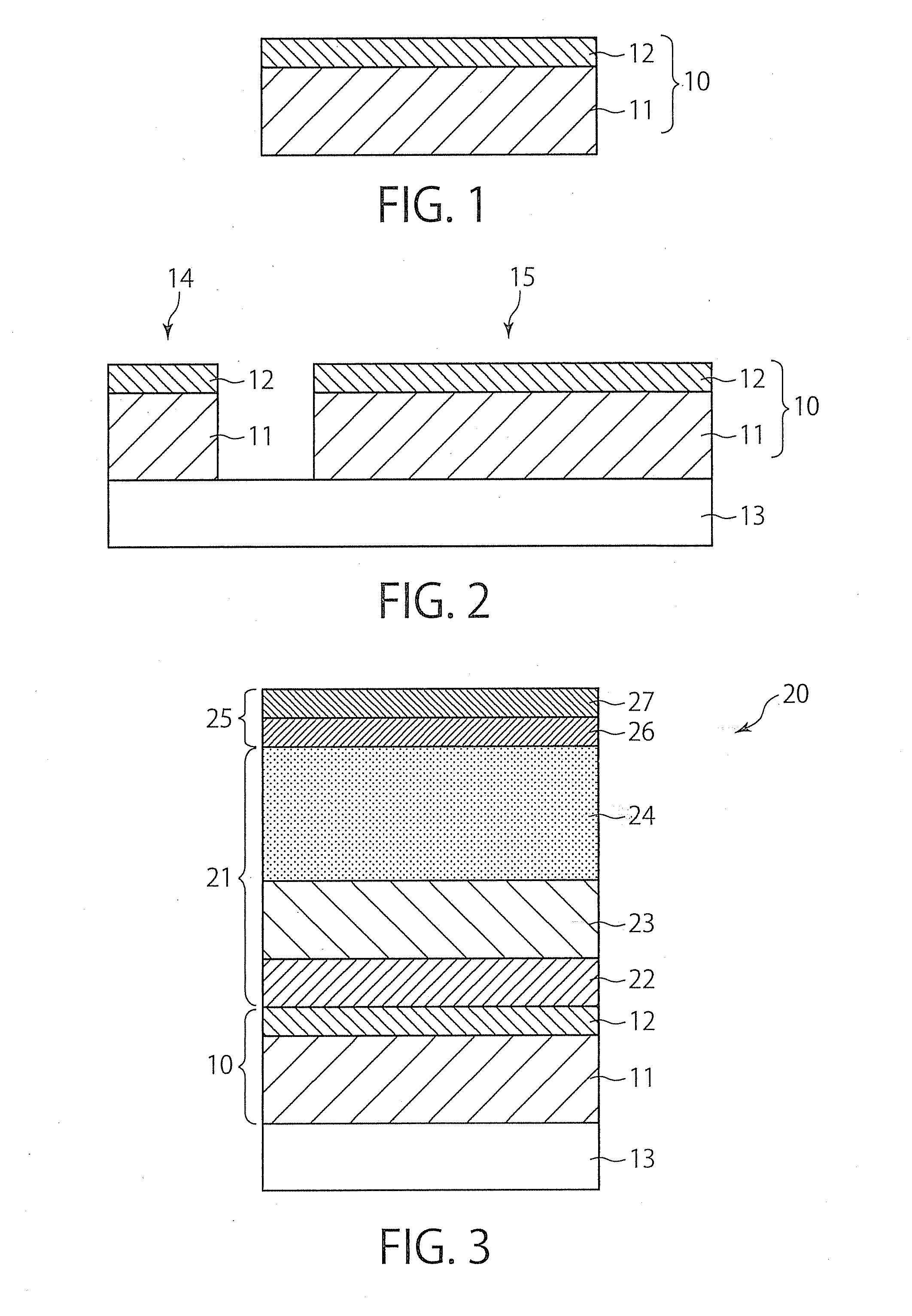

Transparent electrode and production method of same

ActiveUS8198796B2Improve surface smoothnessExcellent in lightweight and flexibilityFinal product manufactureSolid-state devicesFiberOptical transparency

Disclosed are: a transparent electrode with excellent optical transparency, electrical conductivity, and surface smoothness and is capable of providing lightness in weight and flexibility, comprising a transparent conductive layer on a transparent substrate, wherein the transparent conductive layer contains a conductive fiber and a transparent conductive material, the surface of the transparent conductive layer is composed of the conductive fiber and the transparent conductive material, and the smoothness (Ry) of the surface of the transparent conductive layer is greater than or equal to 1 nm and less than or equal to 50 nm; and a production method of same, and the present invention may provide a light emitting element with excellent uniformity of light emission.

Owner:RESONAC CORPORATION

Reflective electrode, display device, and method for producing display device

InactiveUS20100231116A1Excel in contact resistanceExcel in electric resistivityLamp incadescent bodiesSolid-state devicesDisplay deviceAlloy

A reflective electrode (2) includes an aluminum alloy layer (2a) and an aluminum oxide layer (2b) arranged on or above a substrate and is directly connected to a transparent pixel electrode (3) without the interposition of a barrier metal layer. The aluminum alloy layer contains 0.1 to 2 atomic percent of nickel or cobalt and 0.1 to 2 atomic percent of lanthanum. The aluminum oxide layer has a ratio [O] / [Al] of the number of oxygen atoms [O] to the number of aluminum atoms [Al] of 0.30 or less. The aluminum oxide layer has a thickness in its thinnest portion of 10 nm or less. The reflective electrode has a high reflectance and a low contact resistance, even when subjected to a heat treatment at a low temperature of 100° C. or higher but 300° C. or lower. The reflective electrode also has excellent thermal stability and does not cause defects such as hillocks.

Owner:KOBE STEEL LTD

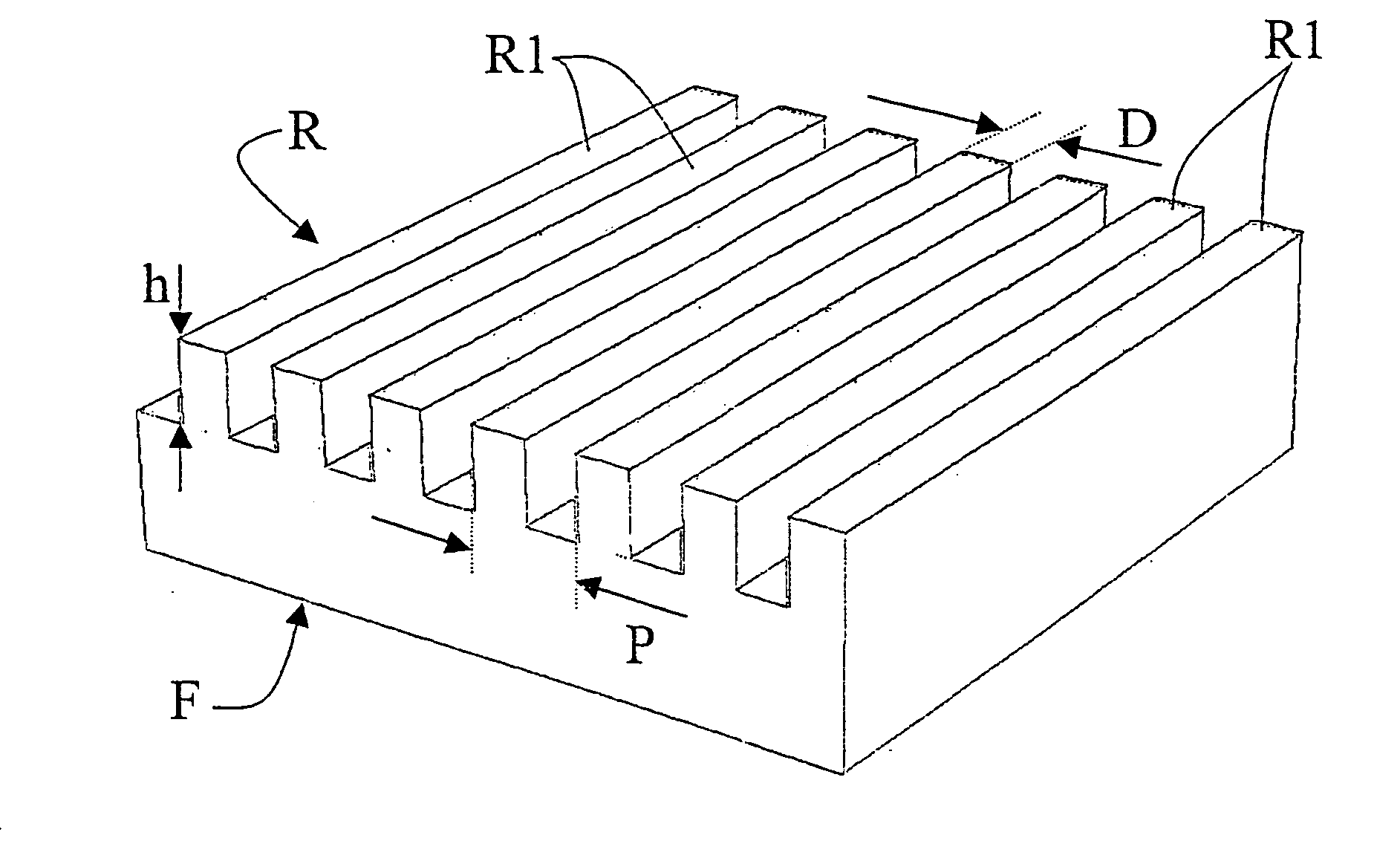

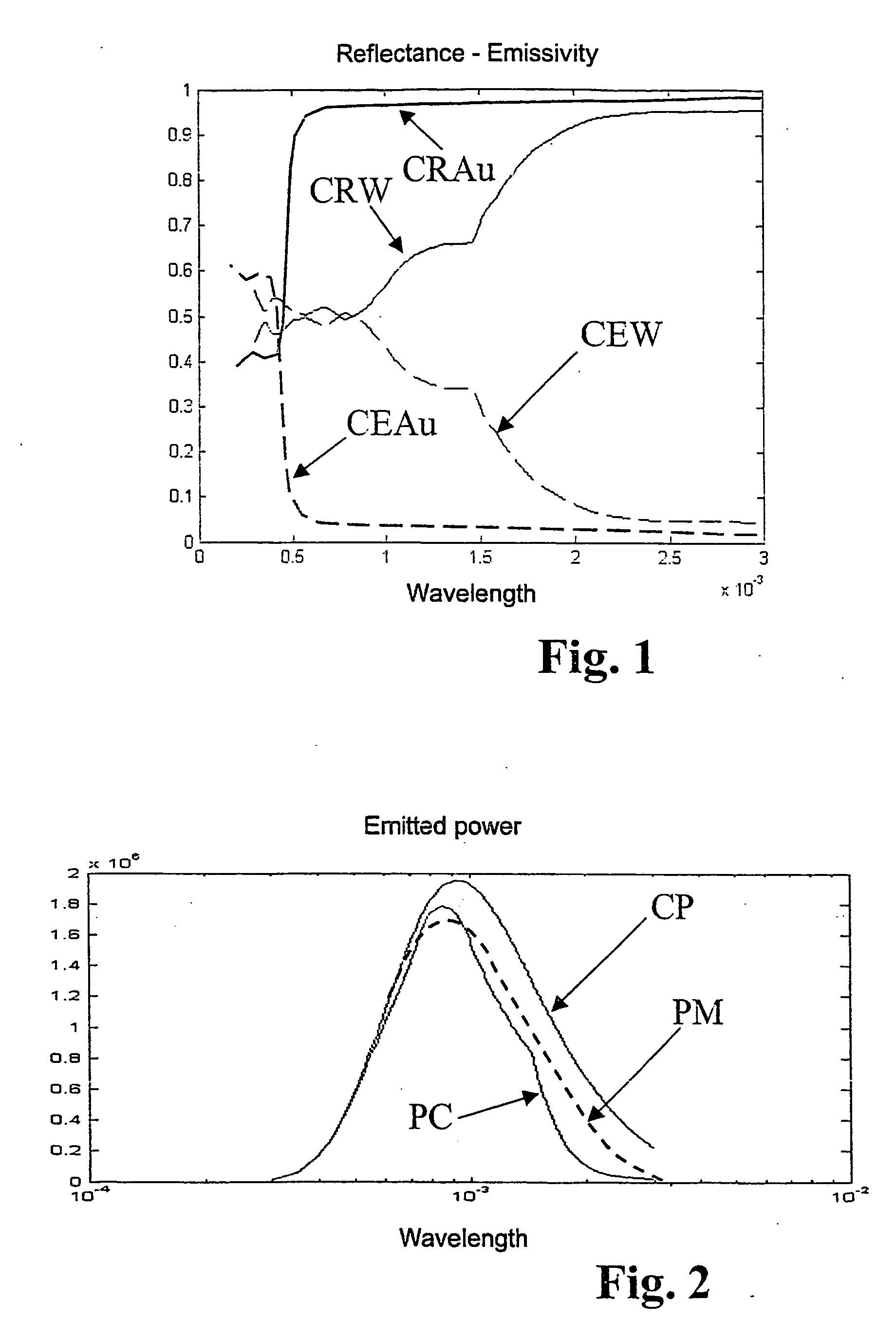

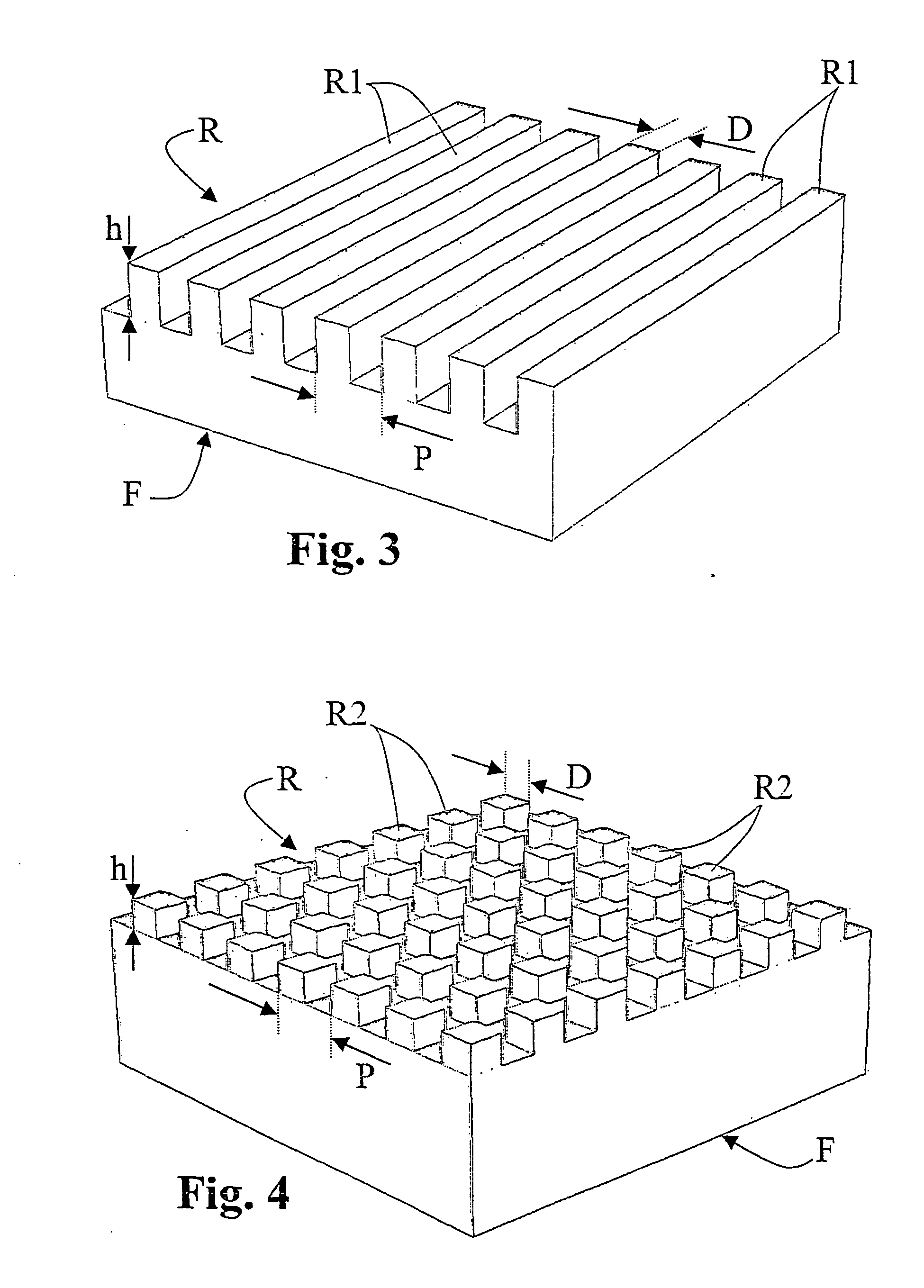

High efficiency emitter for incandescent light sources

InactiveUS20060076868A1Increase absorption selectivelyImprove luminous efficiencyLamp incadescent bodiesThermionic cathodesSpectral transmittanceIncandescence

An emitter (F) for incandescent light sources, in particular a filament, capable of being brought to incandescence by the passage of electric current is obtained in such a way as to have a value of spectral absorption α that is high in the visible region of the spectrum and low in the infrared region of the spectrum, said absorption α being defined as α=1−ρ−T, where ρ is the spectral reflectance and T is the spectral transmittance of the emitter.

Owner:CENT RICERCHE FIAT SCPA

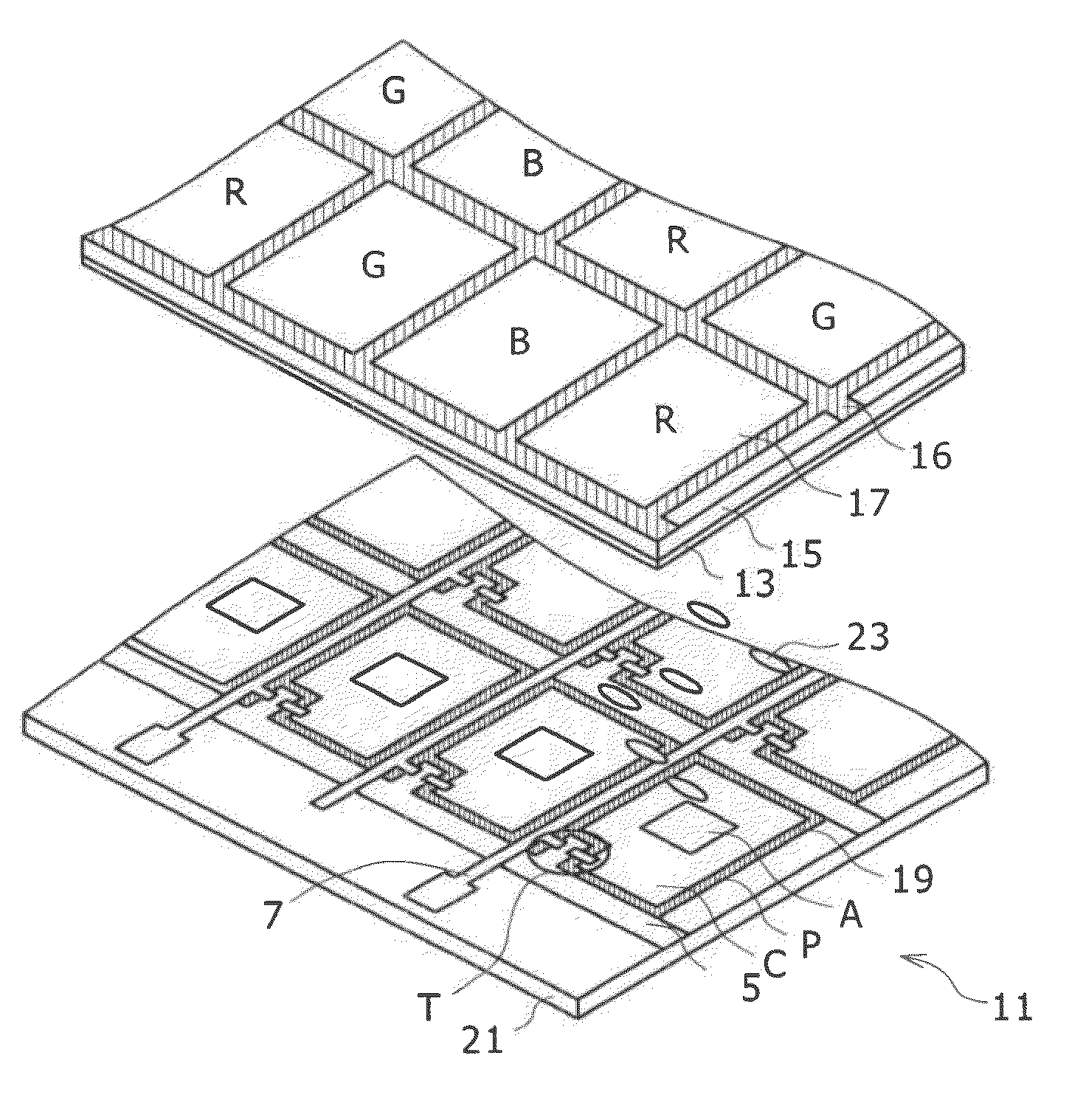

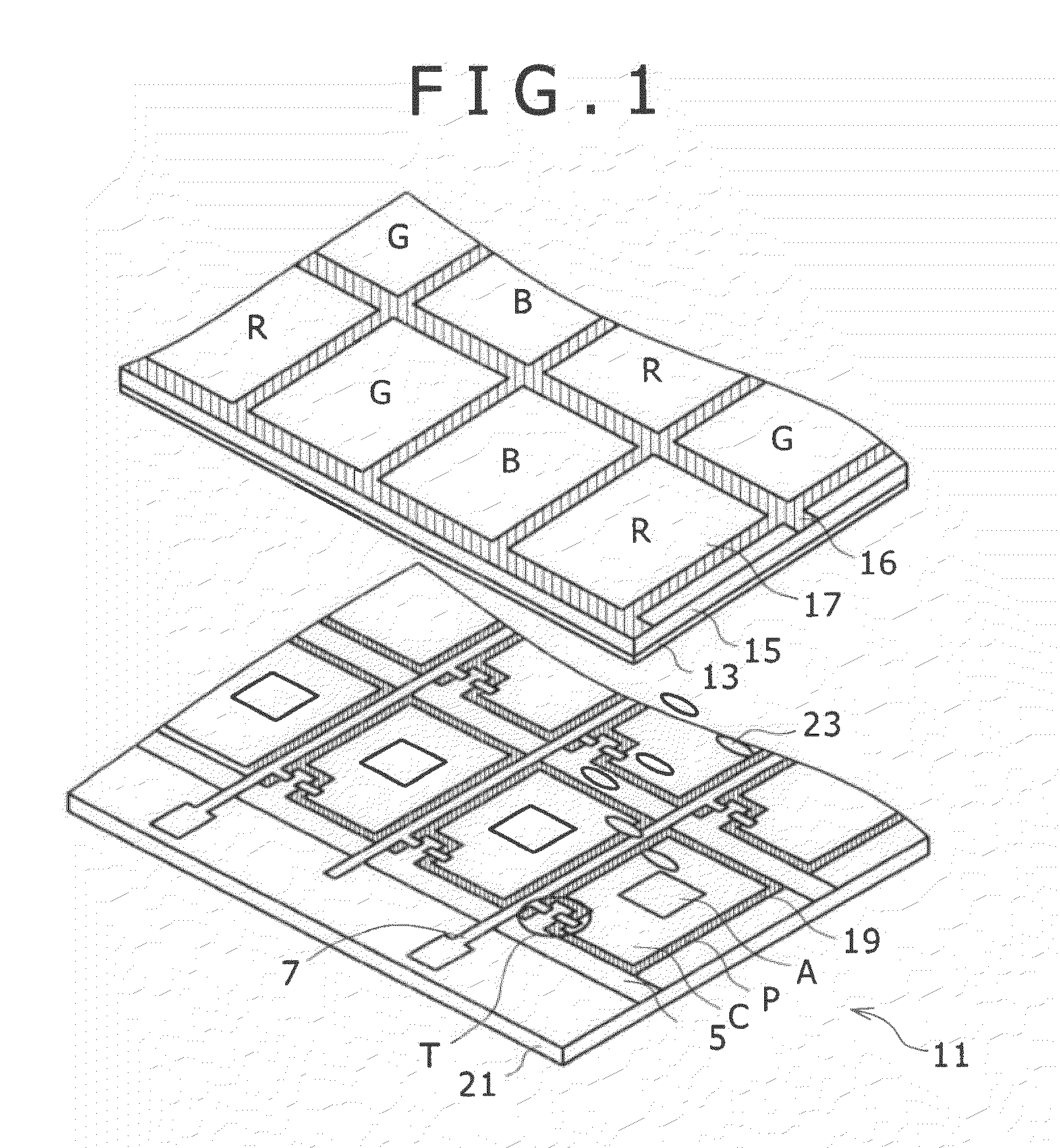

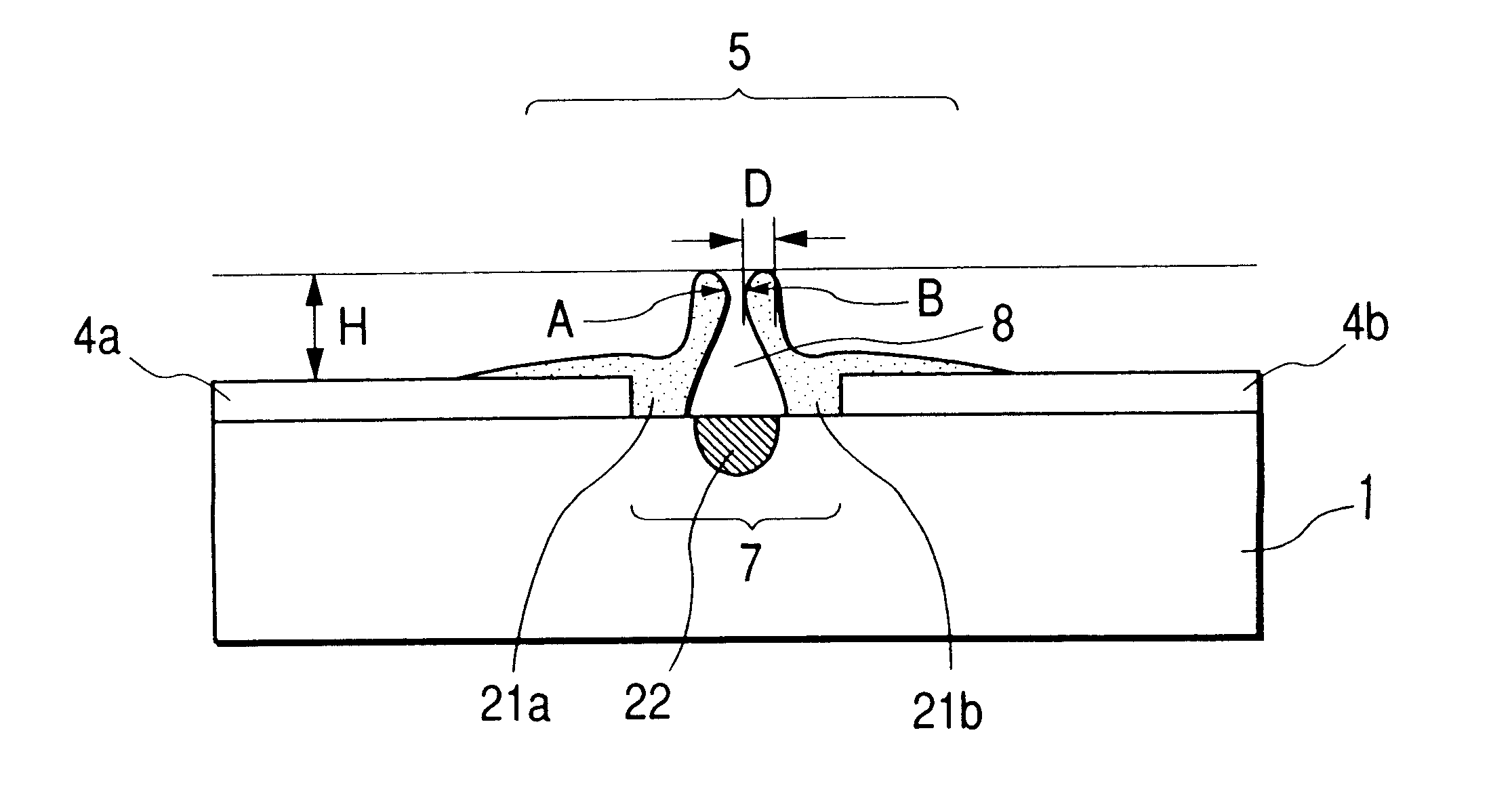

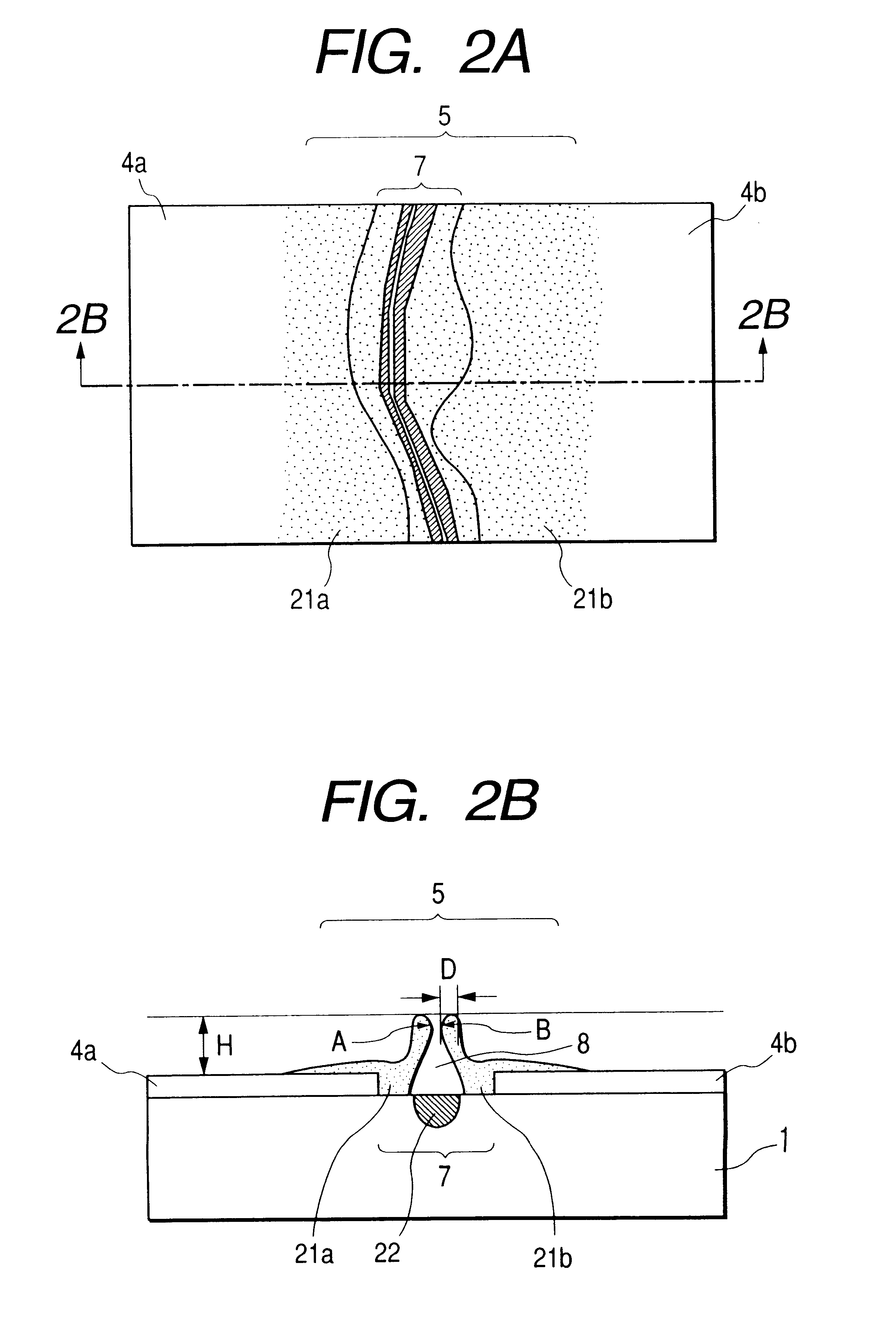

Electron-emitting device, electron source using the electron-emitting devices, and image-forming apparatus using the electron source

InactiveUS6380665B1Discharge tube luminescnet screensLamp incadescent bodiesCarbon filmElectron source

Provided is an electron-emitting device with high electron emission efficiency and with stable electron emission characteristics over a long period. The electron-emitting device has a substrate, first and second carbon films laid with a first gap in between on the surface of the substrate, and first and second electrodes electrically connected to the first carbon film and to the second carbon film, respectively. In the electron-emitting device, a narrowest gap portion between the first carbon film and the second carbon film in the first gap is located above a surface of the substrate and the substrate has a depressed portion, at least, in the first gap.

Owner:CANON KK

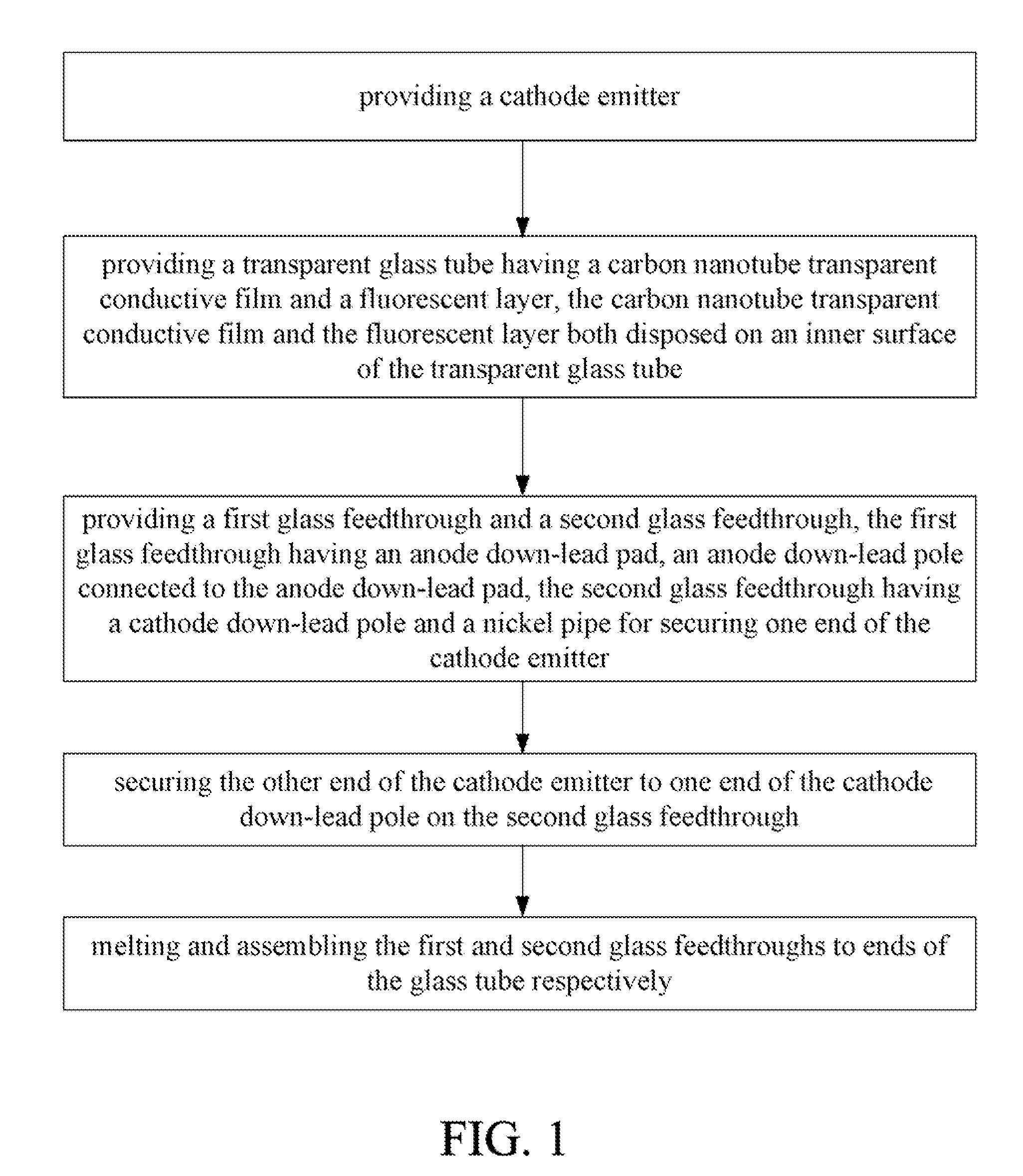

Method for making field emission lamp

ActiveUS20080160865A1Affects performance lifeLow costTube/lamp vessel degassingThermionic cathodesCarbon nanotubeNickel

A method for making a field emission lamp generally includes the steps of: (a) providing a cathode emitter; (b) providing a transparent glass tube having a carbon nanotube transparent conductive film and a fluorescent layer, the carbon nanotube transparent conductive film and the fluorescent layer both disposed on an inner surface of the transparent glass tube; (c) providing a first glass feedthrough and a second glass feedthrough, the first glass feedthrough having an anode down-lead pad, an anode down-lead pole connected to the anode down-lead pad, the second glass feedthrough having a cathode down-lead pole and a nickel pipe for securing one end of the cathode emitter; (d) securing the other end of the cathode emitter to one end of the cathode down-lead pole on the second glass feedthrough; (e) melting and assembling the first and second glass feedthroughs to ends of the glass tube respectively.

Owner:TSINGHUA UNIV +1

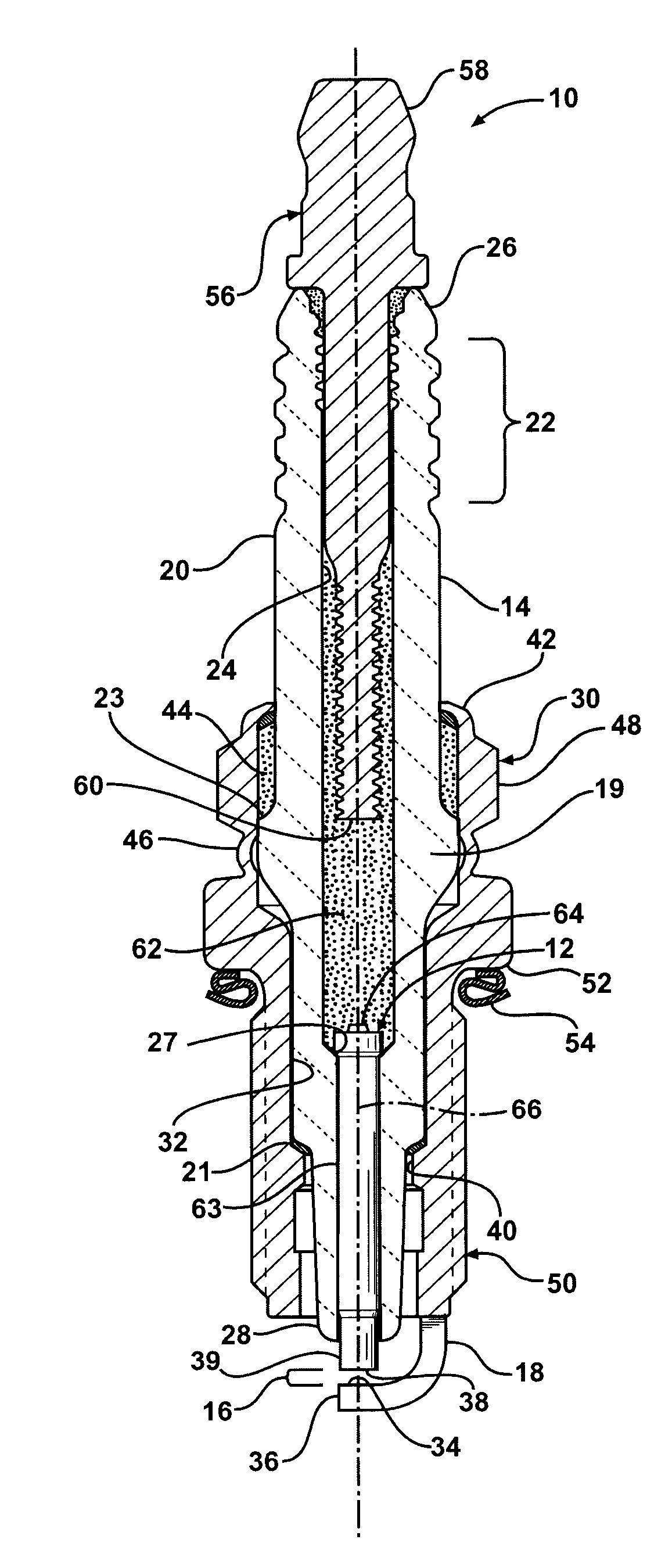

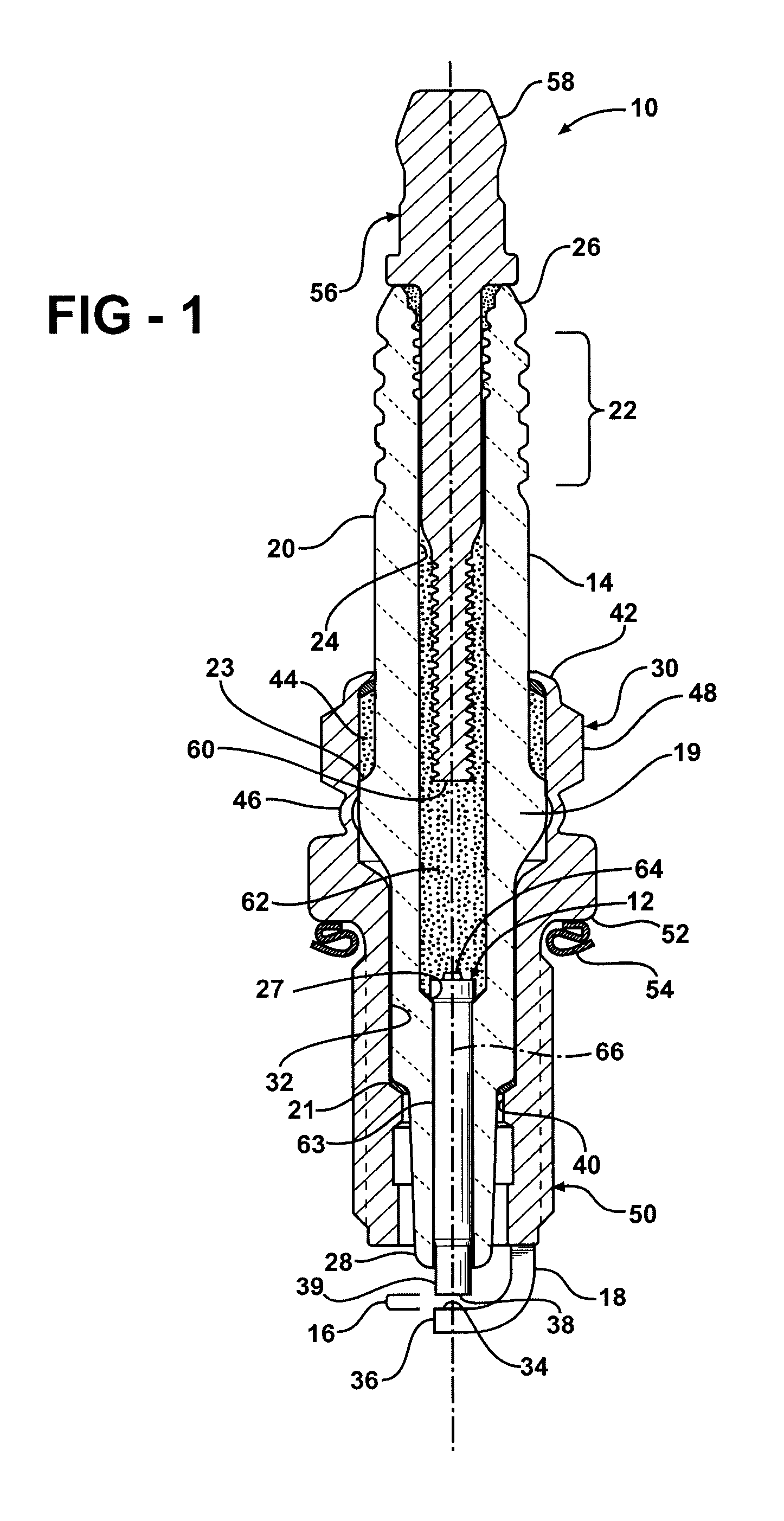

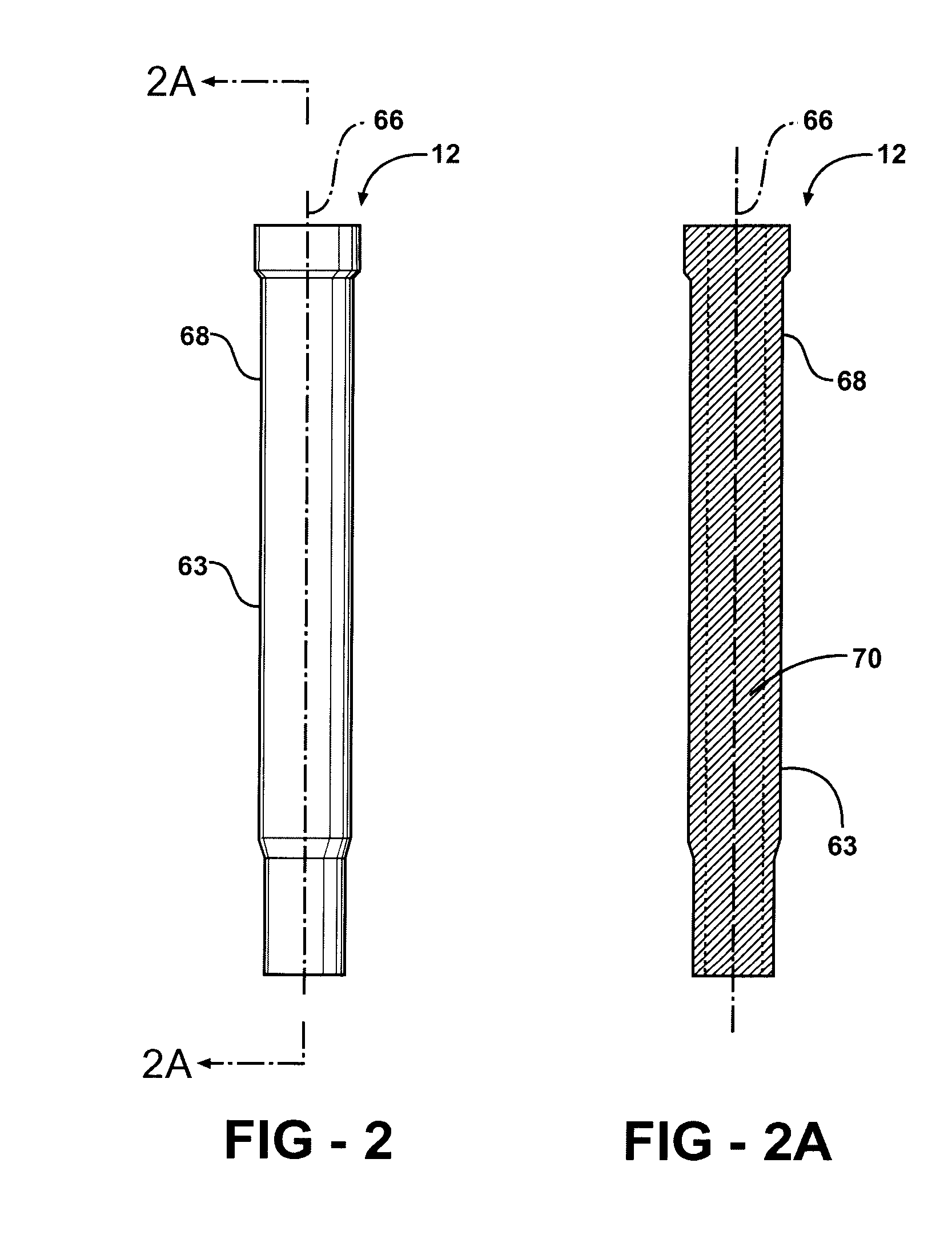

Composite ceramic electrode, ignition device therewith and methods of construction thereof

A spark plug, center electrode and method of construction is provided. The spark plug has a generally annular ceramic insulator and a conductive shell surrounding at least a portion of the ceramic insulator. A ground electrode is operatively attached to the shell, with the ground electrode having a ground electrode sparking surface. A center electrode has an elongate body with a center electrode sparking surface. The center electrode sparking surface and the ground electrode sparking surface provide a spark gap. The center electrode body is constructed of a composite material including at least one ceramic material.

Owner:FEDERAL MOGUL IGNITION

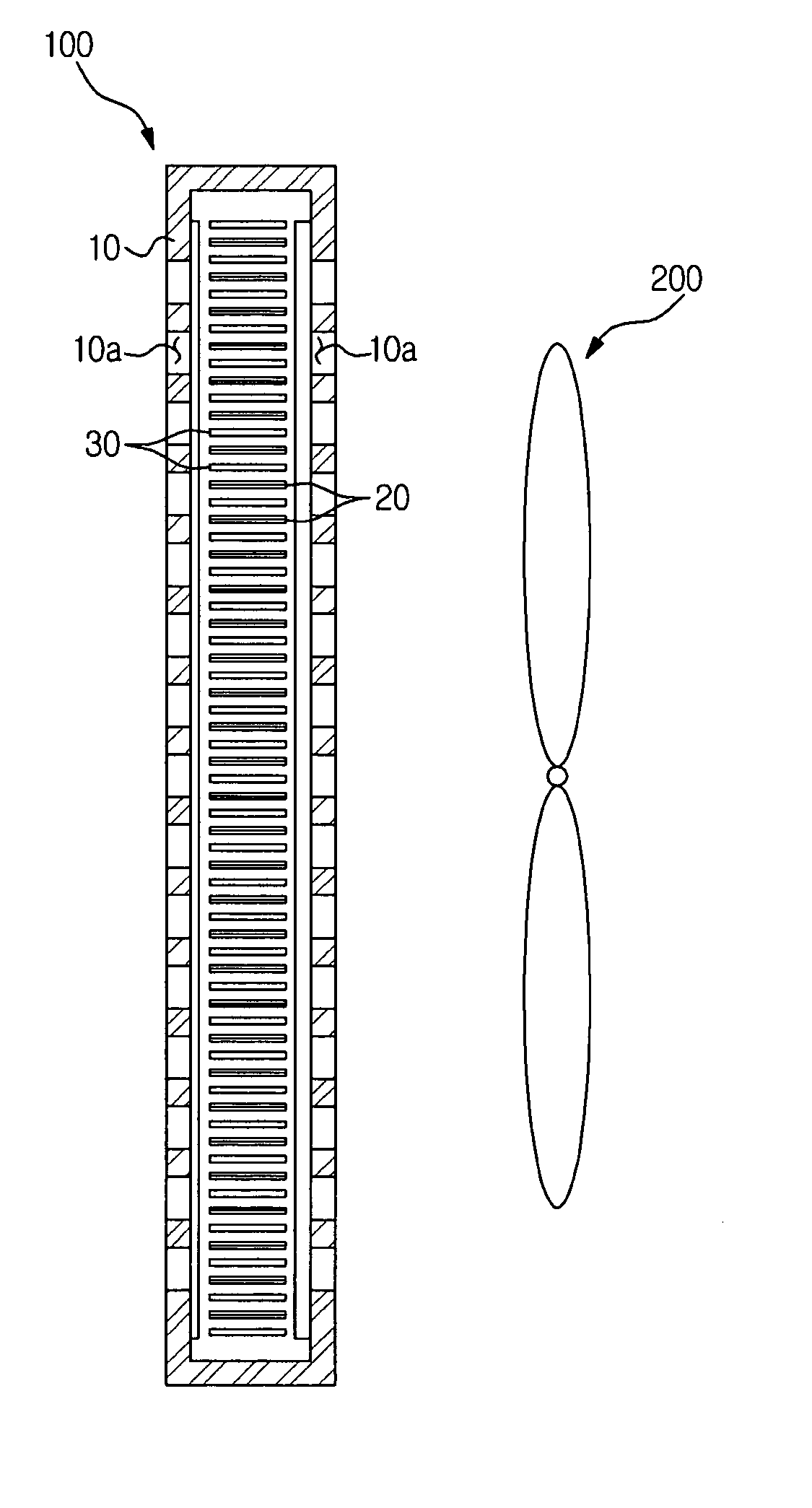

Electric precipitator and high voltage electrode thereof

ActiveUS8470084B2Efficient use ofSmall widthLamp incadescent bodiesThermionic cathodesLow voltageEngineering

An electrode precipitator having a high voltage electrode and a low voltage electrode arranged apart from each other at a desired interval. The high voltage electrode includes a charging part which is positioned upstream of an air flow direction to charge a pollutant, and a dust collection part which is spaced from the charging part and positioned downstream of the air flow direction to precipitate the charged pollutant therein.

Owner:SAMSUNG ELECTRONICS CO LTD

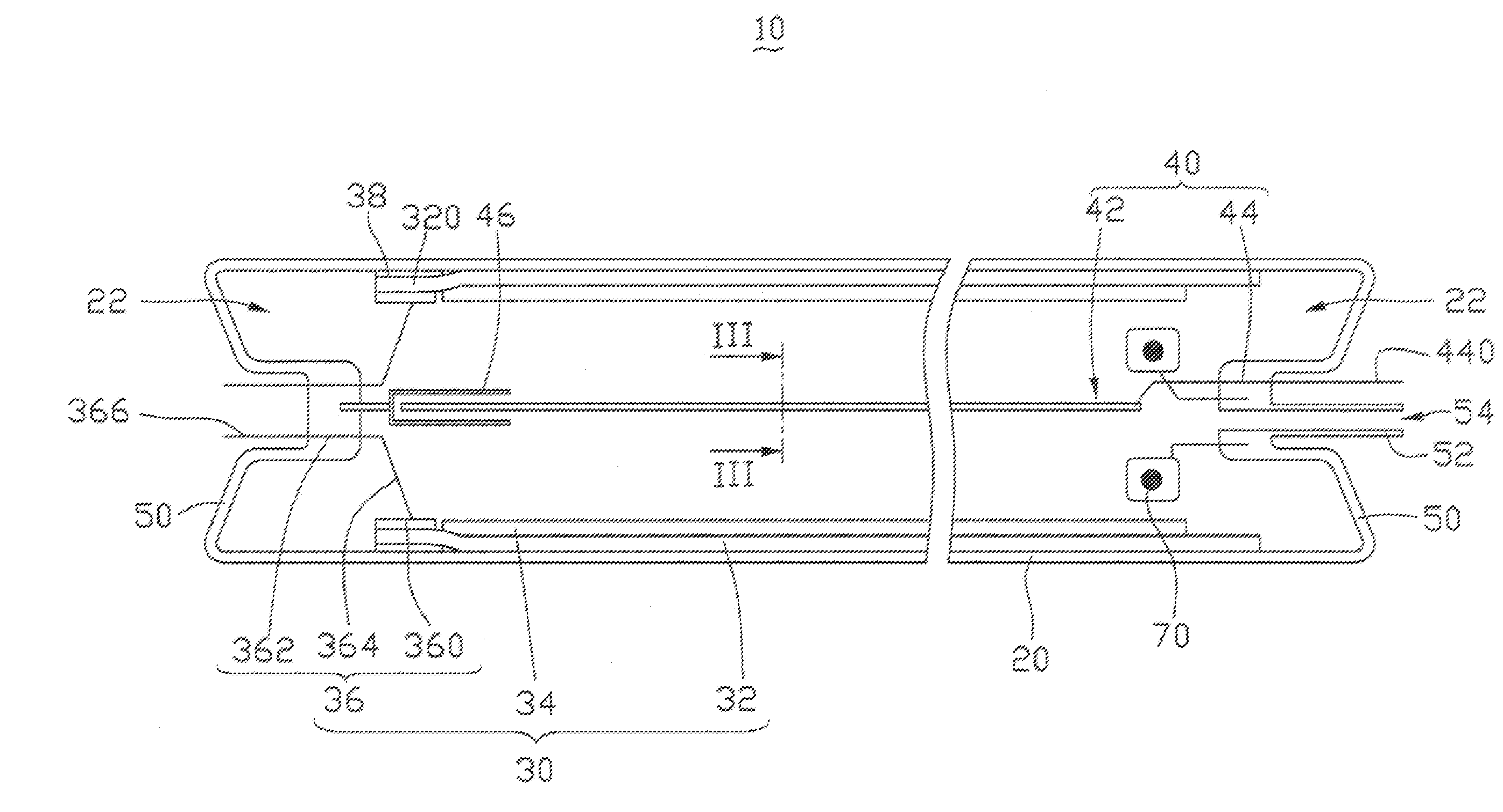

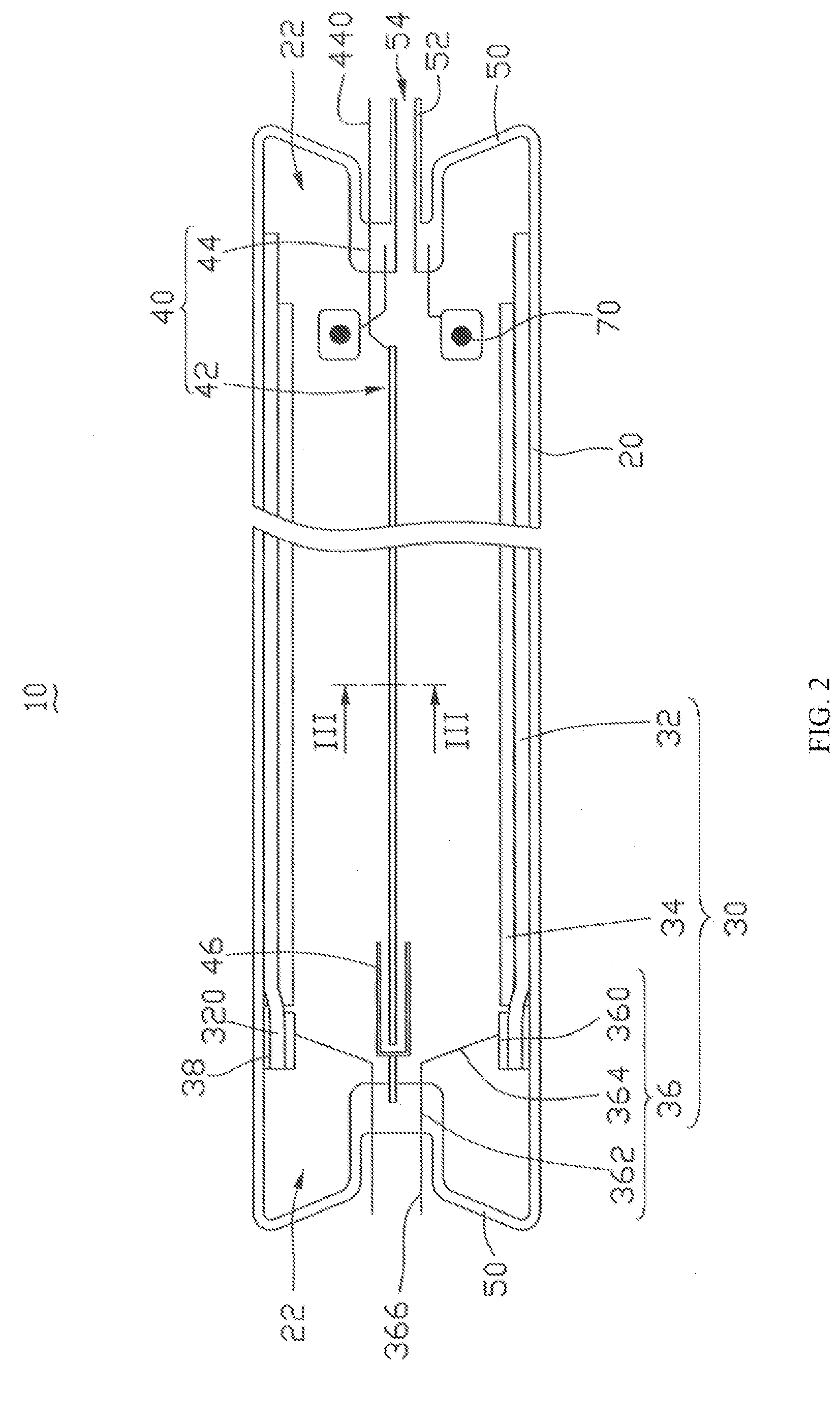

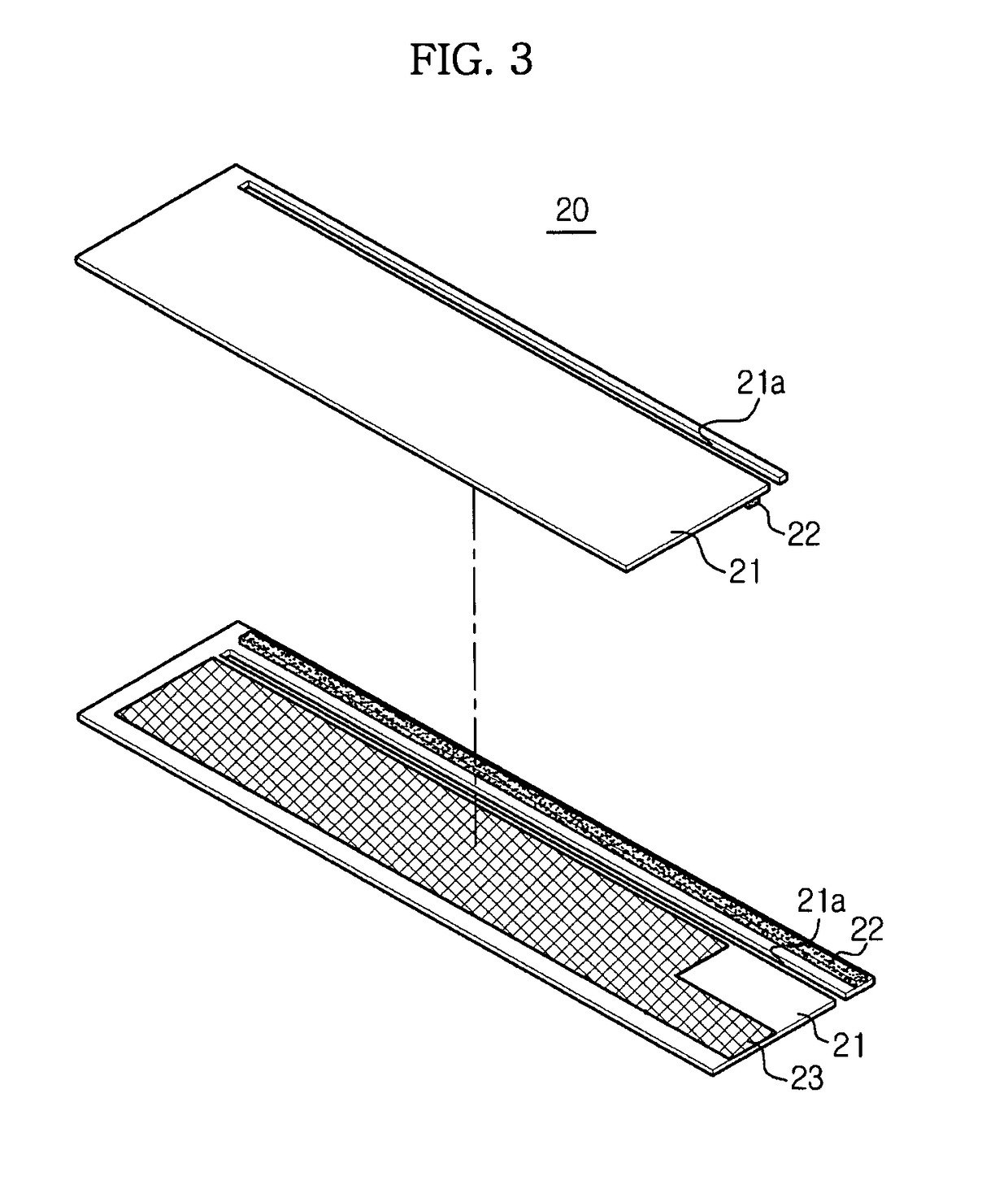

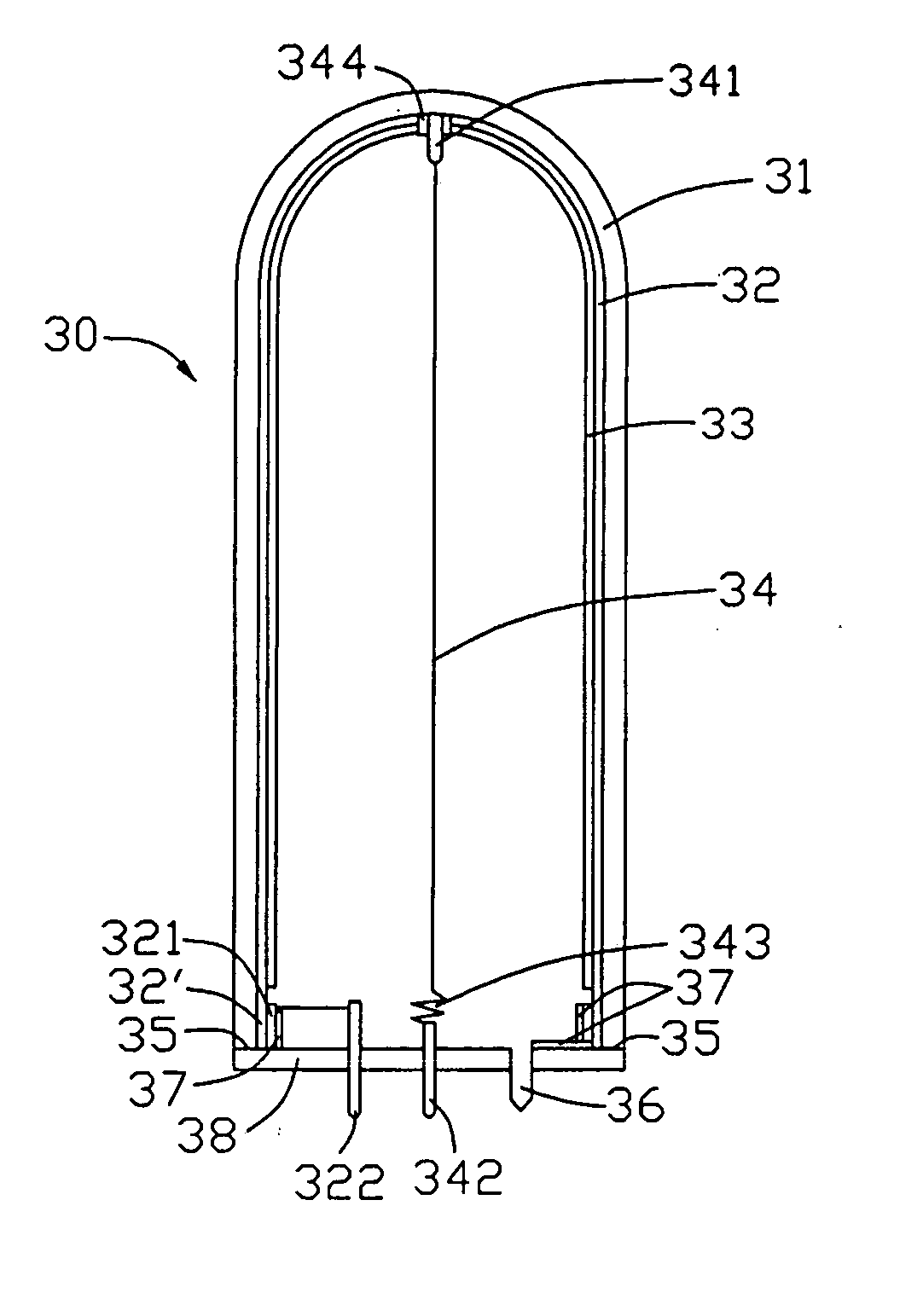

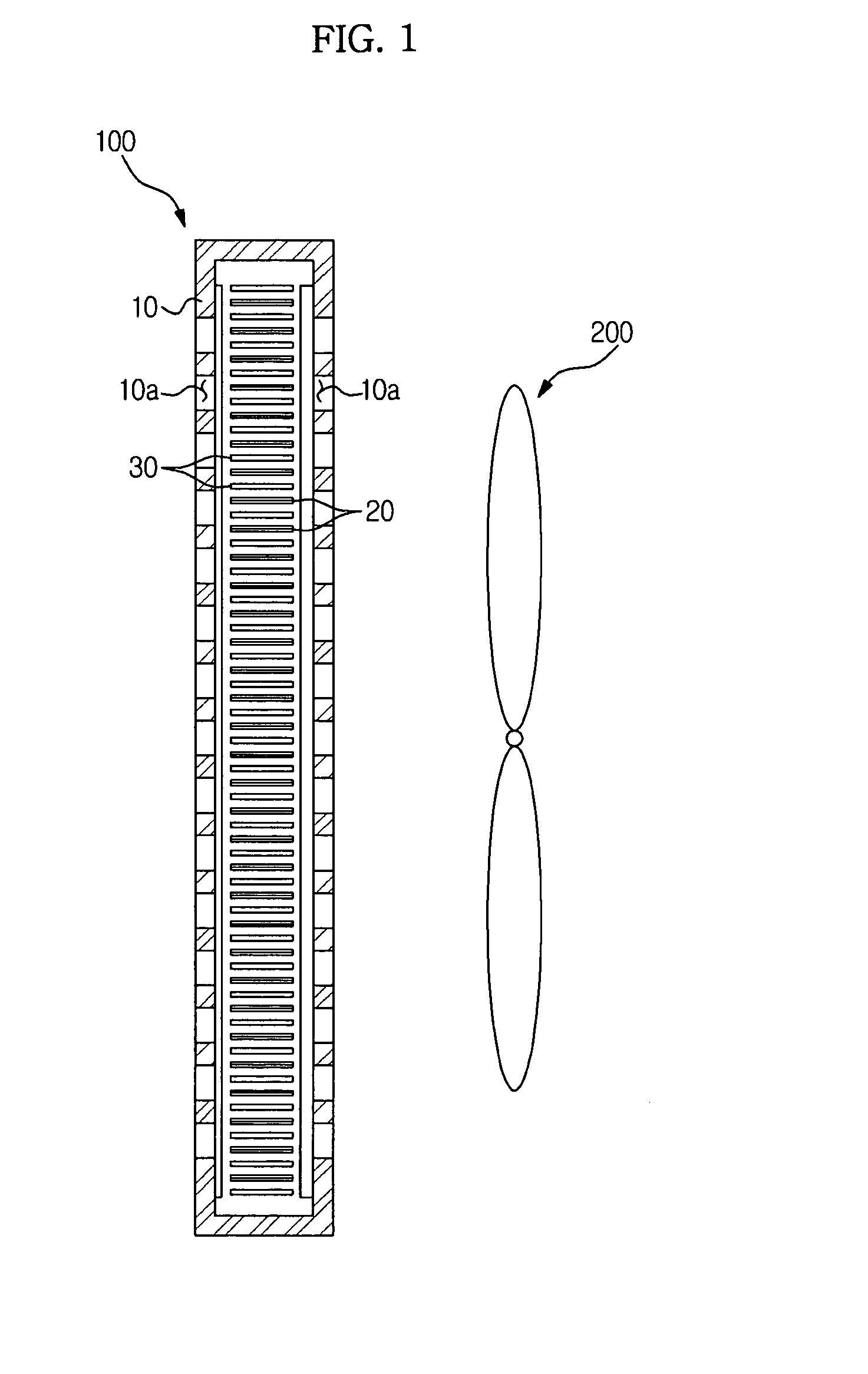

Field emission lamp

ActiveUS20060017370A1Simplify the wrapperIncrease ratingsDischarge tube luminescnet screensLamp incadescent bodiesProduction rateFluorescence

A field emission lamp (30) includes a tube (31) having a closed end and an open end, an encapsulation board (38) mated with the open end, an anode layer (32) formed on an inner surface, a fluorescence layer (33) formed on the anode layer, a cathode down-lead pole (342) located at the encapsulation board, a cathode fixing pole (341) located at the closed end, a cathode filament (34) having a carbon nanotube layer formed on a surface thereof fixed between the cathode down-lead pole and the cathode fixing pole, an anode down-lead ring (321) located at the anode layer near the open end, and an anode down-lead pole (322) located at the encapsulation board and electrically connected with the anode down-lead ring. The field emission lamp has a simple structure, thereby having an enhanced production rate and a reduced cost.

Owner:TSINGHUA UNIV +1

Electrode having gas discharge function and plasma processing apparatus

An electrode having a gas discharge function, where the degree of freedom related to a maximum gas flow rate is abundant, an electrode cover member may be thinned, and a change of a gas behavior according to time is difficult to be generated in a processing chamber during gas introduction. The electrode includes: a base material having a plurality of gas holes; and an electrode cover member having a plurality of gas holes respectively corresponding to the plurality of gas holes of the base material in a one-to-one manner, fixed to the base material, and disposed facing a processing space in which the object is plasma-processed, wherein a gas hole diameter of the electrode cover member is larger than a gas hole diameter of the base material.

Owner:TOKYO ELECTRON LTD

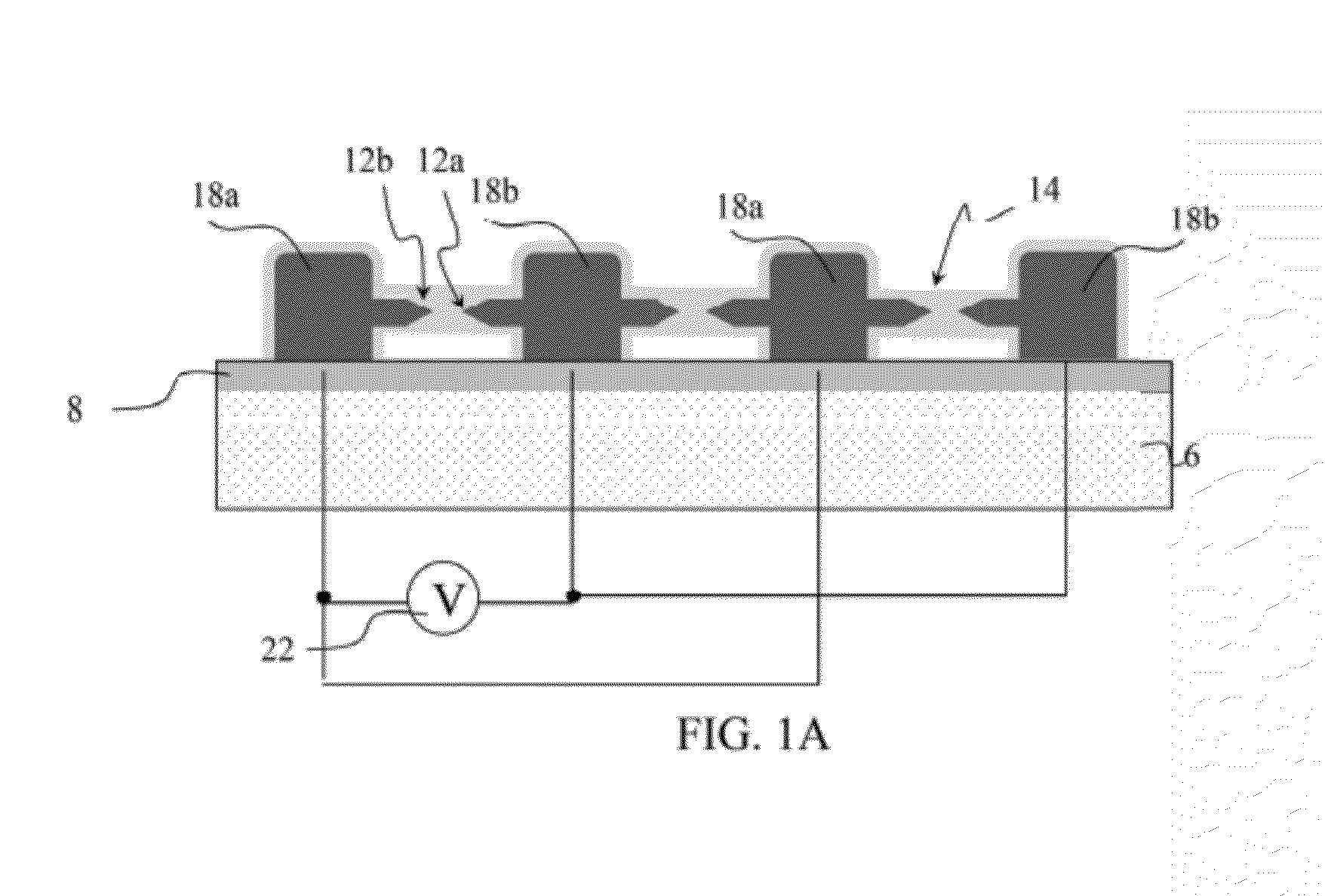

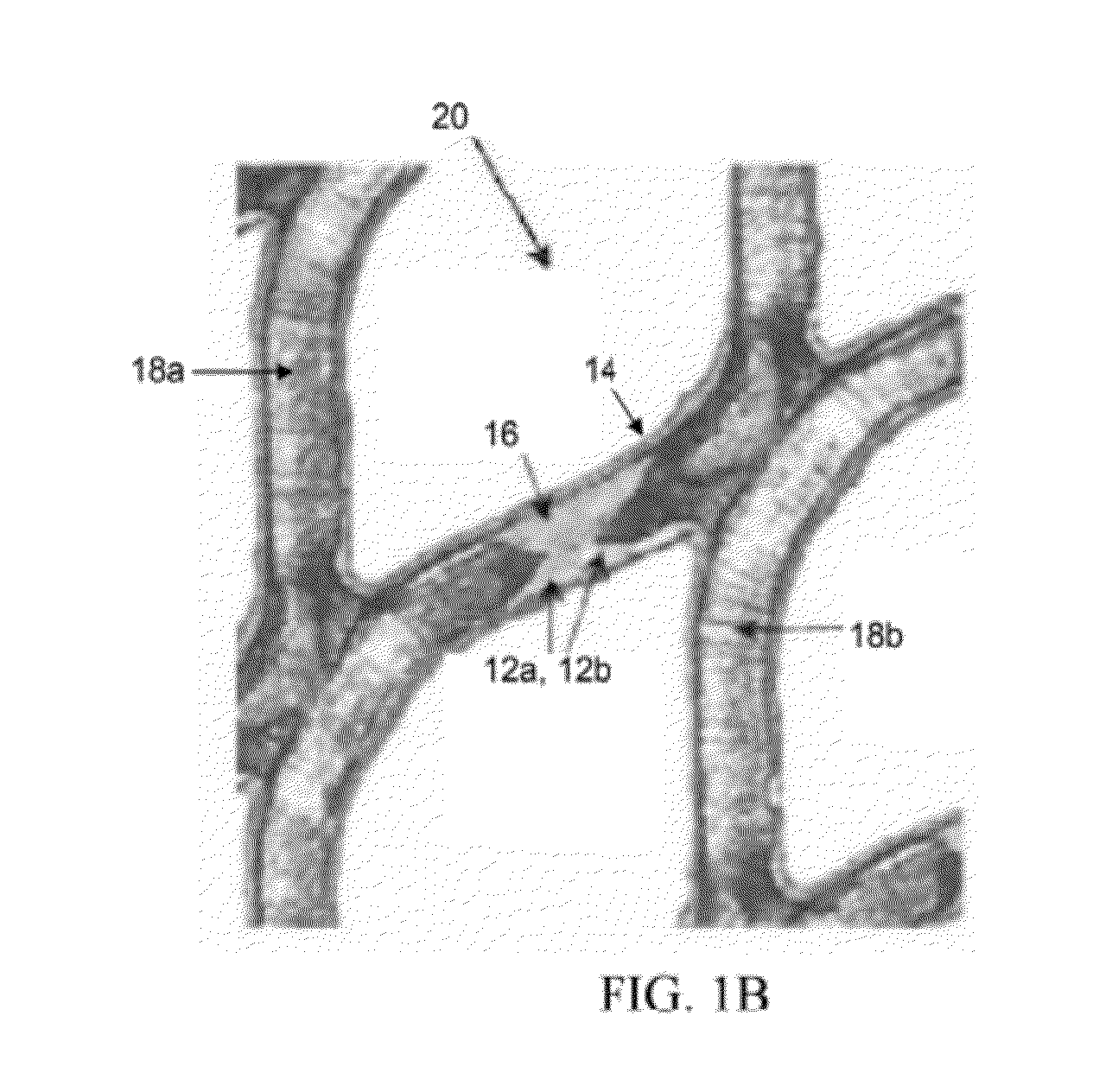

Encapsulated metal microtip microplasma devices, arrays and fabrication methods

ActiveUS8547004B2Alternating current plasma display panelsThermionic cathodesAir filterMaterials science

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

Aligned nanostructured polymers

Novel, simple methods are presented directed to the synthesis of aligned nanofibers of polyaniline and substituted derivatives on a substrate. The production of these fibers is achieved via various methods by controlling the concentration of aniline monomer or substituted aniline derivatives or an oxidant in the reaction medium and maintaining said concentration at a level much lower than conventional polyaniline synthesis methods. Methods are disclosed relating to the use of a permeable membrane to control the release of a monomer and / or oxidant as well as a bulk polymerization method.

Owner:THE OHIO STATE UNIV RES FOUND

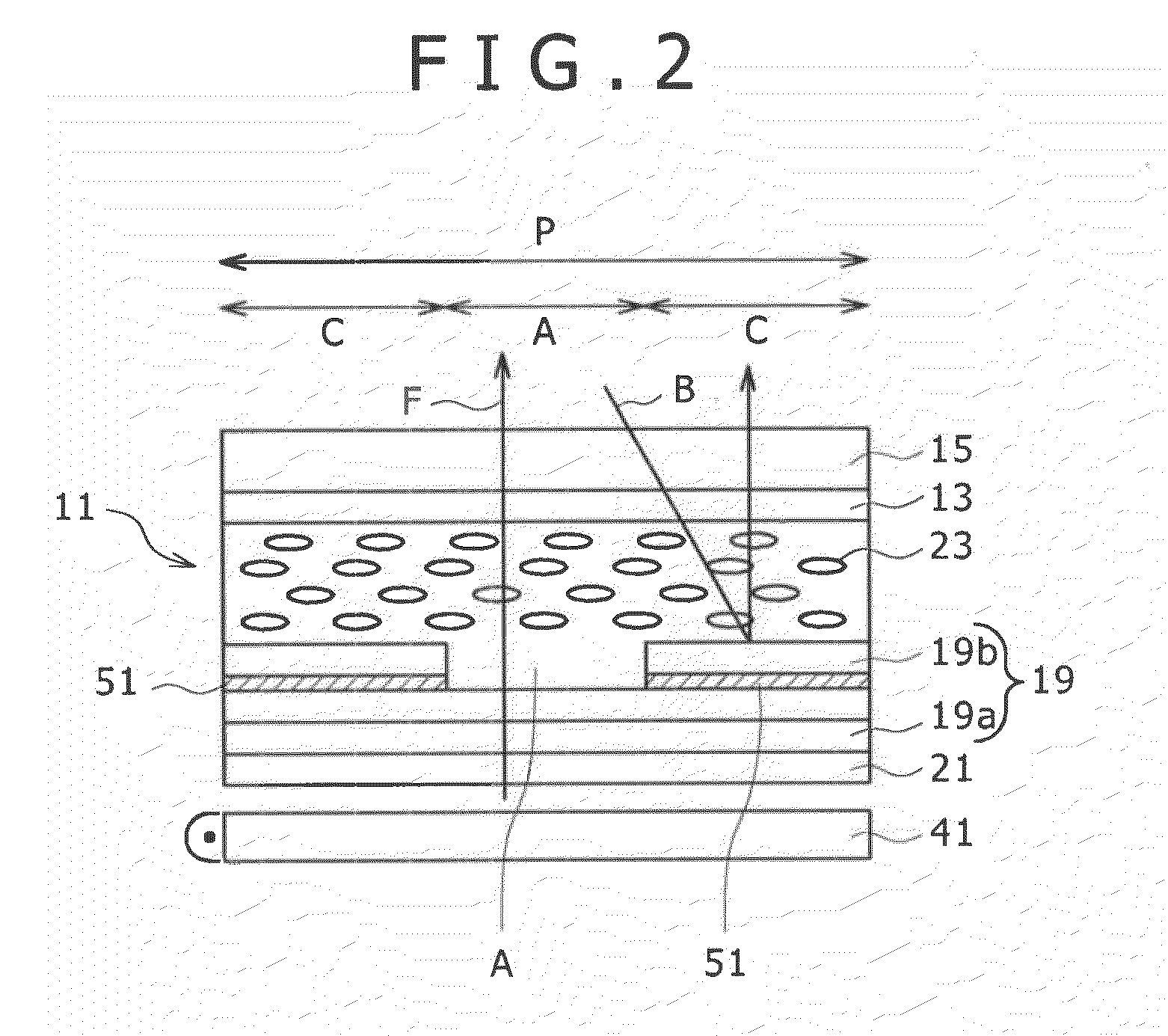

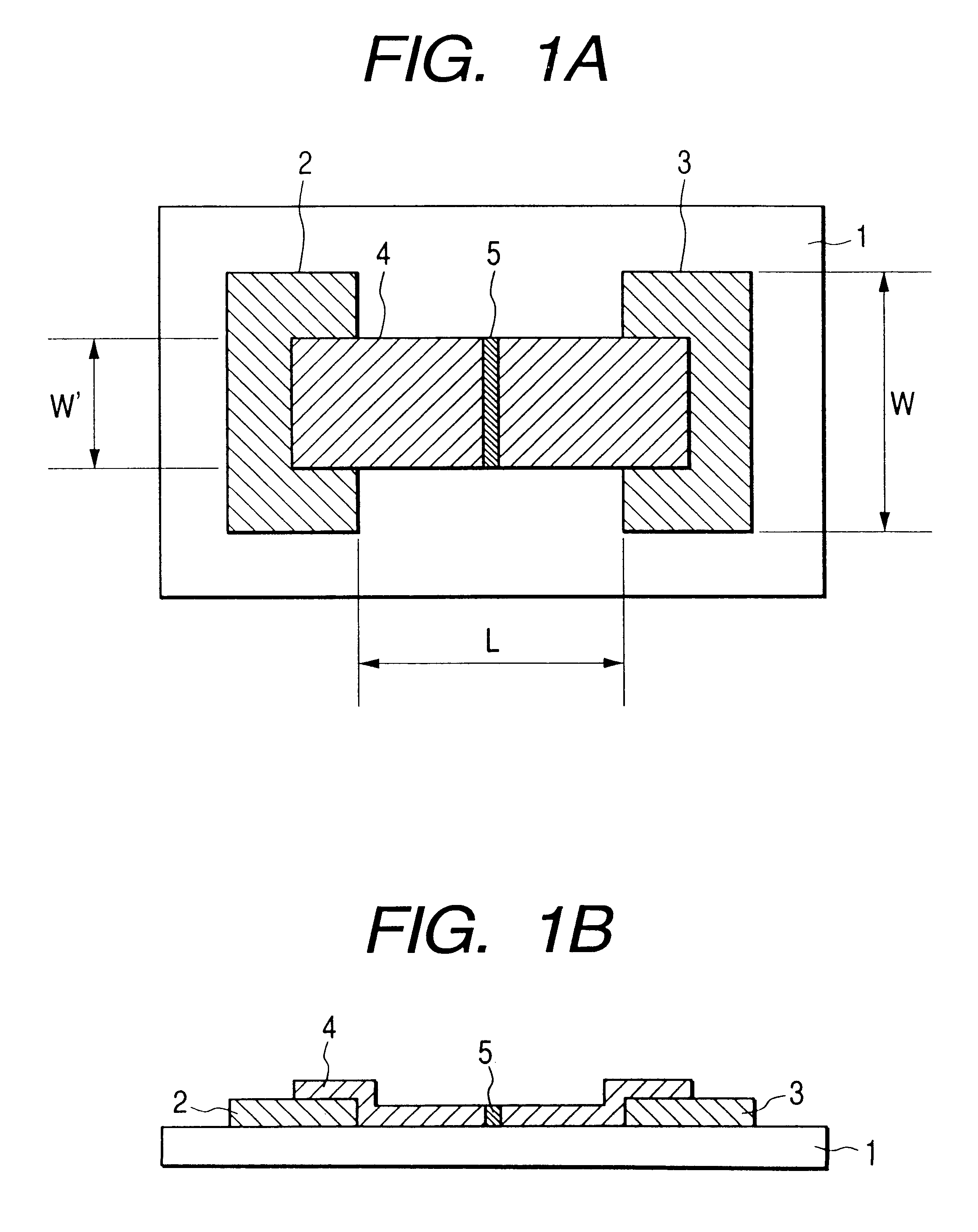

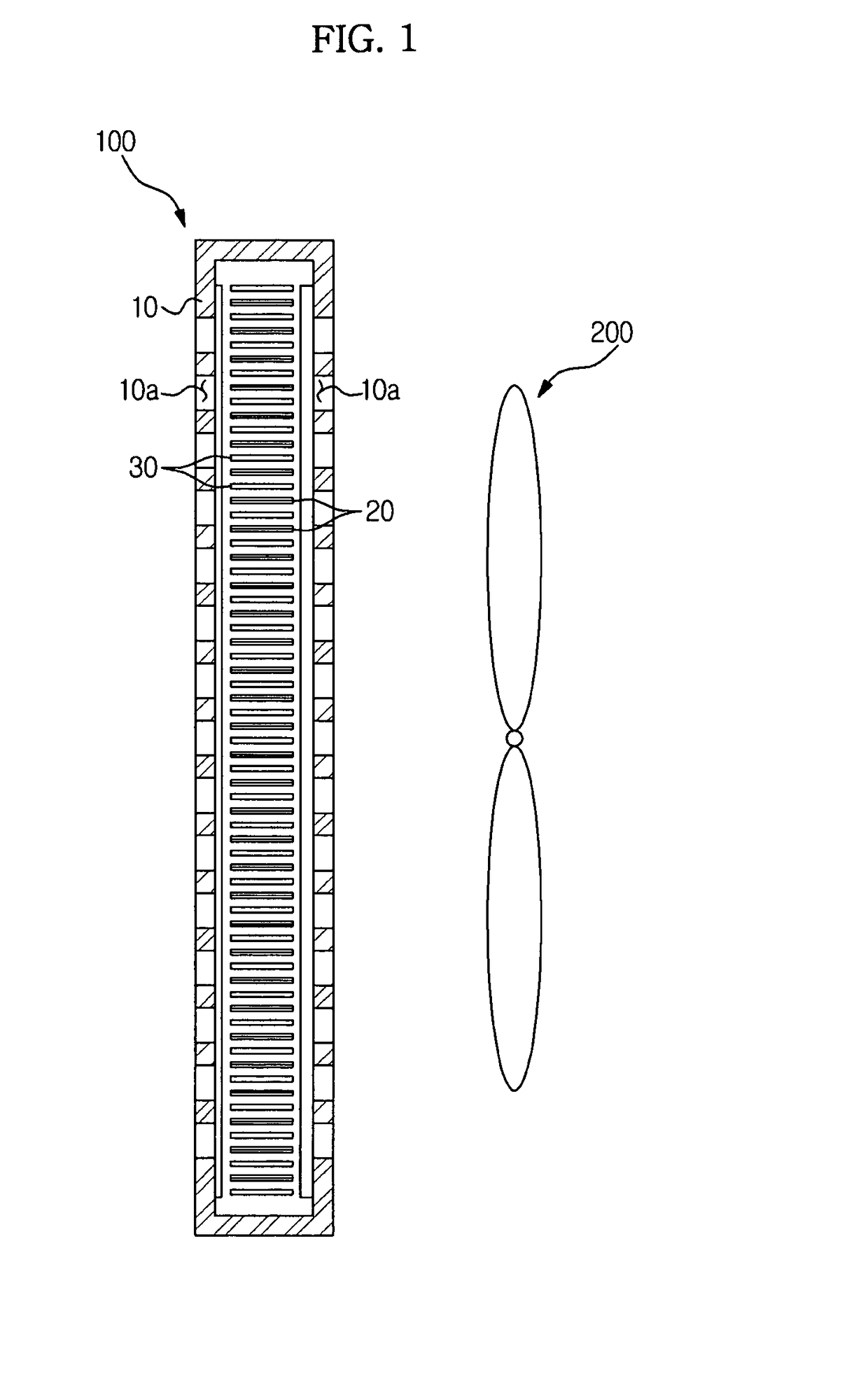

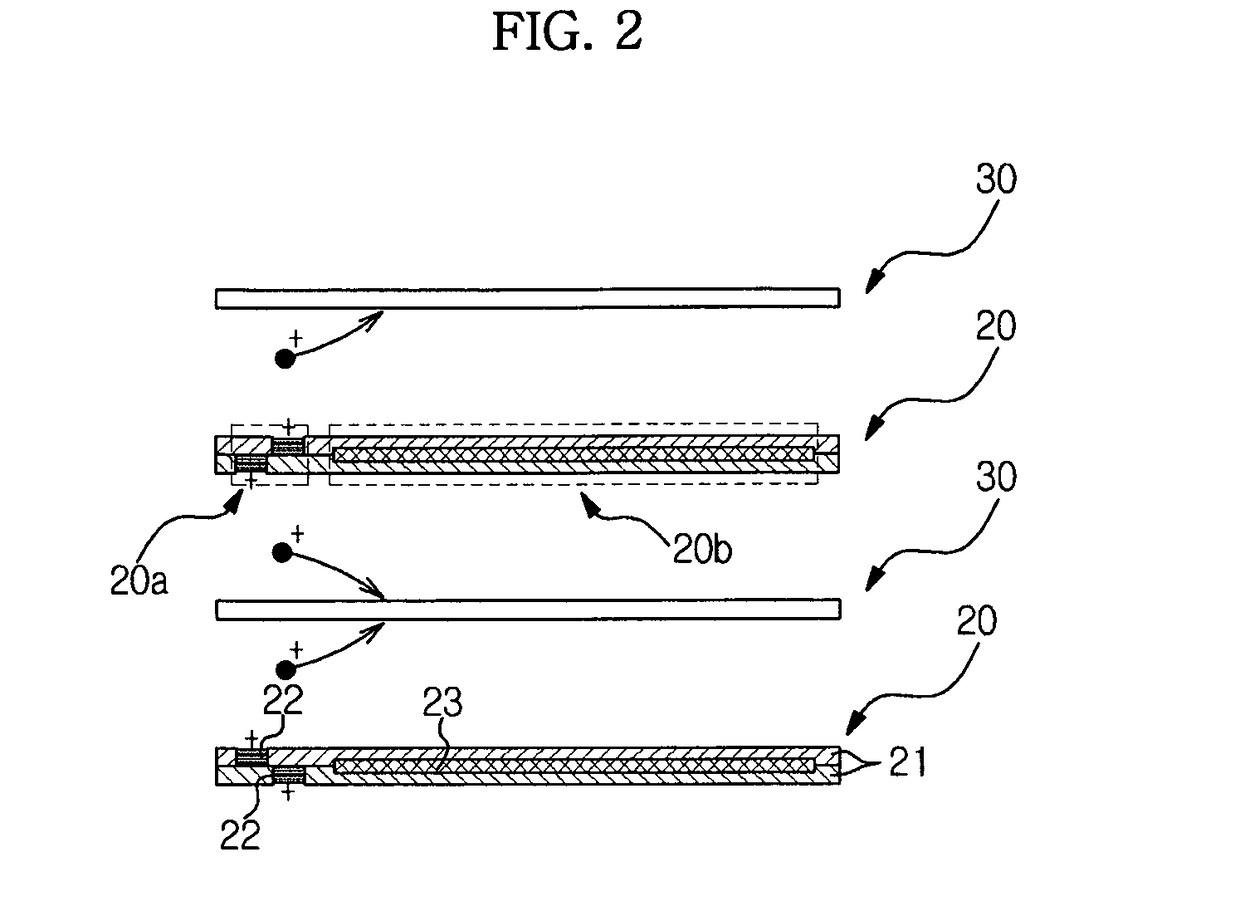

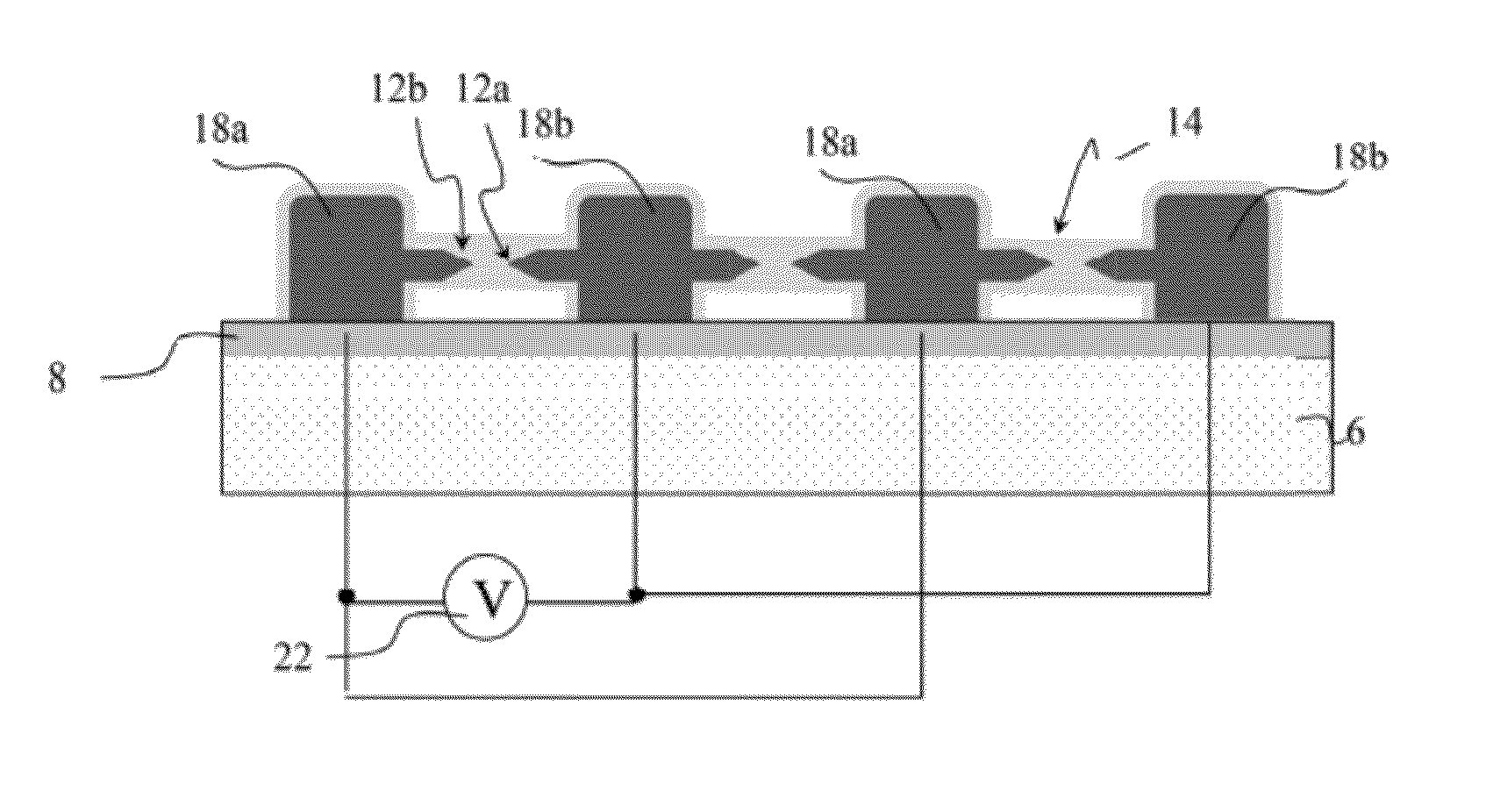

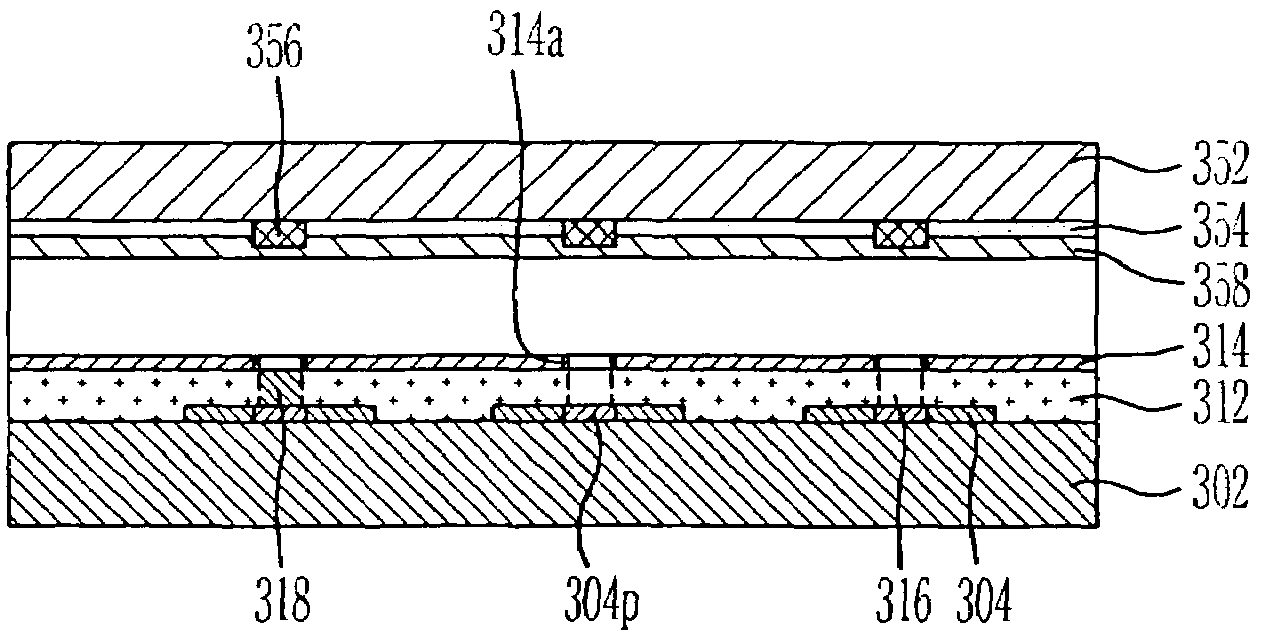

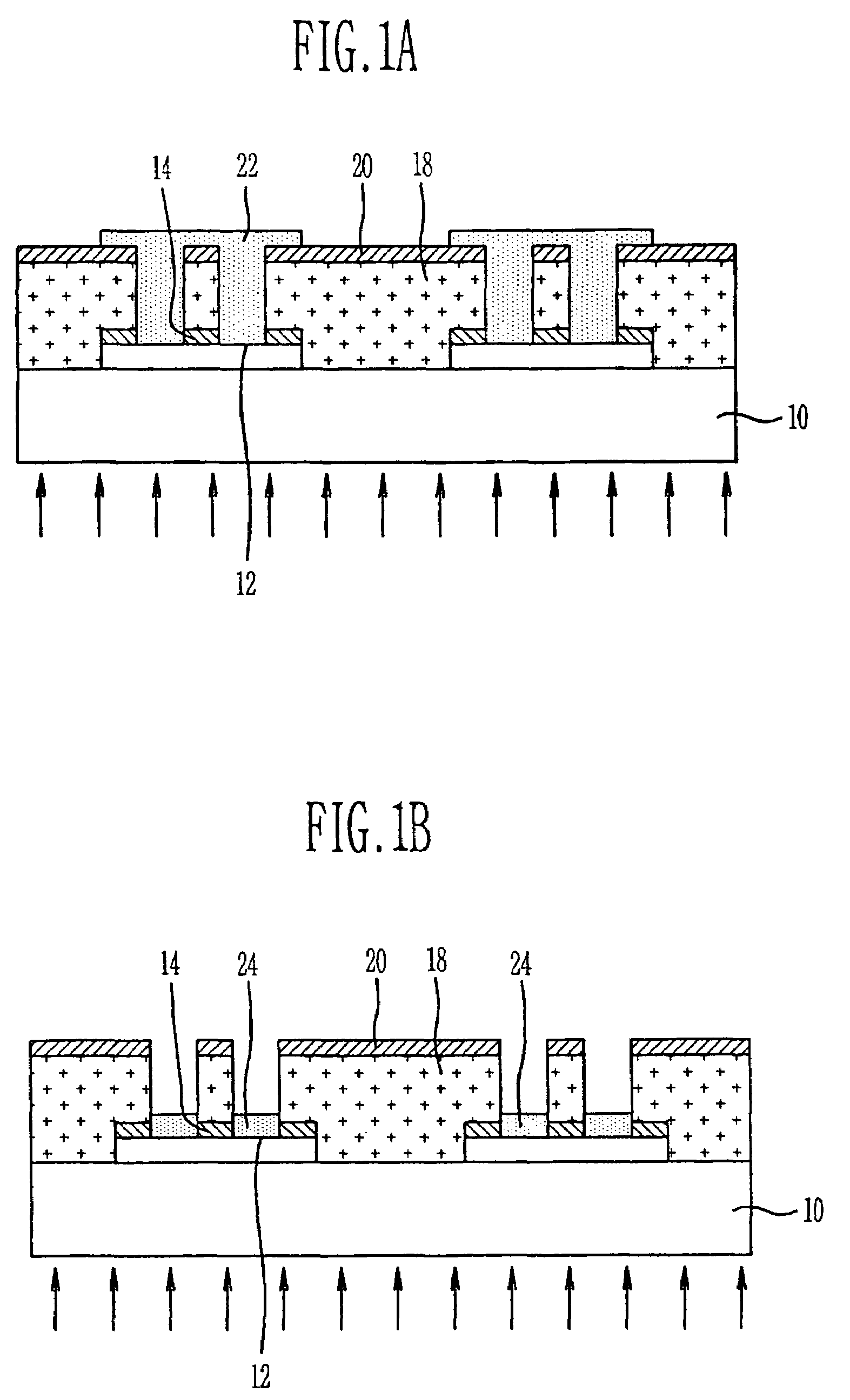

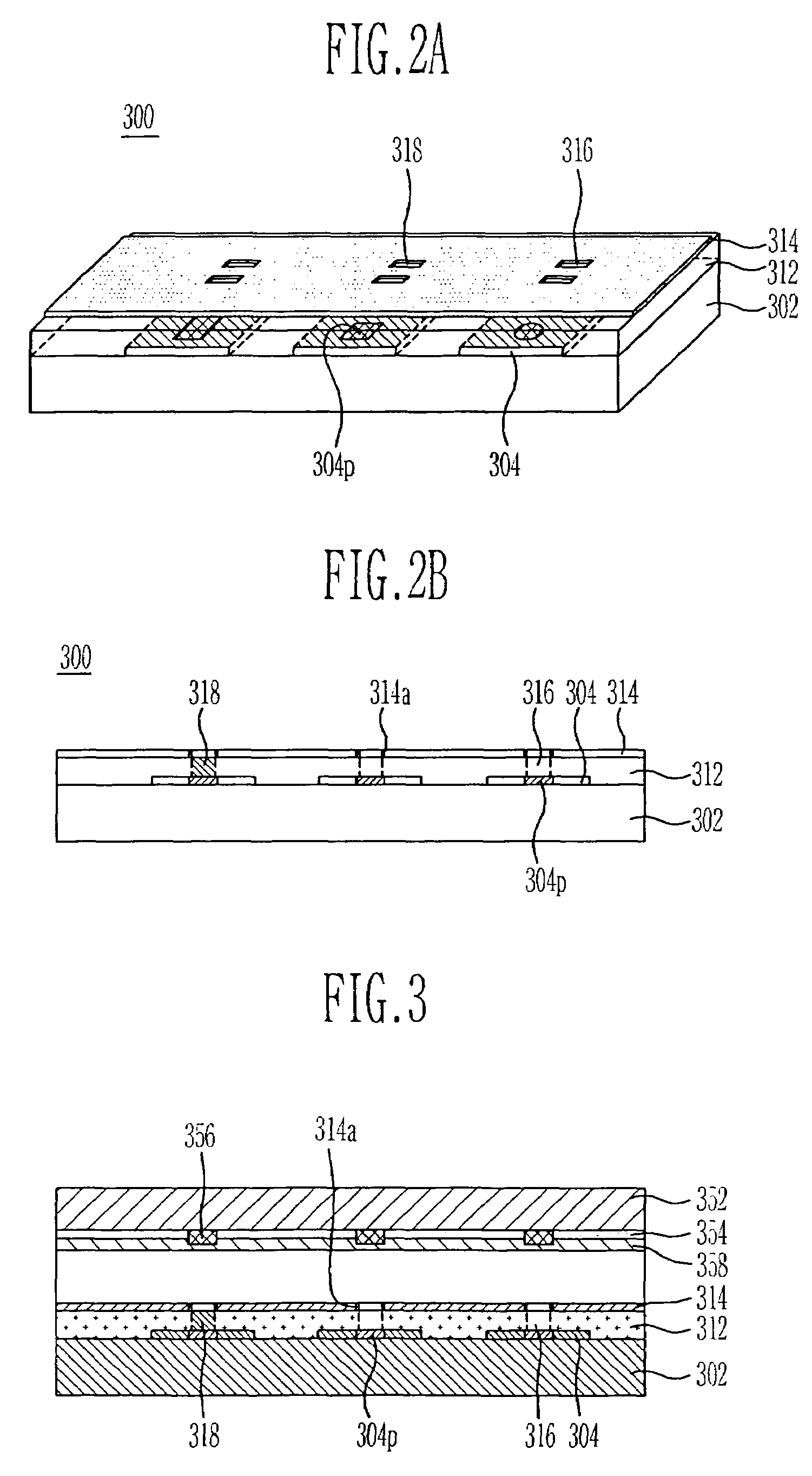

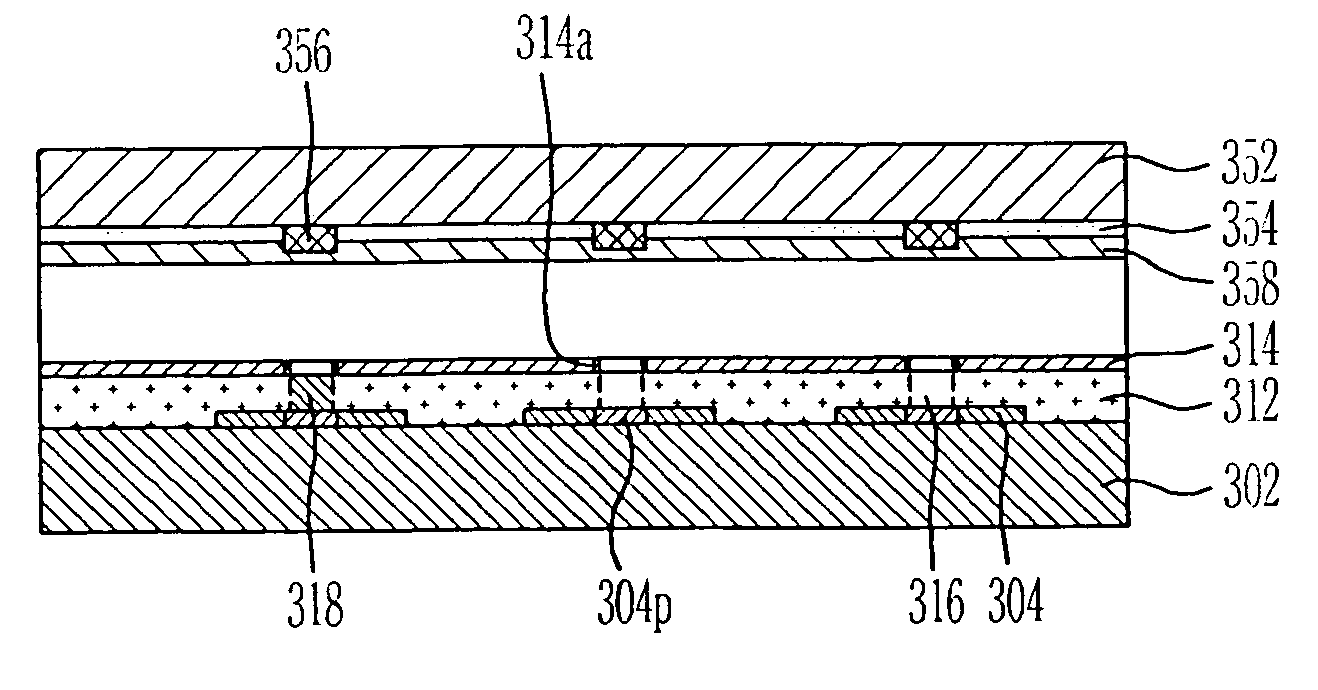

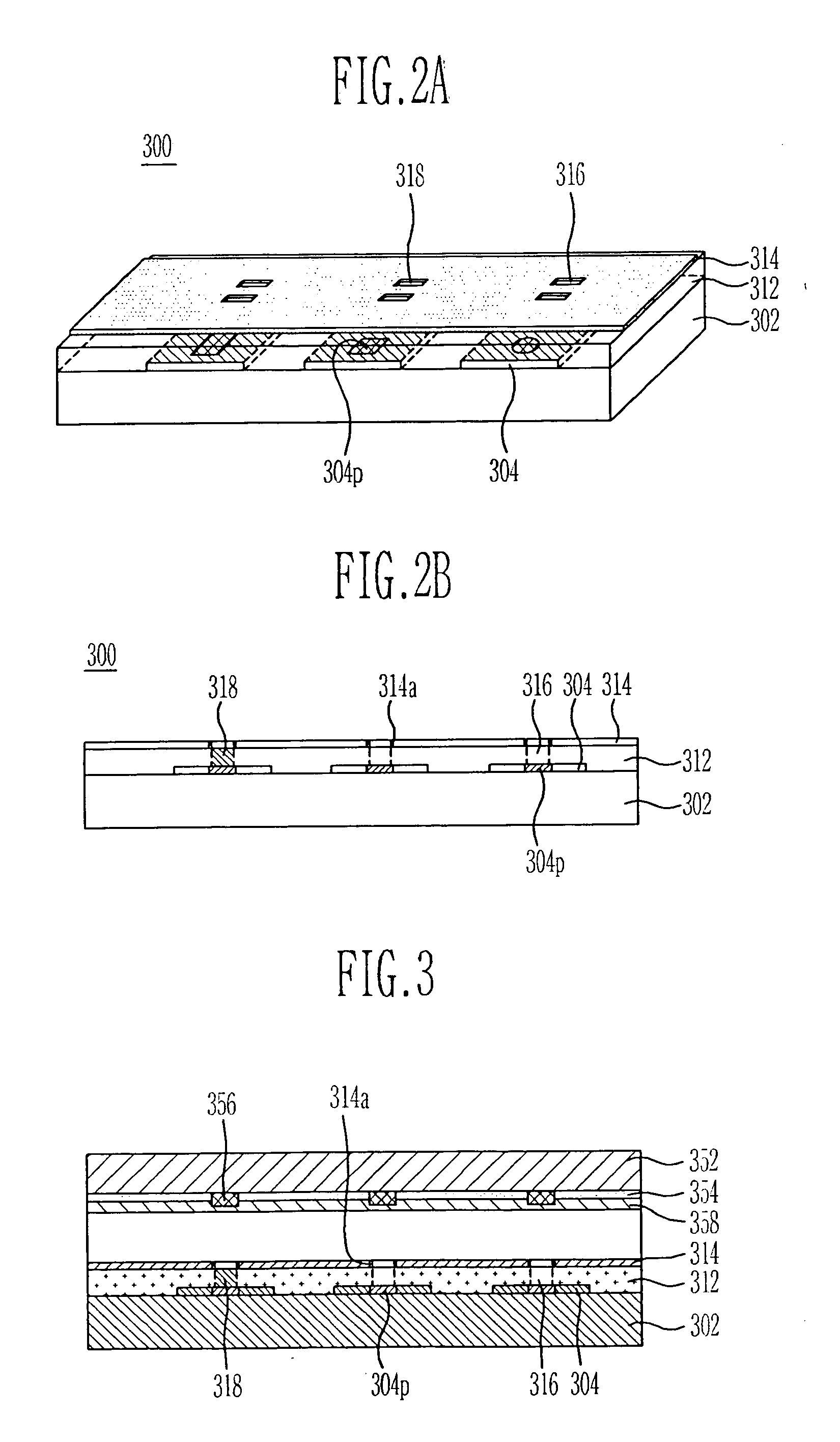

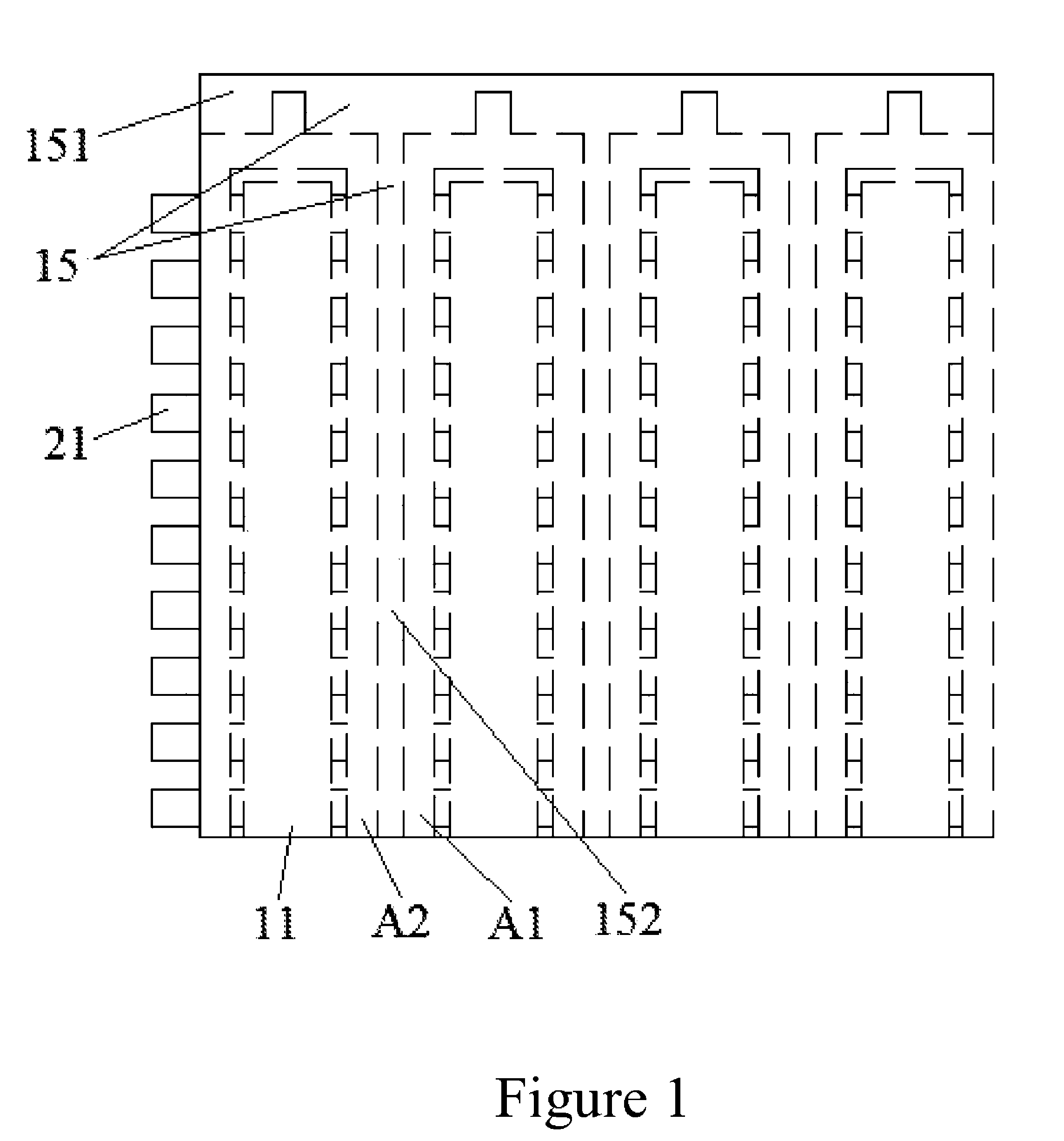

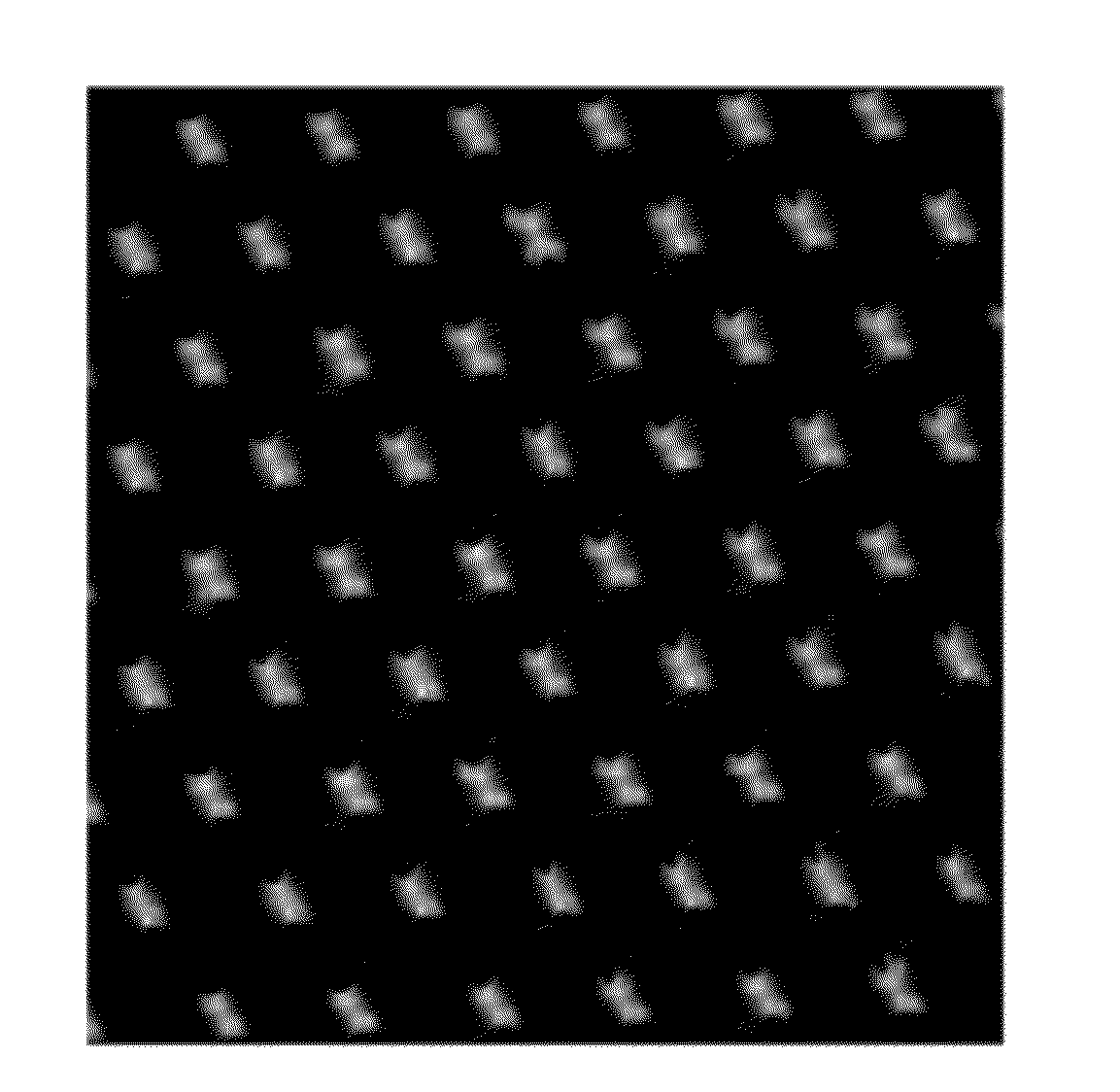

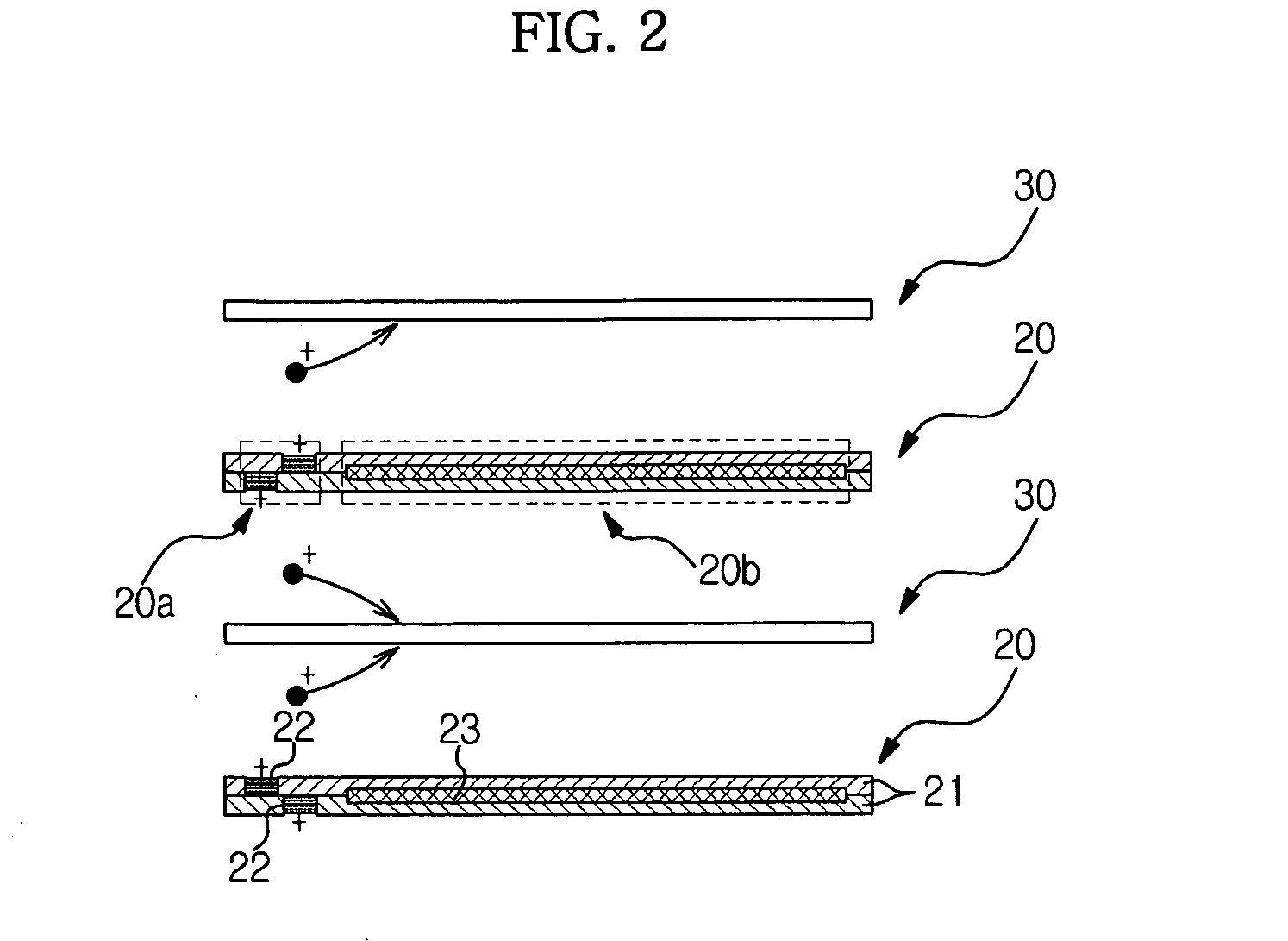

Electron emission device with decreased electrode resistance and fabrication method and electron emission display

InactiveUS7586251B2Lower electrode resistanceControl electrodesThermionic cathodesFluorescenceDisplay device

An electron emission device includes: a substrate; first and second electrodes insulated from each other and having a predetermined shape on the substrate, at least one of the first and second electrodes being formed with a fine mesh pattern; and an electron emission region formed on the substrate and connected to one of the first and second electrodes. Furthermore, an electron emission display includes: first and second substrate arranged opposite to each other; first and second electrodes insulated from each other and having a predetermined shape on the first substrate, at least one of the first and second electrodes being formed with a fine mesh pattern; an electron emission region formed on the first substrate and connected to one of the first and second electrodes; and an image displaying portion including an anode electrode and a fluorescent layer arranged on the second substrate.

Owner:SAMSUNG SDI CO LTD

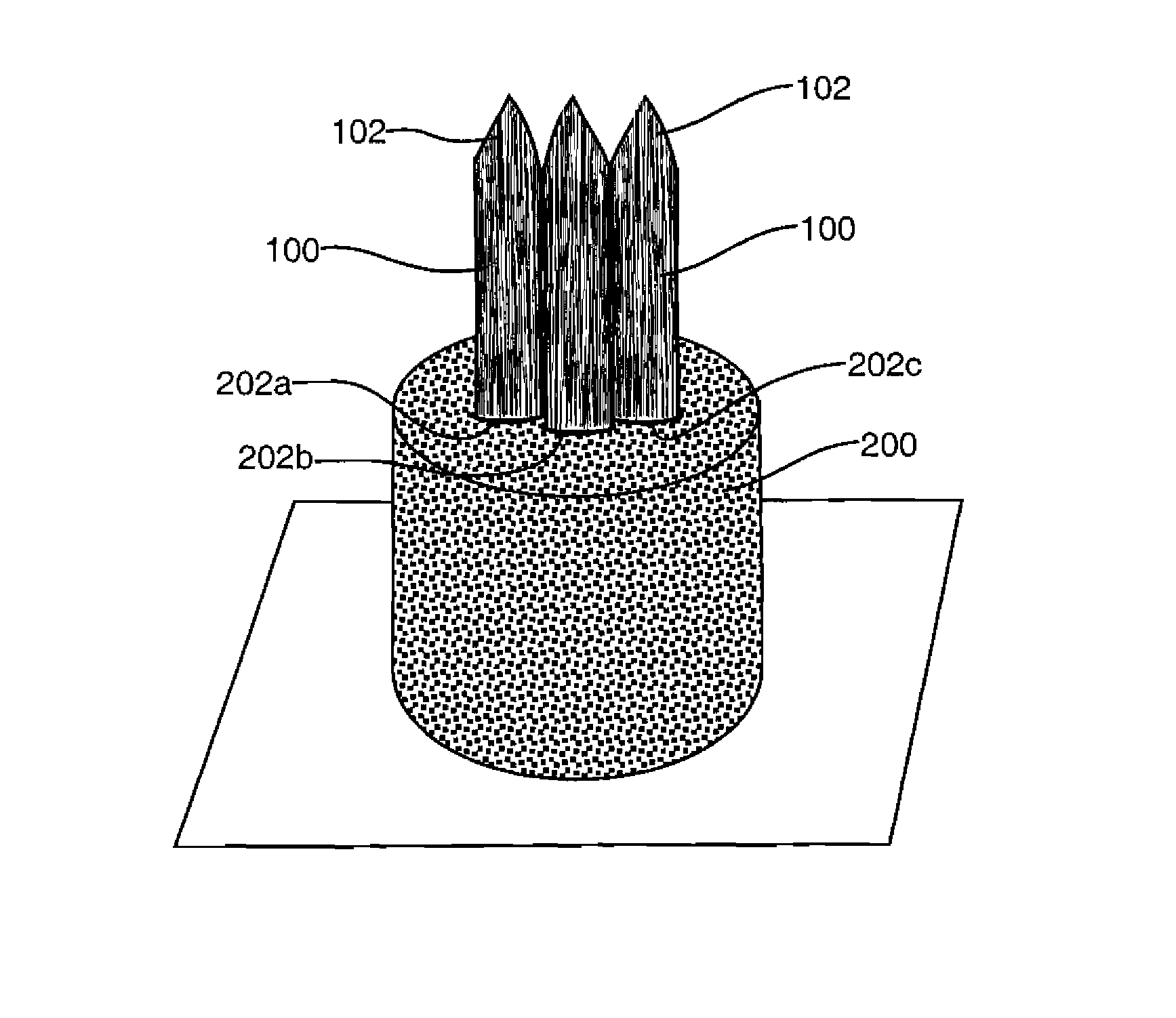

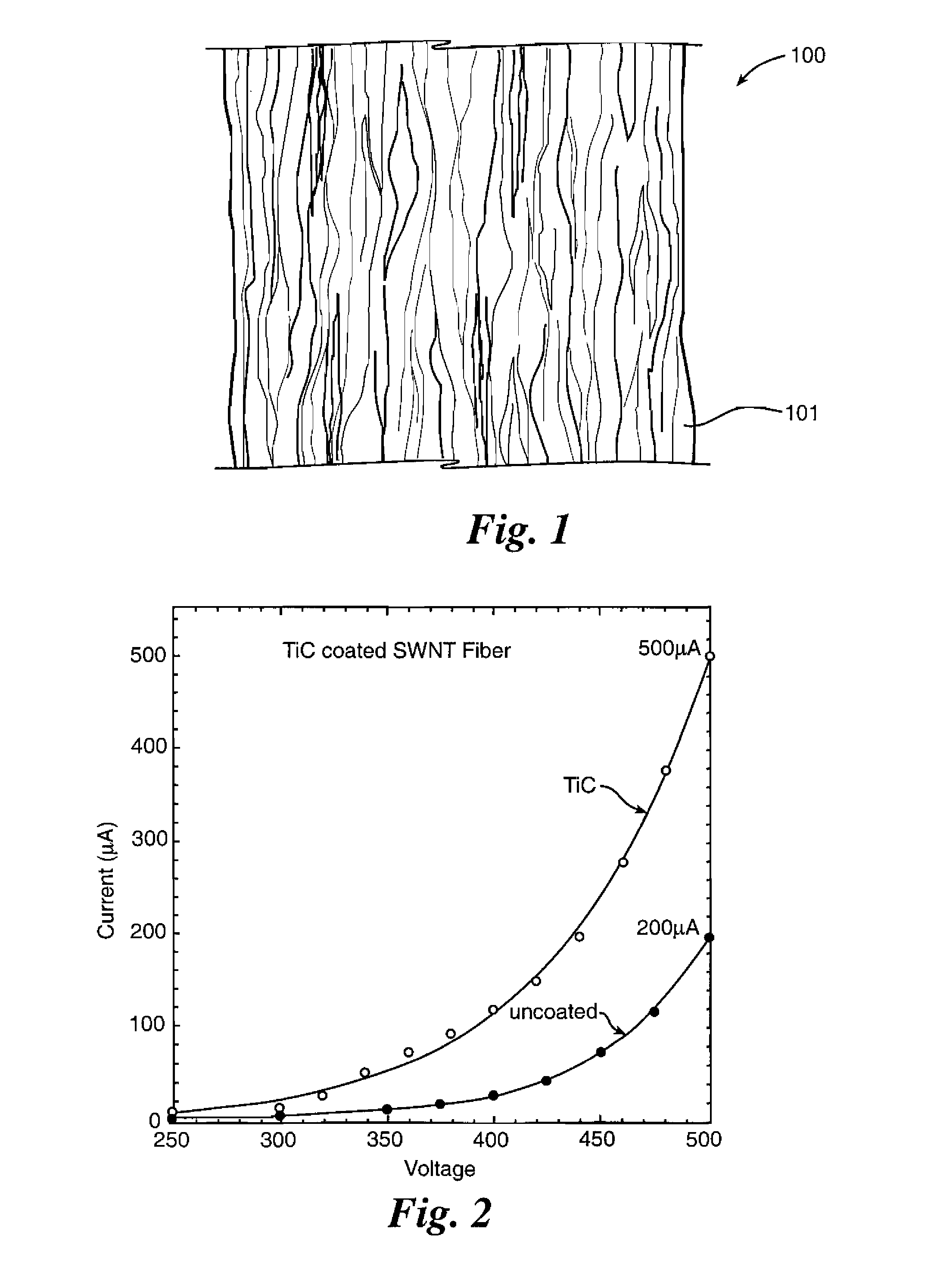

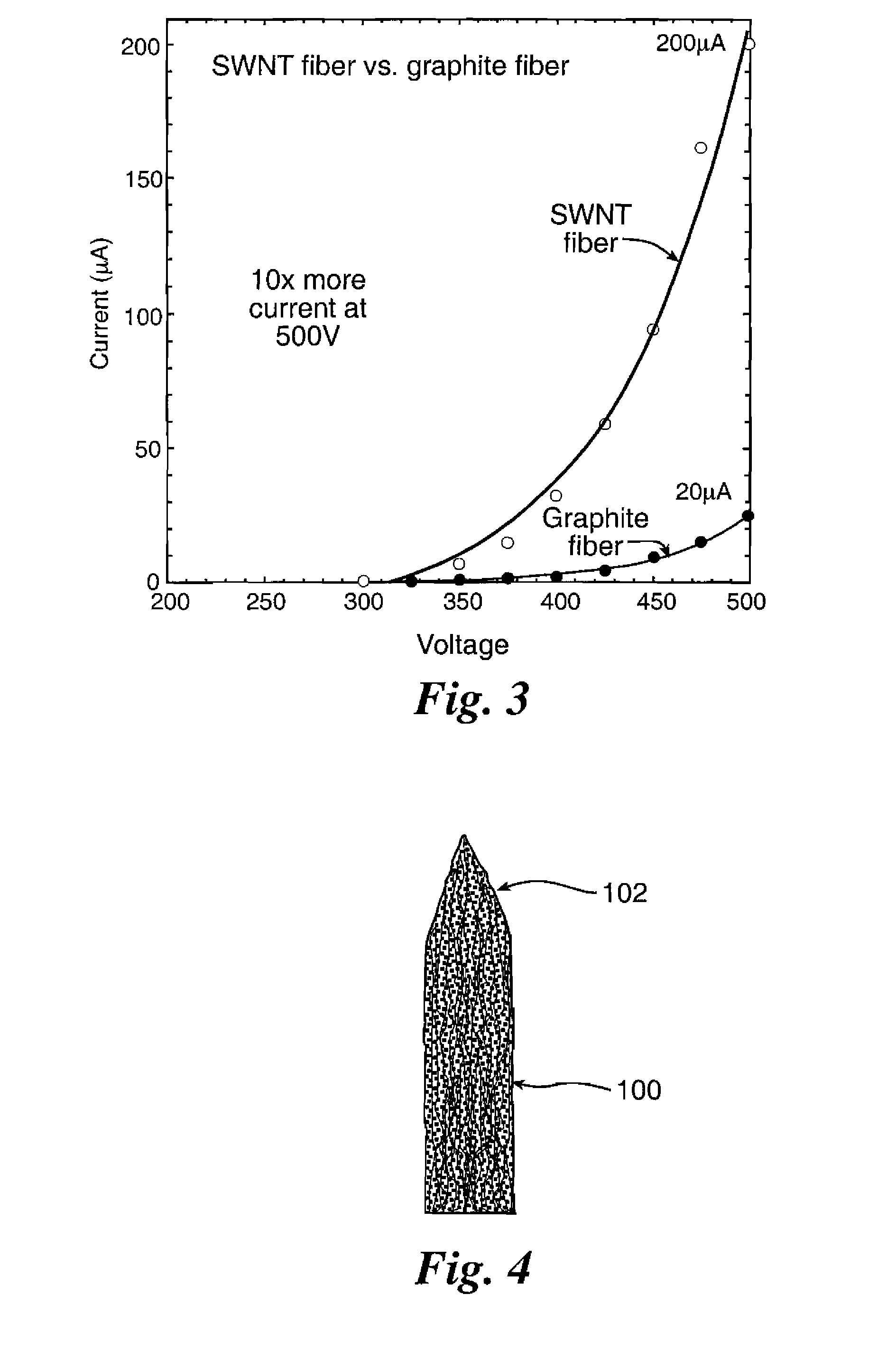

Carbon nanotube fiber cathode

ActiveUS8766522B1Superior and unprecedented performanceImprove fiber performanceGas-filled discharge tubesControl electrodesFiberDouble wall

Improved field emission cathodes comprise a fiber of highly aligned and densely packed single-wall carbon nanotubes, double-wall carbon nanotubes, multi-wall carbon nanotubes, grapheme nanoribbons, carbon nanofibers, and / or carbon planar nanostructures. The fiber cathodes provide superior current carrying capacity without degradation or adverse effects under high field strength testing. The fibers also can be configured as multi-fiber field emission cathodes, and the use of low work function coatings and different tip configurations further improves their performance.

Owner:GOVERNMENT OF THE UNTIED STATES

Electron emission device and fabrication method and electron emission display

InactiveUS20060055311A1Lower electrode resistanceControl electrodesThermionic cathodesDisplay deviceElectron

An electron emission device includes: a substrate; first and second electrodes insulated from each other and having a predetermined shape on the substrate, at least one of the first and second electrodes being formed with a fine mesh pattern; and an electron emission region formed on the substrate and connected to one of the first and second electrodes. Furthermore, an electron emission display includes: first and second substrate arranged opposite to each other; first and second electrodes insulated from each other and having a predetermined shape on the first substrate, at least one of the first and second electrodes being formed with a fine mesh pattern; an electron emission region formed on the first substrate and connected to one of the first and second electrodes; and an image displaying portion including an anode electrode and a fluorescent layer arranged on the second substrate.

Owner:SAMSUNG SDI CO LTD

Symmetric quadrupole structured field emission display without spacer

ActiveUS8803413B2Novel structureSimplify the manufacturing processControl electrodesDischarge tube luminescnet screensCurrent limitingPhosphor

Owner:GUO TAILIANG +5

Reflective electrode, display device, and method for producing display device

InactiveUS8384280B2Improve reflectivityReduce contact resistanceDischarge tube luminescnet screensLamp incadescent bodiesDisplay deviceAlloy

A reflective electrode (2) includes an aluminum alloy layer (2a) and an aluminum oxide layer (2b) arranged on or above a substrate and is directly connected to a transparent pixel electrode (3) without the interposition of a barrier metal layer. The aluminum alloy layer contains 0.1 to 2 atomic percent of nickel or cobalt and 0.1 to 2 atomic percent of lanthanum. The aluminum oxide layer has a ratio [O] / [Al] of the number of oxygen atoms [O] to the number of aluminum atoms [Al] of 0.30 or less. The aluminum oxide layer has a thickness in its thinnest portion of 10 nm or less. The reflective electrode has a high reflectance and a low contact resistance, even when subjected to a heat treatment at a low temperature of 100° C. or higher but 300° C. or lower. The reflective electrode also has excellent thermal stability and does not cause defects such as hillocks.

Owner:KOBE STEEL LTD

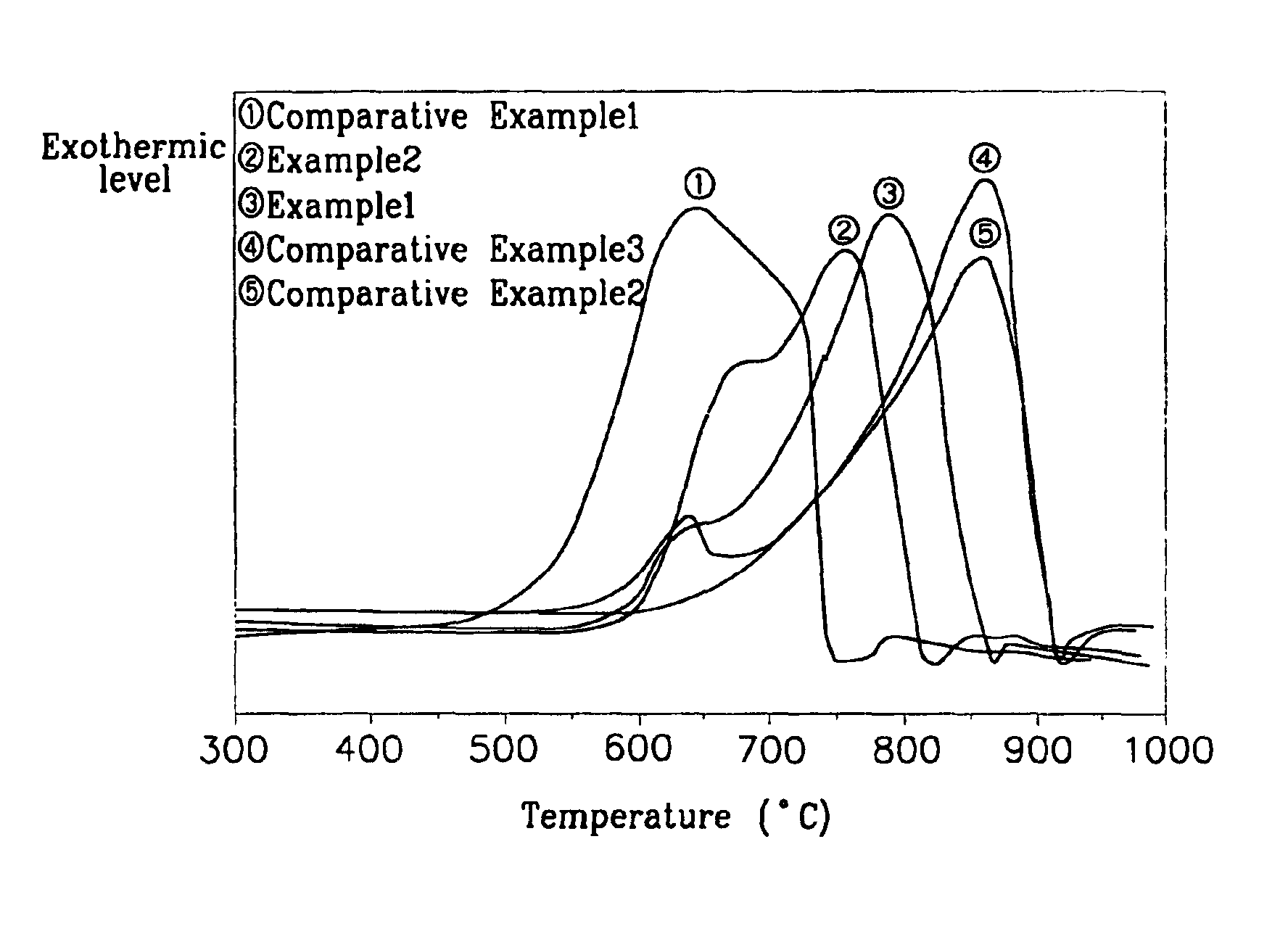

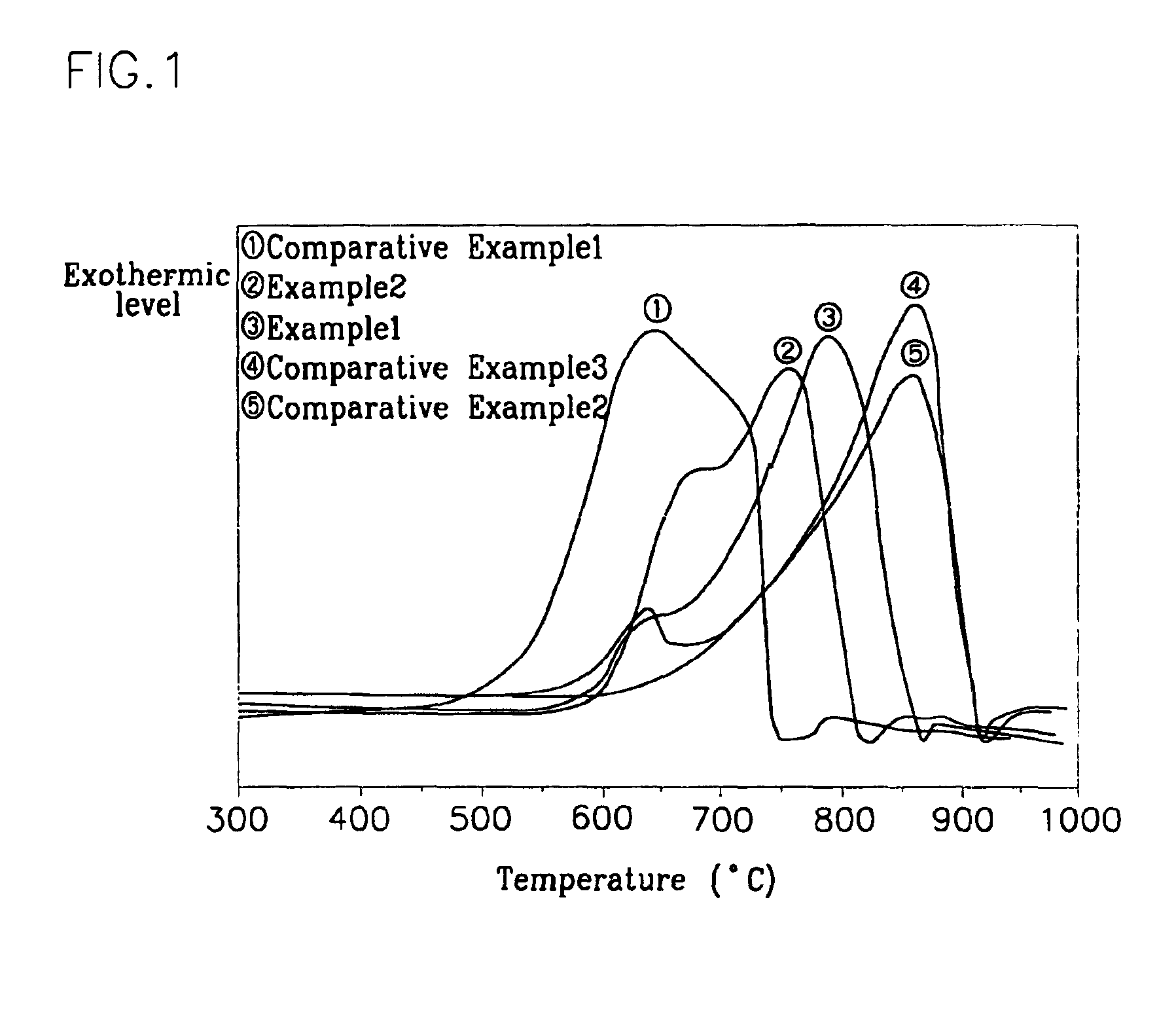

Carbonaceous active material for lithium secondary battery

InactiveUS6887622B2Excellent charge and discharge characteristicsDrawbacks of crystalline graphite and amorphous carbon are minimizedPigmenting treatmentNon-aqueous electrolyte accumulatorsEngineeringLithium-ion battery

Disclosed is carbonaceous active material for a lithium-ion secondary battery. Conducting a differential thermal analysis on the carbonaceous active material results in the displaying of at least two exothermic peaks overlapping to form shoulders.

Owner:SAMSUNG ELECTRONICS DEVICES CO LTD

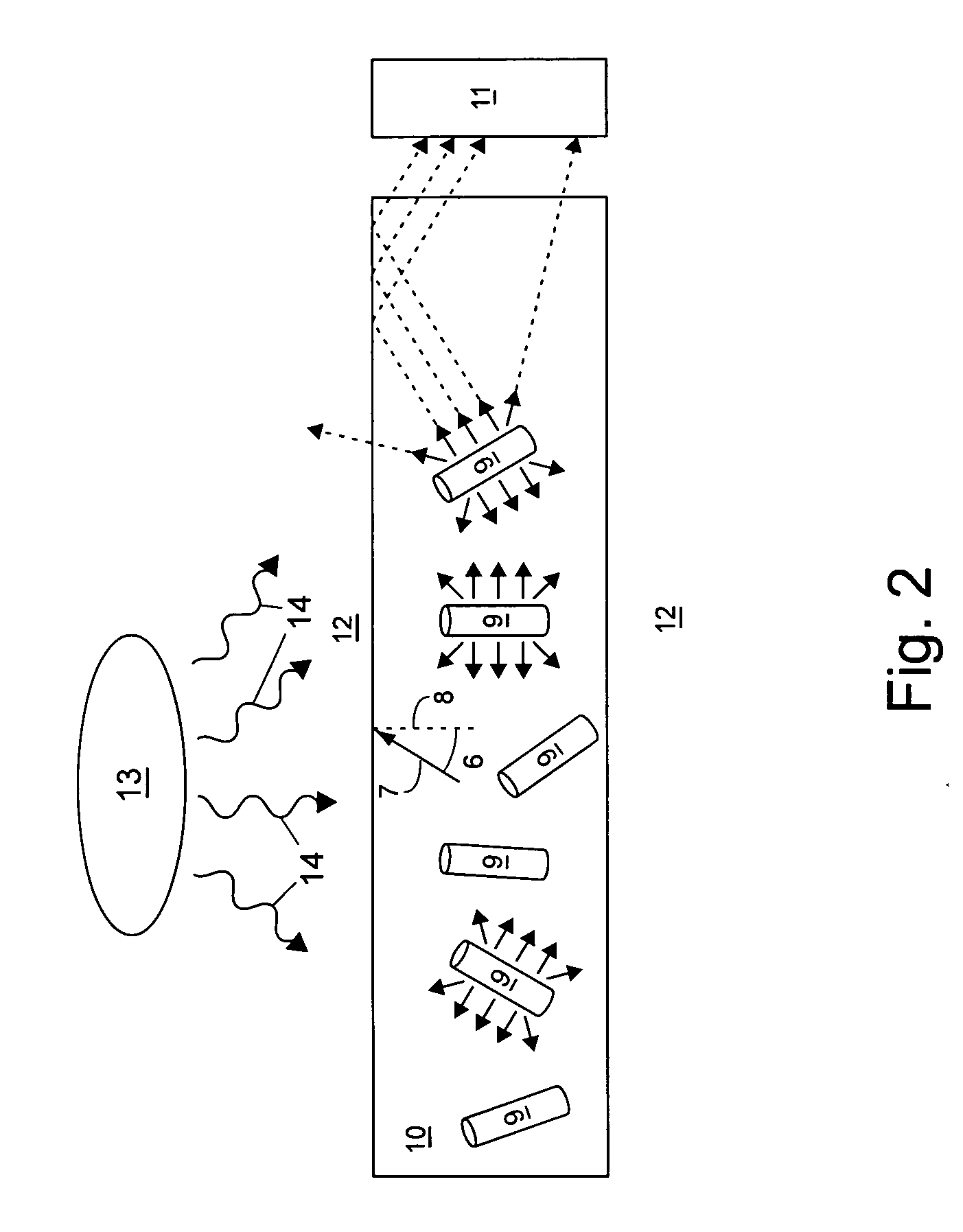

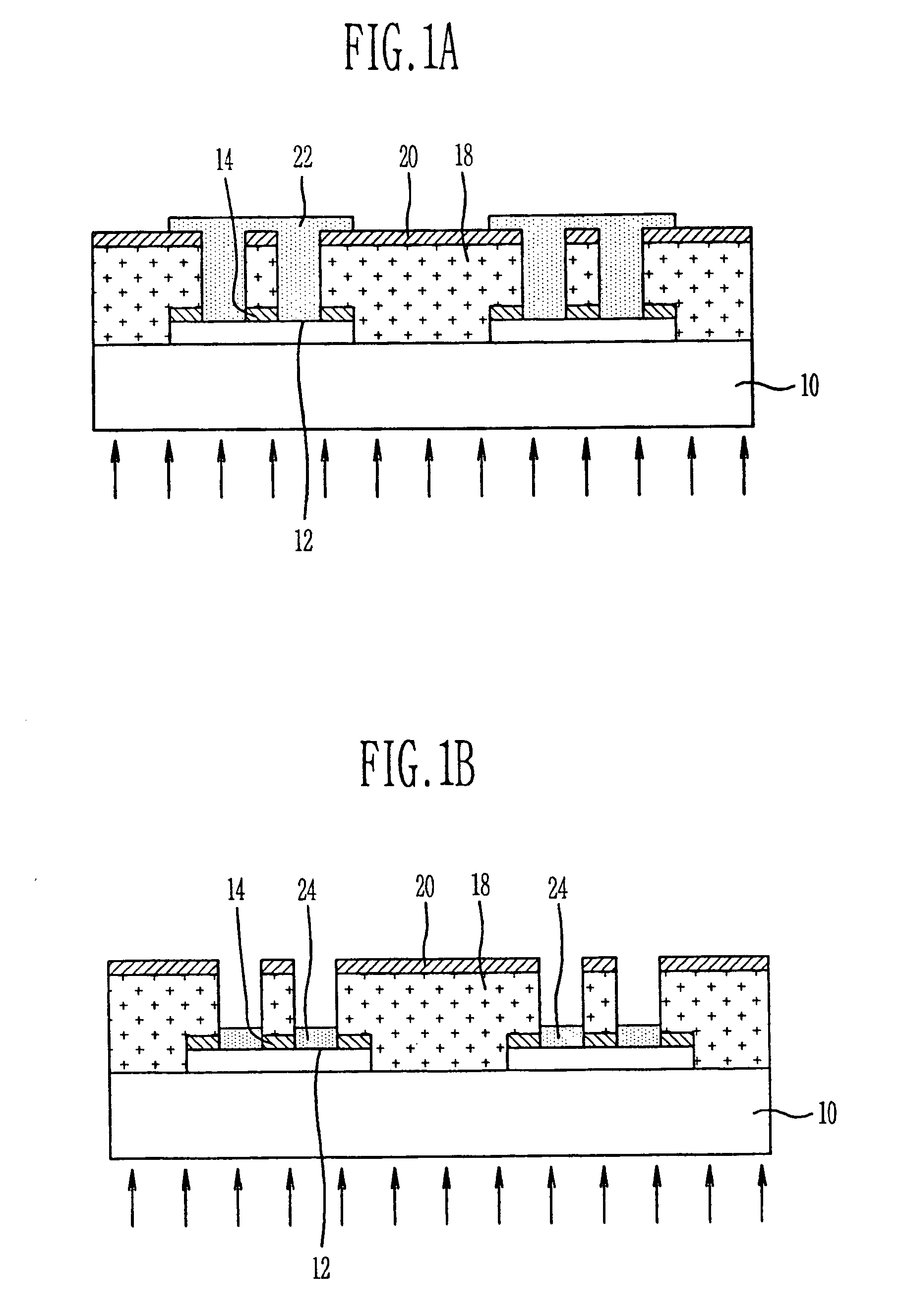

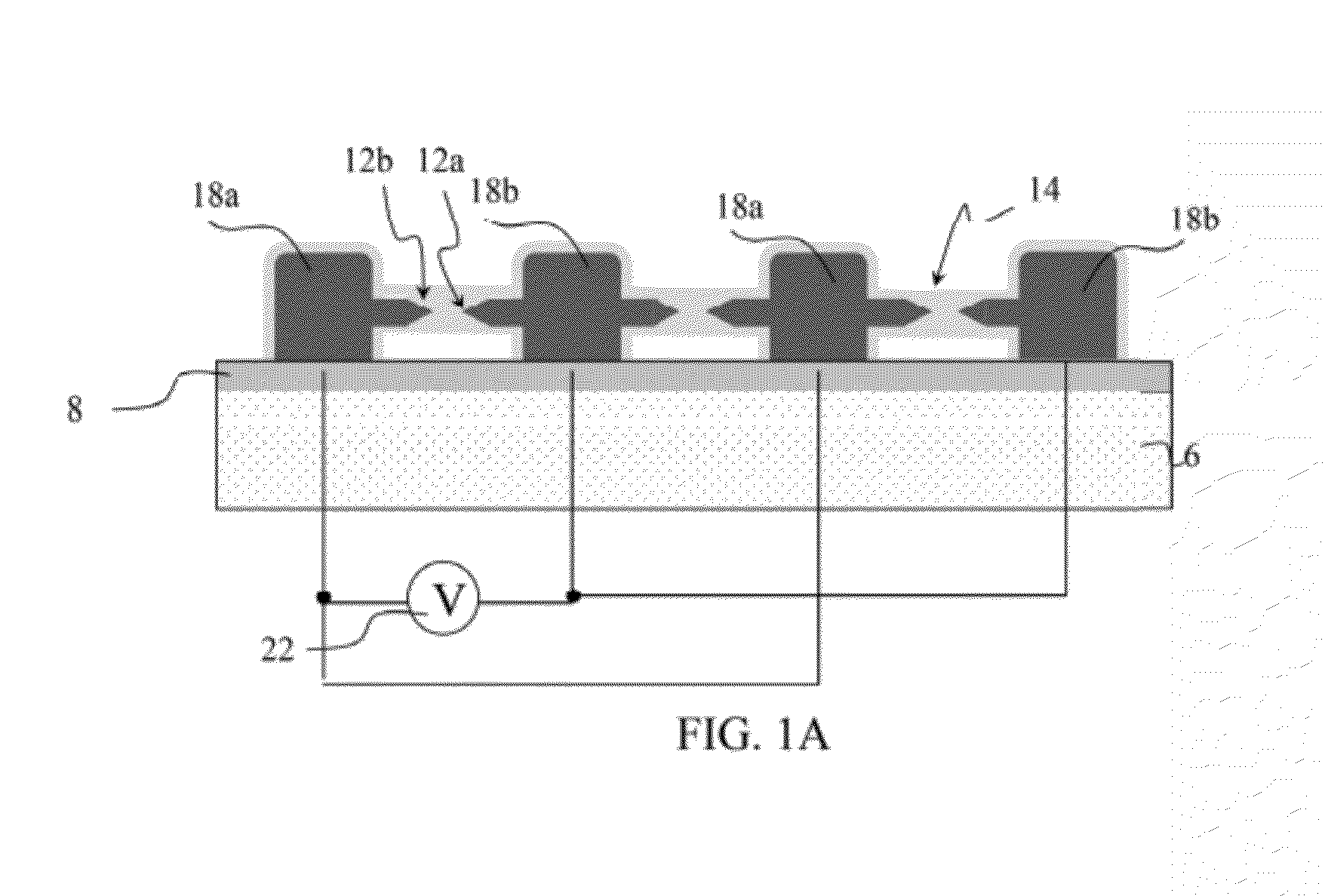

Encapsulated metal microtip microplasma devices, arrays and fabrication methods

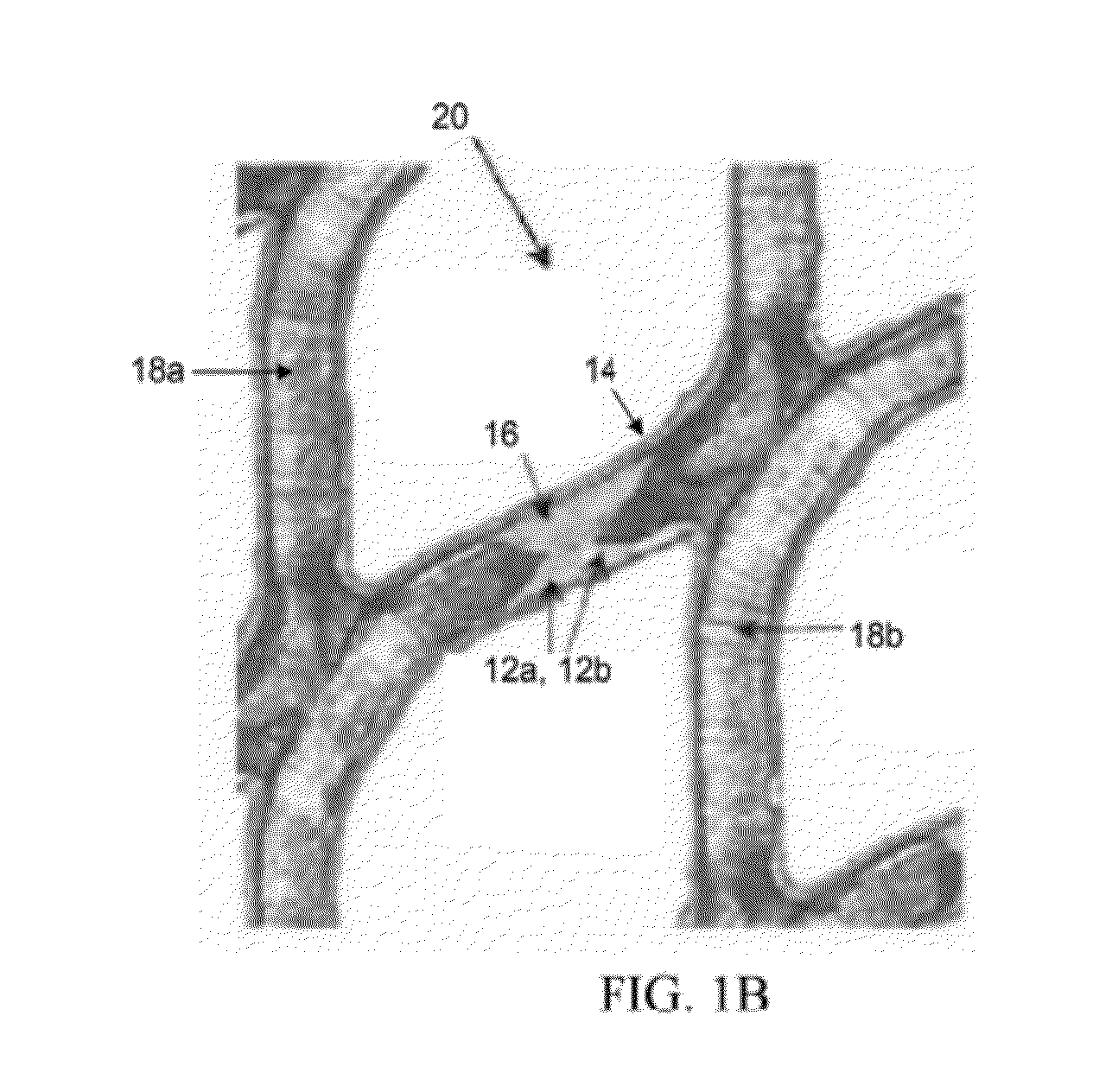

An embodiment of the invention is a microtip microplasma device having a first metal microtip opposing a second metal microtip with a gap therebetween. The first and second metal microtips are encapsulated in metal oxide that electrically isolates and physically connects the first and second metal microtips. In preferred devices, the first and second metal microtips and metal oxide comprise a monolithic, unitary structure. Arrays can be flexible, can be arranged in stacks, and can be formed into cylinders, for example, for gas and liquid processing devices, air filters and other applications. A preferred method of to forming an array of microtip microplasma devices provides a metal mesh with an array of micro openings therein. Electrode areas of the metal mesh are masked leaving planned connecting metal oxide areas of the metal mesh unmasked. Planned connecting metal oxide areas are electrochemically etched to convert the planned connecting metal oxide areas to metal oxide that encapsulates opposing metal microtips therein. The mask is removed. The electrode areas are electrochemically etched to encapsulate the electrode areas in metal oxide.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

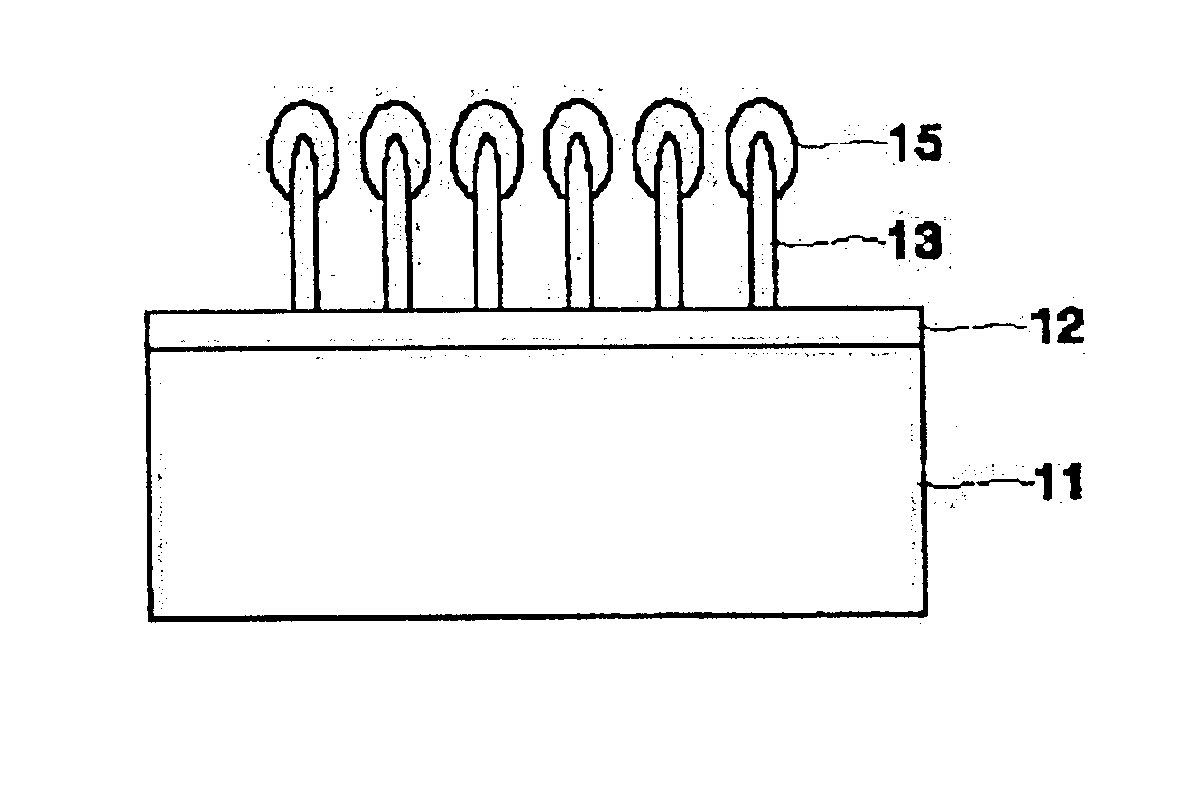

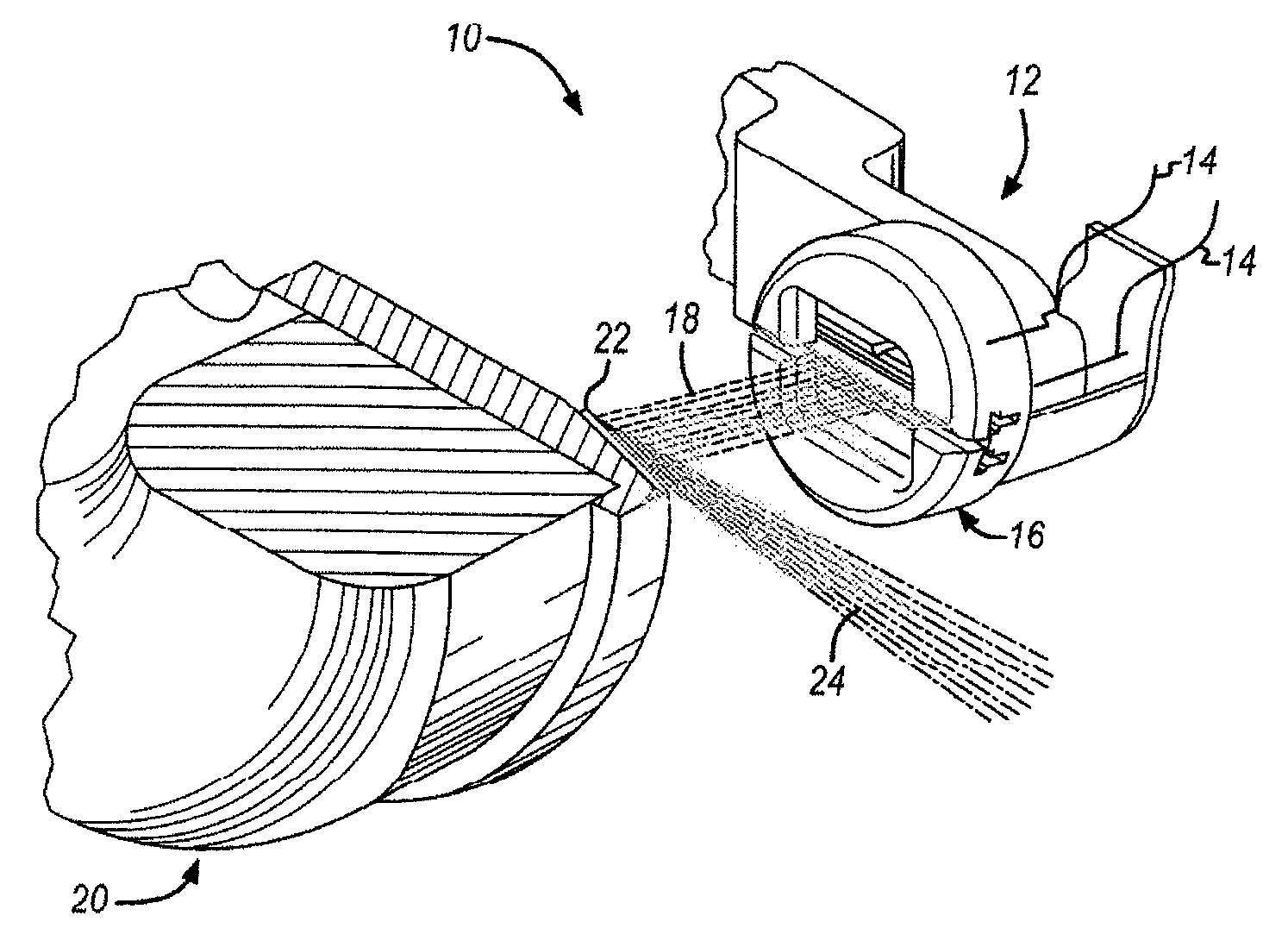

Field emitter device comprising carbon nanotube having protective membrane

InactiveUS6903500B2Accelerate emissionsImprove stabilityLamp incadescent bodiesNanoinformaticsCarbon nanotubeCarbide

A field emitter device including carbon nanotubes each of which has a protective membrane is provided. The protective membrane is formed of a nitride, a carbide, or an oxide. Suitable nitrides for the protective membrane include boron nitride, aluminum nitride, boron carbon nitride, and gallium nitride. The protective membrane protects the carbon nanotubes from damage due to arcing or an unnecessary remaining gas and thus improves field emission characteristics and stability of the field emitter device.

Owner:SAMSUNG ELECTRONICS CO LTD

Electric precipitator and high voltage electrode thereof

ActiveUS20100147151A1Reduce widthIncrease the use of spaceLamp incadescent bodiesThermionic cathodesLow voltageEngineering

An electrode precipitator having a high voltage electrode and a low voltage electrode arranged apart from each other at a desired interval. The high voltage electrode includes a charging part which is positioned upstream of an air flow direction to charge a pollutant, and a dust collection part which is spaced from the charging part and positioned downstream of the air flow direction to precipitate the charged pollutant therein.

Owner:SAMSUNG ELECTRONICS CO LTD

High voltage stable cathode for x-ray tube

InactiveUS7576481B2Electrode and associated part arrangementsThermionic cathodesEngineeringHigh pressure

Owner:GENERAL ELECTRIC CO

Anode structure for use in organic el device, production method thereof and organic el device

ActiveUS20110309349A1Good alkali resistanceExtended service lifeVacuum evaporation coatingSolid-state devicesHydrogen concentrationWork function

The present invention relates to an anode structure for use in a top-emission type organic EL device which comprises a laminated structure comprising an anode layer made of at least one selected from the group consisting of aluminum, aluminum alloys, silver and silver alloys; and a buffer layer directly provided on the anode layer and made of an electrically conductive amorphous carbon having a hydrogen concentration of 15 at. % or less. According to the present invention, there is provided an anode structure which is superior in alkali resistance and can lengthen lifetime of an organic EL device as well as can ensure a high work function suitable for an anode for a high-luminance, high-power-efficient organic EL device.

Owner:MITSUI MINING & SMELTING CO LTD

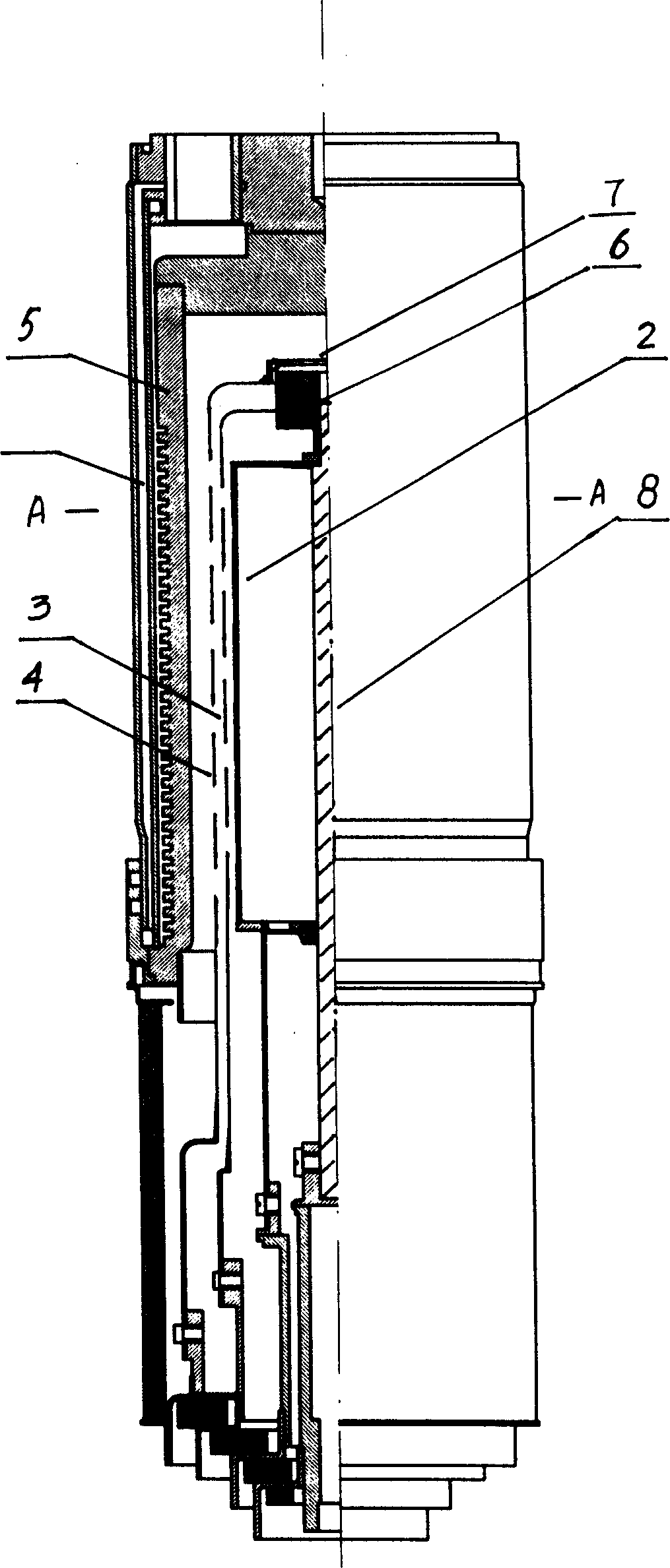

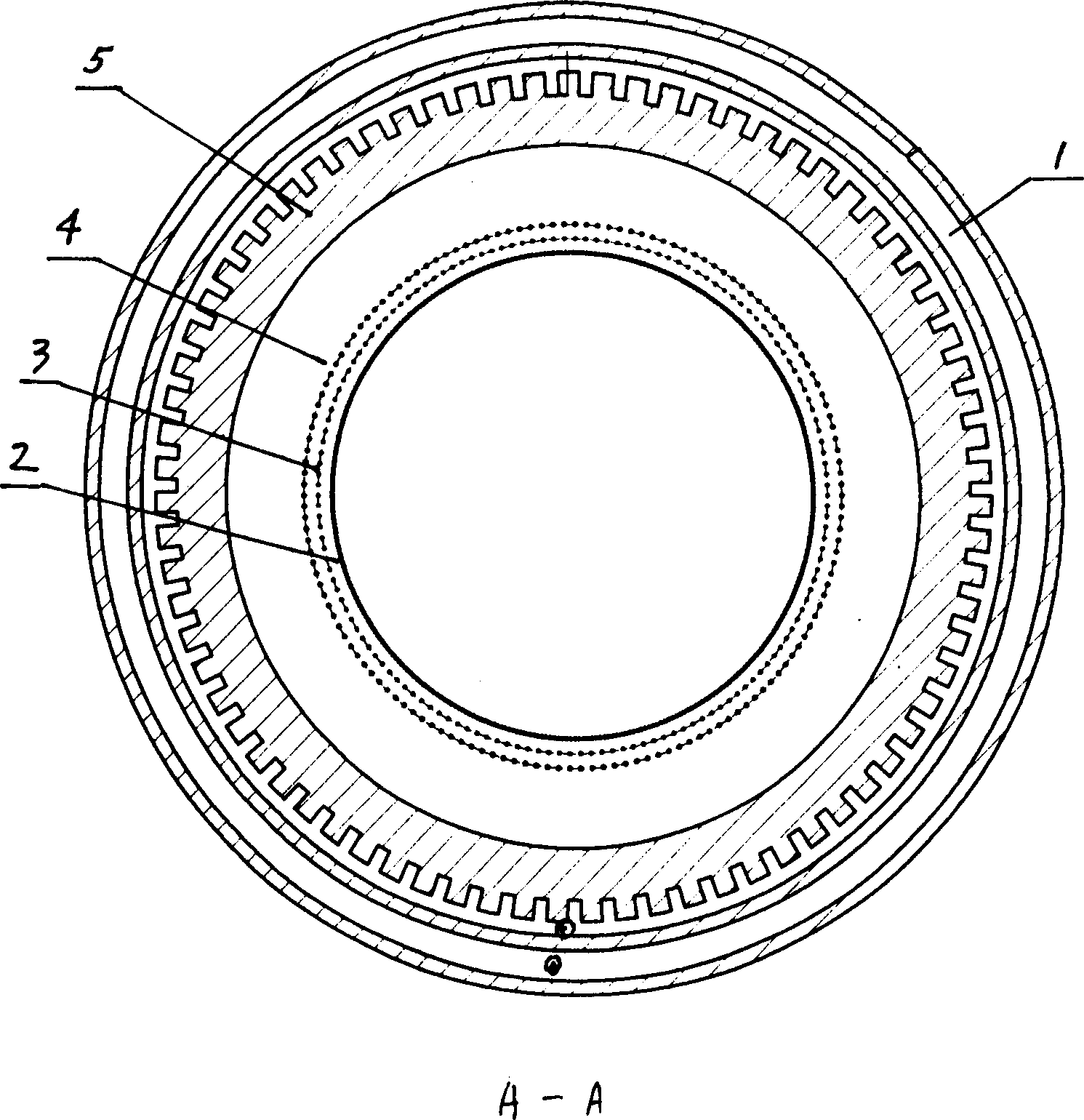

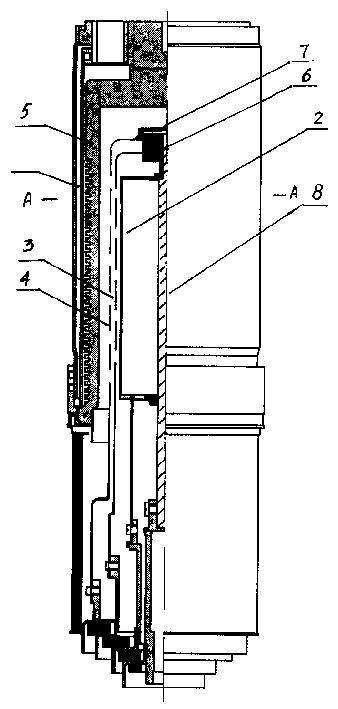

Large power quadrupole delectronic tube and its manufacturing method

InactiveCN1479343ASolve the defect of falling powder and ignitionReduce production conditionsTransit-time tubesNon-electron-emitting electrode materialsRadiation resistantTwo grid

The electron tube consists of cooling water jacket, cathode, first grid, second grid and anode. The improved first grid is made from pyrolytic graphite. The second grid is made from molybdenum filament welded in squirrel cage shape. With surface being sprayed by tungsten carbide, the molybdenum filament is sintered and plated by platinum. The upper parts of two grids are connected to ceramic ring at upper part of cathode. The first grid is made from graphite after dedicated procedure the first grid possesses higher capabilities of high temperature resistant and radiation resistant. The heat dissipation capability of the first grid made from graphite is 5 times of grid made from molybdenum filament so as to reduce size greatly.

Owner:卫军民 +1

Vacuum electron device electrodes and components manufactured from highly oriented pyrolytic graphite (HOPG)

ActiveUS20120313505A1Keep the pressureEliminate voidsMagnetronsLamp incadescent bodiesHighly oriented pyrolytic graphiteErosion rate

Components for use in vacuum electron devices are fabricated from highly oriented pyrolytic graphite (HOPG) and exhibit excellent thermal conductivity, low sputtering rates, and low ion erosion rates as compared to conventional components made from copper or molybdenum. HOPG can be reliably brazed by carefully controlling tolerances, calculating braze joint material volume, and applying appropriate compression during furnace operations. The resulting components exhibit superior thermal performance and enhanced resistance to ion erosion and pitting.

Owner:L3 TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com