Nanocomposites

a technology of nanocomposites and composite materials, applied in the field of nanocomposites, can solve the problems of difficult to find single component materials possessing these properties, difficult to form thin uniform films used in many microelectronics applications, and difficult to achieve the effects of high refraction index, efficient waveguided, and increased refraction percentag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Composite materials comprising nanostructures (nanocomposites) are provided, along with articles comprising nanocomposites and methods and compositions for making such composites.

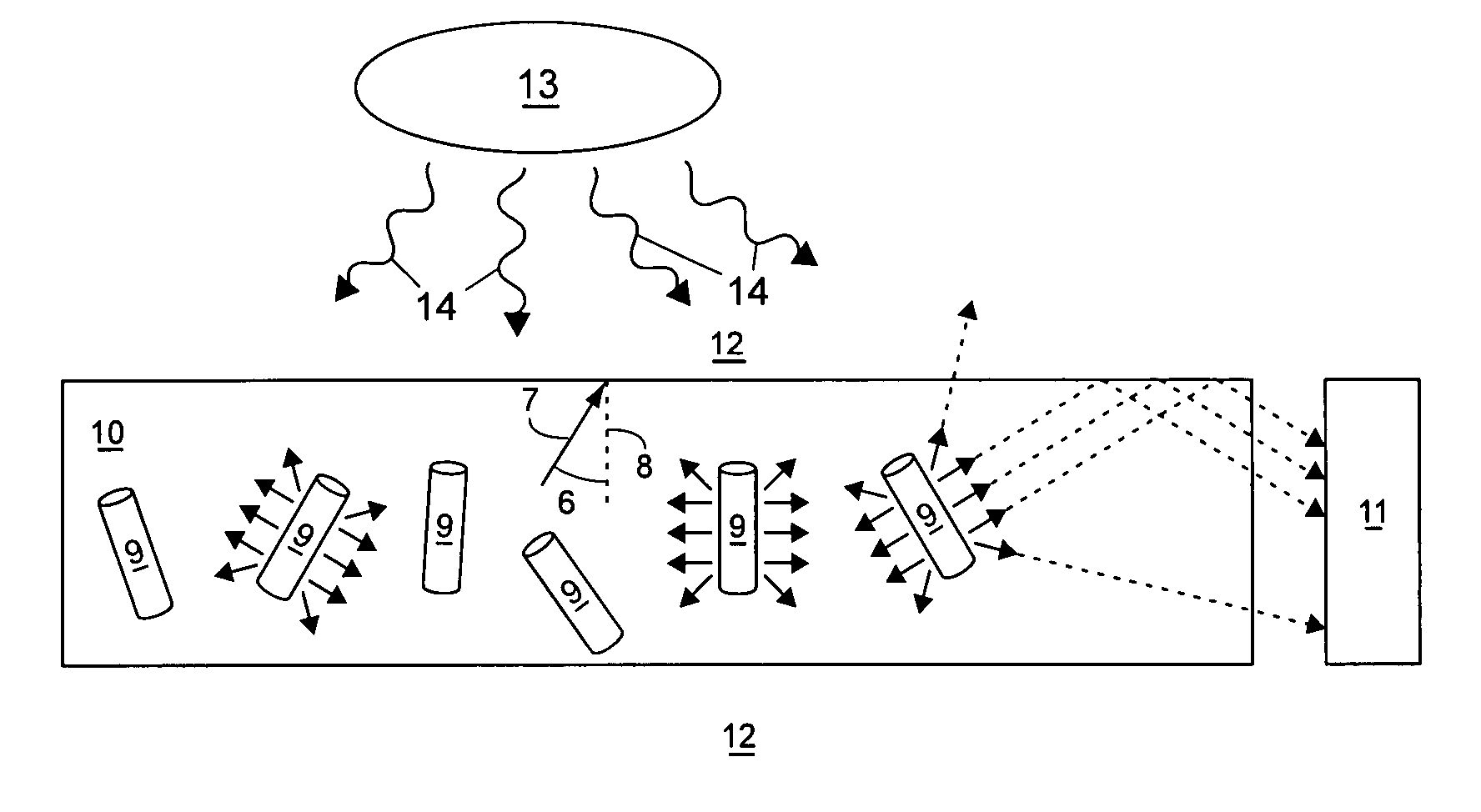

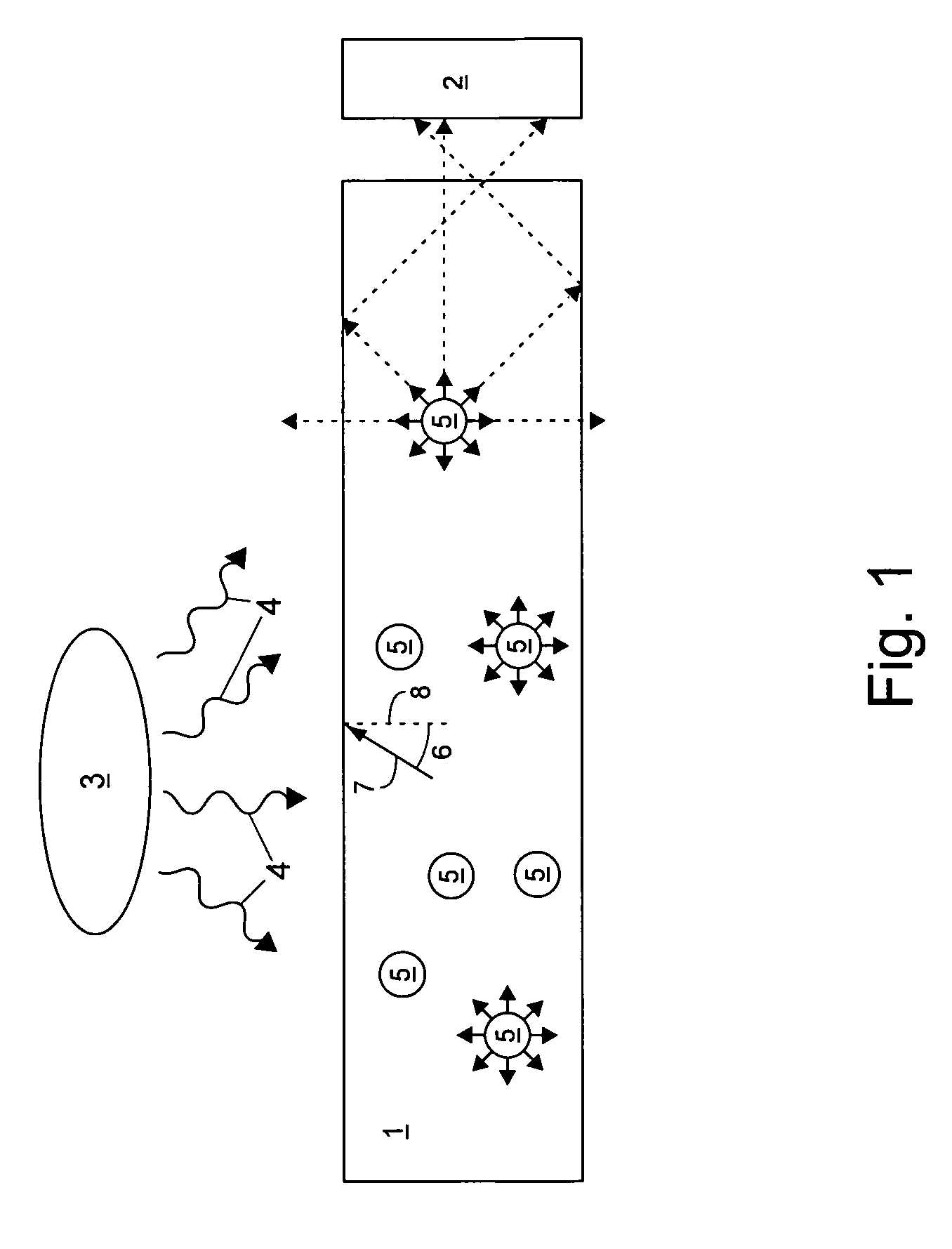

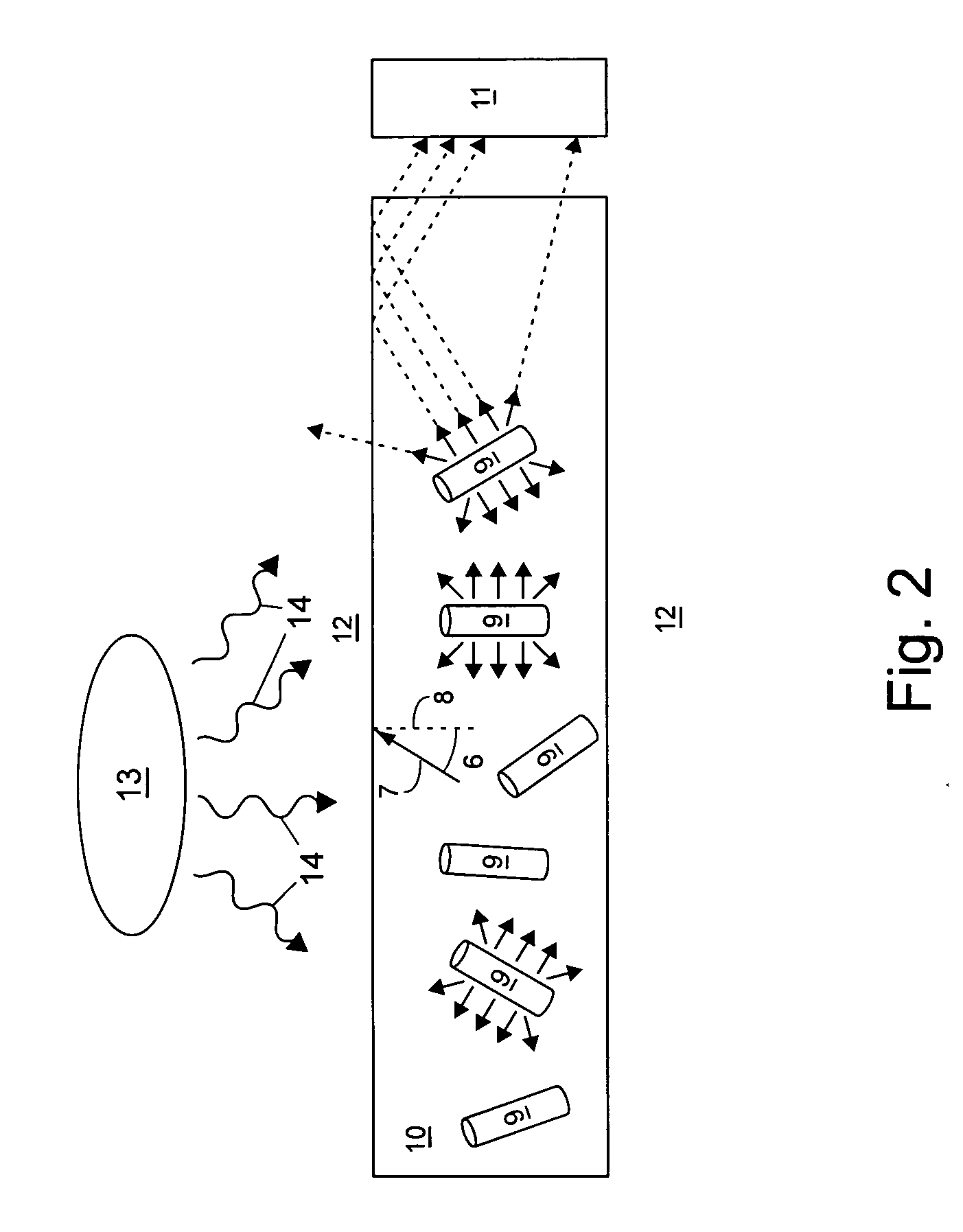

[0048] One class of embodiments provides waveguides and light concentrators comprising nanostructures. This class of embodiments is based on the ability of certain nanostructures (e.g., nanostructures comprising a fluorescent material) to absorb and re-emit light that can then be waveguided by total internal reflection within at least one core. In many but not all embodiments, the nanostructures are provided in the form of a nanocomposite. In some embodiments, the nanostructures are substantially nonrandomly oriented to increase the efficiency of the waveguide or light concentrator.

[0049] Methods for orienting nanostructures within a composite material are discussed, including using the matrix or components thereof to orient the nanostructures. Accordingly, one aspect of the invention provides nano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com