Exhaustion bench for full-automatic glass vacuum system

A glass vacuum and vacuum system technology, applied in the direction of electric tube/lamp exhaust, electrical components, electric tube/lamp degassing, etc. Heat loss, energy saving temperature, effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

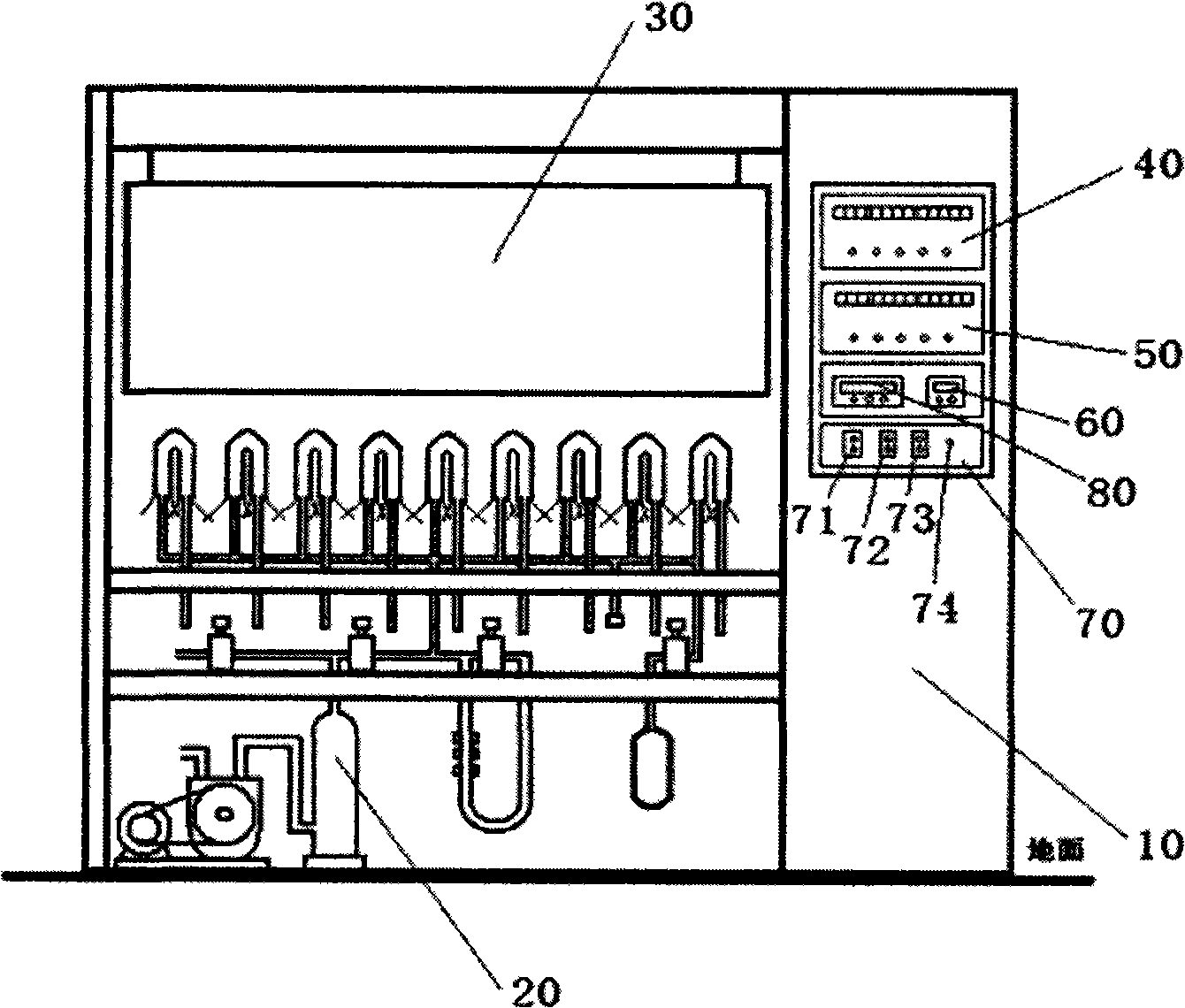

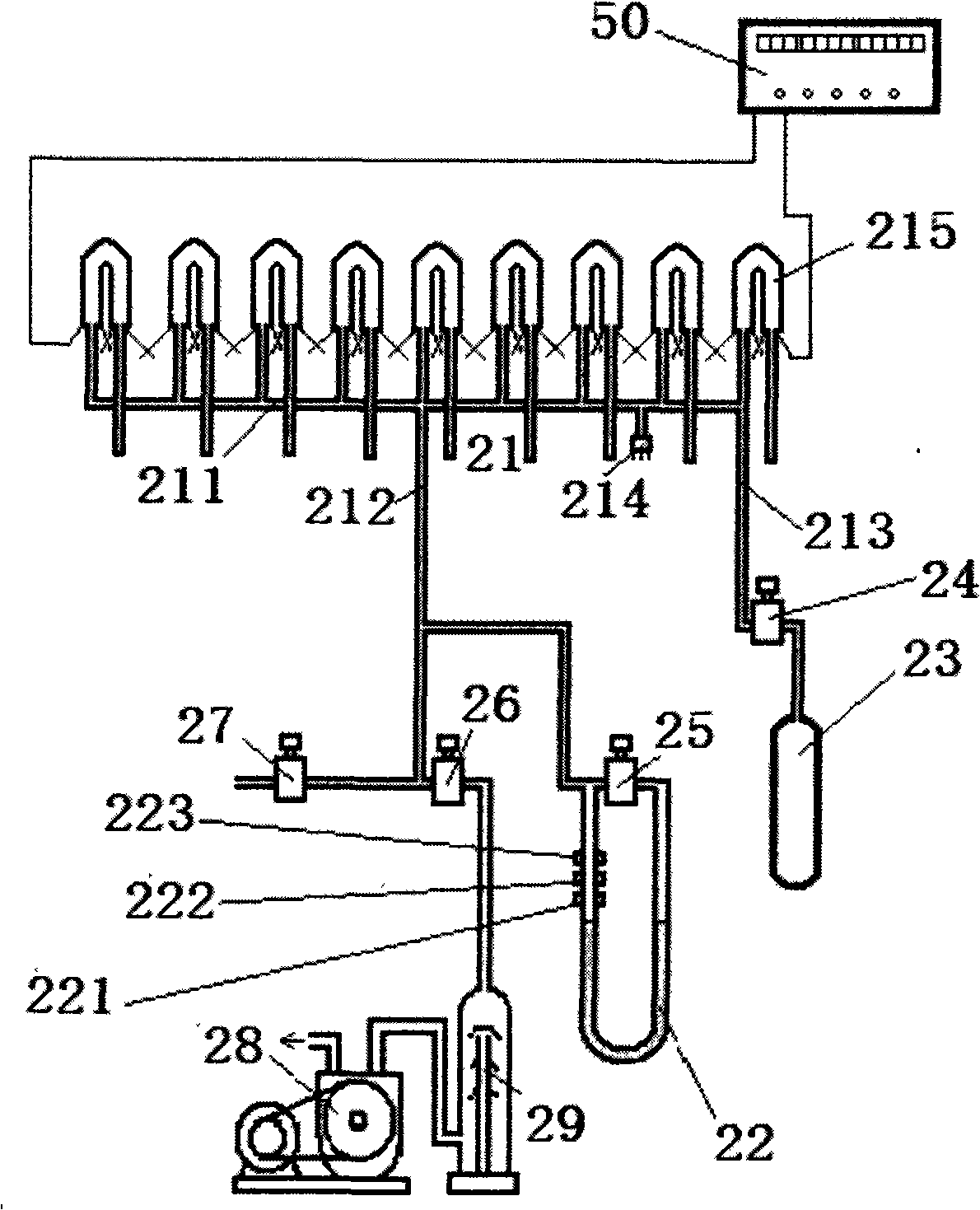

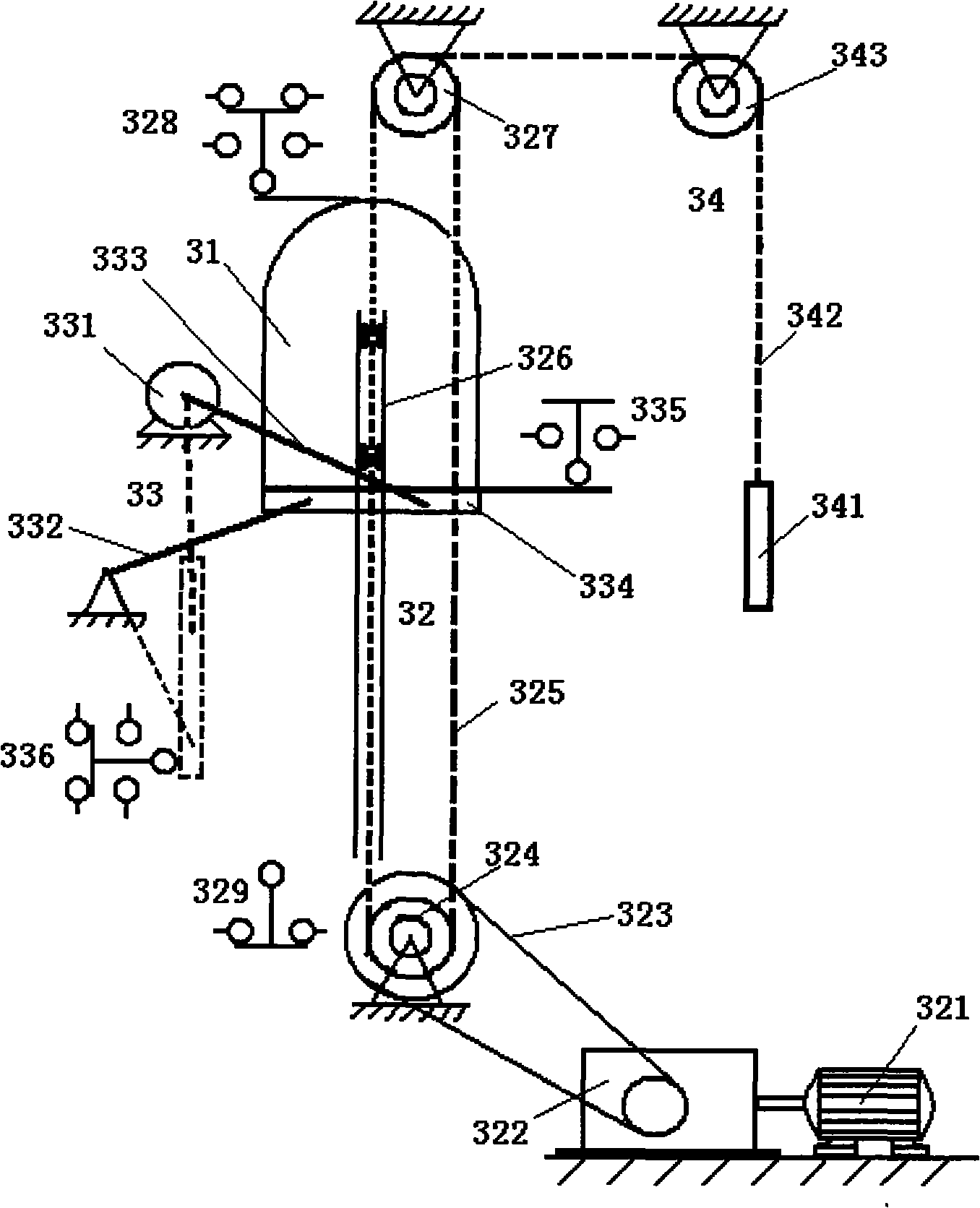

[0035] Specific embodiments of the present invention will be described in detail in conjunction with the above drawings.

[0036] refer to Figure 1 to Figure 7 , when the exhaust begins, press the main power switch 71 on the main control board 70 to turn on the power. Press the mechanical pump switch 72 to start the mechanical pump 28. Press the diffusion pump switch 73 to start the diffusion pump 29. Manually close the vacuum valve 26 and open the vent valve 27 to connect the low-pressure air to the vacuum system for burning the lamp tube. The employee burns the lamp to be exhausted to the lamp rake 211 on the top of the vacuum system 21 of the vacuum system 20, so that the lamp to be exhausted is connected to the vacuum system. Twist the guide wire, hang the weight W, press the filament connection test button 74 on the main control board 70, and check whether all the filaments are connected in series. Close the purge valve 27, open the vacuum valve 26, and the system wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com