Processing apparatus and method of manufacturing electron emission element and organic el display

A technology for processing devices and processing objects, which is applied to electrical components, lighting devices, electric solid devices, etc., can solve problems such as cost increase, degree of freedom limitation, device design freedom degree, expansion limitation, etc., to avoid scars, easy Coping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

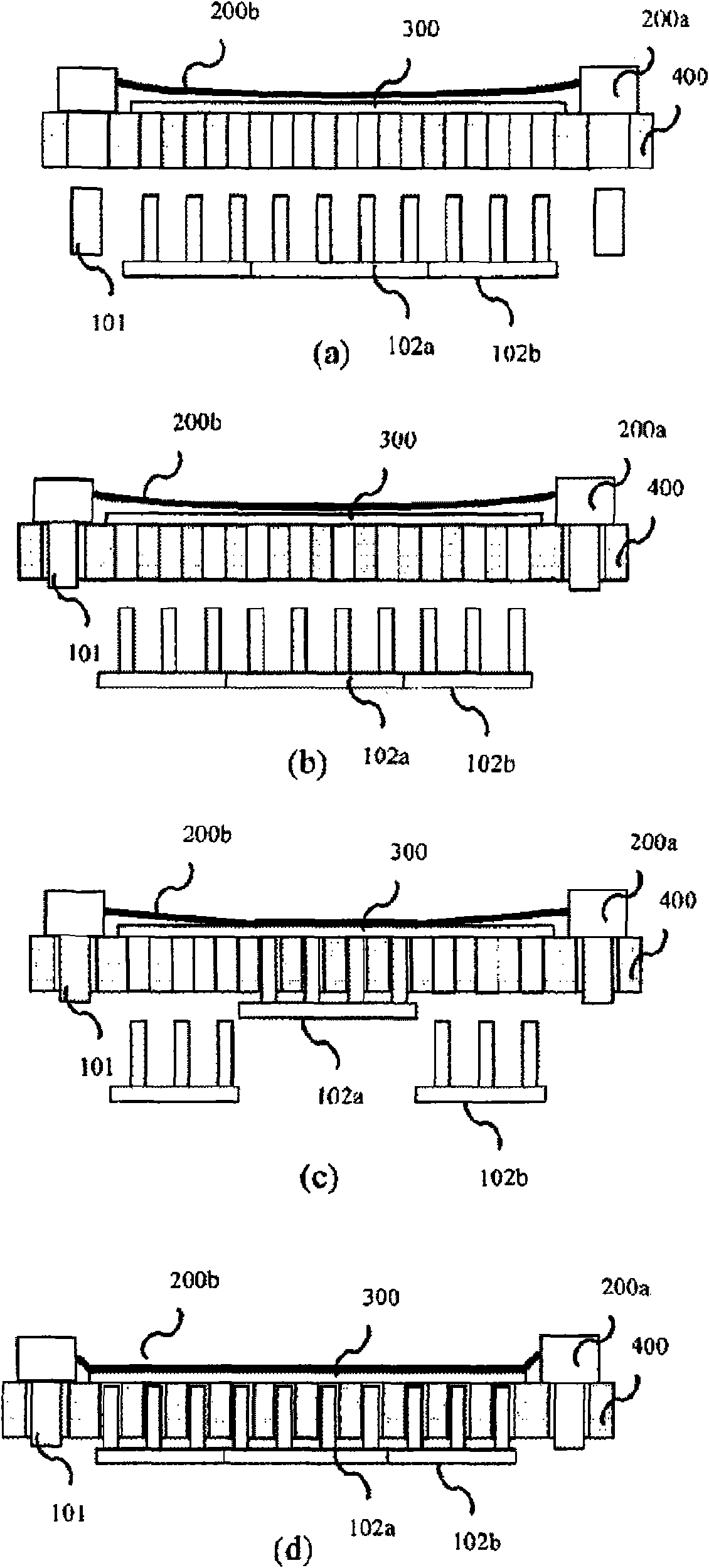

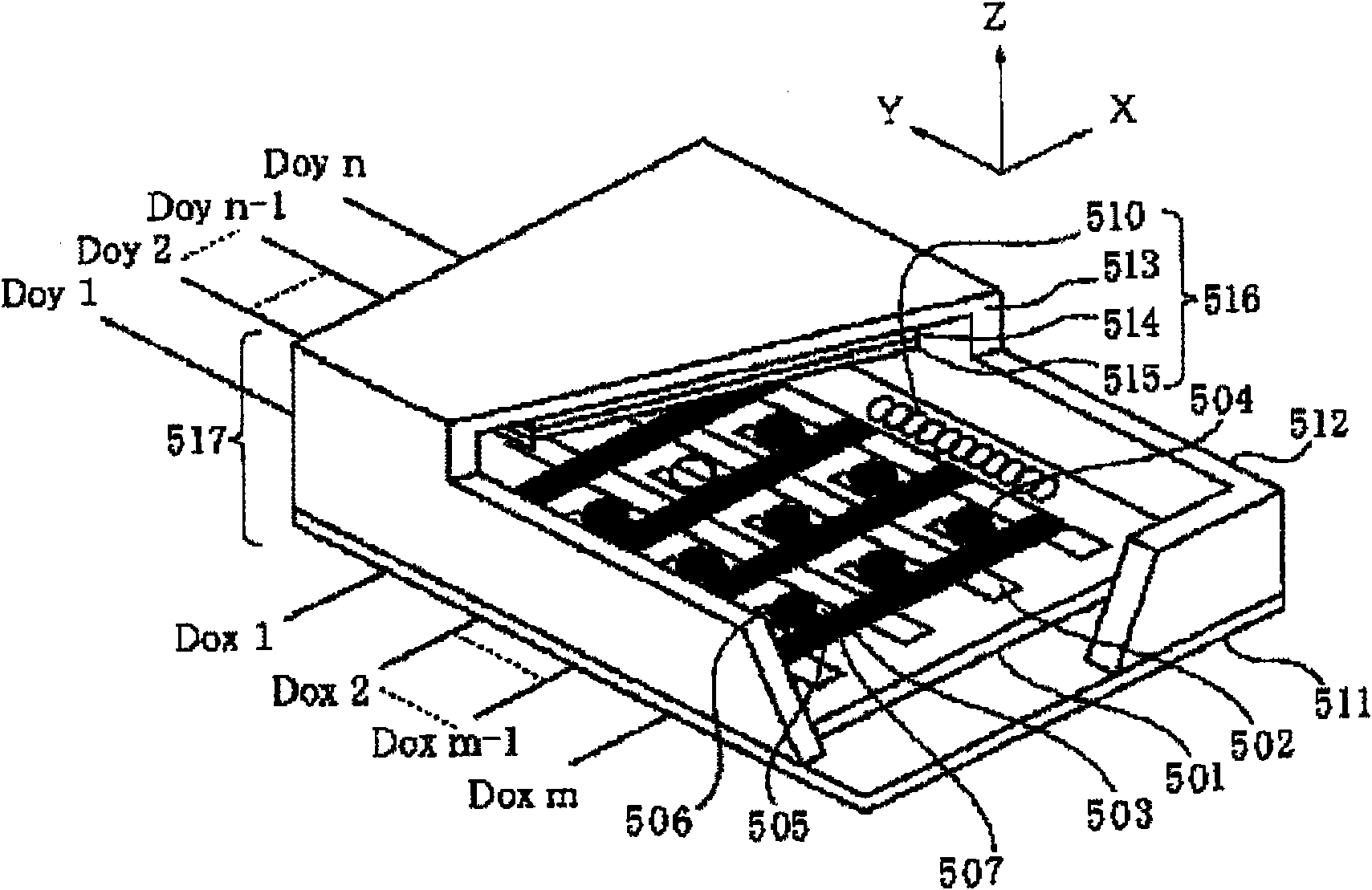

[0057] Embodiments of the present invention will be described below with reference to the drawings. Here, vapor deposition treatment is taken as an example of treatment, but the treatment of the present invention is not limited thereto.

[0058] This application relates to an invention related to a processing device for applying tension to a film-like plane of the mask in which a mask used is formed of a thin-film magnetic material.

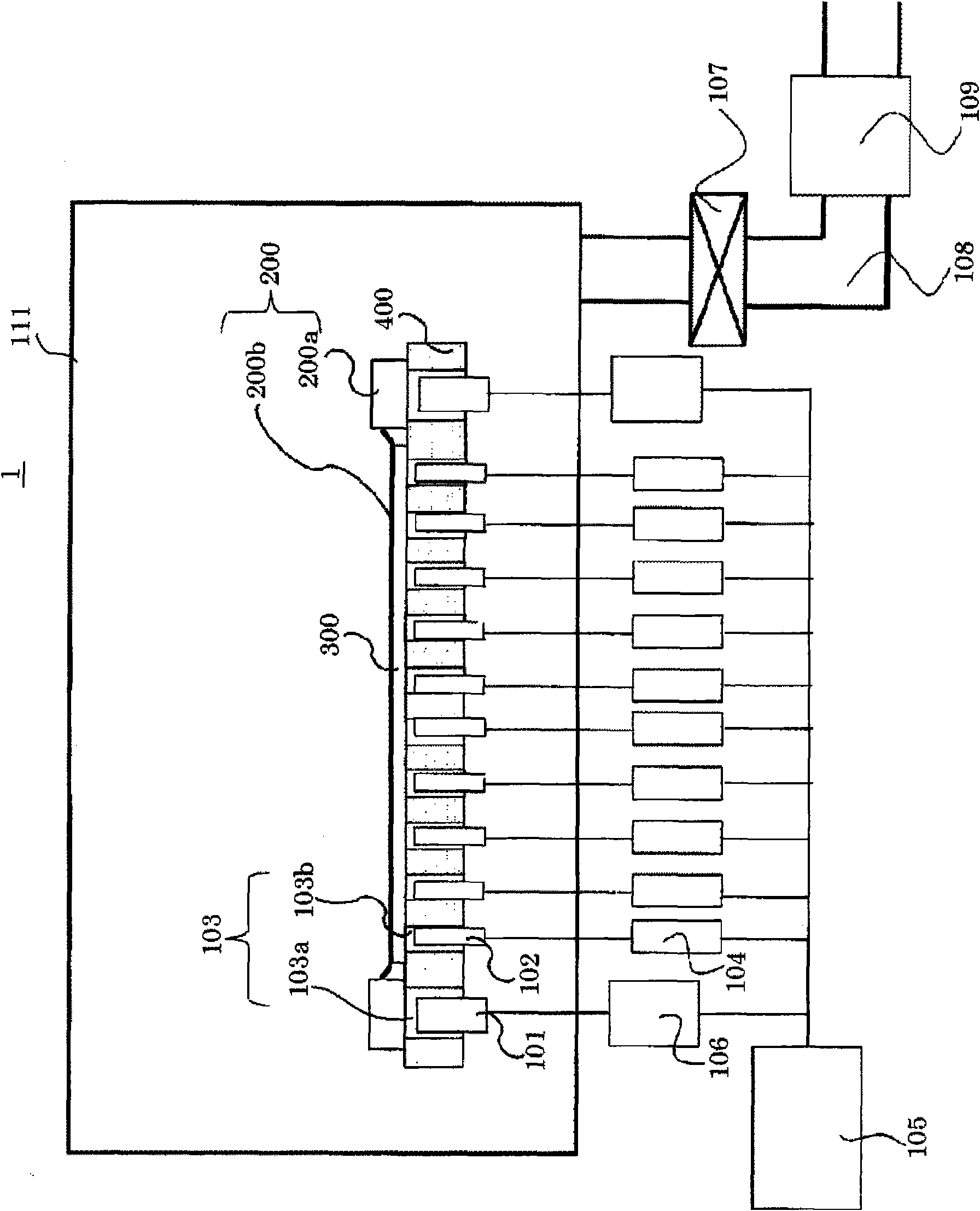

[0059] figure 1 It is a schematic diagram of the processing apparatus of this invention.

[0060] This figure shows the state after the mask fixing operation described later. During vapor deposition, the mask fixing device is turned upside down, and vapor deposition is performed with the processing surface of the mask and the substrate facing downward.

[0061] Reference numeral 1 in the figure is a processing device, reference numeral 101 is a fixing member (second fixing member) of the mask frame 200a, and reference numeral 102 is a mask mem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com