Mercury releasing apparatus for fluorescent lamp

A technology for fluorescent lamps and mercury release, which is applied in the field of materials used in the manufacture of fluorescent lamps, and can solve problems such as easy loss, easy volatilization of mercury, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

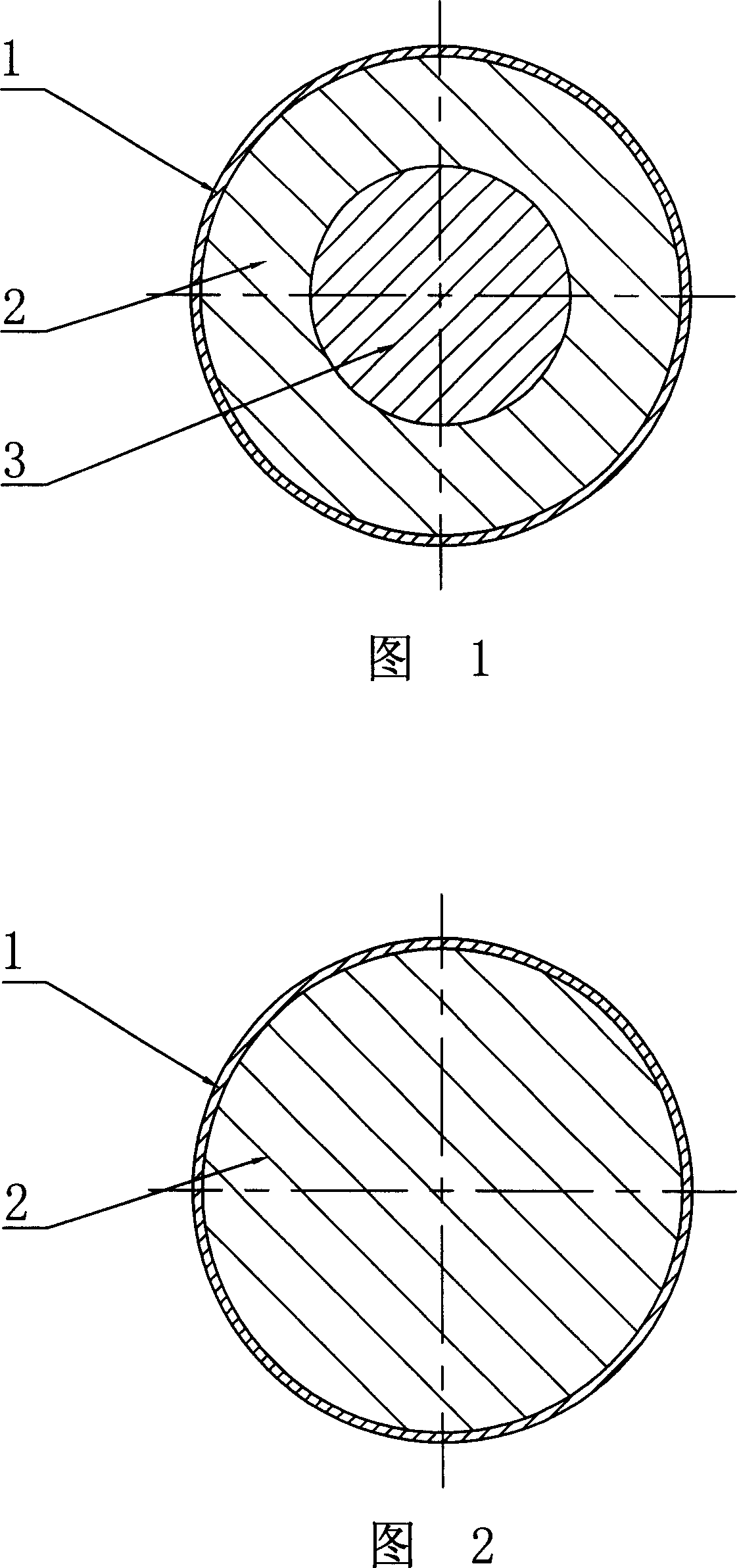

[0014] As shown in Figure 1, it is a mercury release device for fluorescent lamps, which is composed of a coating 1, an amalgam layer 2, and a core 3. The coating 1 is densely covered on the outer surface of the amalgam layer 2, and the core 3 is set on the amalgam. Inside the layer 2; the core 3 is made of a material that is inert to mercury, such as at least one or several of Fe, Co, Ni, Cu, or one of glass, ceramics, and high-temperature-resistant polymers; The core 3 occupies a certain volume to change the external dimensions of the mercury release device. The shape of the amalgam layer 2 is basically close to spherical. The amalgam layer is made of SnZnHg alloy material, and the mass content of mercury in the amalgam layer is 30%; the coating 1 is made of Al 2 o 3 made with a thickness of 50um. The mercury releasing device can be made into a low-power ultraviolet sterilizing lamp, an electrodeless lamp, and the like.

Embodiment 2

[0016] It is another mercury release device for fluorescent lamps, which is composed of a film, an amalgam layer and a core. The film is densely covered on the outer surface of the amalgam layer, and the core is set inside the amalgam layer; the core is made of ceramics, and its volume It can be adjusted arbitrarily, and the external dimensions of the mercury releaser can be changed by occupying a certain volume, so as to facilitate the application of lamps; the shape of the amalgam layer is basically close to spherical, and it is made of AgSnZnHg alloy material, and the mass content of mercury in the amalgam layer is 50%; the coating is made of ZnO 2 Made with a thickness of 80um. The mercury release device can be made into 3U, spiral lamp, ring, 2D lamp and so on.

Embodiment 3

[0018] As shown in Figure 2, it is a mercury release device for the third fluorescent lamp, which is composed of an amalgam layer 2 and a coating 1, the coating 1 is densely covered on the outer surface of the amalgam layer 2, and the amalgam layer 2 is made of BiSnZnHg alloy material , the mass content of mercury in the amalgam layer 2 is 40%; the covering film 1 is made of fluorescent powder with a thickness of 50nm. Can be made into 2D, 2U and other compact lamps.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com