Patents

Literature

50results about How to "Novel composition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fluorinated carbon for metal/fluorinated carbon batteries

InactiveUS20040013933A1Effectively wettedMaintain good propertiesOrganic electrolyte cellsActive material electrodesFiberCarbon fibers

A novel cathode composition for use in a metal / fluorinated carbon battery is produced by mixing fluorinated carbons made from anisotropic and isotropic carbon, where the anisotropic carbon is carbon fiber and the isotropic carbon is graphite. This cathode composition has higher specific capacity and higher discharge rate capability than commonly used industrial products made using fluorinated petroleum cokes or similar materials. In addition this composition undergoes much less swelling (increase in volume) during discharge when compared with the commonly used fluorinated carbon.

Owner:SANDIA

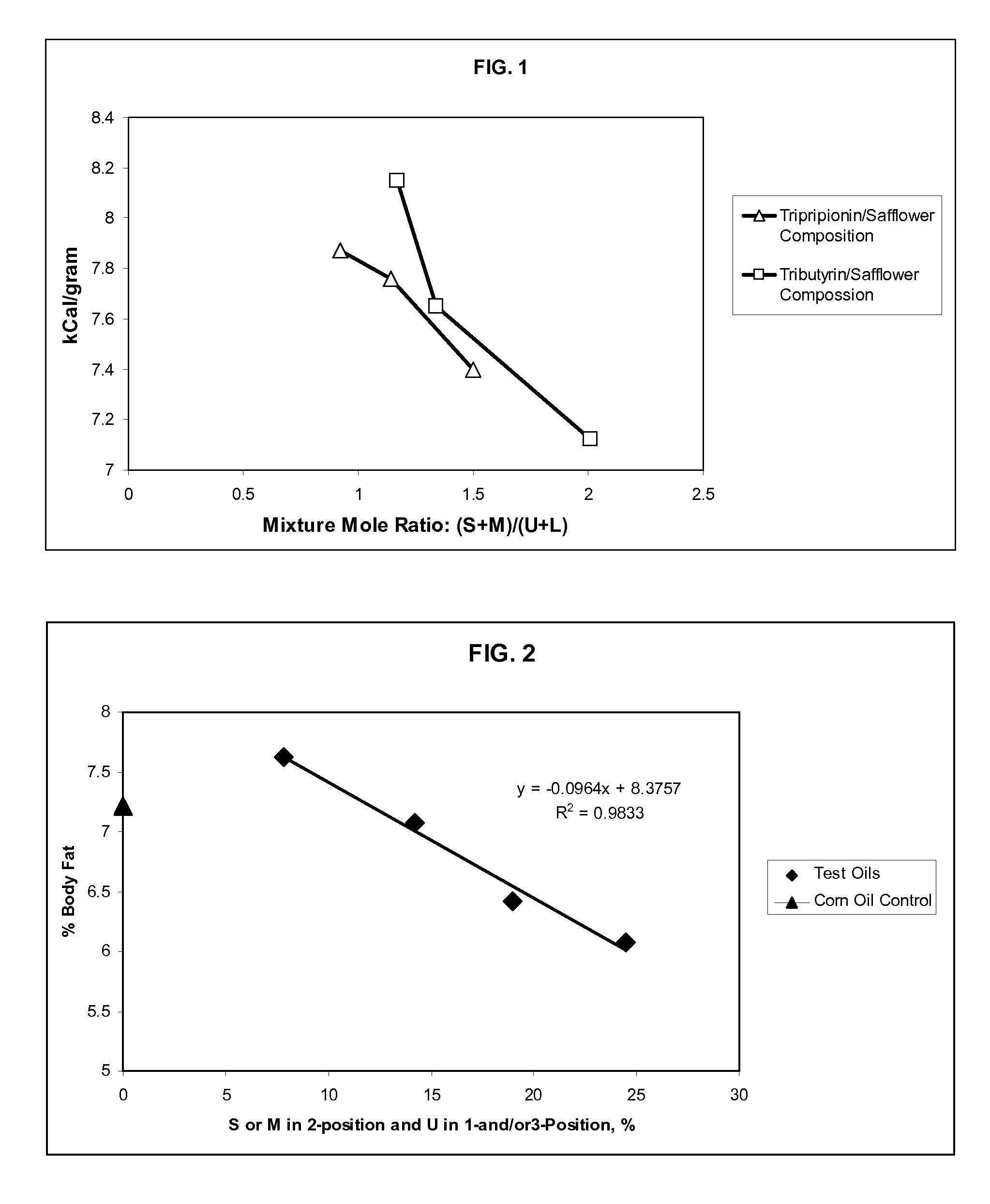

Structured Lipid Compositions And Methods Of Formulation Thereof

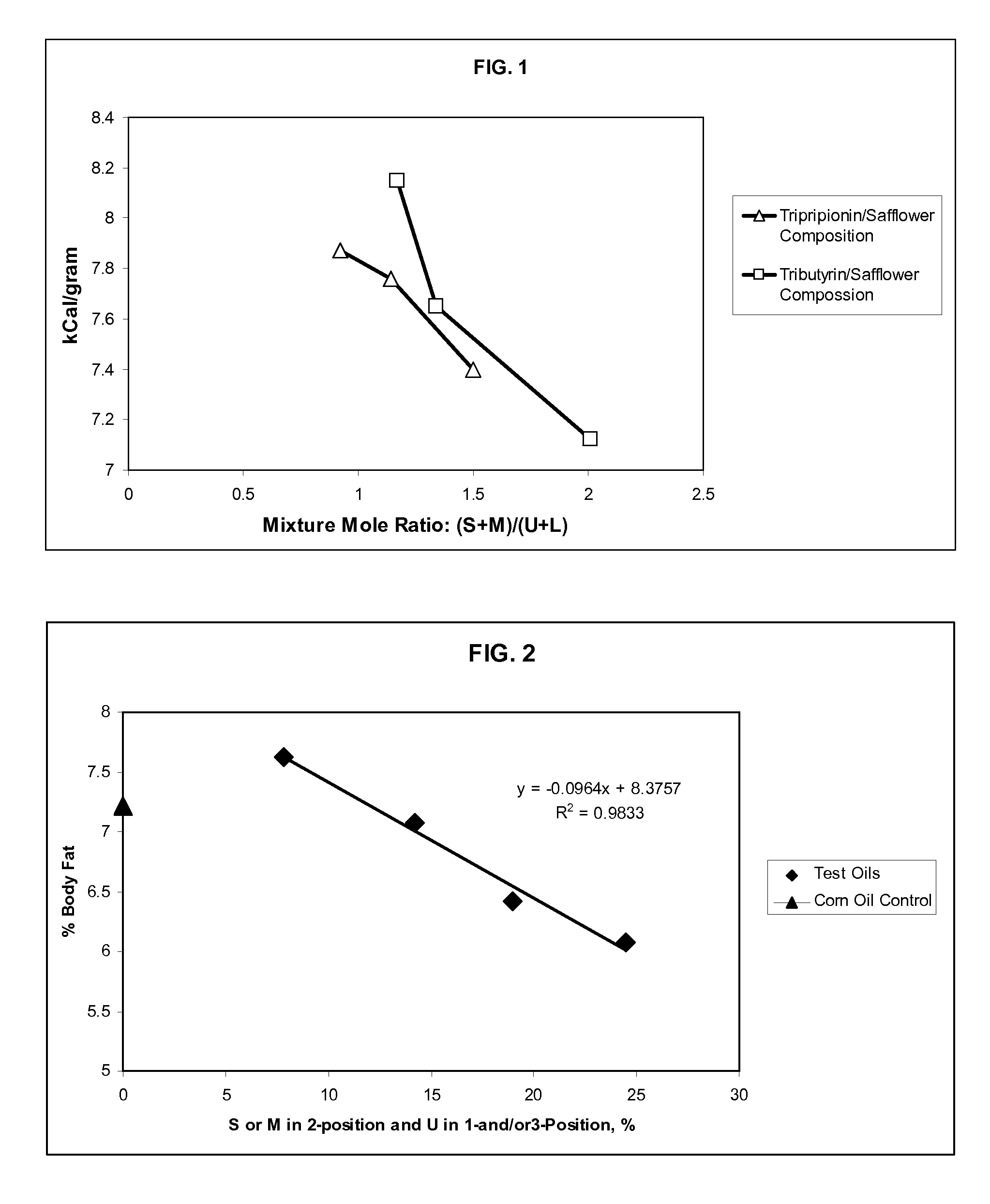

ActiveUS20090123634A1High energyIncrease valueFood preparationEdible oils/fats with aqeous phaseTriglycerideWeight management

Lipid compositions comprising specific mixtures of edible synthetic triglycerides are provided that are useful in formulating food products having highly desirable dietary benefits. The novel lipid compositions allow simultaneous access to highly desirable dietary benefits such as delivery of calorie reduction, weight management, health benefits, or any combination thereof, and they also may be formulated trans-fatty acid free.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

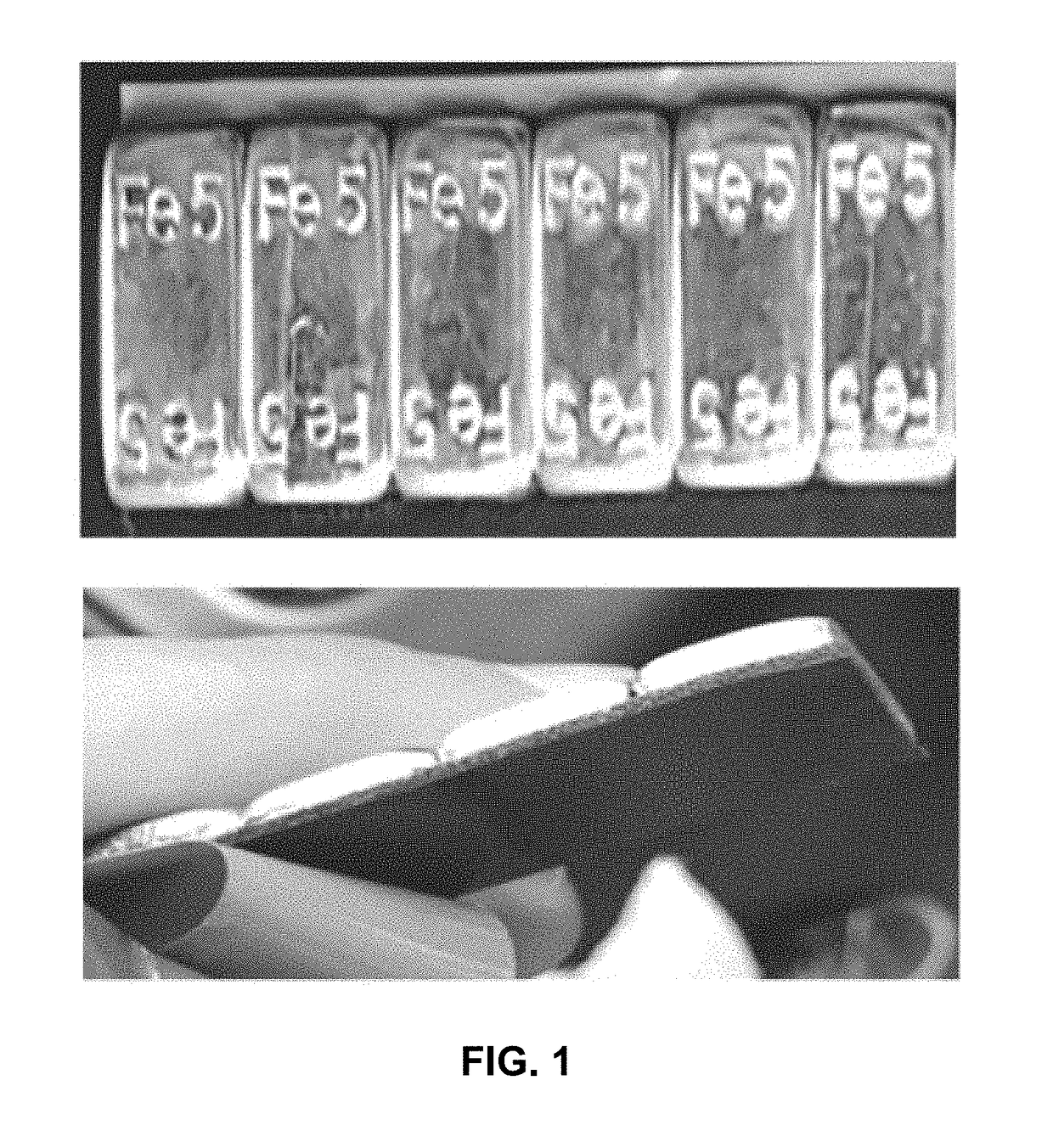

Investment casting shells having an organic component

ActiveUS20120148736A1Novel compositionImprove breathabilityFoundry mouldsCeramic shaping apparatusInvestment castingCellulose fiber

A composition for use in investment casting shells and a method of making the composition is disclosed. The composition includes an engineered binder and a refractory flour. The engineered binder comprises a siliceous material and at least one organic component selected from: at least one type of wood pulp; at least one species of cellulose fiber; and combinations thereof. A particular benefit of the investment shell composition is simultaneously increased permeability and load bearing capacity.

Owner:ECOLAB USA INC

Ointment with clindamycin and metronidazole and method for preparing the same

InactiveCN1732969ANon-irritatingNovel compositionAntibacterial agentsOrganic active ingredientsParaffin waxPolyethylene glycol

Disclosed is an ointment using the salts or esters of clindamycinum and metronidazole as the active constituents, the constituents of the ointment include (by weight percent): clindamycinum or its medicinal salts or its esters 0.25-5%, metronidazole 0.2-4%, oleaginous base 10-40%, water soluble base 5-50%, and balancing water, wherein the oleaginous base is selected from stearinic acid, glyceryl monostearate, paraffin wax, fluid wax, Vaseline, lanoline, cetyl alcohol, stearyl alcohol, Span series, bee wax, animal or vegetable fat, the water soluble base is selected from glycerin, propylene glycol, sorbitol, polyethylene glycol series, Tween series, sodium dodecylsulfate, dimethyl sulfoxide, triethanolamine, and ethanol.

Owner:王卫阳

Fat-reduced soybean protein material and soybean emulsion composition, and processes for production thereof

ActiveUS20130078363A1High phytosterol contentLess peculiar tasteProtein composition from vegetable seedsVegetable proteins working-upOrganic solventEmulsion

Disclosed are: a fat-reduced soymilk having a reduced fat content, which is produced by separating a fat from a fat-containing soybean efficiently without relying on an organic solvent; and a novel fat-rich soybean material. Specifically disclosed are: a fat-reduced soybean protein material characterized by containing a protein and a carbohydrate at a total content of 80 wt % or more in terms of dried form content, containing a fat (as an extract from a chloroform / methanol mixed solvent) at a content of less than 10 wt % relative to the content of the protein, and containing campesterol and stigmasterol (as plant-derived sterols) at a total content of 200 mg or more relative to 100 g of a fat; and a soybean emulsion composition characterized by containing a protein at a content of 25 wt % or more in terms of dried form content, containing a fat at a content of 100 wt % or more in terms of dried form content relative to the content of the protein in terms of dried form content, and having an LCI value of 60% or more.

Owner:FUJI OIL CO LTD

Cleaner composition consisting of alkalic agent, sodium polyacrylate and sterilizer and cleaning method using the same

InactiveUS20090050179A1Novel compositionInorganic/elemental detergent compounding agentsDetergent mixture composition preparationIonIon exchange

The present invention relates to a cleaner composition comprising an alkalic agent, sodium polyacrylate as ion exchanger, a sterilizer and water, and a cleaning method using the same. More particularly, the present invention relates to a cleaner composition comprising 5 to 15 weight % of an alkalic agent, 5 to 20 weight % of sodium polyacrylate having a molecular weight 4,000 to 10,000 as ion exchanger, 0.5 to 30 weight % of a sterilizer, and water as remainder, and a cleaning method using the same. The cleaner composition of the present invention provides the effect of removing fats, proteins, minerals, etc. comparable to or better than that of the conventional cleaner, and can reduce cleaning time and cost because the cleaning process is simplified. Hence, it can be utilized to clean milking machines or other appliances.

Owner:REPUBLIC OF KOREA (MANAGEMENT RURAL DEV ADMINISTRATION) +1

Toughened dried powder coating material

InactiveCN1380367ANovel compositionEasy to makeCellulose coatingsPowdery paintsMethyl celluloseMaterials science

The present invention relates to a toughened dry power paint made up by using (wt%) 0.44-11.01% of hydroxyethyl cellulose, 0.44-11.01% of methyl cellulose, 16.59-55.07% of shuangfei powder, 5.53-33.04% of light calcium carbonate powder, 11.06-44.05% of sierozem powder, 8.30-33.04% of talcum powder and 2.77-22.03% of white cement through the processes of respectively pulverizing, mixing, stirring and packaging to obtain finished product.

Owner:艾国友

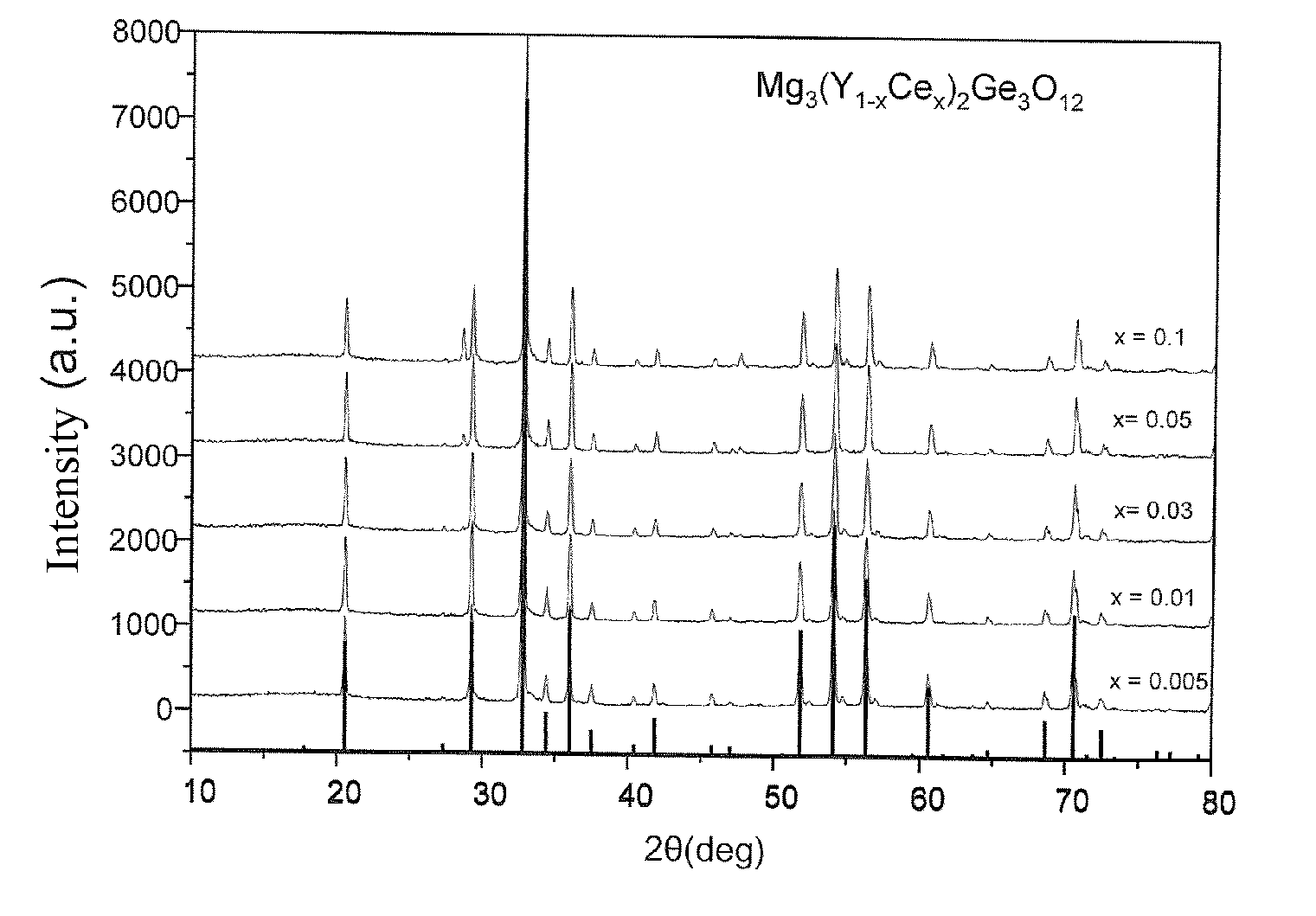

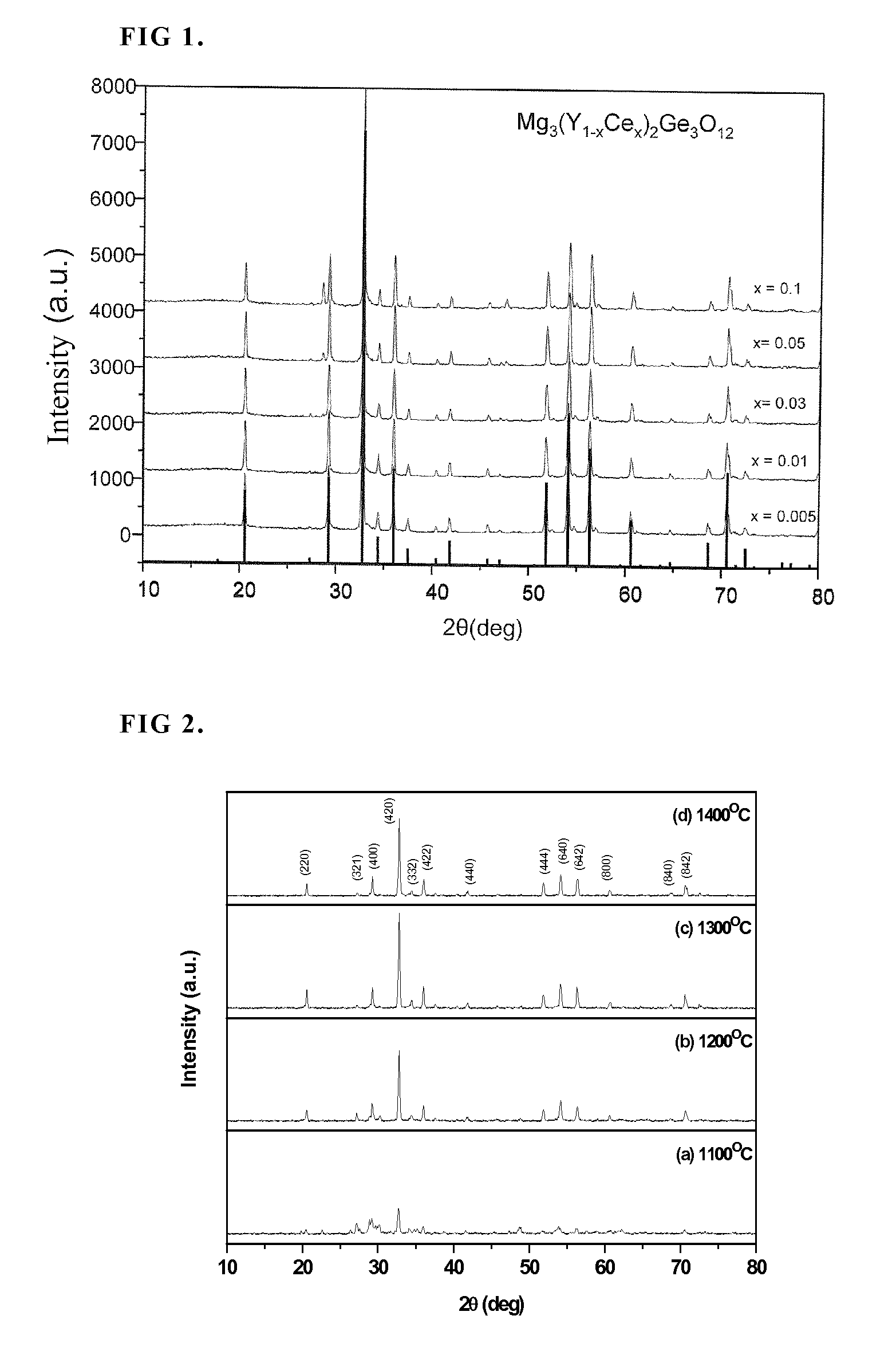

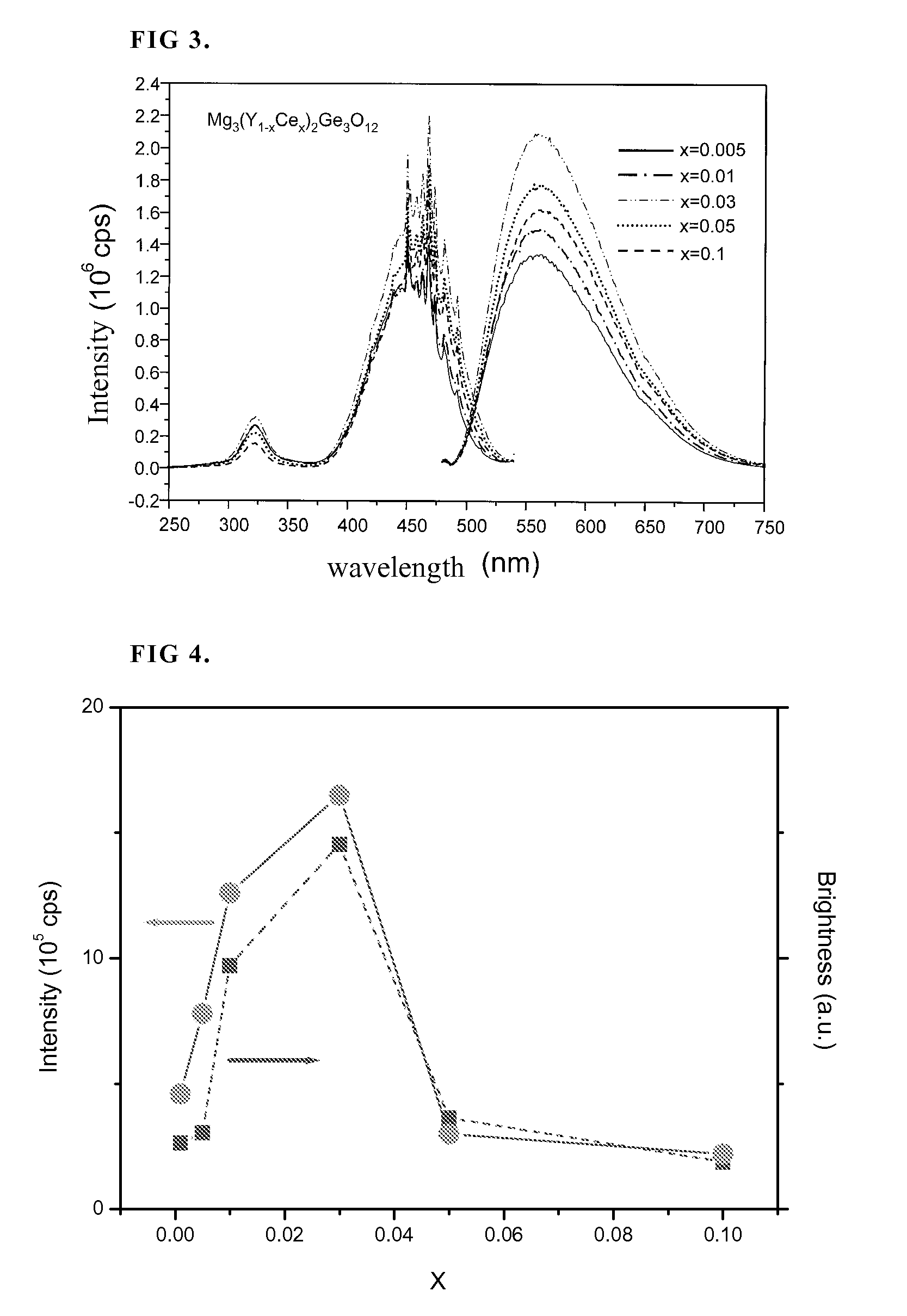

Novel phosphor and fabrication of the same

InactiveUS20090026477A1Stable materialNovel compositionGermanium compoundsGas discharge lamp usagePhosphorPhosphorus

The present invention provides a novel phosphor represent by the following general formula:Am(B1-xCex)nGeyOz wherein A is at least one element selected from Mg and Zn; B is at least one element selected from the group consisting of La, Y and Gd; each of m, n, y and z is the number larger than 0 provided that 2m+3n+4y=2z; and x is in the range 0.0001≦x≦0.8.

Owner:NAT CHIAO TUNG UNIV

Composition of cationic phospholipid nanoparticles for effective delivery of nucleic acids

InactiveUS20100203112A1Reduce deliveryLow cytotoxicityOrganic active ingredientsGenetic material ingredientsNanoparticleCholesterol

The present invention provides a cationic phospholipid liposome composition comprising 1,2-dioleoyl-sn-glycero-S-ethylphosphocholine (EDOPC), 3β-[N—(N′,N′-dimethylaminoethane)-carbamoyl] cholesterol (DC-cholesterol) and 1,2-diphytanoyl-sn-glycero-3-phosphoethanolamine (DPhPE), a liposome-nucleic acid complex which is capable of forming a complex therewith, and a pharmaceutical composition comprising the same. The cationic phospholipid liposome of the present invention is highly effective for intracellular delivery of nucleic acids and reduction of cytotoxicity, as compared to conventional liposome products. Therefore, the present invention can be useful for gene therapy via intracellular delivery of a desired material to target cells.

Owner:KOREA UNIV IND & ACADEMIC CALLABORATION FOUND +1

Black coarse cereal powder with functions of kidney tonifying and hair blackening

InactiveCN108323719APromote circulationNovel compositionFood freezingFood ingredient as colourVomit blackFood material

The invention discloses black coarse cereal powder with functions of kidney tonifying and hair blackening, wherein the raw materials comprise, by weight, 1-5 parts of black Chinese wolfberry, 1-10 parts of Polygonatum sibiricum, 10-25 parts of black sesame, 10-15 parts of black rice, 1-30 parts ofblack bean, 1-10 parts of Chia seed, 1-10 parts of black fungus, and 1-10 parts of black mulberry. According to the present invention, the black coarse cereal powder is prepared by selecting the eight black food materials through scientific compatibility, wherein the formula is novel, the functions are significant, and various raw materials can provide the effects; and the black coarse cereal powder has effects of kidney tonifying, hair blackening, qi enriching, blood enriching, blood circulationimproving, immunity enhancing, swelling subsiding, qi descending, lung moistening, stomach benefiting, spleen strengthening, sleep improving, beautifying, face nourishing and the like, further has characteristics of convenient eating, good taste, excellent taste and low cost, is suitable for ordinary consumers, and has good application prospects.

Owner:ANHUI QIUGUO FOOD

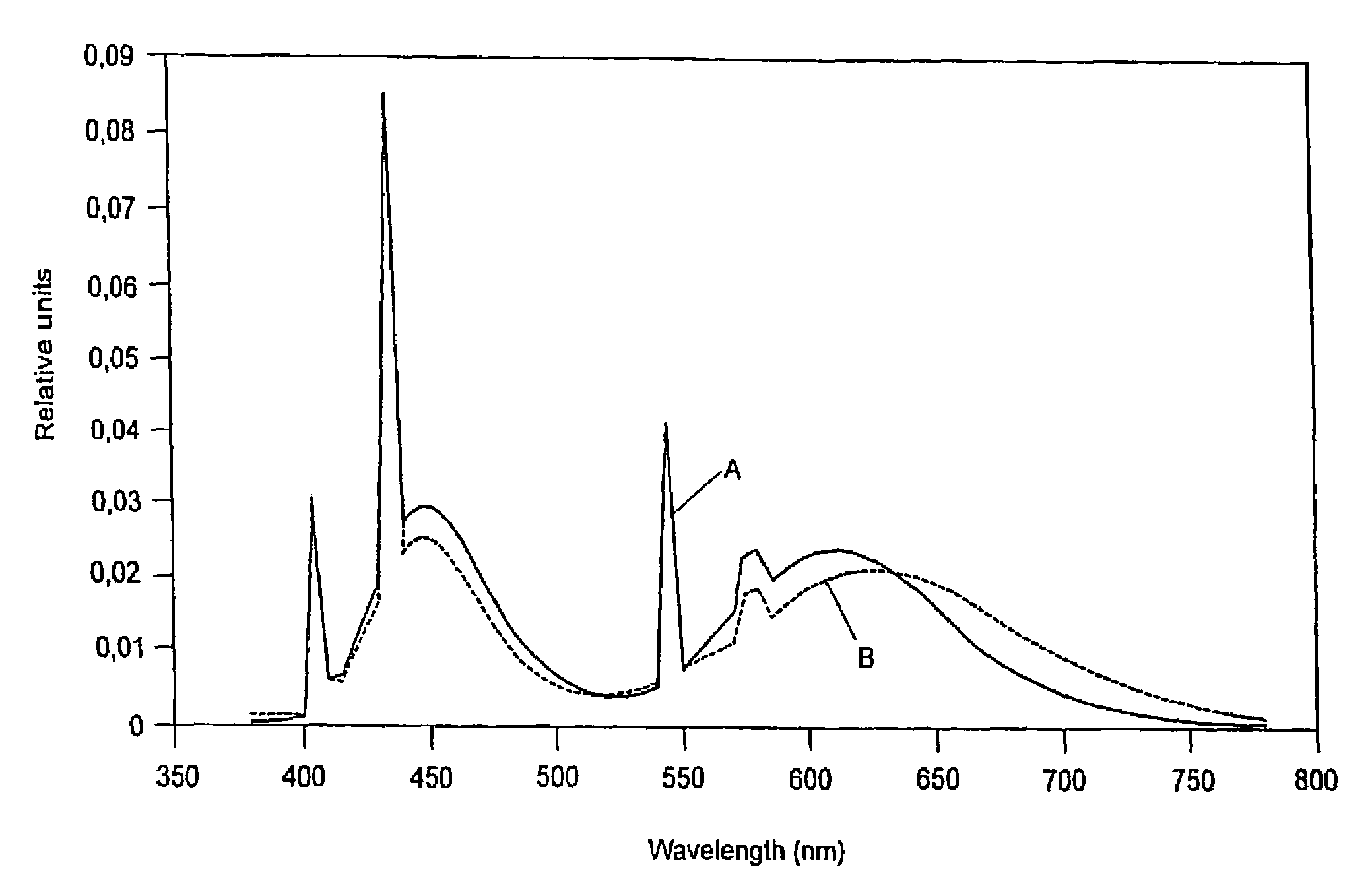

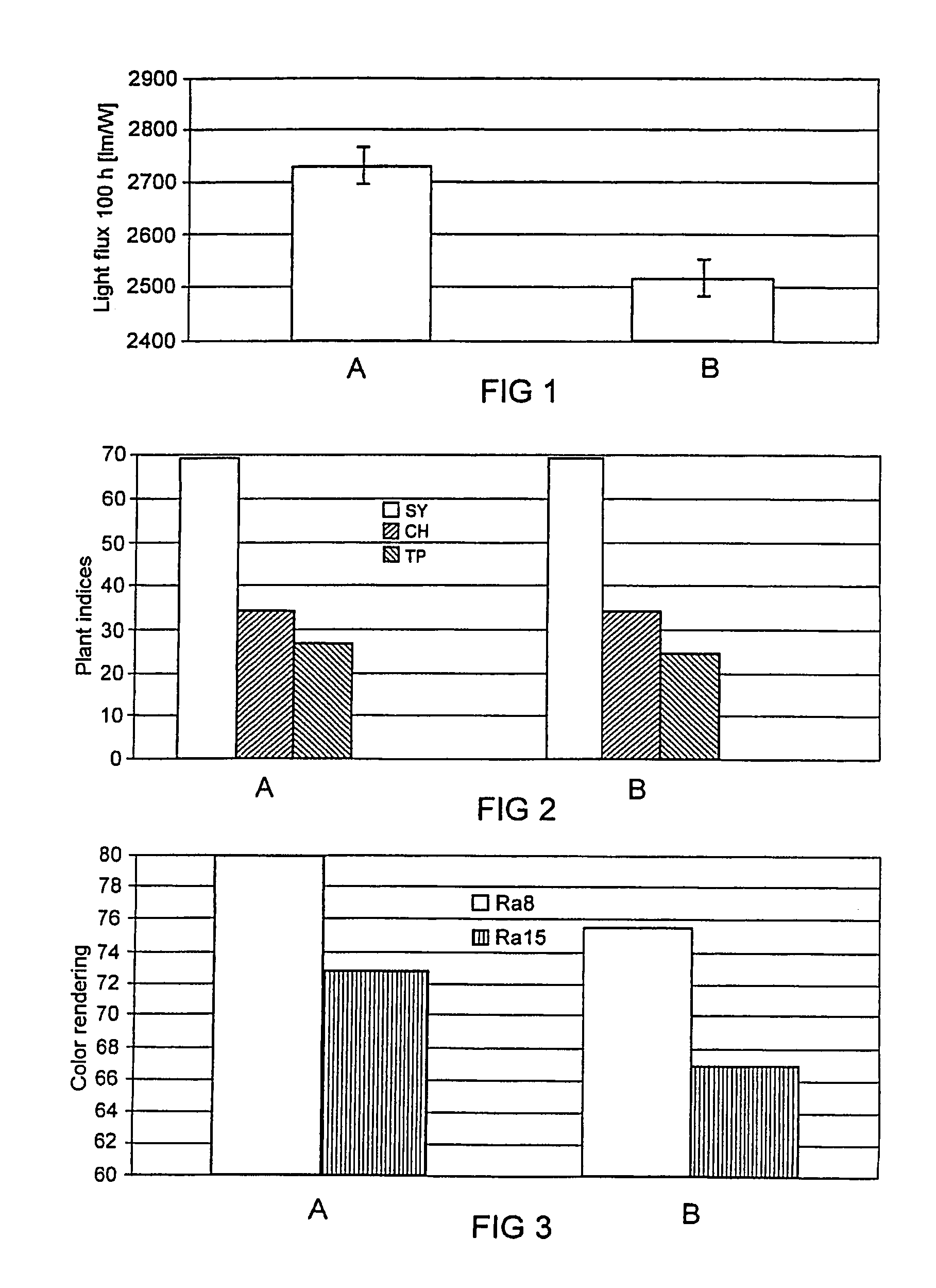

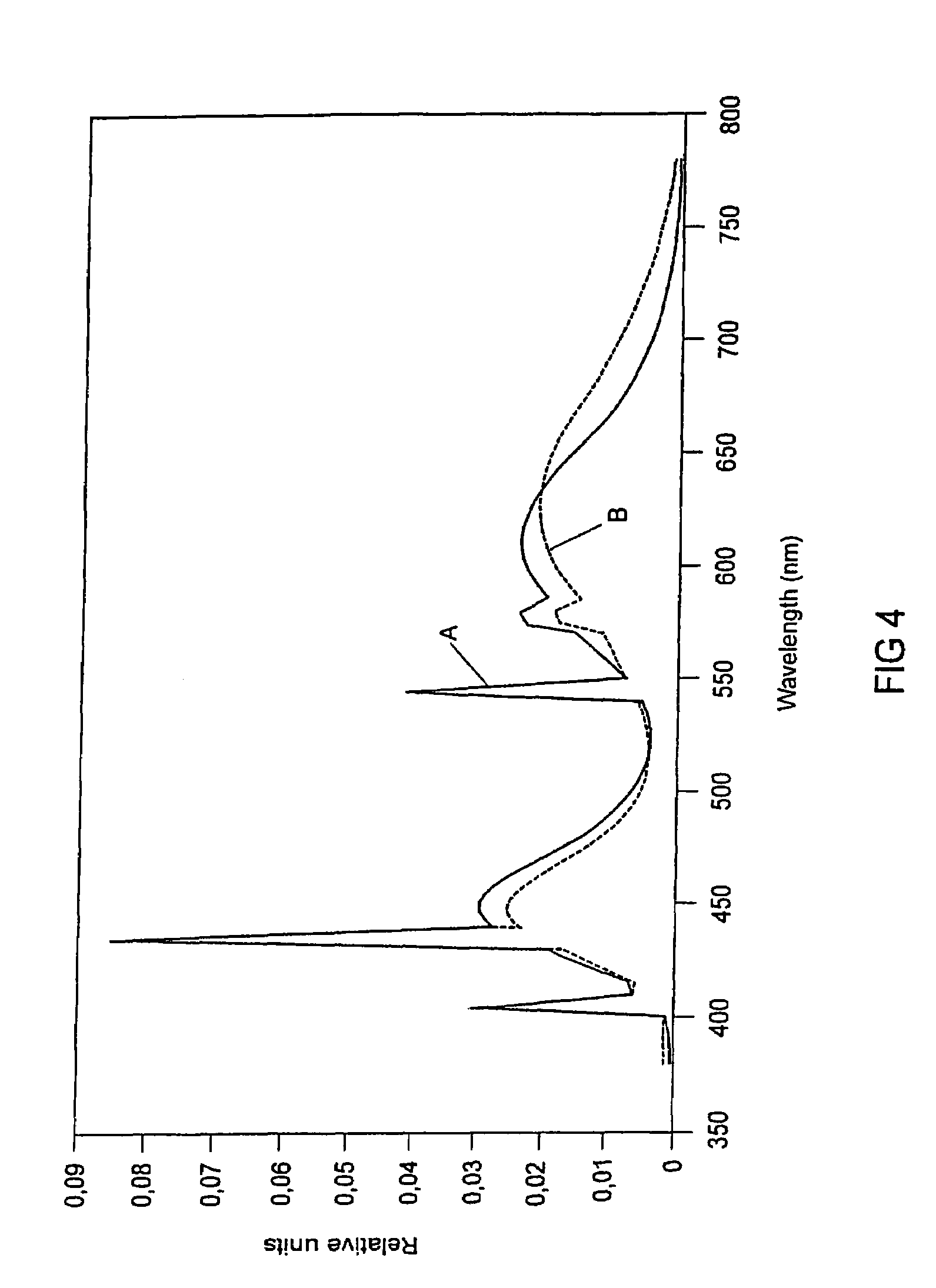

Phosphor coating composition for a mercury low-pressure discharge lamp for illuminating plants

InactiveUS7259509B2Novel compositionDischarge tube luminescnet screensLamp detailsNoble gasFluorescence

Owner:LEDVANCE GMBH

Electromagnetic induction heat emitting paint and its preparing method

The electromagnetic inducing heating paint consists of silver hydroxide 28.4 wt%, silver oxide 25.2 wt%, nickel oxide 0.5 wt%, glass powder 4.1 wt% and adhesive 41.8 wt%. The preparation process of electromagnetic inducing heating paint includes successive material pre-treatment, weighing, ball milling and mixing. After the electromagnetic inducing heating paint is painted onto the surface of ceramic or glass utensil and high temperature sintered, film is formed and attached firmly. The film is induced to heat in electromagnetic furnace, and compared with heating metal material, the film of the present invention has certain heat insulating function. During use, the electromagnetic inducing heating paint has no denaturation and falling off.

Owner:陈梓平

Graphene oxide/polymer composition for manufacturing inner liners and inner tubes of tires and method for preparing the same

ActiveUS20140309331A1Increase flexibilityImprove adhesionOther chemical processesSpecial tyresEpoxyPolymer science

A composition for manufacturing the inner liners and inner tubes of tires, and a method of preparing the same. The composition includes the following two phases: A) a continuous phase of a composition of graphene oxide / rubber including graphene oxide, a reactive rubber, and a solid rubber; and B) a dispersion phase of an epoxy natural rubber or a thermoplastic resin. In the composition of graphene oxide / rubber, the graphene oxide leads to low gas permeability and remarkably reinforces the rubber composition. The epoxy natural rubber or thermoplastic resin is dispersed in the composition of graphene oxide / rubber and forms an islands-in-the-sea structure. The composition has low gas permeability, excellent mechanical properties, and flexibility, and is adhesive to adjacent rubber.

Owner:BEIJING UNIV OF CHEM TECH

Man-made vitreous fibres

Man-made vitreous fibers have a solubility of pH 4.5 of at least 20 nm per day and a melt viscosity of 10 to 70 poise at 1400° C. Novel fibers contain at least 18% Al2O3. Particular products include external wall insulation or cladding and pipe sections. A composition for making suitable fibers may be selected by determining solubility at pH 4.5 or in macrophage.

Owner:ROCKWOOL INT AS

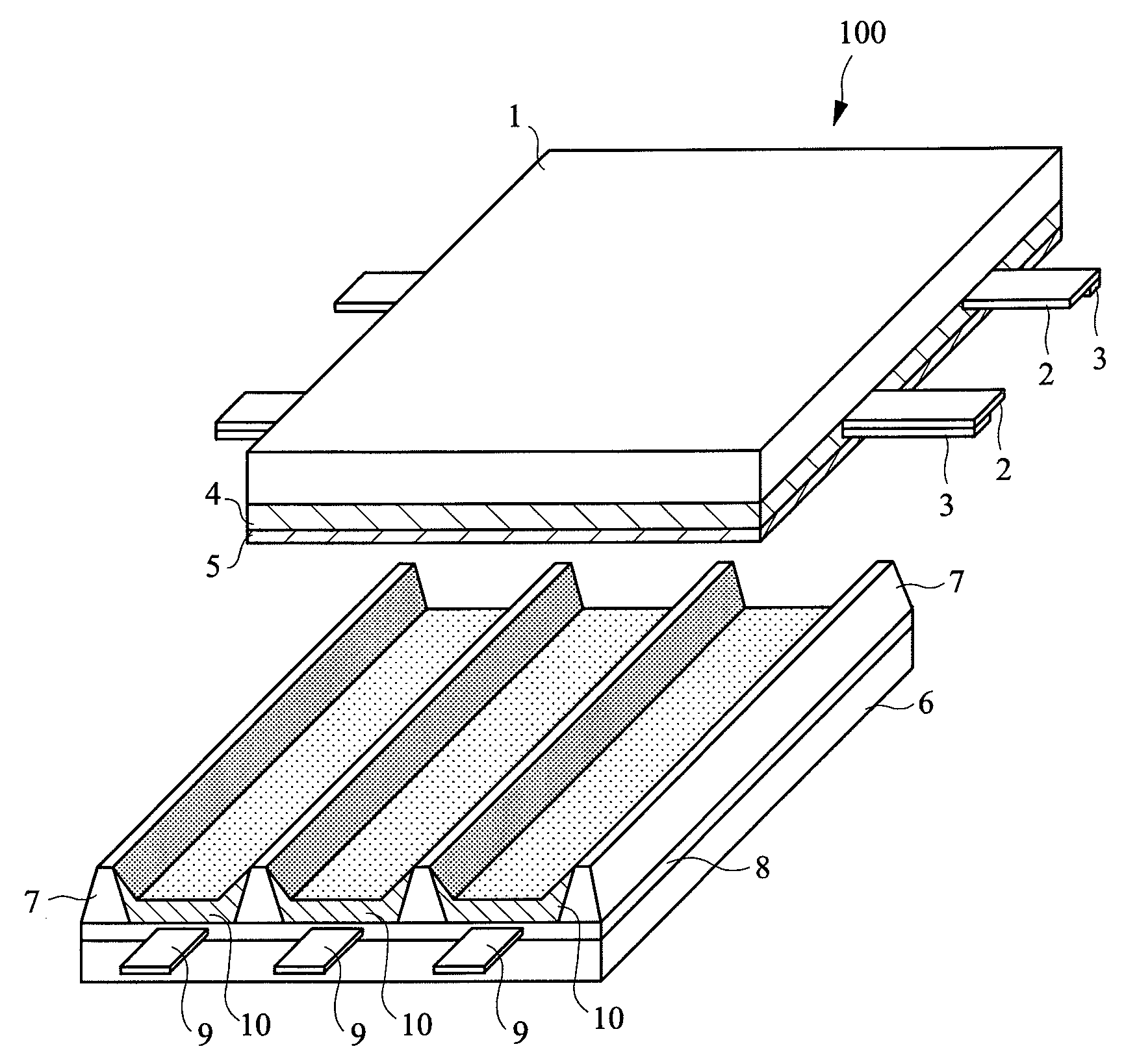

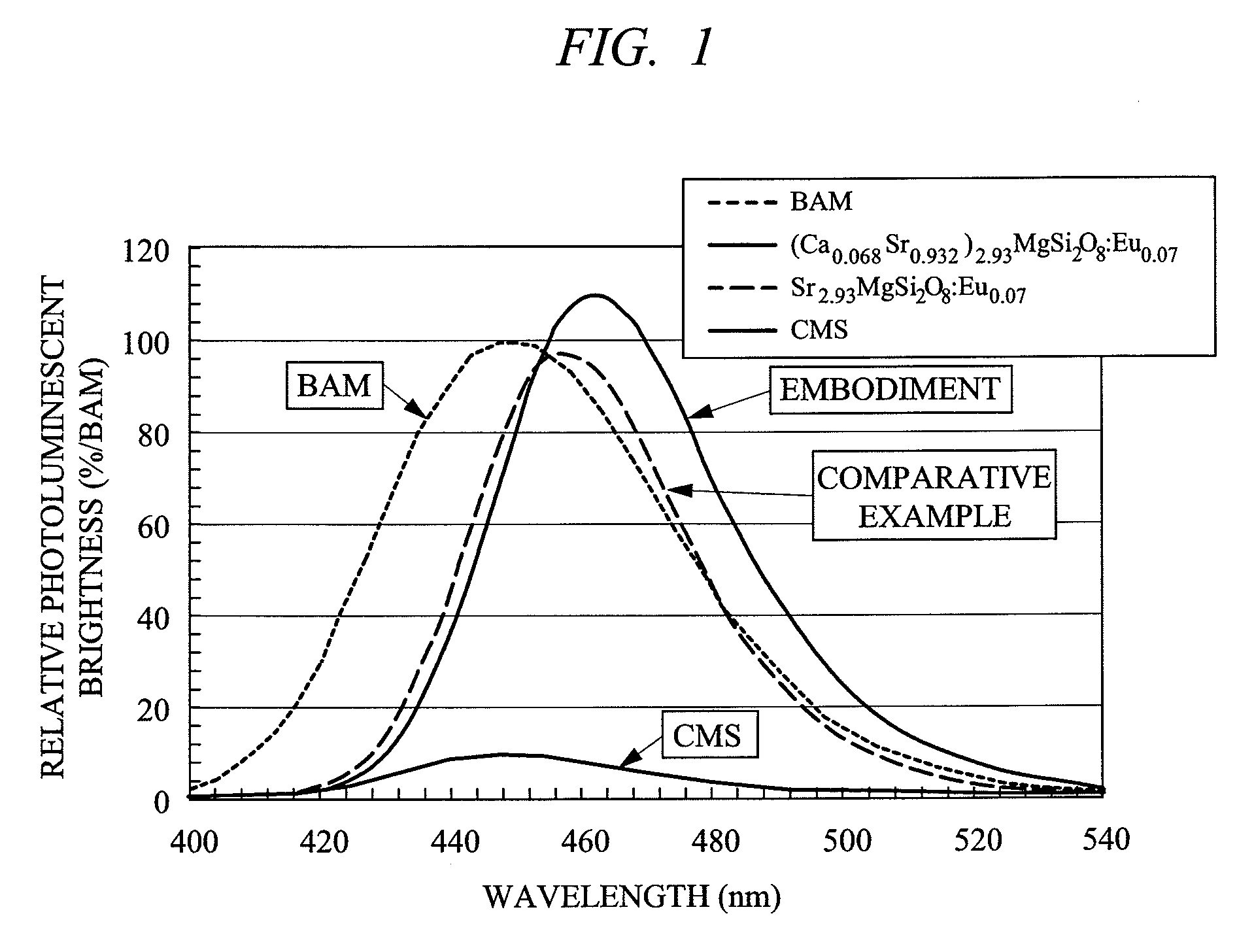

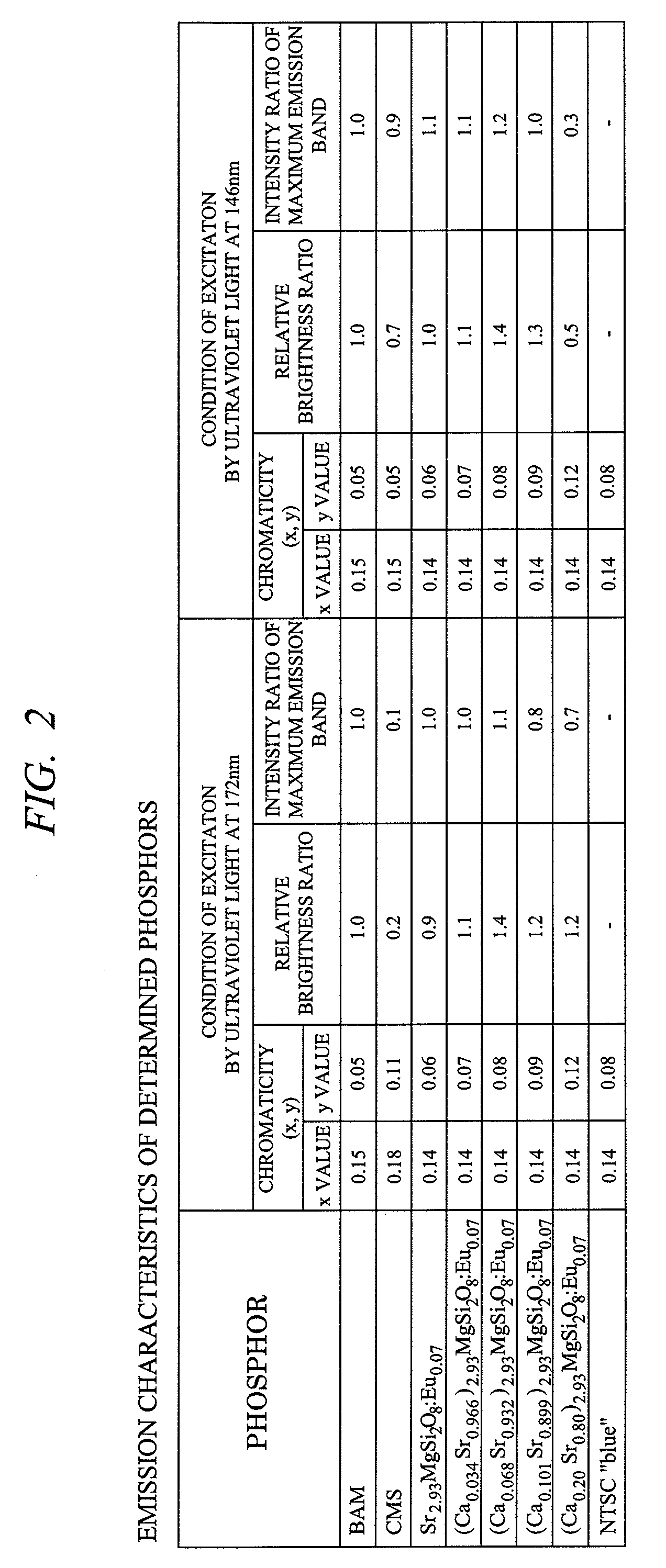

Plasma display device and light emitting device

InactiveUS20080048547A1High Brightness FeaturesImprove luminous efficiencyAddress electrodesSustain/scan electrodesFluorescencePlasma display

A plasma display panel including a discharge gas for generating ultraviolet light as a result of electric discharge, and a phosphor layer containing a phosphor for emitting light upon excitation by ultraviolet light is provided. The phosphor contains a novel Eu-activated silicate phosphor represented by (CaxM11-x)3-e.M2.Si2O8: Eue. In the formula, M1 is at least one element selected from the group consisting of Sr and Ba; M2 is at least one element selected from the group consisting of Mg and Zn; x is the mole fraction of the component Ca satisfying the condition of 0<x≦0.2, and e is the mole fraction of Eu satisfying the condition of 0.001≦e≦0.2.

Owner:HITACHI LTD +1

Transition layer slurry for membrane electrode and preparation method thereof, and membrane electrode and preparation method thereof

The invention provides transition layer slurry for a membrane electrode. The transition layer slurry comprises an ionomer, heteropolyacid, an anti-reverse oxide and a solvent, wherein the mass of theionomer is 5-20%, the mass of the heteropolyacid is 0-15% of the mass of the ionomer and does not include 0, the mass of the anti-reverse oxide accounts for 0-10% of the mass of the ionomer and does not include 0, the solvent is composed of deionized water, ethanol and ethylene glycol, the mass of the ethylene glycol accounts for 5-10% of the total mass of the solvent, the sum of the mass of the deionized water and the mass of the ethanol accounts for 90-95% of the total mass of the solvent, and the deionized water and the ethanol are mixed in any proportion. The invention further provides a preparation method of the transition layer slurry. Meanwhile, the invention further provides a membrane electrode prepared from the transition layer slurry and a preparation method of the membrane electrode. The transition layer slurry for the membrane electrode is simple and novel in composition and simple in preparation method, and the membrane electrode prepared from the transition layer slurrycan eliminate a gap between a catalyst layer and a proton exchange membrane, improve the proton conduction performance and reduce the anti-pole effect.

Owner:先进储能材料国家工程研究中心有限责任公司

Stable Fat-soluble Active Ingredient Composition, Microcapsule and Process Of Preparation and Use Thereof

ActiveUS20180207277A1Eliminate hidden dangersNovel compositionCosmetic preparationsHydrocarbon active ingredientsOxidation resistantVitamin C-palmitate

The present invention provides a stable fat-soluble active ingredient composition, microcapsule and process for preparation and use thereof. The fat-soluble active ingredient composition comprises tocopherol, vitamin C palmitate and a fat-soluble active ingredient; wherein the weight ratio of tocopherol to vitamin C palmitate is 2-8:1, the weight ratio of a combination of tocopherol with vitamin C palmitate to the fat-soluble active ingredient is 7-13:100. The present invention obtains a novel antioxidant composition without hidden dangers for improving the stability of the fat-soluble active ingredient by screening a combination of antioxidants and adjusting their proportion and dose.

Owner:ZHEJIANG MEDICINE CO LTD XINCHANG PHAMACEUTICAL FACTORY +1

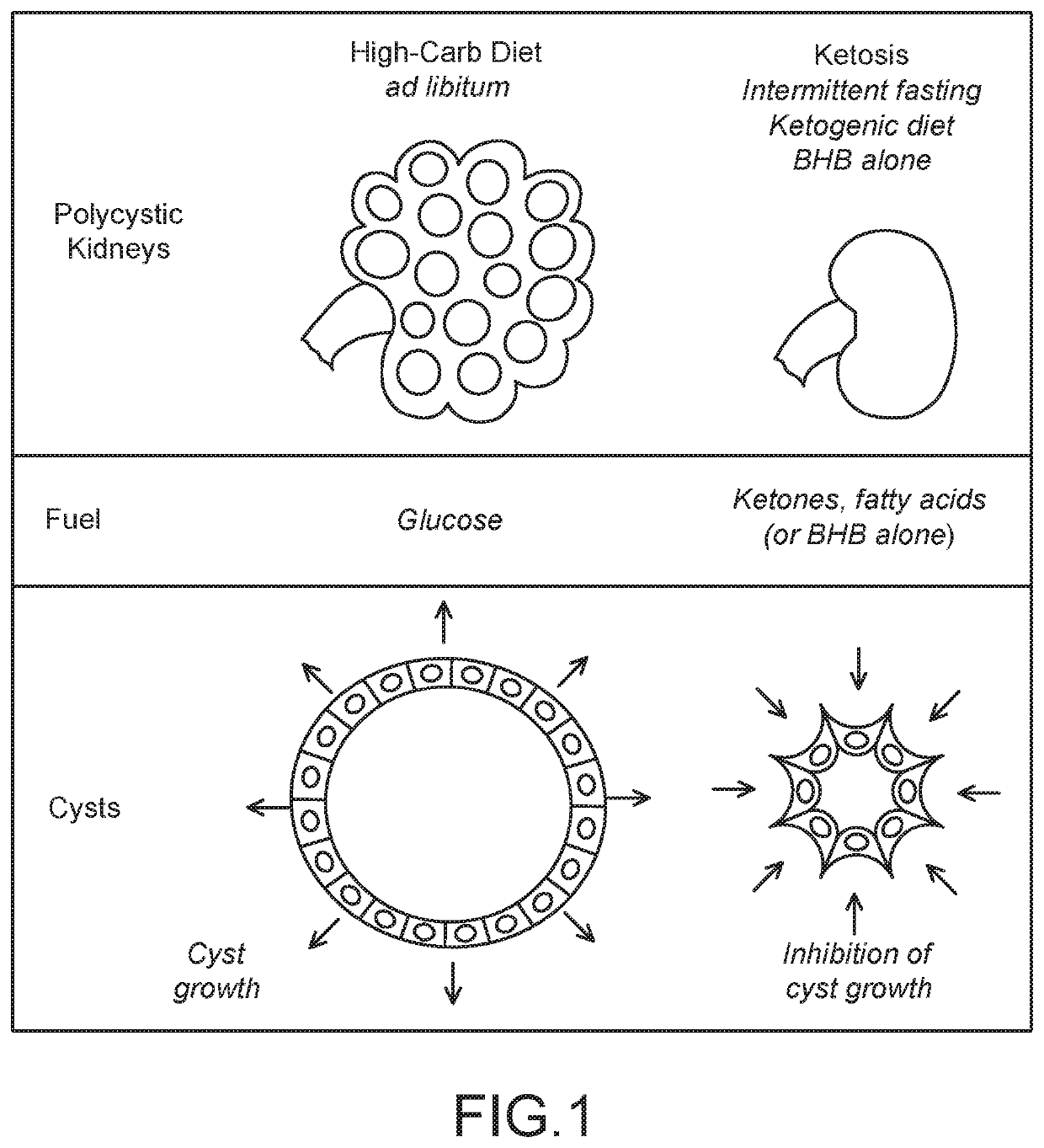

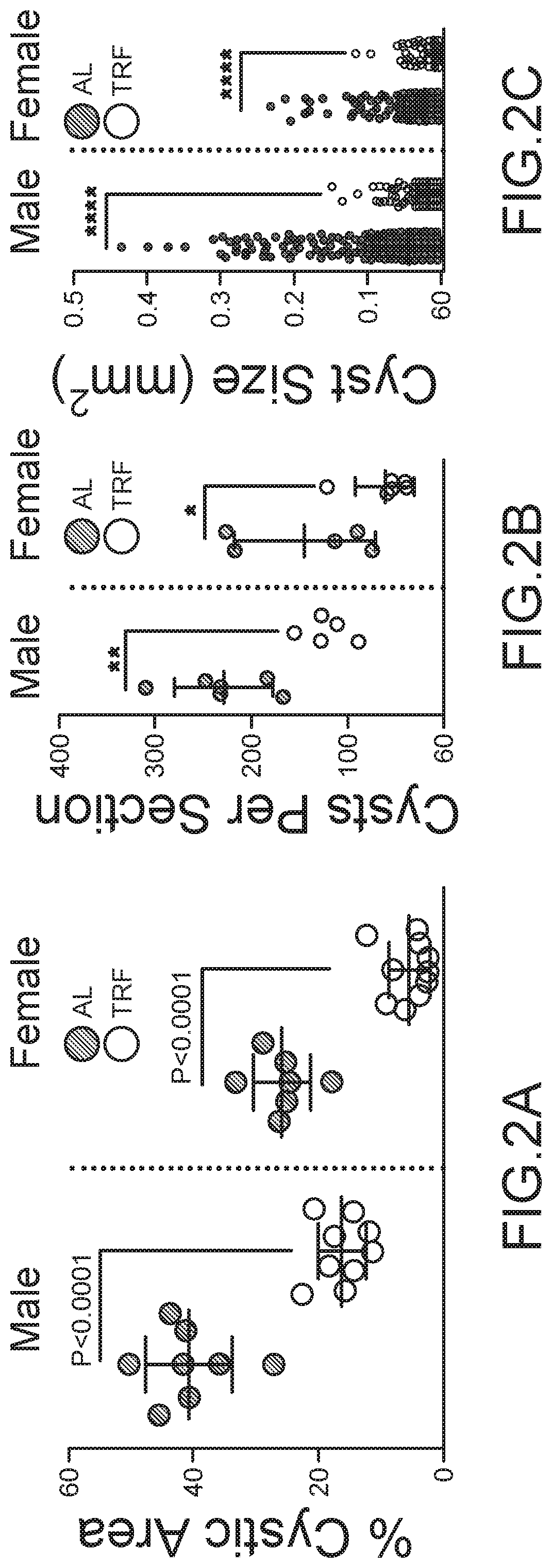

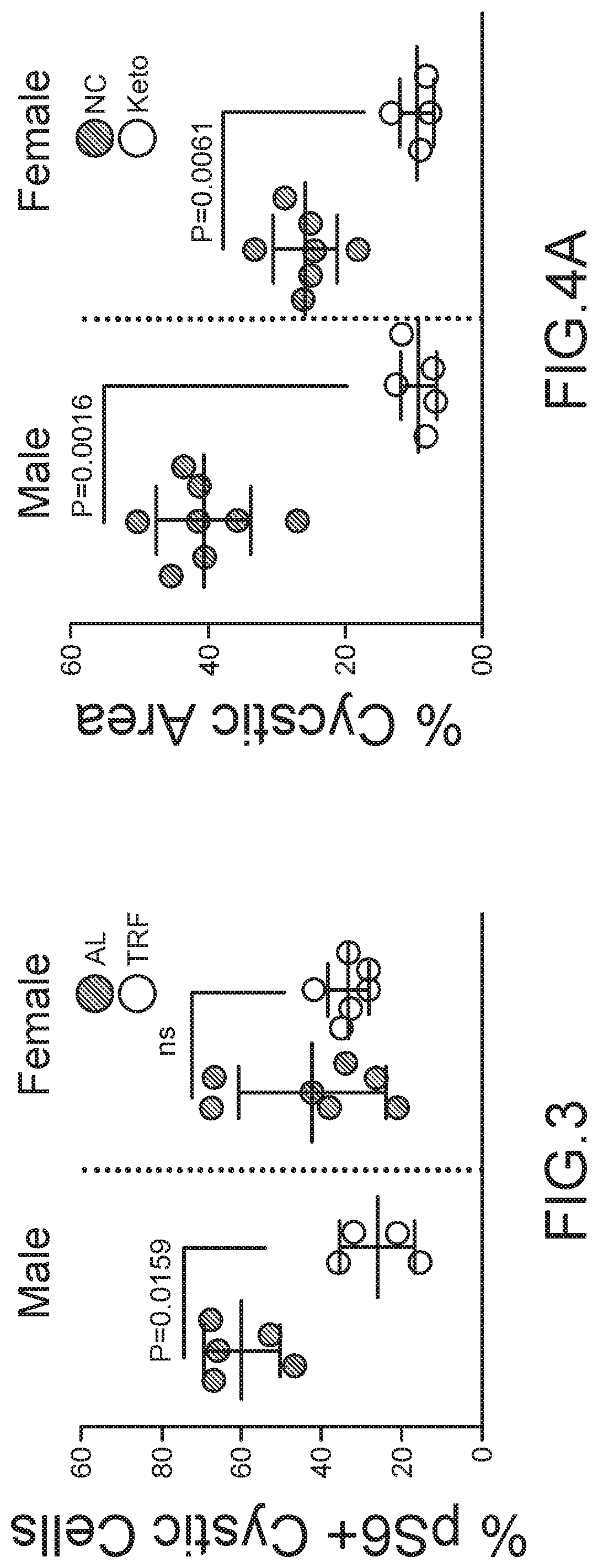

Methods and Compositions for Supporting Renal Health

ActiveUS20200289444A1Prevent and ameliorate severityAmeliorate riskHydroxy compound active ingredientsUrinary disorderCystic kidneyNephrosis

Compositions and methods for supporting health, especially renal health, comprising ketonic agents that recapitulate beneficial effects of ketosis by exogenously administered agents. The agents include BHB, analogs thereof, and GPR109A agonists. The agents may further include crystal precipitation inhibitors which synergistically improve treatment of certain renal conditions. The agents may be used in dietary supplements and therapeutic compositions for the treatment of cystic kidney diseases such as polycystic kidney disease, ciliopathies, and other conditions.

Owner:RGT UNIV OF CALIFORNIA +1

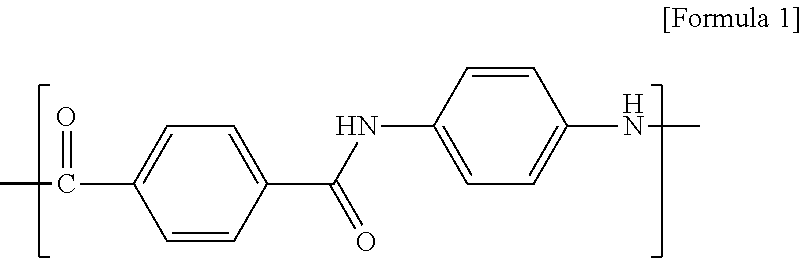

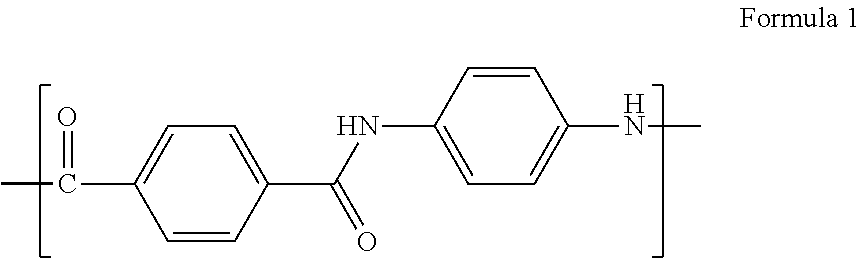

Polyoxymethylene resin composition

ActiveUS20150184110A1Improve friction and wear resistanceImprove thermal stability and tribology propertyWing fastenersAdditivesChemistryThermoplastic polyurethane

A novel polyoxymethylene resin composition is provided, which may be availably used as engineered plastics in various industrial fields and products, such as vehicle parts. The poly resin includes polyoxymethylene, aramide fibers, and thermoplastic polyurethane, thereby providing the novel composition of polyoxymethylene resin and improving various physical properties thereof, such as thermal stability.

Owner:HYUNDAI MOTOR CO LTD +1

Green color-protecting bacteriostatic crisp-preserving fresh-cut sweetheart apple and biological preservation technology

InactiveUS20210120831A1Improve the bactericidal effectEasy to operateFruits/vegetable preservation by irradiation/electric treatmentLactobacillusBiotechnologyXanthomonas campestris

The present disclosure relates to a green color-protecting bacteriostatic crisp-preserving fresh-cut sweetheart apple and biological preservation technology. Two fermentation liquids of Xanthomonas campestris and Lactobacillus plantarum are separately fermented, and are removal of the bacterial species, and then mixed in the ratio of 1:1 to obtain a bacterial solution, the bacterial solution is diluted 20-30 times for use, and then calcium chloride with a final concentration of 1-5 wt % is added to the bacterial solution. The extracellular polysaccharide produced by the metabolism of xanthomonas in the fresh keeping agent in the present disclosure is a safe food additive, which has good film-forming, thickening, stabilizing and water-holding effects, and strong biological activity. Acidic substances produced by the metabolism of Lactobacillus plantarum have bacteriostatic effects. Besides, calcium is a common substance used to keep the fruits and vegetables crisp after harvest.

Owner:SDIC ZHONGLU FRUIT JUICE

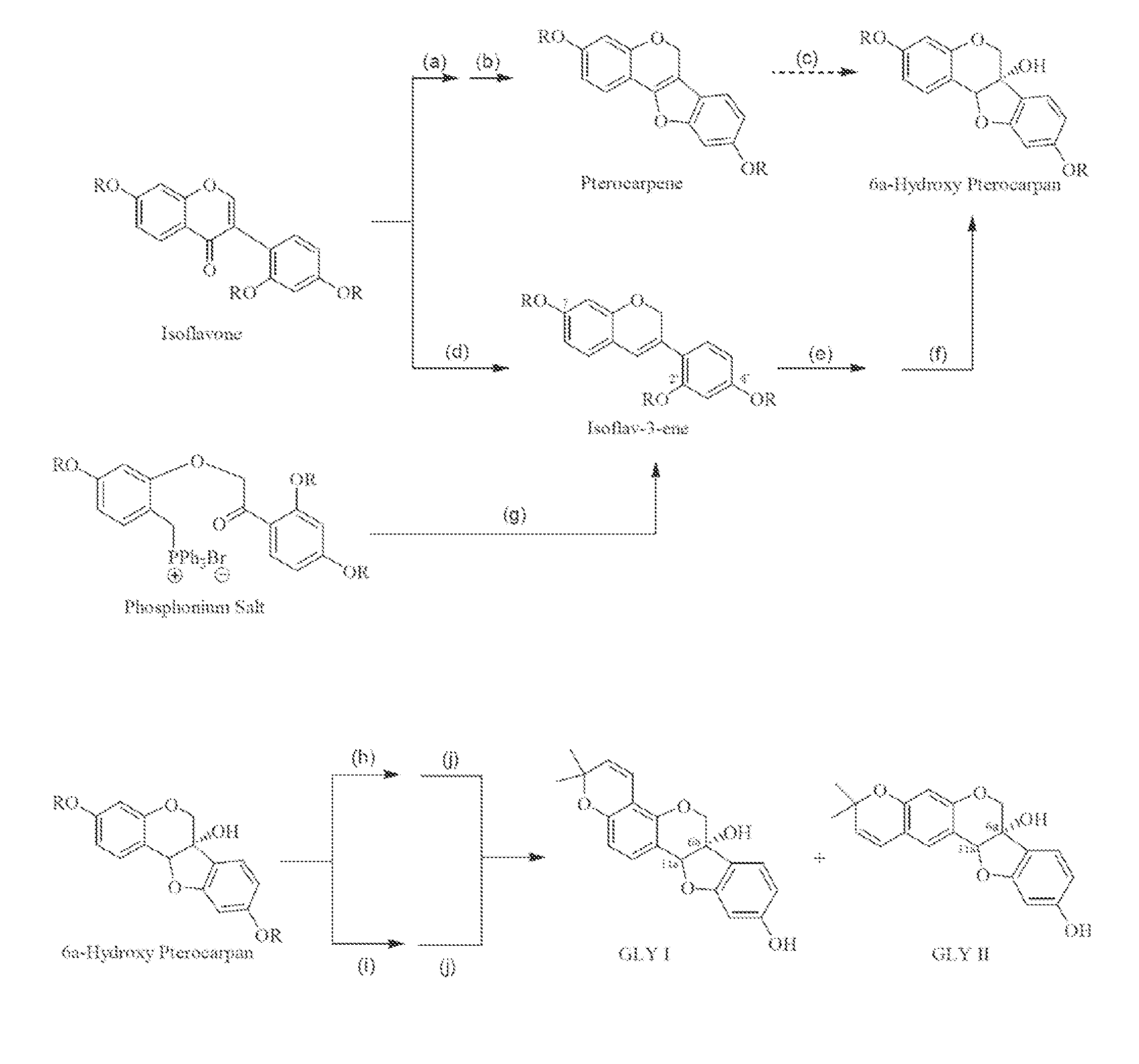

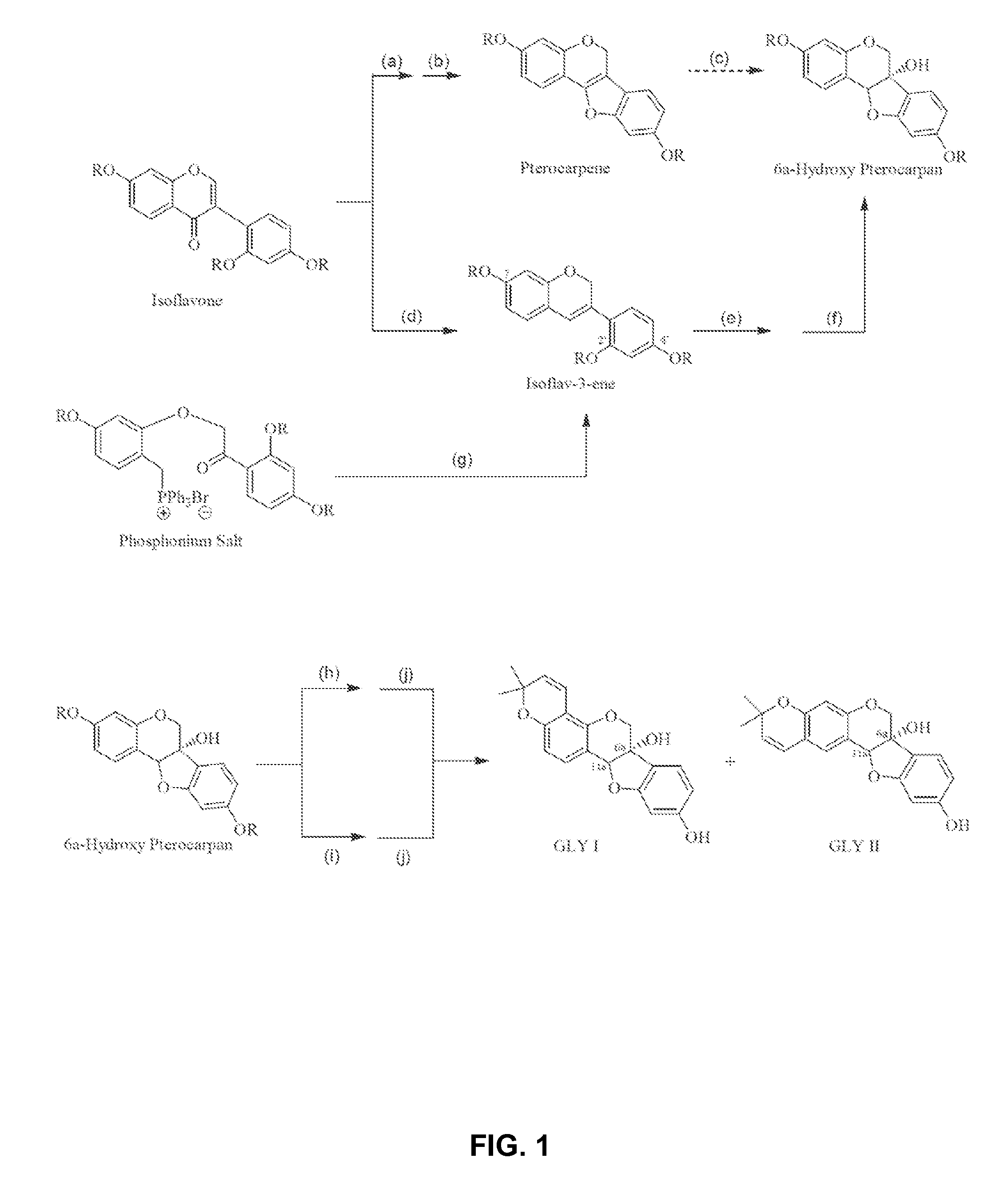

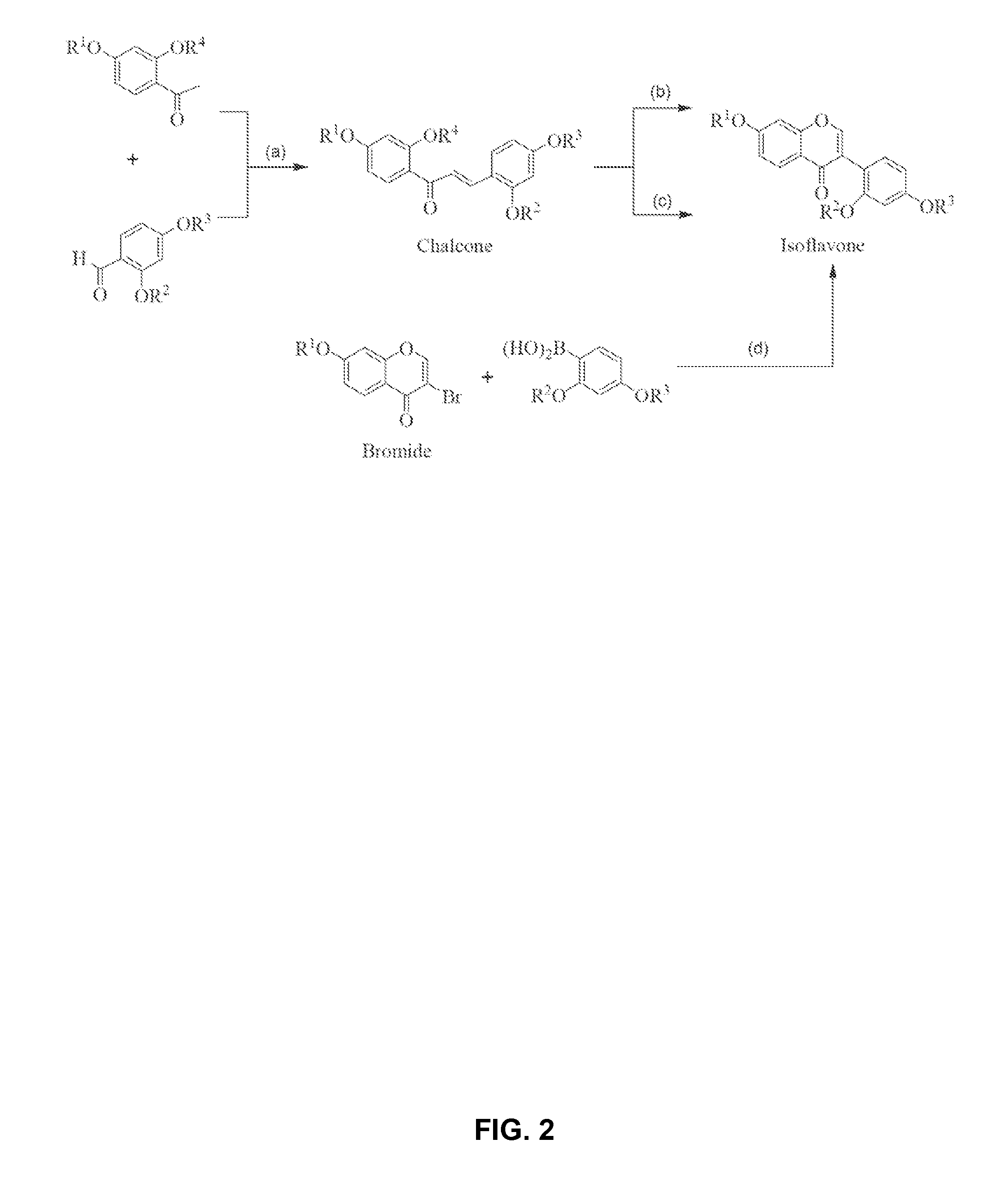

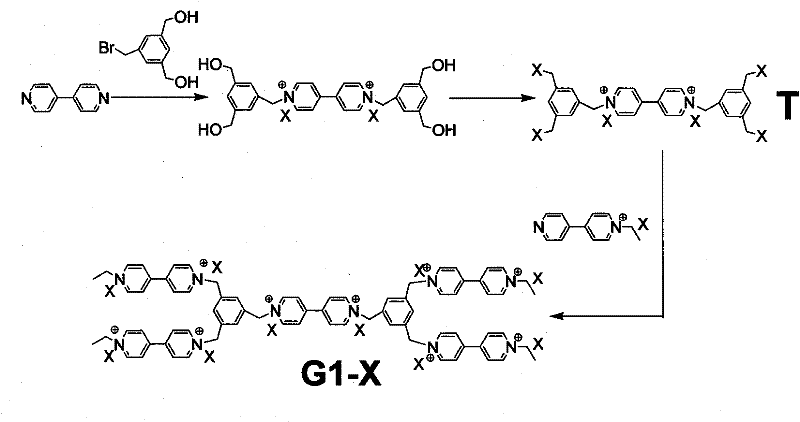

Methods for synthesizing glycinols, glyceollins i and ii, compositions of selected intermediates, and therapeutic uses thereof

Two distinct methods are disclosed and claimed for synthesizing glyceollin I plus glyceollin II as a mixture and as their pure forms. Stereochemical isomers and various synthetic intermediates are also synthesized and claimed for their novel compositions of matter. All compounds and their mixtures are claimed for use in formulations that are useful to treat or prevent cancer, or that have utility as selective estrogen receptor modulators, such formulations including enhanced or medical foods, dietary supplements and ethical pharmaceutical agents.

Owner:XAVIER UNIVERSITY OF LOUISIANA +2

Hinokitiol As A Plant Pesticide

InactiveUS20090029856A1Not harm environmentNovel compositionBiocideKetone active ingredientsWeedGermination

The present invention discloses that a natural tropolone compound, hinokitiol, also known as β-Thujaplicin as an effective biopesticide for use in controlling plant pests. In particular, hinokitiol and / or salts thereof may be used in modulating non-Erwinia plant microbial infection or in the formulation of a non-Erwinia antimicrobial agent. Alternatively, hinokitiol may be used as a natural herbicide to control the germination and growth of weeds. The formulation used in the present invention may contain a chelator, pH adjustor and UV protection agent in an amount effective to stabilize said hinokitiol.

Owner:POINT FINANCIAL

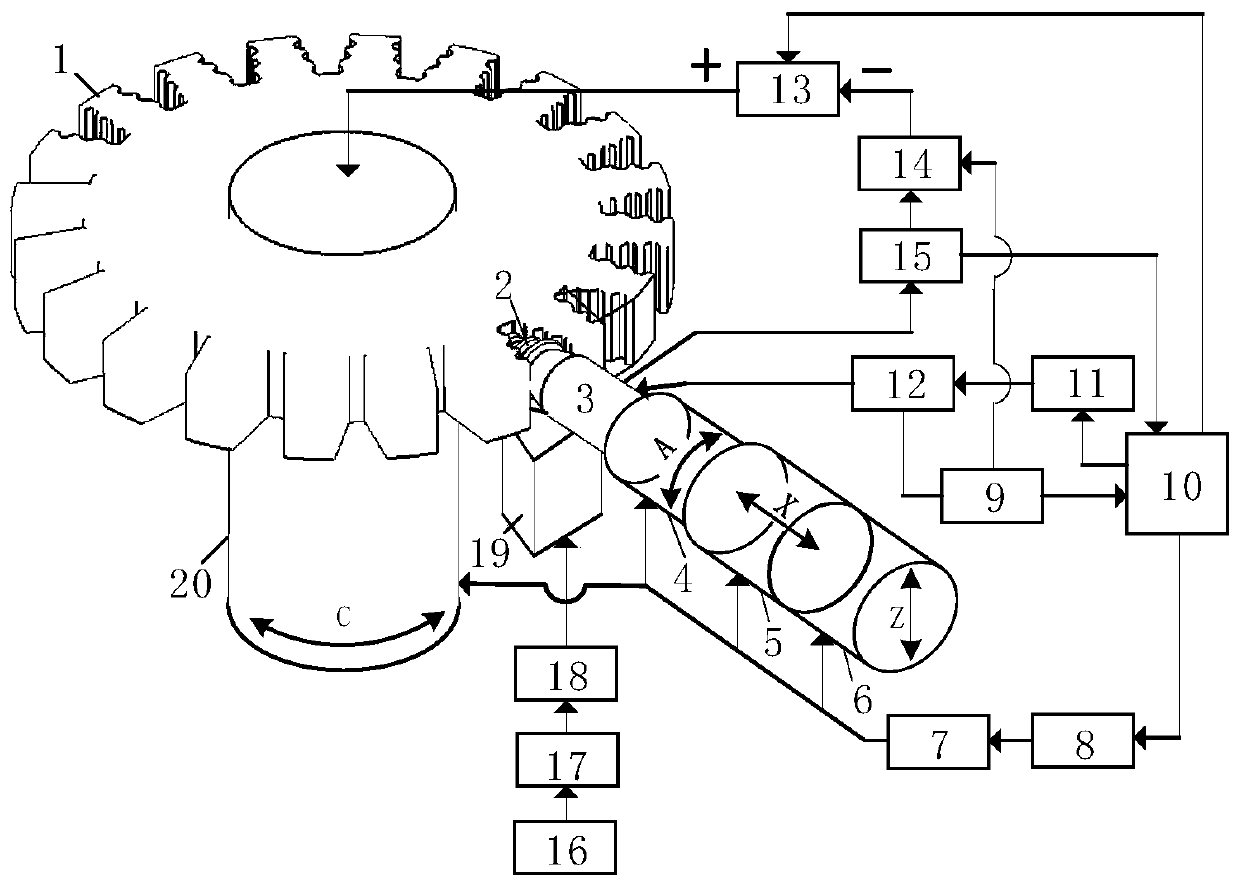

Ultrasonic-assisted precision electrolytic grinding system and method for turbine mortise

ActiveCN110524377AStable and adjustable electrolytic machining parametersTimely updateGrinding machinesAutomatic grinding controlWorking fluidElectrolysis

The invention discloses an ultrasonic-assisted precision electrolytic grinding system and method for a turbine mortise, and belongs to the technical field of electrolytic grinding combined machining.According to the present invention, during the process of electrolytic grinding the turbine mortise, a multi-dimensional ultrasonic vibration effect is added, a working fluid flow field in a gap is improved, the loss of a tool grinding wheel is reduced, and the high-quality and low-cost machining of the turbine mortise structure are realized. The ultrasonic-assisted precision electrolytic grindingsystem is constructed, and all-direction vibration of multi-dimensional ultrasound is regulated and controlled through a control computer, the follow-up ultrasonic vibration effect of the tool grinding wheel in a feeding direction is achieved and is coupled with the parameters of an electrolytic machining pulse power source, so that the stability of the machining process is guaranteed, and the reliable guarantee is provided for the application and popularization of the electrolytic grinding machining technology in the turbine mortise structure machining process. By replacing the tool grindingwheels and the working fluid nozzles of different structures, the system and the method are suitable for the precision machining of the turbine mortise structures of different types.

Owner:YANGZHOU UNIV

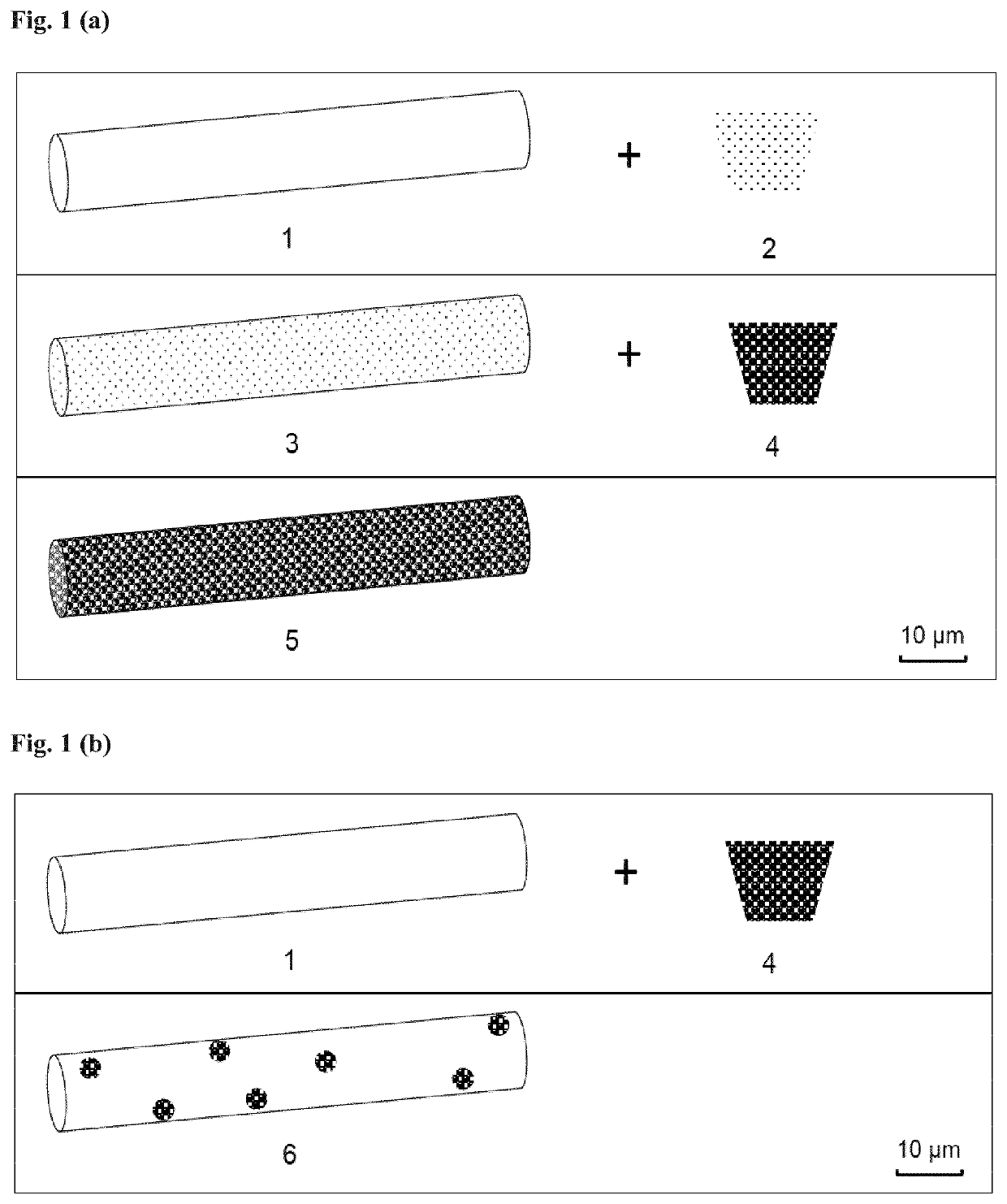

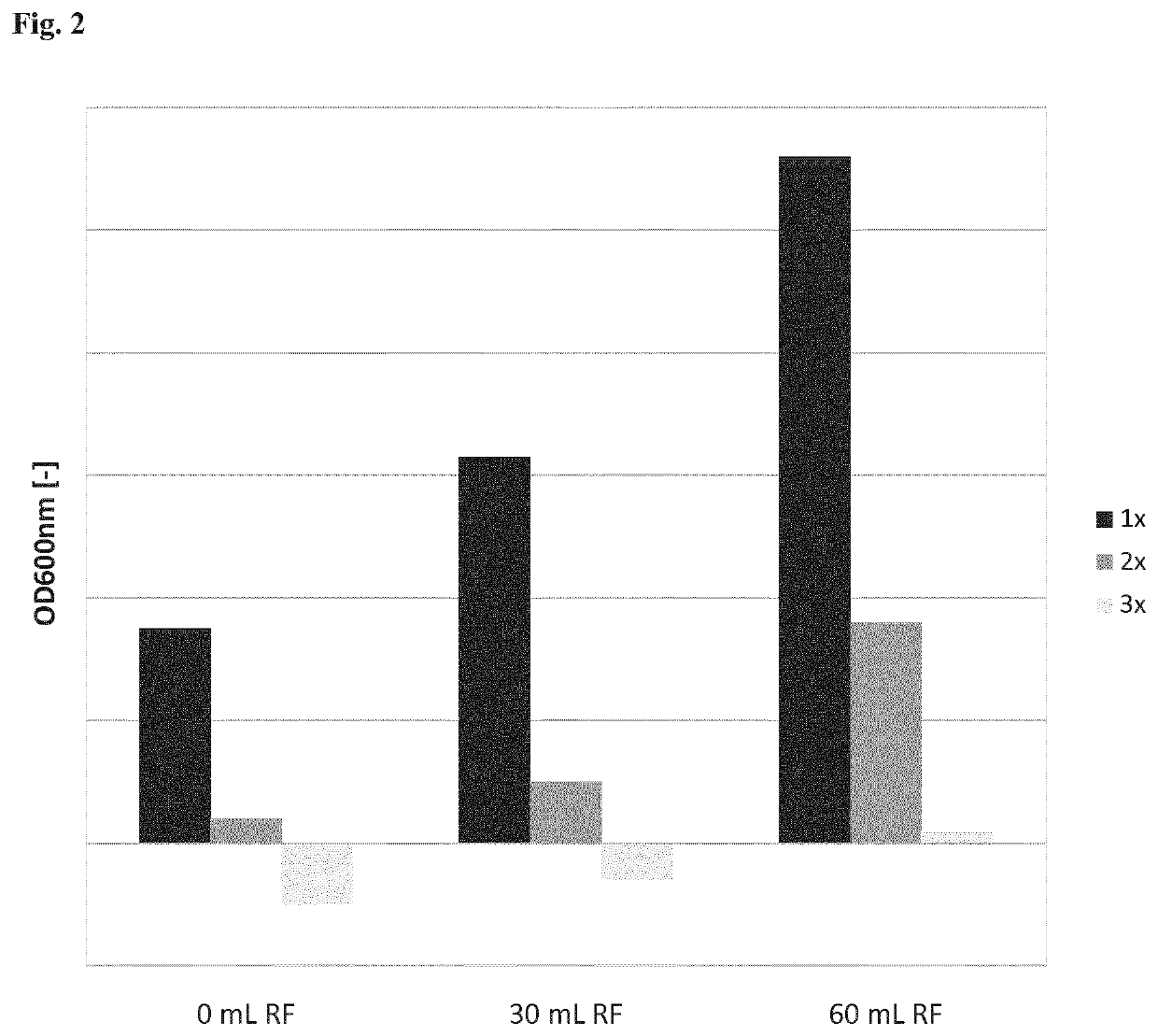

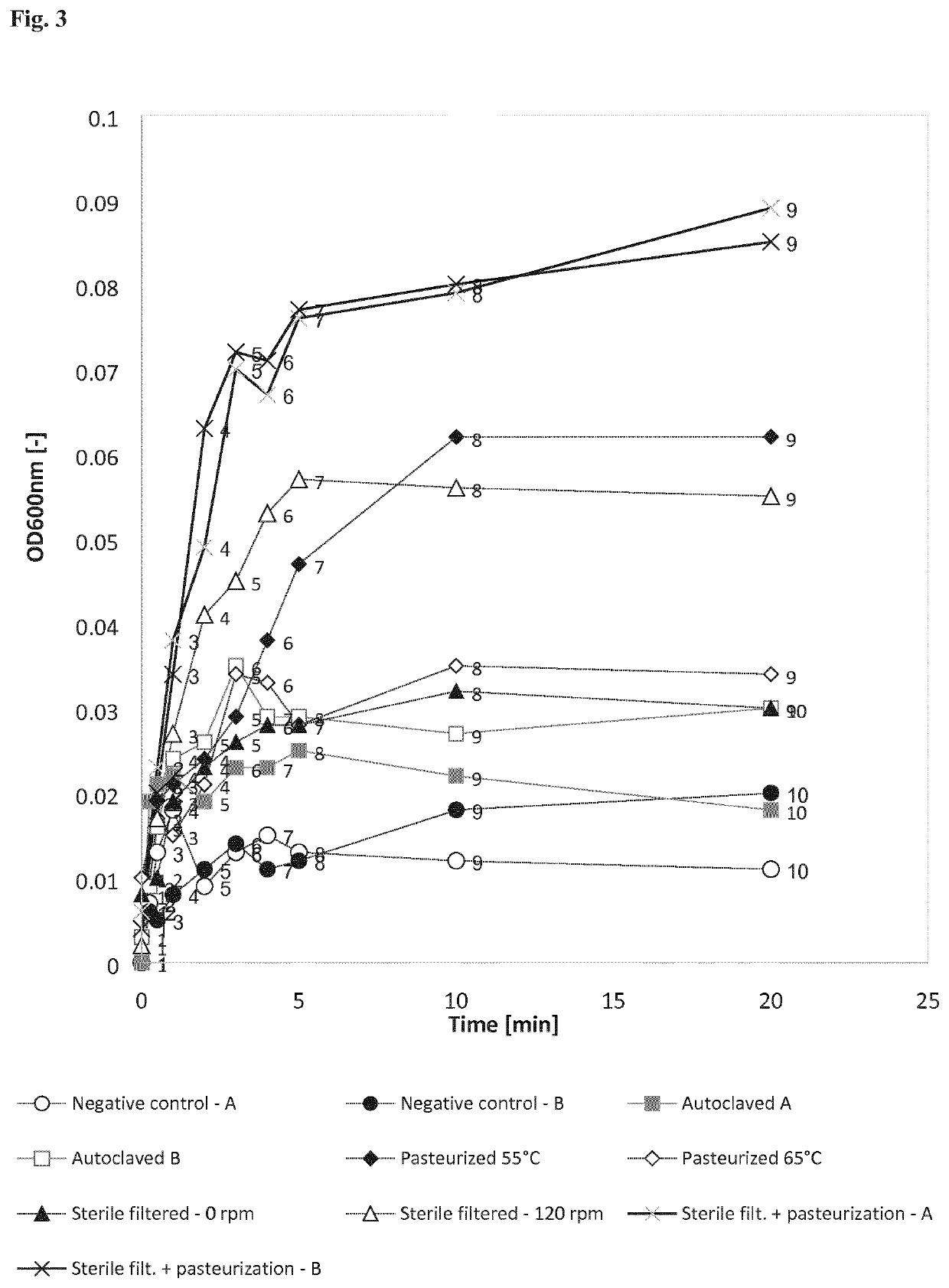

Method of preparing prebiotic dietary fiber and probiotic-fibre complexes

PendingUS20210368823A1Improves nutrient absorptionImprove immune fitnessAnimal feeding stuffUnknown materialsBiotechnologyDietary fiber

Owner:TWENTYGREEN AG

Structured lipid compositions and methods of formulation thereof

ActiveUS8206772B2Less availableTotal calories lowFermentationFood preparationTriglycerideWeight management

Lipid compositions comprising specific mixtures of edible synthetic triglycerides are provided that are useful in formulating food products having highly desirable dietary benefits. The novel lipid compositions allow simultaneous access to highly desirable dietary benefits such as delivery of calorie reduction, weight management, health benefits, or any combination thereof, and they also may be formulated trans-fatty acid free.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

Yinhuang oral liquor and its producing process

ActiveCN1616050ANovel compositionNovel production processUnknown materialsRespiratory disorderChlorogenic acidCurative effect

The present invention discloses a kind of Yinhuang oral liquid and its preparation process. The Yinhuang oral liquid consists of honeycuckle extract accounting in chlorogenic acid 6-24 mg / ml, skullcap root extract accounting in baicalin 12-48 mg / ml, stabilizer 18-72 mg / ml and pH regulator 0.1-1 mg / ml. The medicine has stable quality and high curative effect.

Owner:LUNAN PHARMA GROUP CORPORATION

Balancing weight composition with excellent extrudability

A balancing weight composition with excellent extrudability is provided. More specifically, the balancing weight composition includes a stainless steel and a resin base, wherein the resin base includes a polyester-based engineering plastic, an epoxy resin and an ionically cross-linked elastomer at a suitable content ratio to improve extrusion flowability, flexural strength and adhesive strength of a molded material.

Owner:HYUNDAI MOTOR CO LTD +1

Silver alloy etching solution

A silver alloy etching solution comprises 1-60 weight portions of hydrogen peroxide, 1-60 wt. portions of sulfuric acid, nitric acid or organic acid, and 5-90 wt. portions of water. The other silver alloy etching liquid comprises 1-60 weight portions of ammonium, 1-60 weight portions of hydrogen peroxide, and 0-96 portions of water.

Owner:RITDISPLAY

Solar cell gel electrolyte and preparation method and application thereof

InactiveCN101901692BPromote migrationImprove conductivityLight-sensitive devicesSolid-state devicesSolventIonic liquid

Owner:SUZHOU UNIV

Clindamycin metronidazole liniment and preparation process thereof

InactiveCN110496133ANovel compositionEasy to carry and useOrganic active ingredientsAntipyreticChemistryClindamycin Hydrochloride

The invention relates to a clindamycin metronidazole liniment. The liniment specifically includes the following ingredients in percentage by weight: 16-24% of ethanol, 12-18% of glycerin, 15-30% of clindamycin hydrochloride or metronidazole, 3-5% of tazarotene, 3-7% of white vaseline, 0.02-0.1% of ethylparaben, and the balance of purified water. A preparation process of the liniment includes the following steps: firstly adding the ethanol and the glycerin into a stirring blending pot, uniformly sprinkling 2-4% of a transdermal absorbent, and then adding the metronidazole, the tazarotene and the ethylparaben; stirring the clindamycin hydrochloride in a stainless steel vessel until the clindamycin hydrochloride dissolves, and adding the dissolved clindamycin hydrochloride to the blending pot; and finally, adding the white vaseline and the purified water to reach the full amount, and performing stirring for 30 to 35 minutes to form the liniment. The liniment is novel in drug composition,has no irritation to the skin, and reduces the side effects such as dryness, desquamation and erythema. The production process of the invention is simple. The finished product is uniform and delicate,has high curative effect, and is easy to wash after external use.

Owner:江苏晨牌邦德药业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com