Ultrasonic-assisted precision electrolytic grinding system and method for turbine mortise

An electrolytic grinding, ultrasonic-assisted technology, applied in metal processing equipment, grinding machine parts, grinding/polishing equipment, etc. Grinding wheels and anode workpieces, etc., to achieve stable and reliable processing, novel system composition, and high-quality processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

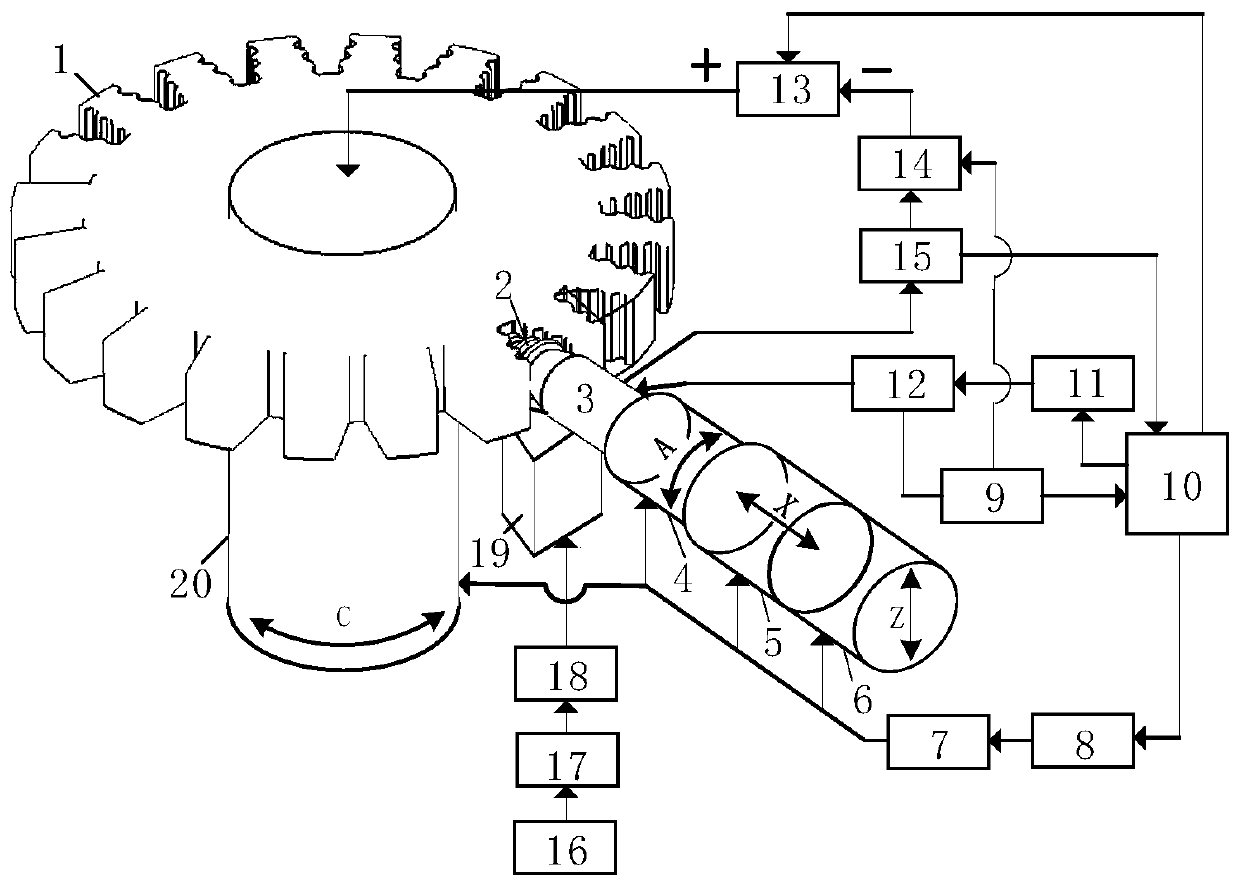

[0024] The present invention will be further described below in conjunction with accompanying drawing:

[0025] Such as figure 1 As shown, a turbine tenon and groove ultrasonic-assisted precision electrolytic grinding processing system includes a semi-finished turbine disc 1, a tool grinding wheel 2, a multi-axis machine tool motion mechanism and drive system, a multi-dimensional ultrasonic coordinated vibration and micro-displacement detection system, and an electrolytic grinding composite. Processing power supply and electrical parameter detection system, working fluid circulation system; multi-axis machine tool motion mechanism and drive system consists of A-axis rotation mechanism 4, X-axis feed mechanism 5, Z-axis feed mechanism 6, C-axis rotation mechanism 20, motion The drive unit 7, CNC controller 8, and control computer 10 are connected to form; the control computer 10 transmits motion instructions to the motion drive unit 7, and then the motion drive unit 7 simultane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com