Microwave freeze-drying and dehydrating method of fruits and vegetables

A technology of microwave freezing and processing method, which is applied in the fields of freeze-drying and dehydration processing and microwave freeze-drying and dehydration processing of fruits and vegetables, can solve the problems of affecting the appearance of freeze-dried products, damage to the texture of yam tablets, and long draining time, and achieves accelerated microwave freeze-drying. Speed, reduce microwave low-voltage discharge problems, and complete cooling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

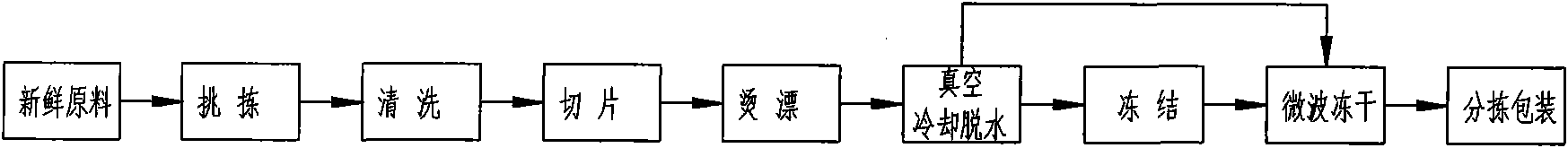

[0020] Embodiment one: carrot slice microwave freeze-drying dehydration processing production (referring to figure 1 )

[0021] 1. Cleaning steps

[0022] Select carrots with a smooth surface, thick and short, and the same size (moisture content on a wet basis is about 90%), cut off 5 mm of the head and 2 to 3 cm of the tail, and then wash with water. Adjust the slicer to cut round slices along the length of the carrot, with a slice thickness of about 5mm.

[0023] 2. Blanching steps

[0024] Immediately blanch the sliced carrots with hot water at 90°C for 1-2 minutes, quickly remove them, put them into a mesh plastic tray, spread the material evenly, the thickness of the material is about 3cm, and control the water for 1 minute.

[0025] 3. Pre-drying step (vacuum cooling and dehydration treatment)

[0026] Put the blanched material into microwave freeze-drying equipment or vacuum cooling equipment, and vacuum cool the blanched material. Turn on the refrigerator before...

Embodiment 2

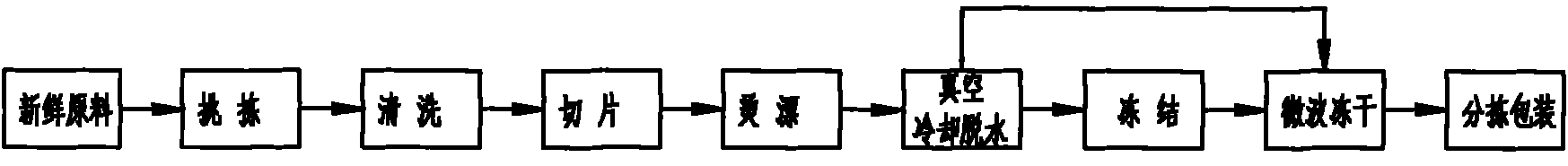

[0033] Embodiment two: carrot slice microwave freeze-drying dehydration processing production (not freezing)

[0034] 1. Raw material selection, cleaning and slicing:

[0035] Same as "step 1" in Example 1.

[0036] 2. Blanching treatment:

[0037] Same as "step 2" in Example 1.

[0038] 3. Vacuum cooling and dehydration treatment:

[0039] Compared with Example 1, the vacuum cooling and dehydration time was extended from 30 minutes to 50 minutes. After cooling and dehydration, the carrot slices were frozen to the eutectic point temperature of the material, that is, the central temperature was frozen to about -25°C, and other conditions were similar.

[0040] 4. Microwave freeze drying:

[0041] Same as "step 5" in the first embodiment.

[0042] 5. Sorting and packing:

[0043] Same as "step 6" in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com