A kind of production method of m-aminoacetanilide

A technology of aminoacetanilide and m-aminoacetanilide hydrochloride, which is applied in the field of m-aminoacetanilide preparation, and achieves the effects of simple process flow, simple operation control and high total yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

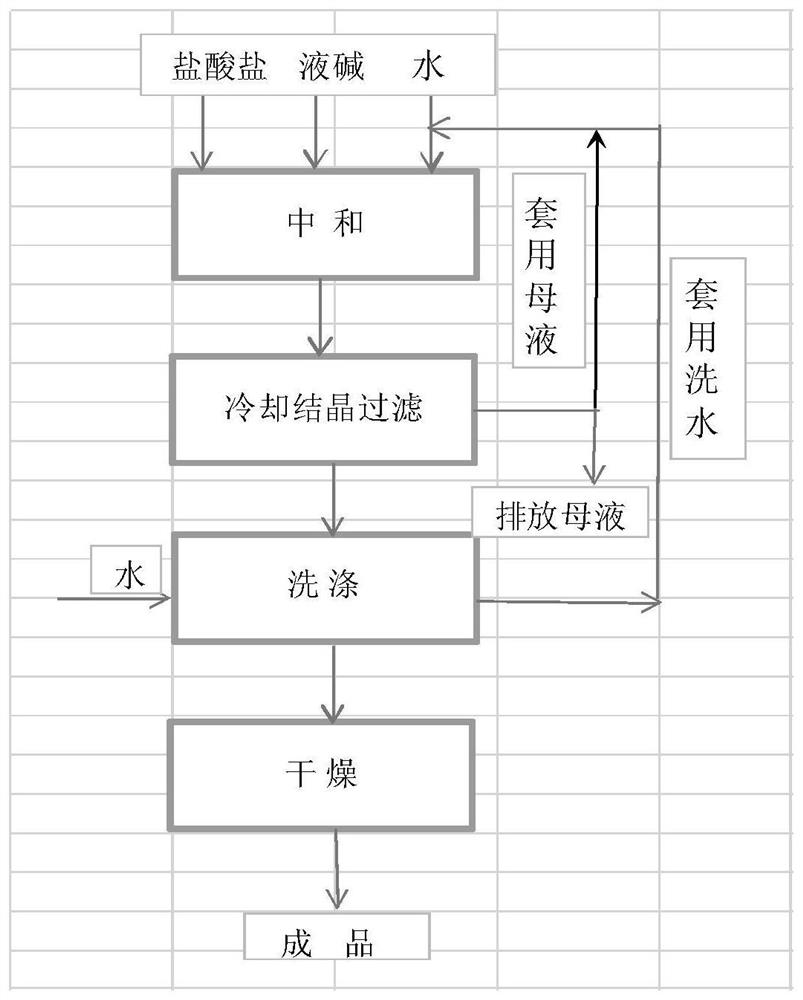

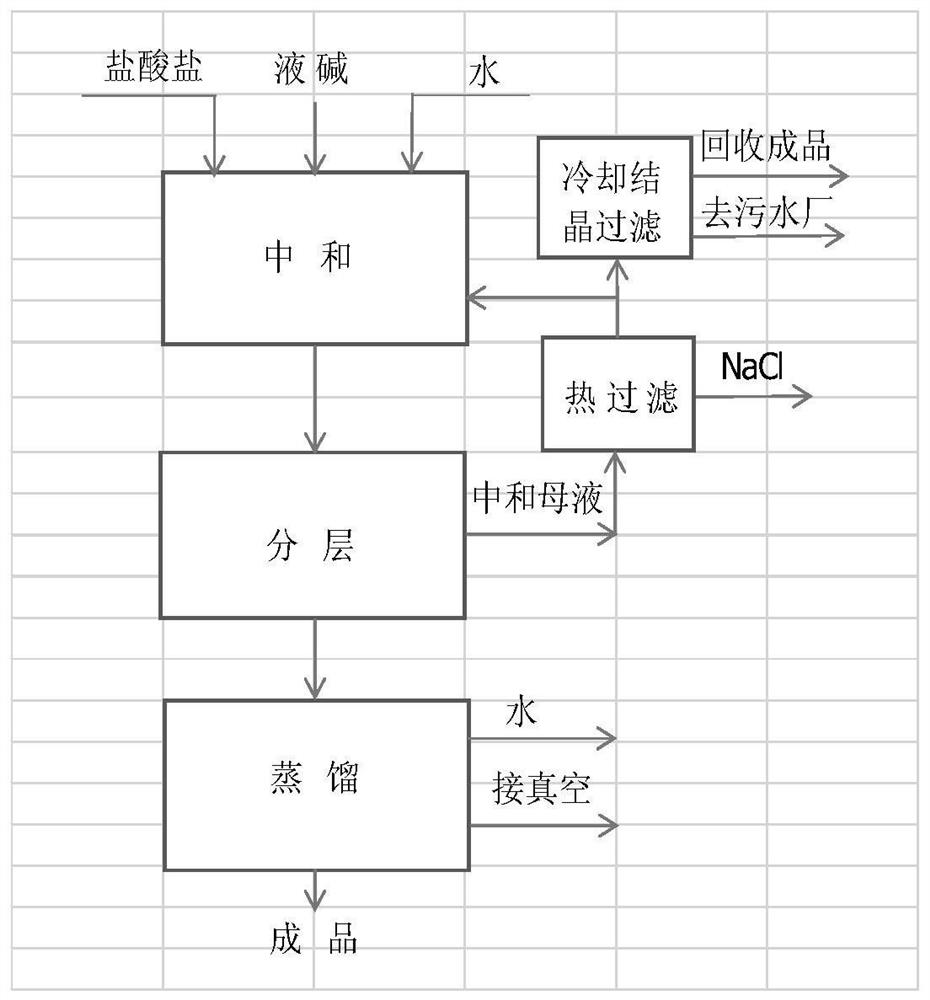

Method used

Image

Examples

Embodiment 1~12

[0024] 1. Neutralization - 500mL beaker + 100g hydrochloride + 90mL water (all or part of the neutralization mother liquor from the previous batch was applied from the second batch), the temperature was raised to 50°C, and 32% liquid caustic soda was added dropwise , to pH=8~9, continue to stir at 60~65°C for 10 minutes, retest and adjust pH=8~9 with liquid caustic soda.

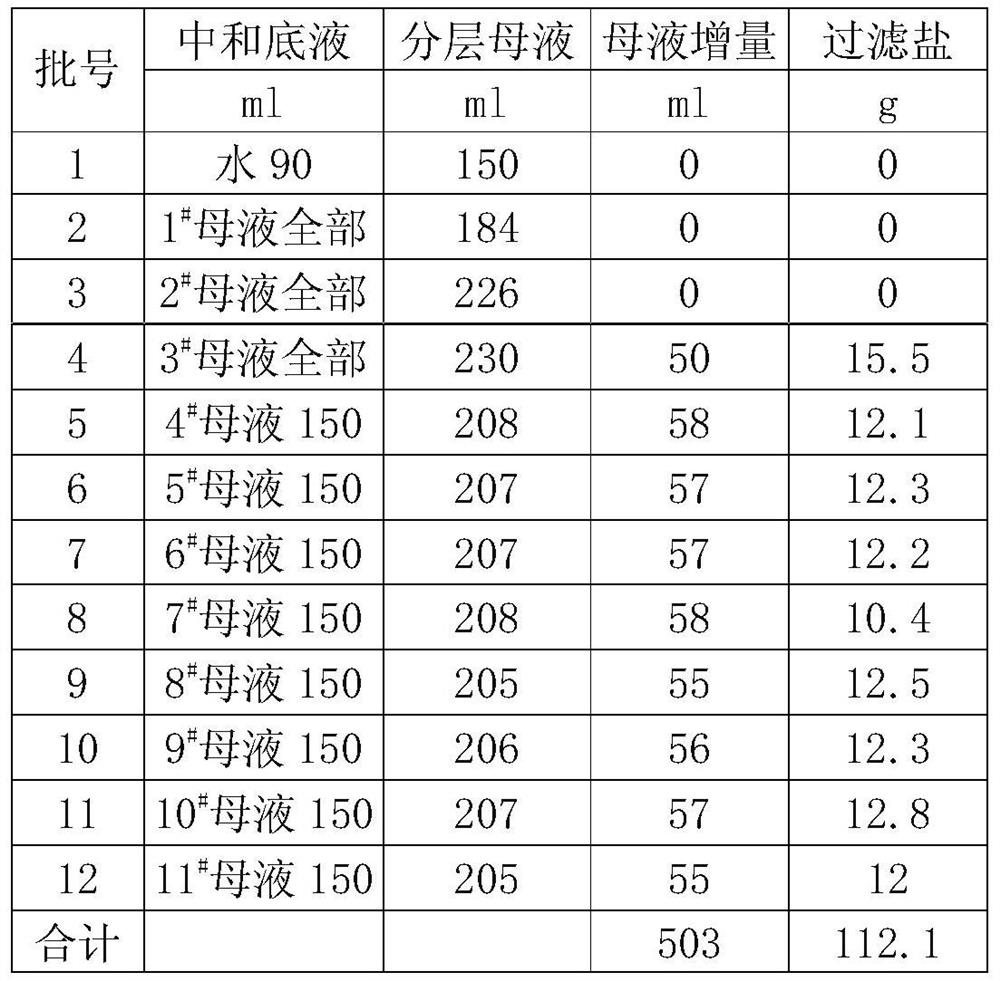

[0025] 2. Layering——The neutralized material is transferred into the separatory funnel, and settles for 10-15 minutes. The oil phase of the first batch is in the lower layer, and the oil phase is in the upper layer from the second batch. The oil phase is separated, and finally centralized distillation Dehydration treatment. The first batch of mother liquor is all applied mechanically as the second batch of neutralization bottom water, the second batch of mother liquor is all applied mechanically as the third batch of neutralization bottom water (a small amount of salt has been precipitated), the third batch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com