Preparation method of water-soluble sand core used for aluminium alloy or magnesium alloy thin wall complex casting

A magnesium alloy and aluminum alloy technology, applied in the field of aerospace materials, can solve the problems of high hygroscopicity, low strength, and difficult operation, and achieve excellent water-soluble collapsibility, good chemical stability, moisture absorption resistance, and convenient recycling simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

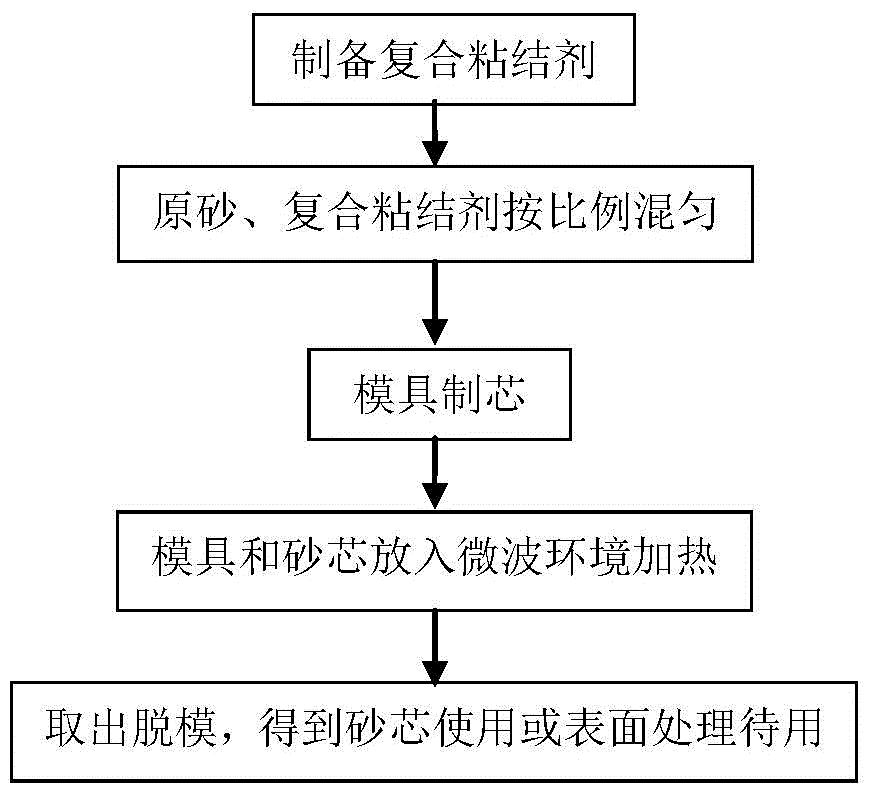

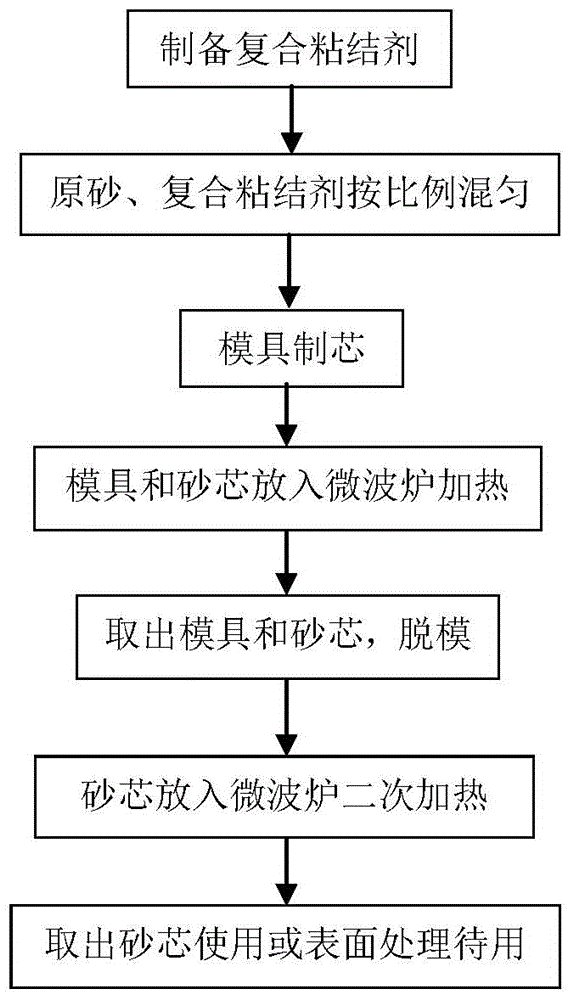

Method used

Image

Examples

Embodiment 1

[0021] Sand core material preparation: 100 parts of 50 / 100 mesh Dalin scrub sand, 5.5 parts of composite binder.

[0022] Prepare magnesium sulfate heptahydrate and water into 30% magnesium sulfate aqueous solution, take 5 parts of magnesium sulfate aqueous solution, then add 0.5 part of aluminum sulfate octadecahydrate into the magnesium sulfate aqueous solution and heat to 70°C to form a composite binder solution; Dalin sand is pre-mixed in a sand mixer for 15 seconds, then mixed with a composite binder for 90 seconds to obtain a core sand mixture; then wood molded cores are placed in a microwave oven (1400W, the same below) to heat for 40 seconds, and then removed from the mold , put it into the microwave oven again and heat it for 50s, and wait for cooling to room temperature to obtain the sand core.

[0023] By preparing the "8" sample, its tensile strength is measured to be 1.2-1.3MPa, which can be directly used for pouring; the relative humidity of the environment is 70...

Embodiment 2

[0025] Sand core material preparation: 100 parts of 50 / 100 mesh pearl sand, 4.5 parts of composite binder.

[0026] Magnesium sulfate heptahydrate and water are prepared into a 30% magnesium sulfate aqueous solution, 4 parts of magnesium sulfate aqueous solution are taken, and 0.5 parts of aluminum sulfate octadecahydrate is added to the magnesium sulfate aqueous solution and heated to 70° C. to form a composite binder solution; Baozhu sand is pre-mixed in a sand mixer for 15 seconds, and then mixed with a composite binder for 90 seconds to obtain a core sand mixture; then wood molded cores are placed in a microwave oven for heating for 40 seconds, removed from the mold, and placed in the microwave oven again Heating for 50s, and cooling to room temperature to obtain sand cores.

[0027] By preparing the "8" sample, its tensile strength is 1.7-1.9MPa, which can be directly used for pouring; the relative humidity of the environment is 20%-30%, and the storage strength of the sa...

Embodiment 3

[0029] Sand core material preparation: 100 parts of 70 / 140 mesh Duchang scrub sand, 6.5 parts of composite binder.

[0030] Magnesium sulfate heptahydrate and water are prepared into a 30% magnesium sulfate aqueous solution, 6 parts of magnesium sulfate aqueous solution are taken, and 0.5 parts of aluminum sulfate octadecahydrate is added to the magnesium sulfate aqueous solution and heated to 70° C. to form a composite binder solution; Duchang sand is pre-mixed in a sand mixer for 15 seconds, then mixed with a composite binder for 90 seconds to obtain a core sand mixture; then wood molded cores, heated in a microwave oven for 40 seconds, removed from the mold, and placed in the microwave oven again Heated in medium temperature for 50s, and cooled to room temperature to obtain sand cores.

[0031] By preparing the "8" sample, its tensile strength is measured to be 0.8-1.0MPa, which can be directly used for pouring; the relative humidity of the environment is 70%-80%, and the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com