Novel propellant management device used in propellant storage box

A propellant storage tank and management device technology, which is applied in the field of new propellant management devices, can solve the problems of propellant management devices such as heavy weight, low reliability, and small effect of inhibiting liquid sloshing, and realize repeated large-flow filling on the ground and discharge, high reliability of on-orbit work, and the effect of facilitating liquid circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

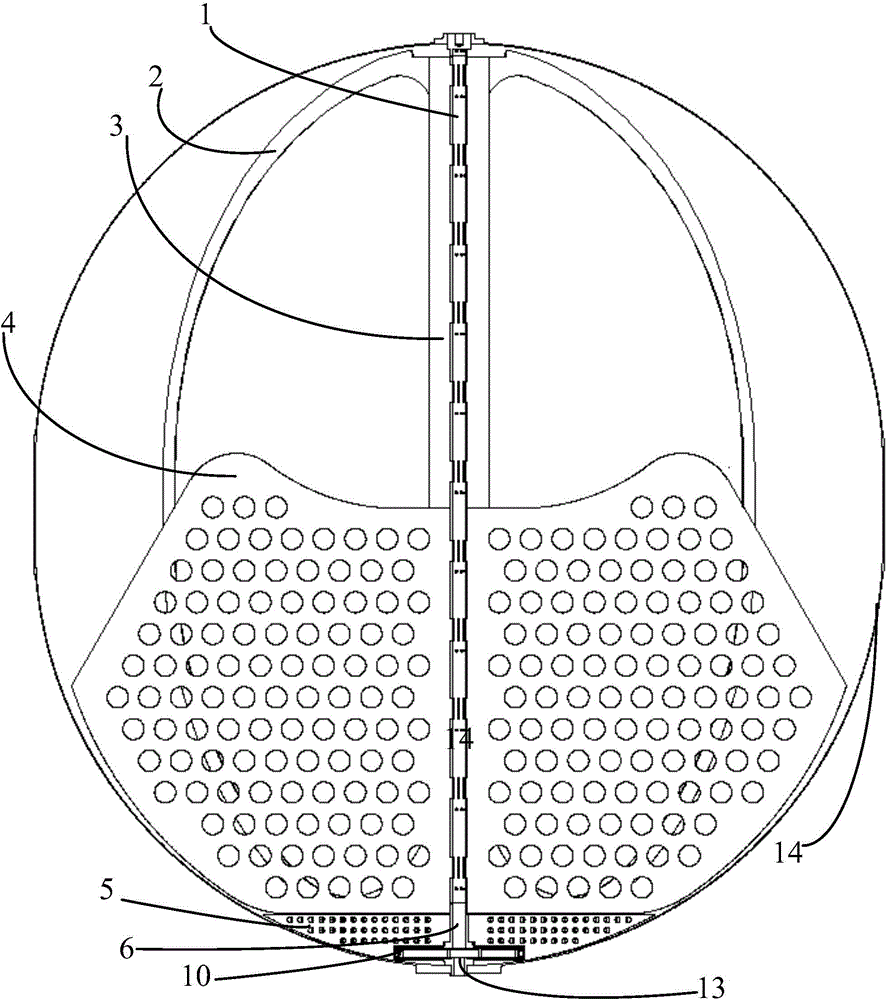

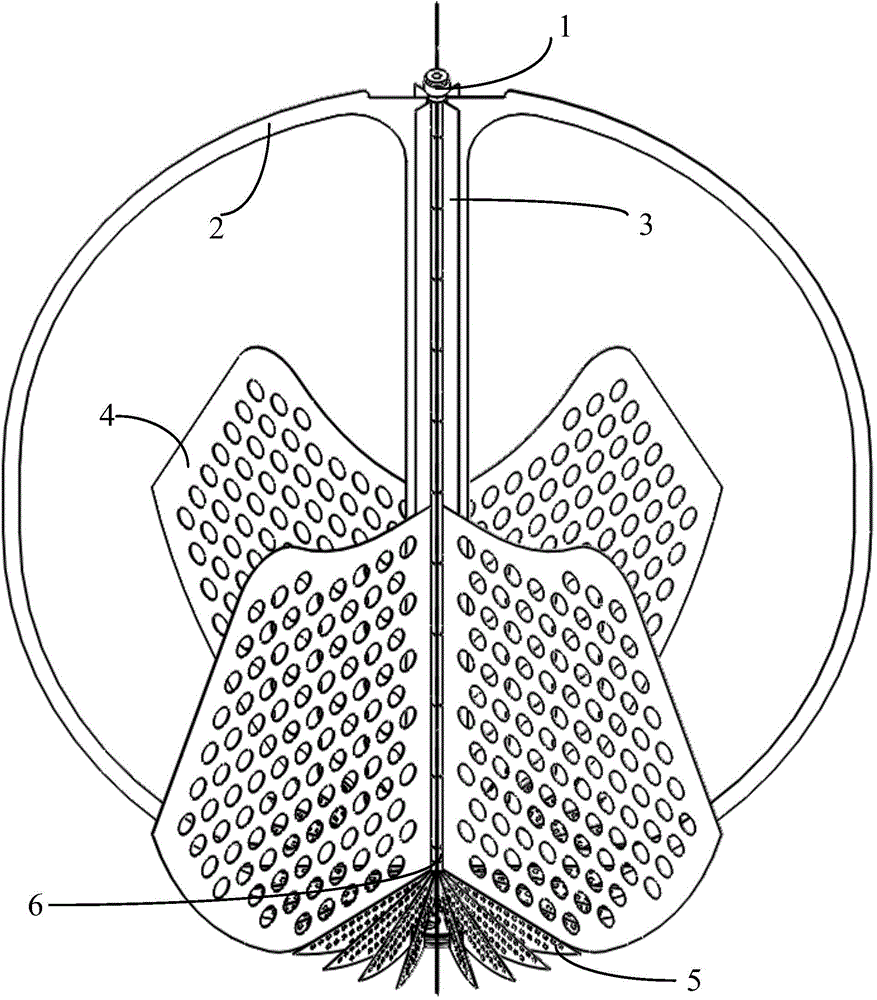

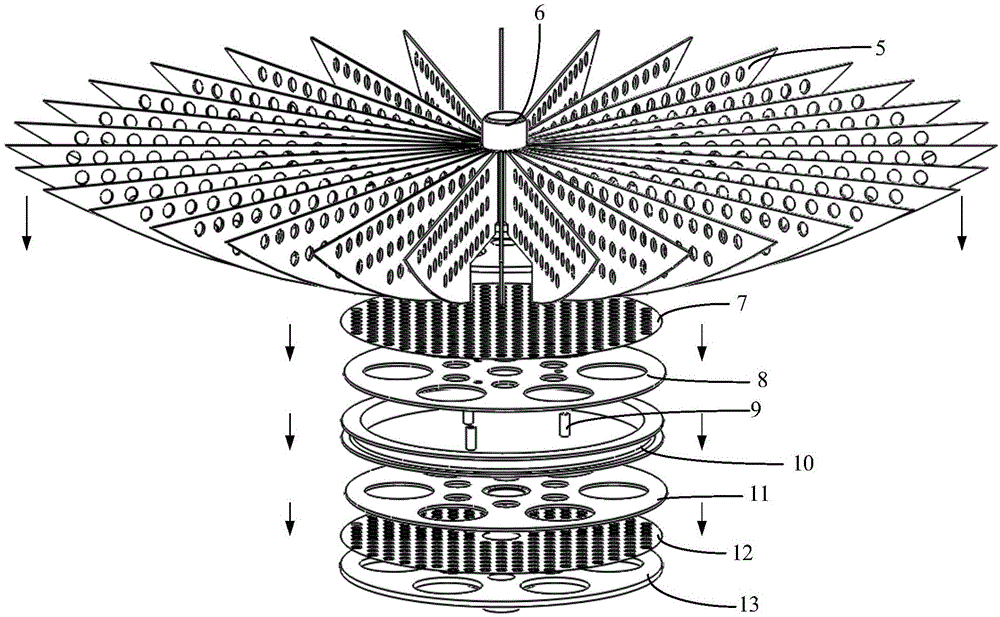

[0042] Such as figure 1As shown, the present invention provides a novel propellant management device used in a propellant storage tank, which includes a central pillar 1, a guide vane 2, a pillar vane 3, a large vane 4, a liquid storage vane 5, an upper pressure plate 6, The upper sheet 7, the upper support plate 8, the small cylinder 9, the skeleton 10, the lower pressing plate 11, the lower mesh sheet 12, and the lower support plate 13; the upper sheet 7 and the lower mesh sheet 12 are titanium alloy materials.

[0043] Such as figure 2 As shown, the central pillar 1 is a cylindrical tubular structure, and the outer wall of the column section is evenly distributed with installation structures in the axial direction, and there is no contact between the installation structures. slit; guide vanes 2, pillar blades 3, and large blades 4 are fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com