Hard mouth tube of infusion bag

An infusion bag and mouth tube technology, which is applied to the field of hard mouth tubes, can solve the problems of material waste, easy water leakage, high cost, and achieve the effects of material saving, good heat sealing quality and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

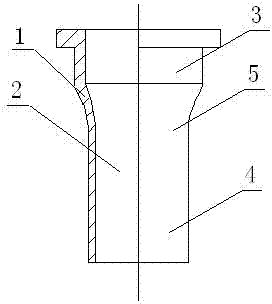

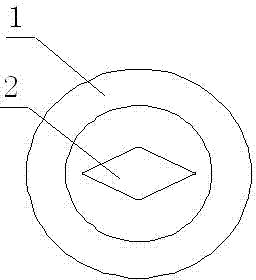

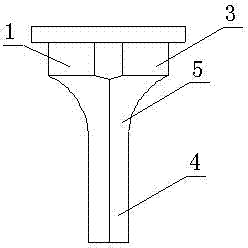

[0011] As shown in the figure, the hard mouth tube of the infusion bag of the present invention includes a body 1, and a vertical through hole 2 is provided on the body 1. One end of the body 1 is a connecting portion 4, and the other end is an outlet portion 3. There is a transition part 5 in the middle of the body 1 for connecting the outlet part 3 and the connection part 4. The through hole 2 is circular in the outlet part 3 and flat rhombus in the connection part 4. The transition part 5 The wall thickness of the connecting portion 4 transitions from thick to thin from the outlet portion 3 to the connecting portion 4, and the outer wall of the connecting portion 4 is oblate rhombus. The flat diamond-shaped design makes the thickness of the side wall of the connection part of the hard mouth tube of the infusion bag uniform and thinner, so that the heat sealing will not be uneven, the heat sealing quality is good, and the material is saved. At the same time, the design of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com