Processing method for controlling abnormal pressure rise in shale fracturing process

A treatment method and pressure technology, which is applied in the direction of earthwork drilling, production fluid, wellbore/well components, etc., can solve problems such as high risk of shale fracturing process, failure to achieve the purpose of transformation, abnormal pressure rise, etc., to improve the process Compliance rate and final measure effect, effect of ensuring smooth progress and reducing construction pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing.

[0027] This embodiment provides a treatment method for controlling abnormal pressure rise during shale fracturing, which includes the following steps:

[0028] S1. Early fracturing (same as conventional fracturing method): according to the fracturing construction design, inject the pre-fluid into the formation through the fracturing equipment, and continue to inject the fracturing fluid and fracturing sand into the formation according to the designed amount;

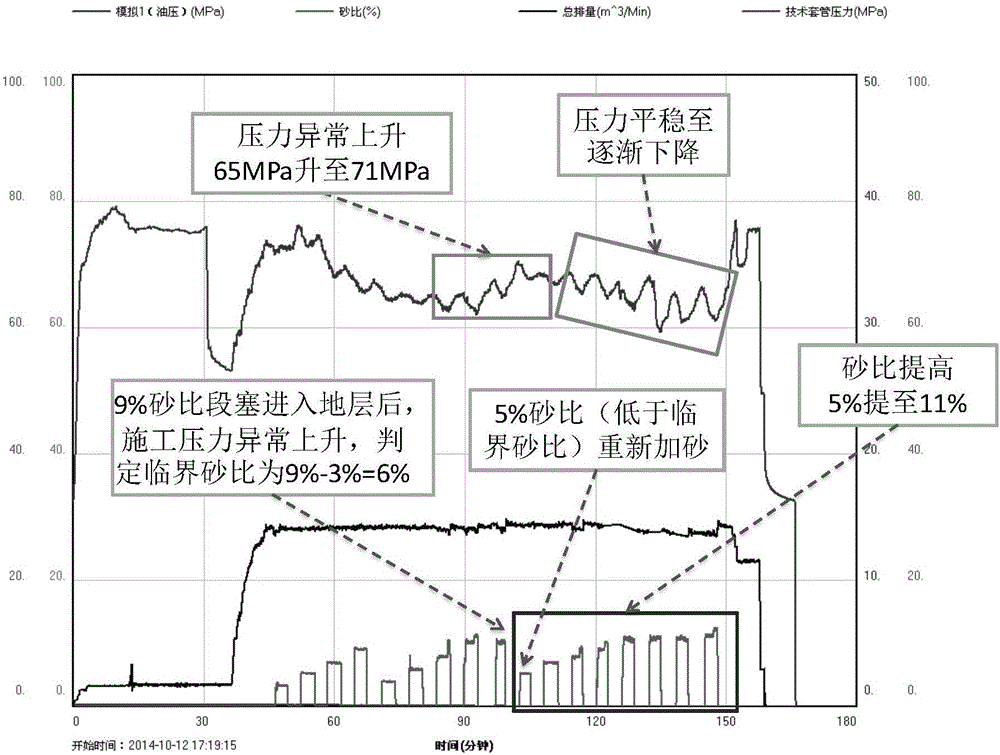

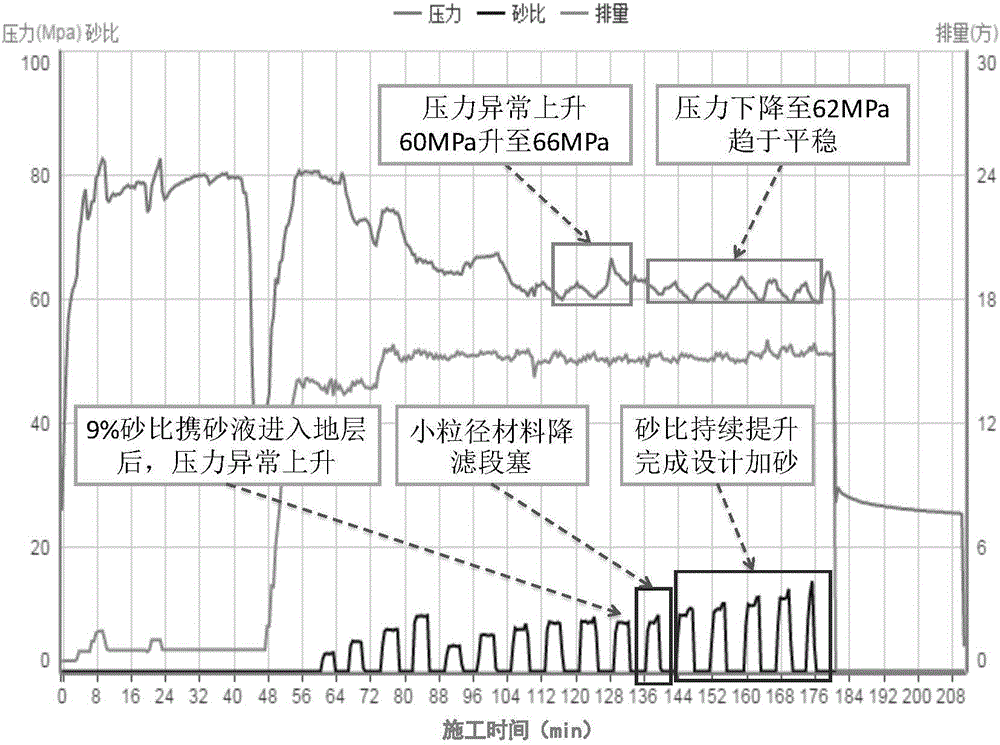

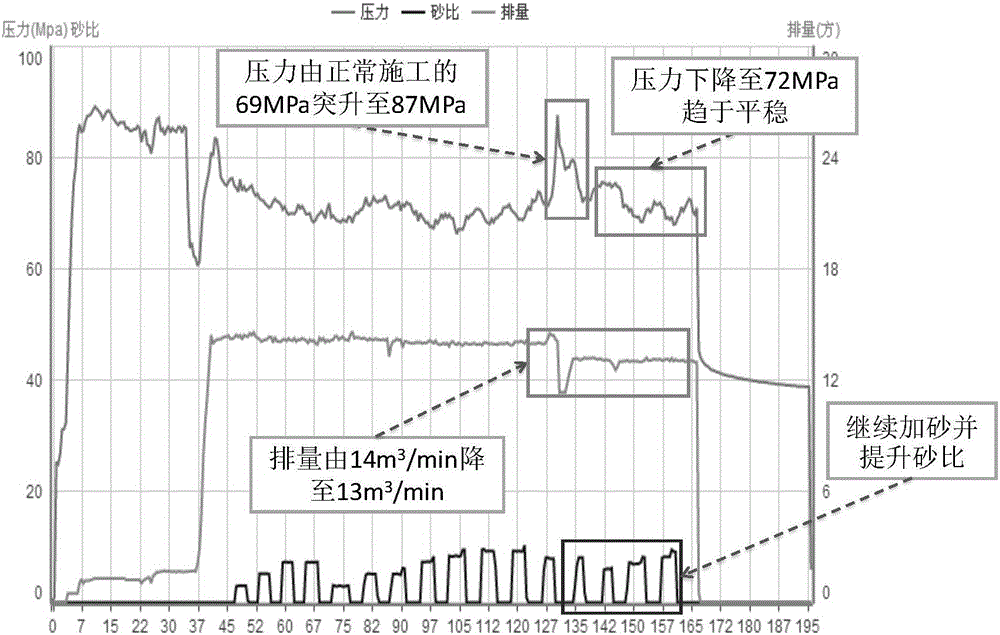

[0029] S2. In the middle and late stages of fracturing: when the pressure rises abnormally, the critical sand ratio method is used for construction, such as figure 1 As shown, specifically:

[0030] ①Determination of critical sand ratio: During the process of adding sand, the pressure rises with a slope greater than 1 / 2. Determine the range of critical sand ratio as the sand ratio at this time minus 2% to 5%. Stop ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com