Preparation method of double-layer composite low-cost lithium-rich manganese-based precursor

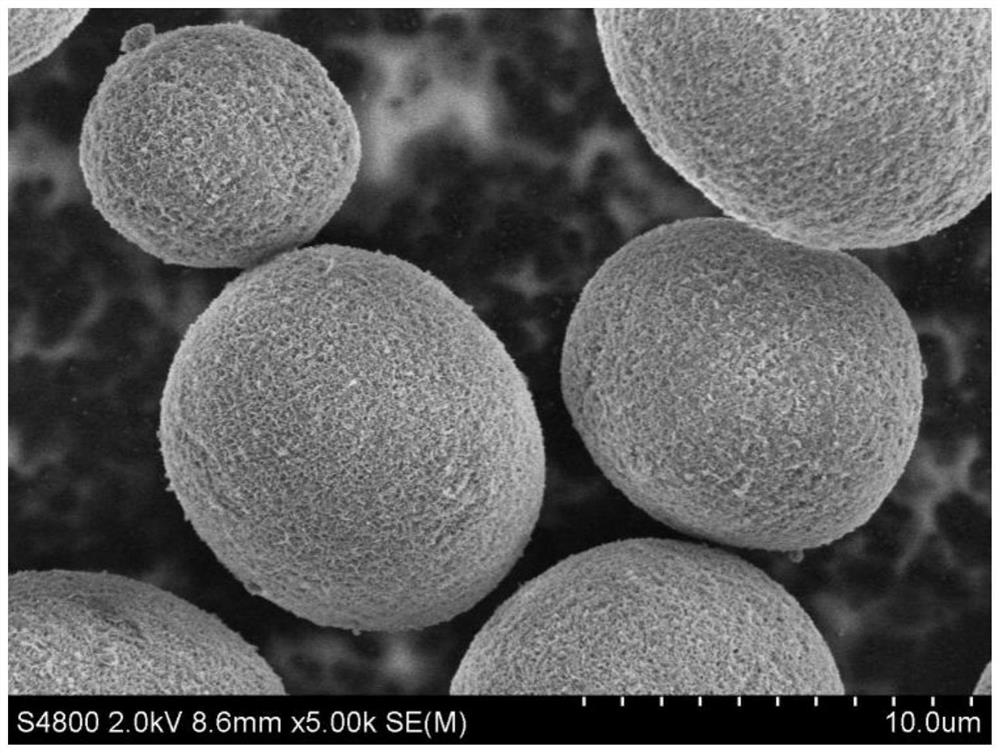

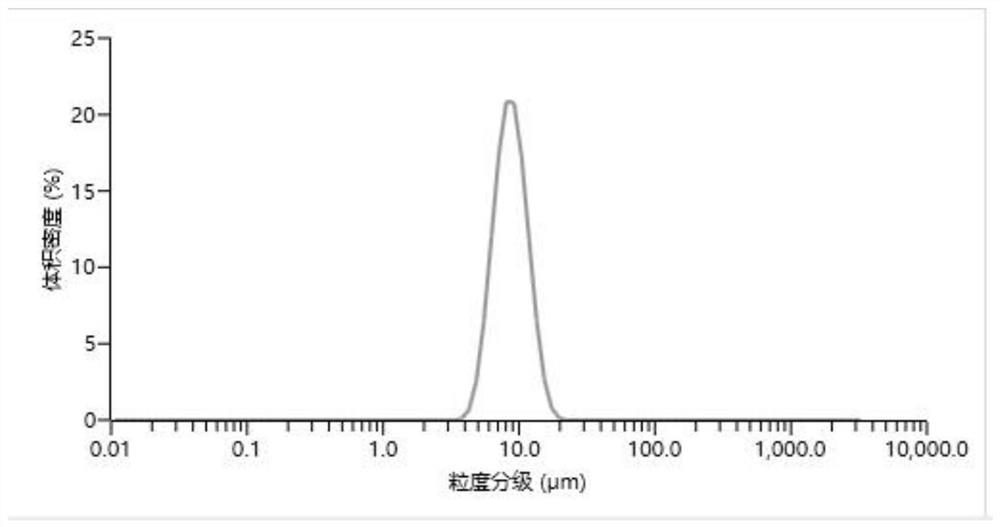

A lithium-rich manganese-based, double-layer composite technology, applied in chemical instruments and methods, nickel compounds, structural parts, etc., can solve the problems of narrow particle size distribution, high sphericity, high vibration, etc., to achieve narrow particle size distribution, sphericity High, high vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

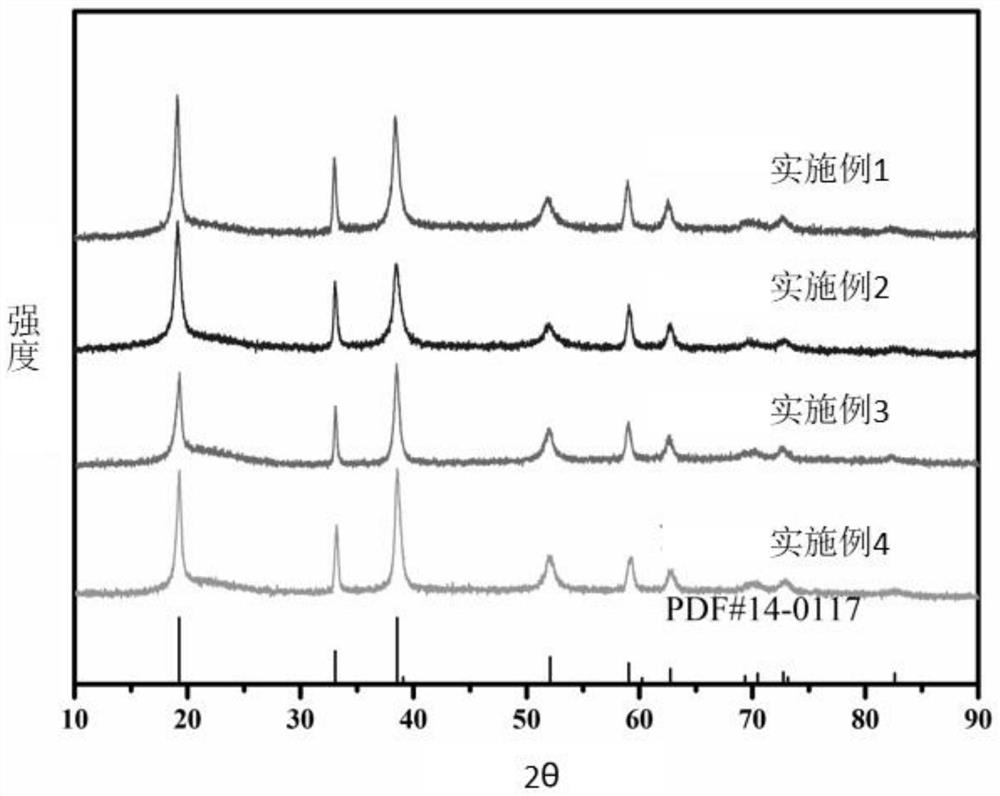

Embodiment 1

[0027] Prepare soluble nickel-manganese sulfate in a ratio of 1:3 (nickel element to manganese element is 1:3), and prepare a mixed solution with a concentration of 1.6mol / L; add citric acid with a concentration of 1.5g / L to the mixed solution , configure a mixed alkali solution with a molar ratio of sodium hydroxide and sodium carbonate of 1:40; add 35L of pure water to a 50L reactor, add 3.5g of ascorbic acid, 2L of ammonia water and 400ml of sodium hydroxide solution to prepare a bottom solution; heat up to 50°C , pass nitrogen gas for 2 hours, wait for the temperature and rotation speed to be constant, the first stage of reaction: flow sodium hydroxide solution, ammonia water and metal salt solution into the reactor; adjust the flow rate of sodium hydroxide solution, adjust the ph at about 11.8, and make the particle size grow steadily to 5 microns; the second stage of reaction: stop feeding ammonia water, and replace the sodium hydroxide solution with the above-mentioned m...

Embodiment 2

[0029] The soluble nickel-manganese sulfate is formulated into a mixed solution with a concentration of 1.8mol / L according to the ratio of 1:3; citric acid with a concentration of 2.0g / L is added to the mixed solution, and the molar ratio of sodium hydroxide and sodium carbonate is configured as 1:30 mixed alkali solution; add 35L of pure water to a 50L reactor, add 3.5g of ascorbic acid, 2L of ammonia water and 400ml of sodium hydroxide solution to make a bottom solution; raise the temperature to 55°C, blow nitrogen for 2 hours, wait until the temperature and speed are constant, and react The first stage: flow sodium hydroxide solution, ammonia water and metal salt solution into the reactor; by adjusting the flow rate of sodium hydroxide solution, adjust the pH at about 11.6, so that the particle size can grow steadily to 5 microns; the second stage of the reaction: stop the process ammonia water, and replace the sodium hydroxide solution with the above-mentioned mixed alkali ...

Embodiment 3

[0031] The soluble nickel-manganese sulfate is formulated into a mixed solution with a concentration of 1.8mol / L according to the ratio of 1:3; citric acid with a concentration of 2.0g / L is added to the mixed solution, and the molar ratio of sodium hydroxide and sodium carbonate is configured as 1:20 mixed alkali solution; add 35L of pure water to a 50L reactor, add 3.5g of ascorbic acid, 2L of ammonia water and 400ml of sodium hydroxide solution to make a bottom solution; raise the temperature to 55°C, blow nitrogen for 2 hours, wait until the temperature and speed are constant, and react The first stage: flow sodium hydroxide solution, ammonia water and metal salt solution into the reactor; by adjusting the flow rate of sodium hydroxide solution, adjust the pH at about 11.4, so that the particle size can grow steadily to 5 microns; the second stage of the reaction: stop the process ammonia water, and replace the sodium hydroxide solution with the above-mentioned mixed alkali ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com