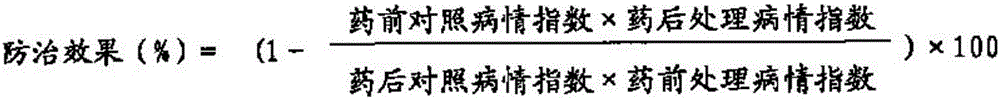

Patents

Literature

43results about How to "Slow down the speed of development" patented technology

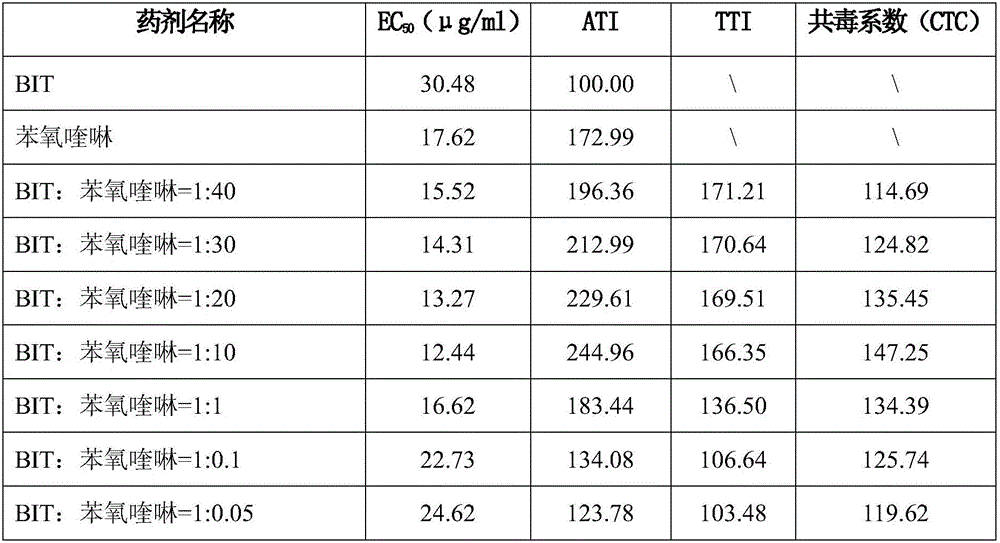

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

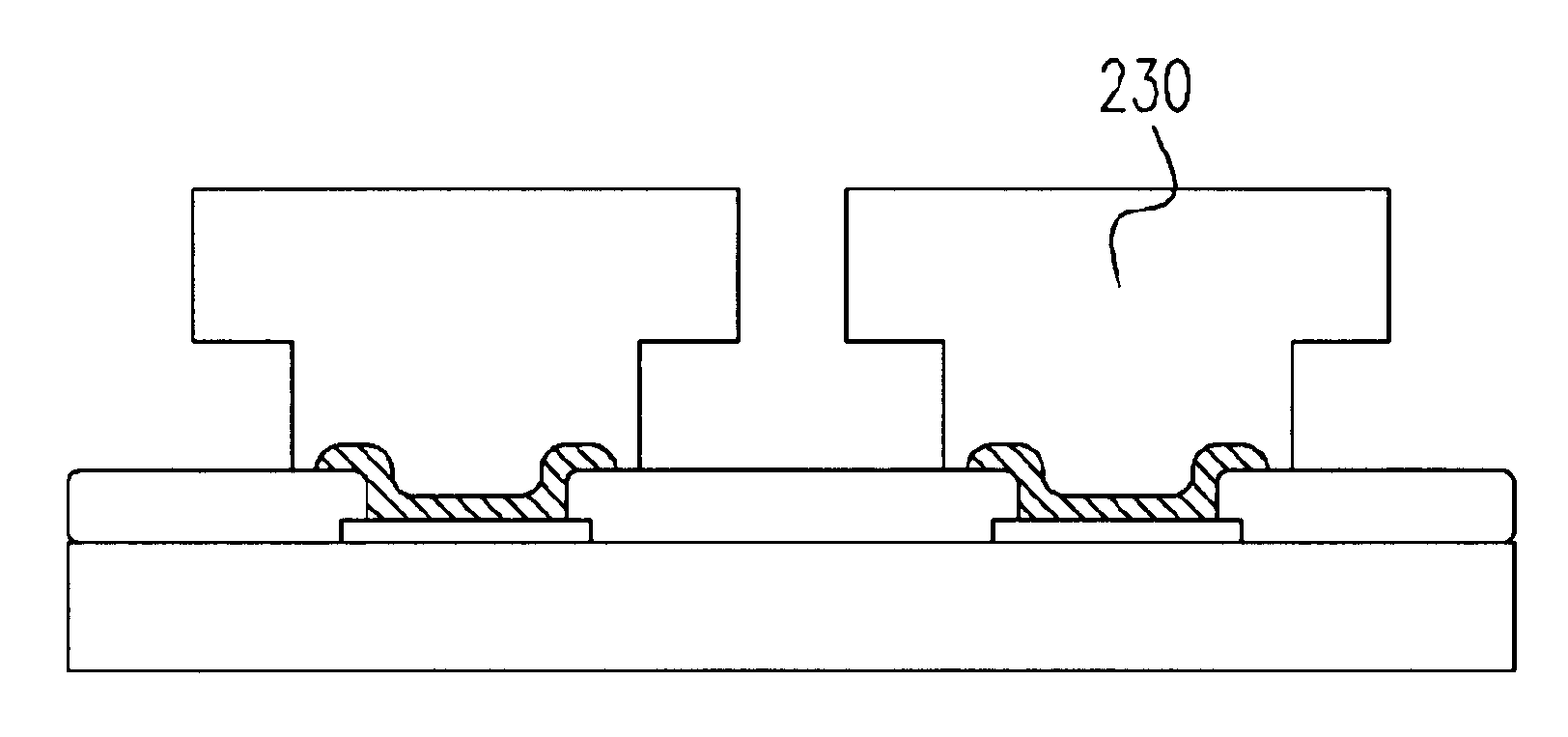

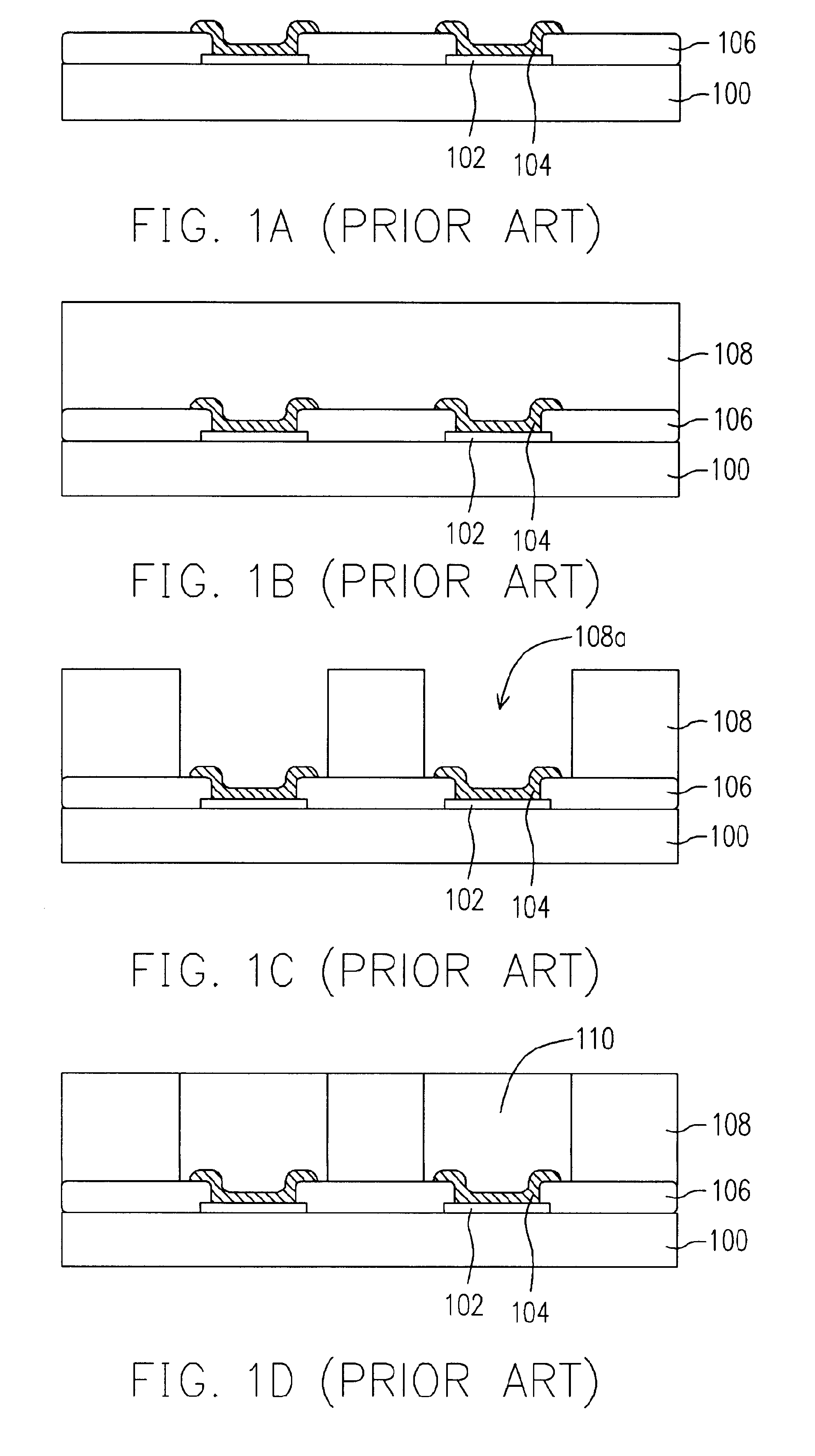

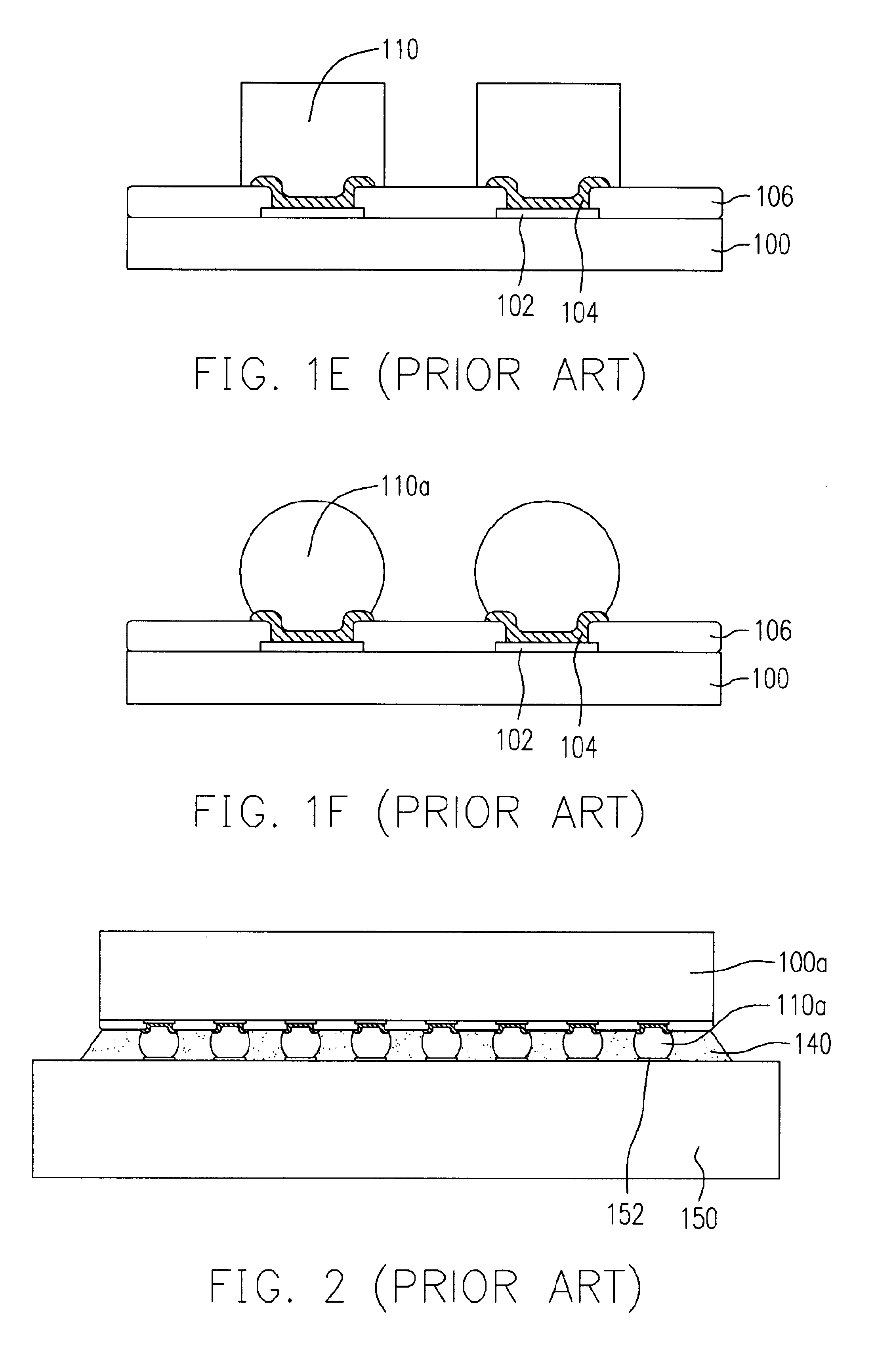

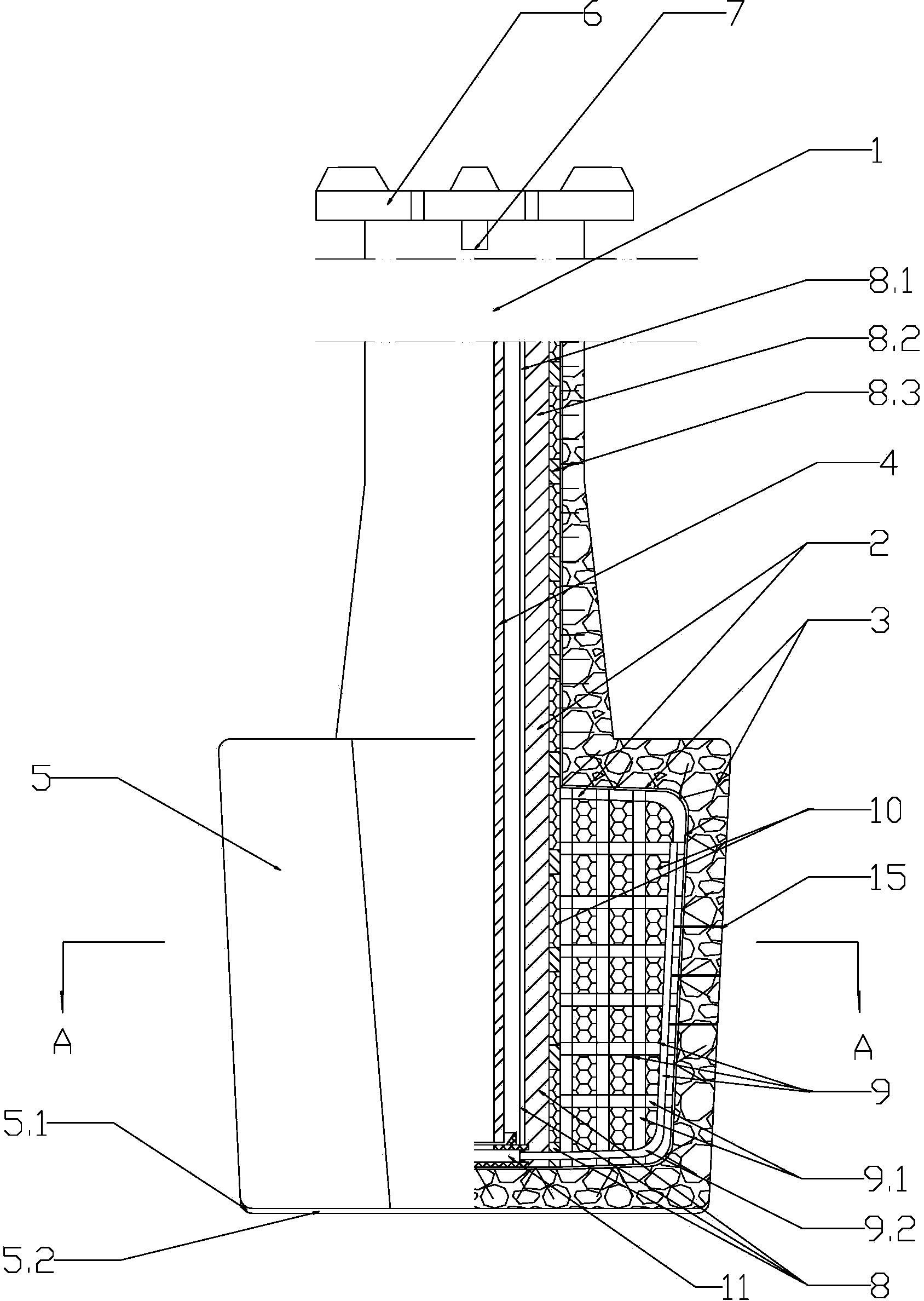

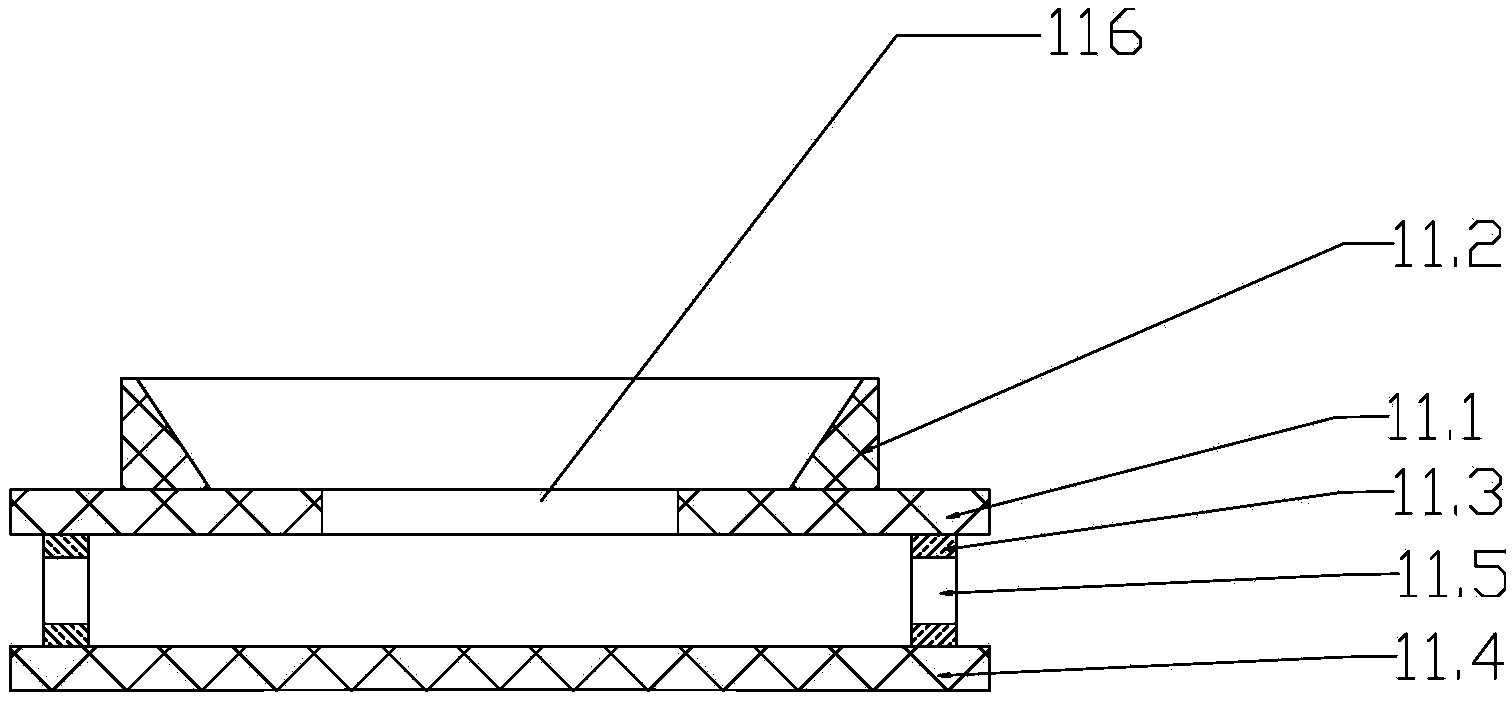

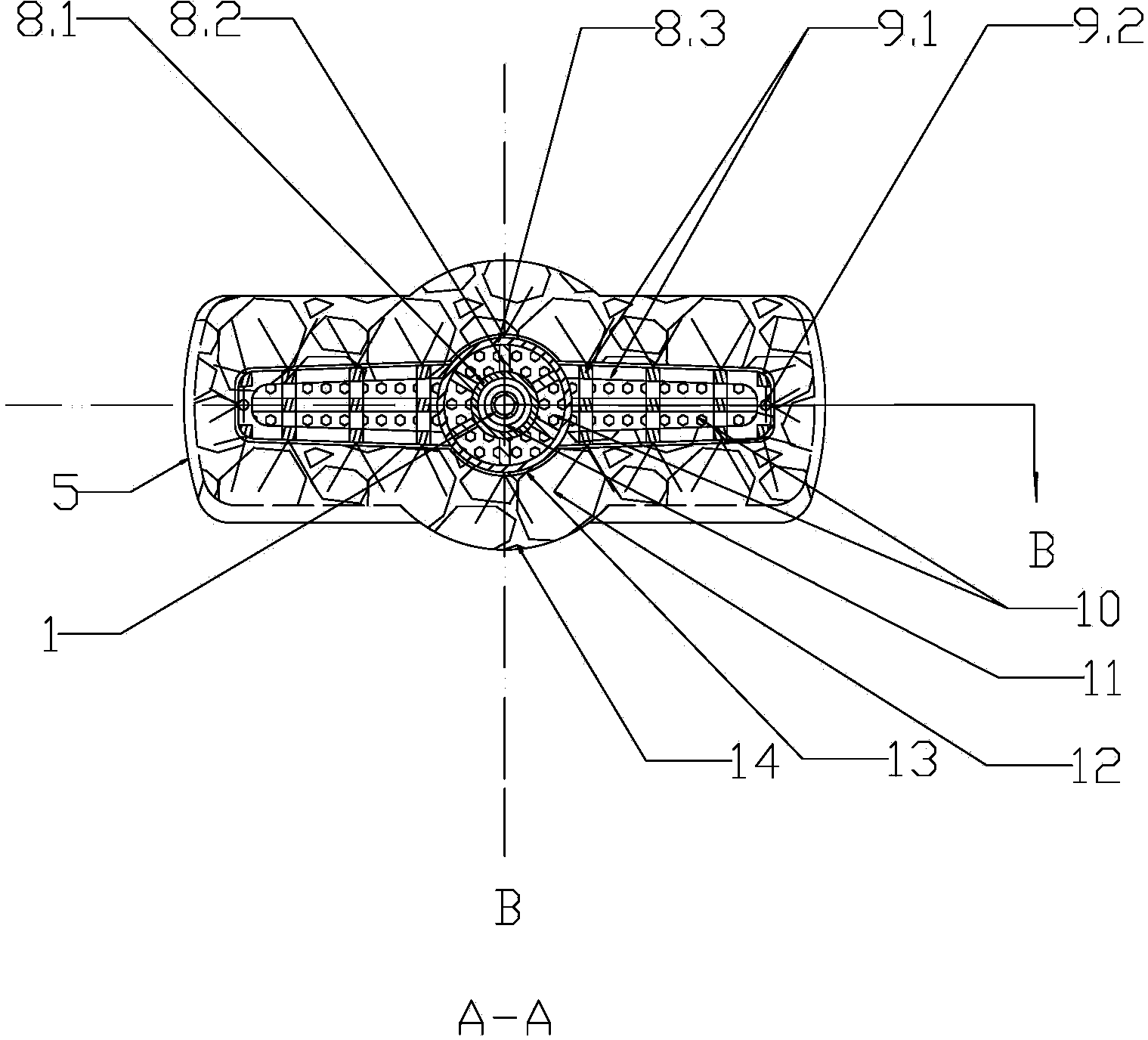

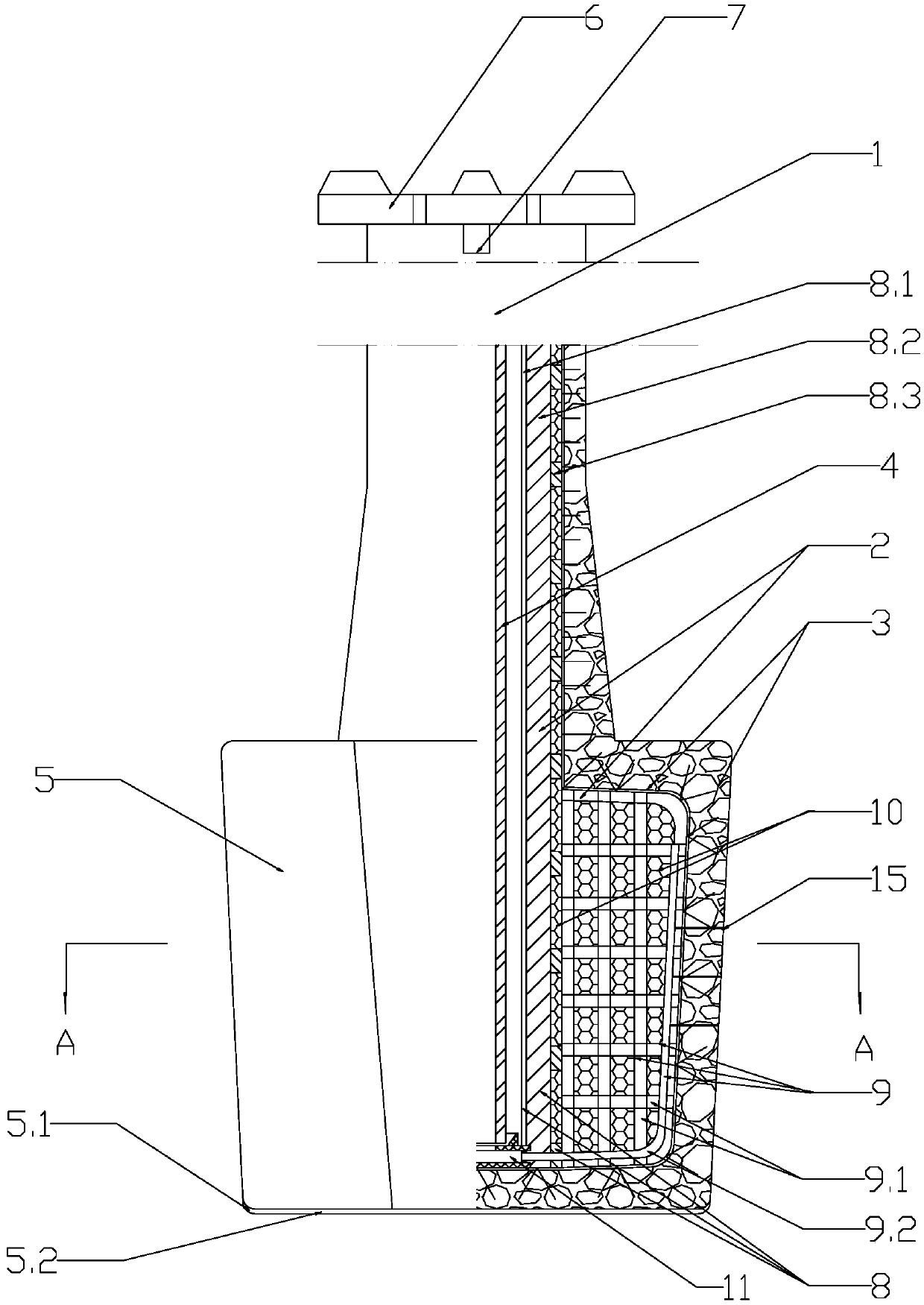

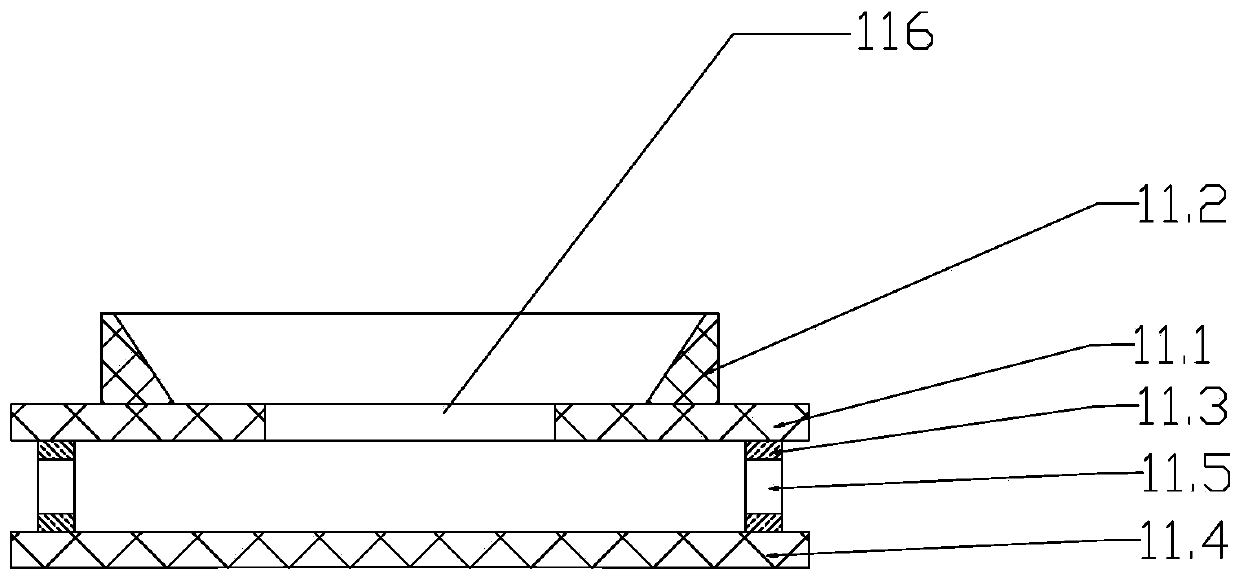

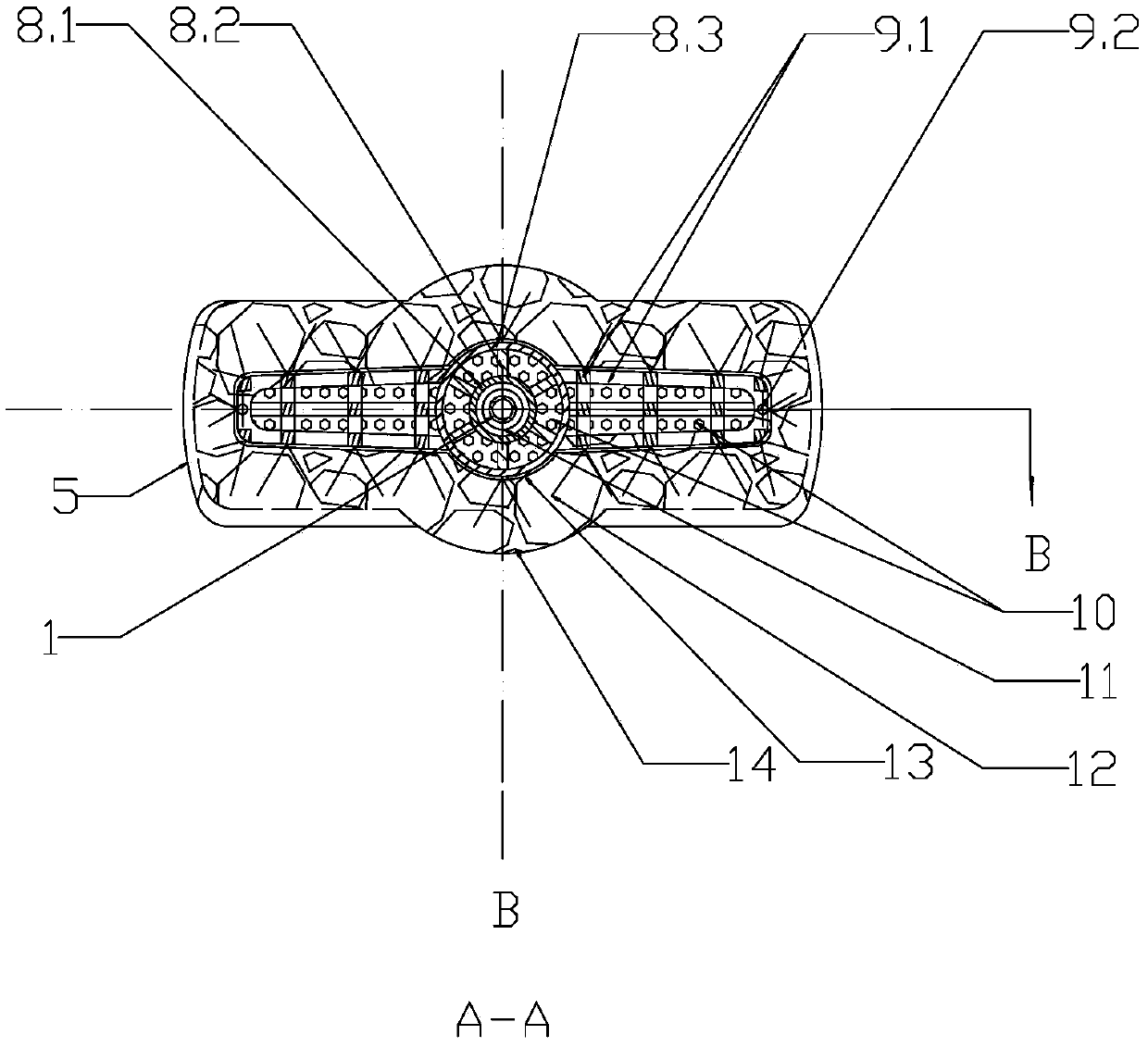

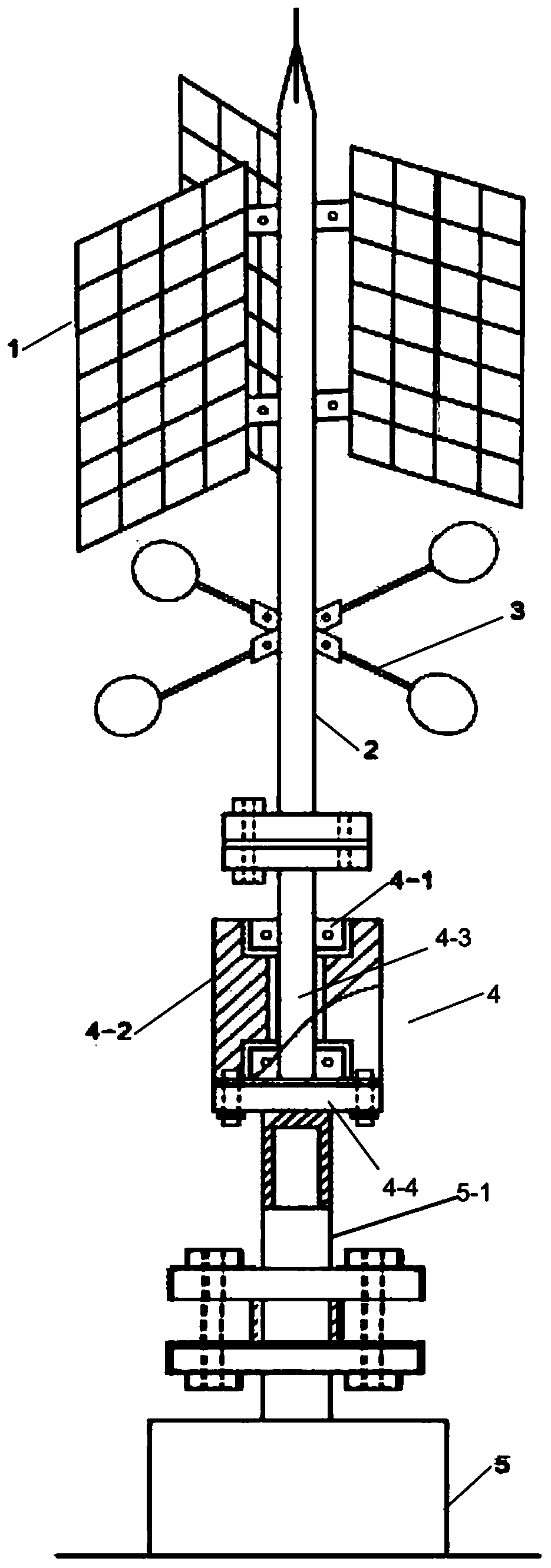

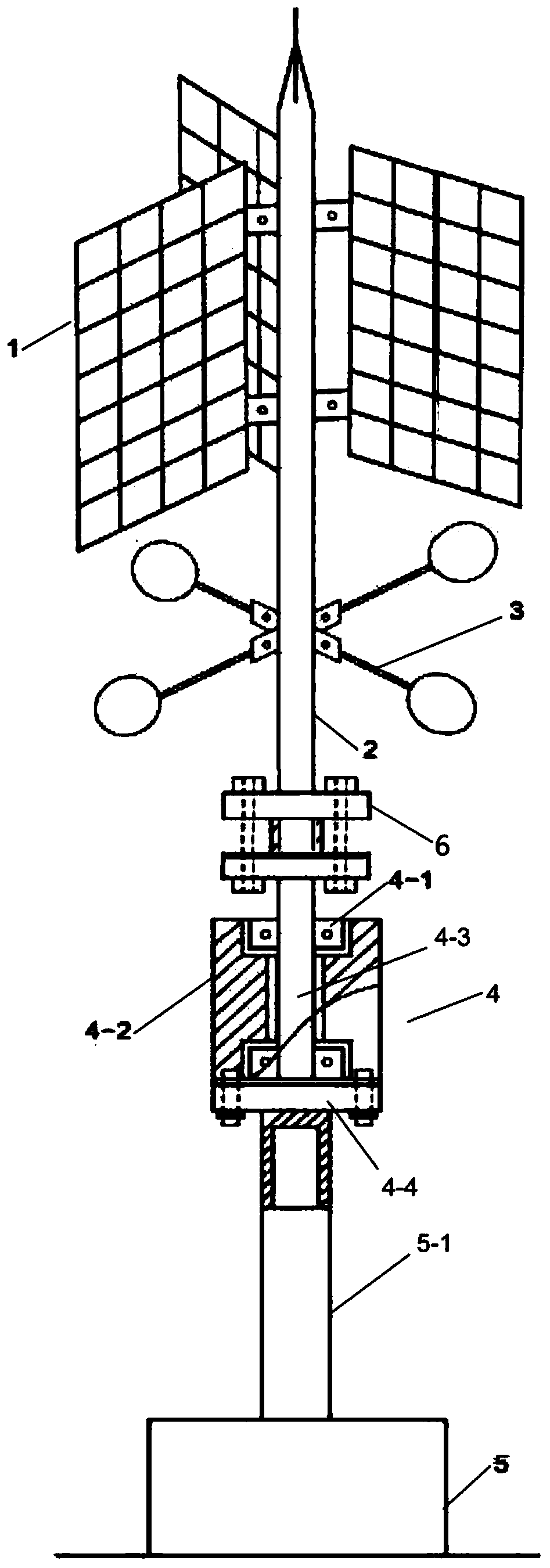

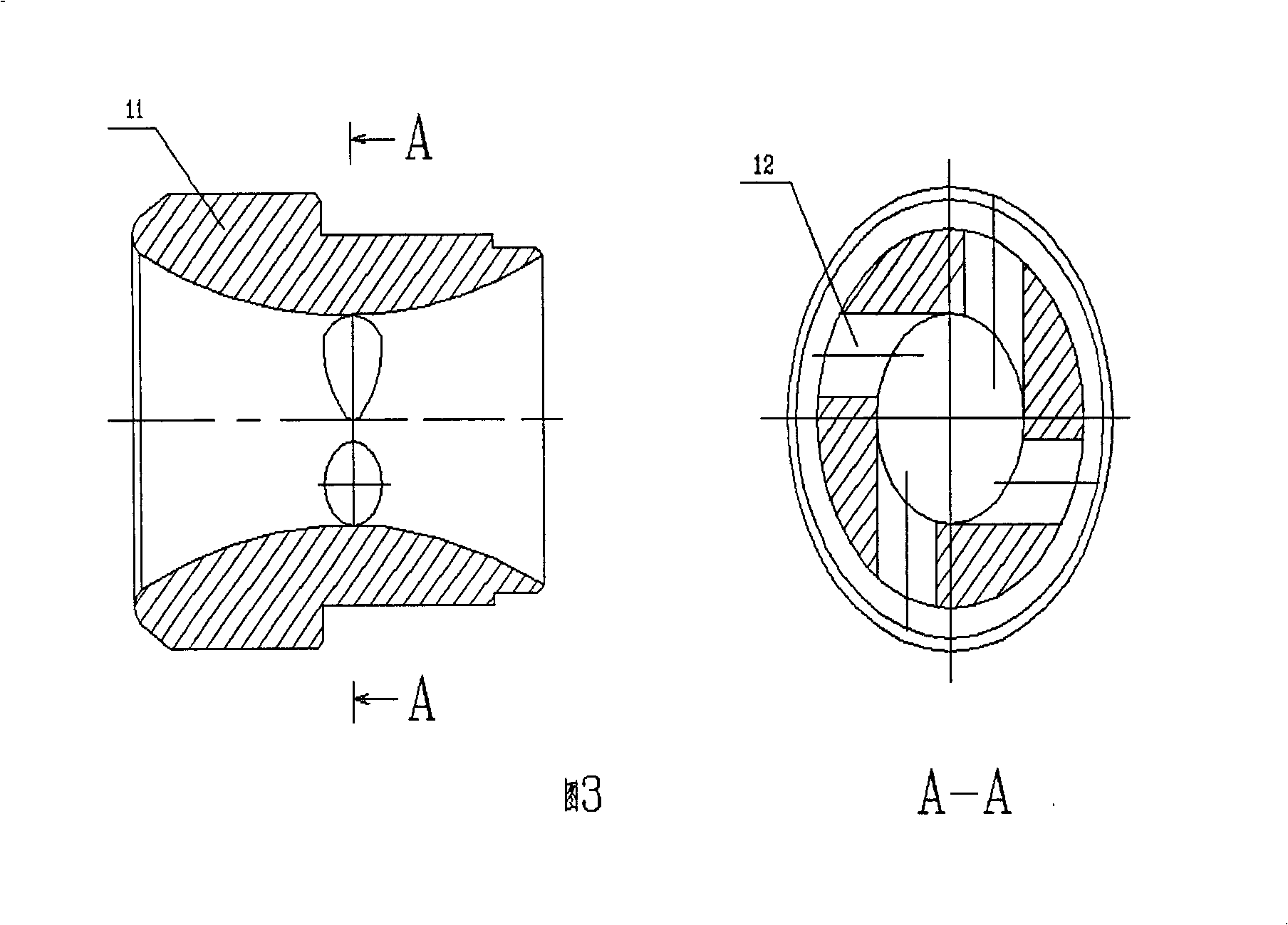

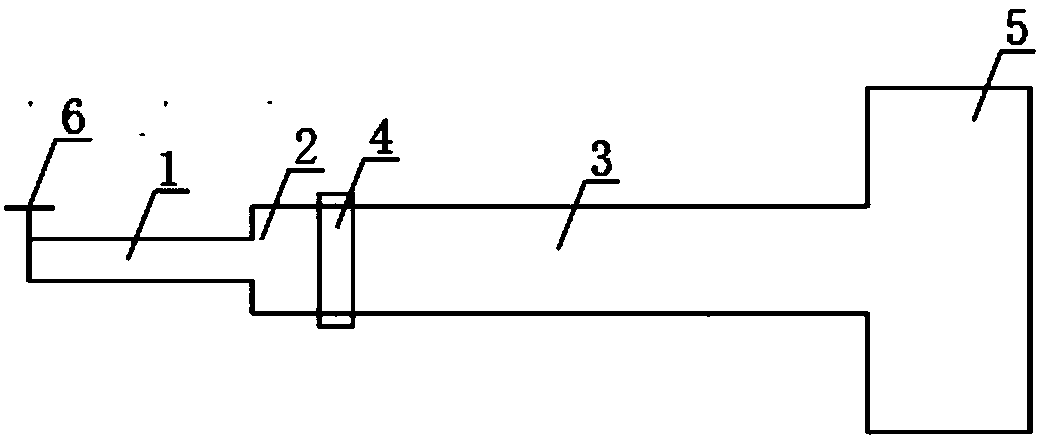

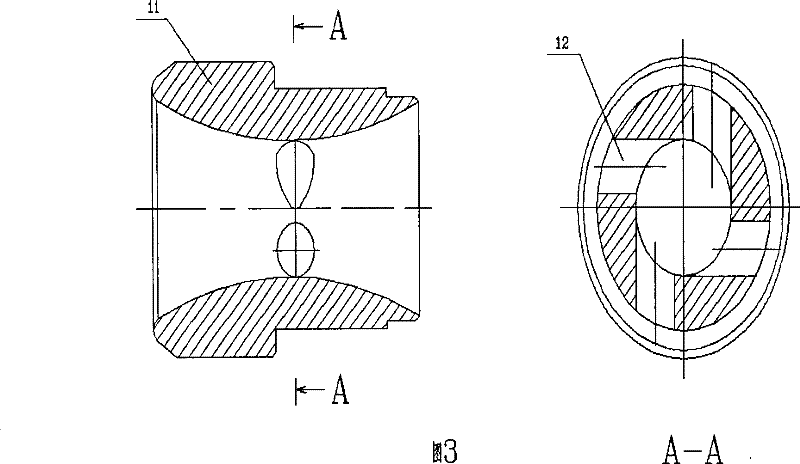

[bumping process]

ActiveUS20050020050A1Taller in heightLow costSemiconductor/solid-state device detailsSolid-state devicesSingle exposureEngineering

A bumping process is disclosed. The bumping process comprises the steps of: providing a wafer having a plurality of bonding pads and a passivation layer, wherein the passivation layer exposes the bonding pads; forming an UBM layer over the wafer to cover the bonding pads; forming two or more photoresist layers over the wafer, wherein the photoresist layers have different exposure and development characteristics; forming at least one or more stair-shaped openings in the photoresist layers by a single exposure corresponding to the bonding pads; filling solder into the stair-shaped openings to form a plurality of solder bumps; removing the entire photoresist layer. The bumping process can provide bumps with higher heights, so that the connection between chips and carriers becomes more reliable.

Owner:ADVANCED SEMICON ENG INC

Bumping process

ActiveUS6930031B2Increase heightBondingSemiconductor/solid-state device detailsSolid-state devicesSingle exposureEngineering

A bumping process is disclosed. The bumping process comprises the steps of: providing a wafer having a plurality of bonding pads and a passivation layer, wherein the passivation layer exposes the bonding pads; forming an UBM layer over the wafer to cover the bonding pads; forming two or more photoresist layers over the wafer, wherein the photoresist layers have different exposure and development characteristics; forming at least one or more stair-shaped openings in the photoresist layers by a single exposure corresponding to the bonding pads; filling solder into the stair-shaped openings to form a plurality of solder bumps; removing the entire photoresist layer. The bumping process can provide bumps with higher heights, so that the connection between chips and carriers becomes more reliable.

Owner:ADVANCED SEMICON ENG INC

Method of preparing Ni-Co nano compound multi-layered alloy

The invention provides a method of preparing a Ni-Co nano compound multi-layered alloy. The method comprises the following steps of: S1, preparing a Ni-Co nano compound electrolyte; and S2, putting a plating article in the Ni-Co nano compound electrolyte, performing electrodeposition by means of a three current cyclic step change method, taking out the plating article after electrodeposition, washing the plating article thoroughly and naturally airing the plating article. According to the method of preparing the Ni-Co nano compound multi-layered alloy provided by the invention, the obtained plating layer is a multi-layered structure. Nanoparticles are uniformly dispersed, and the invention provides a novel method for electrodepositing preparation of the corrosion-resistant wear-resistant compound multi-layered alloy.

Owner:HOHAI UNIV

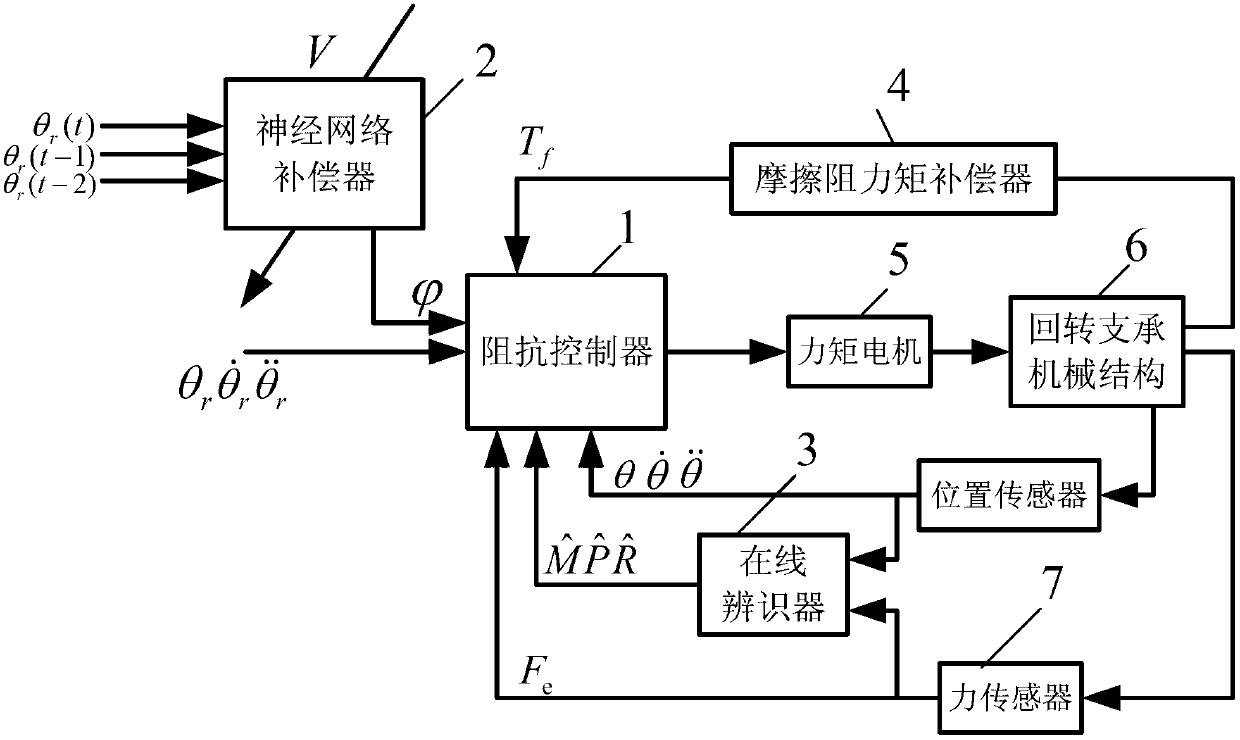

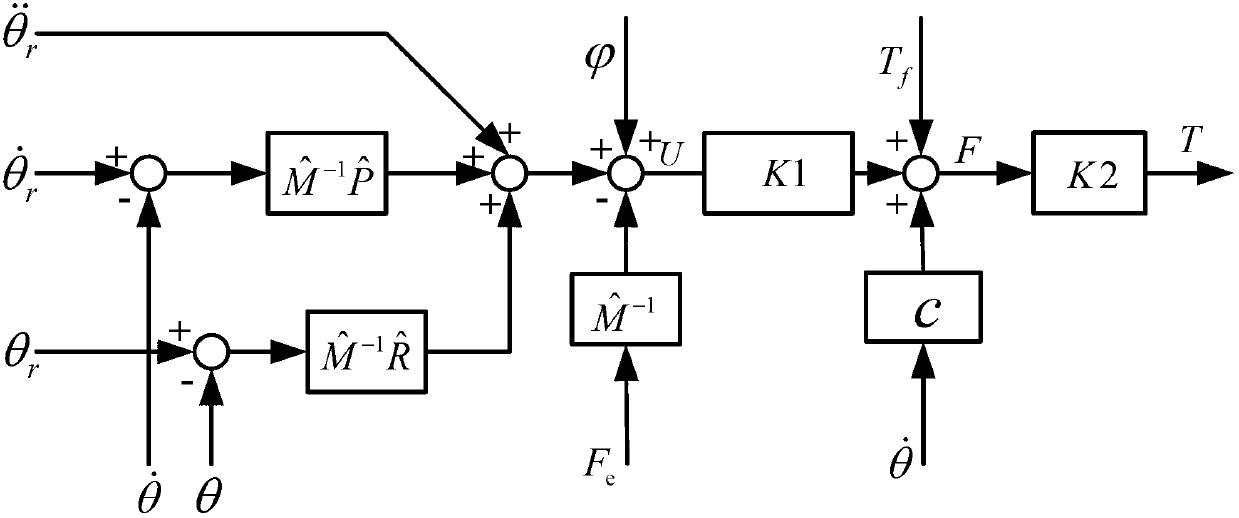

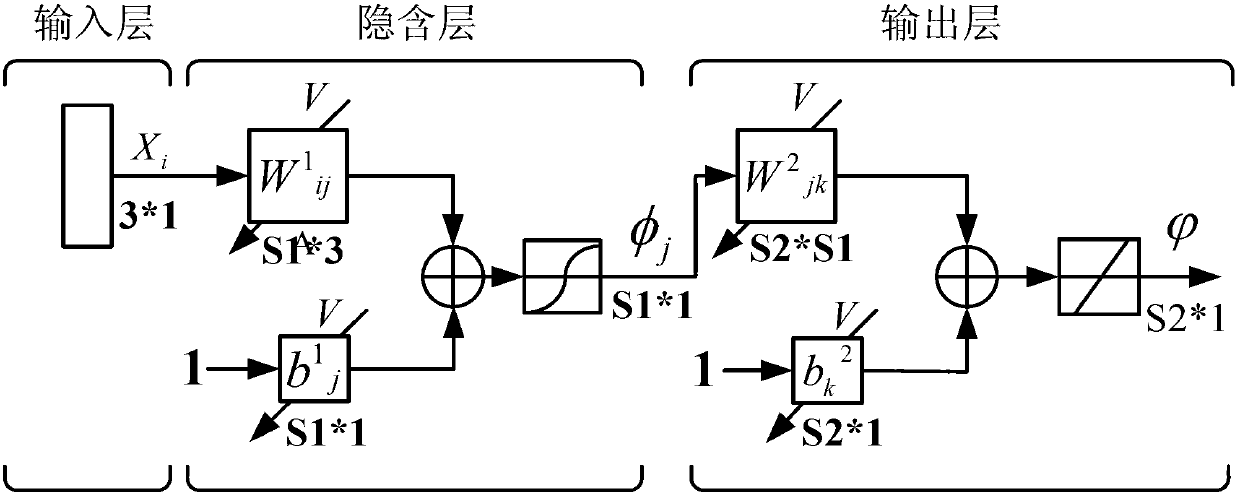

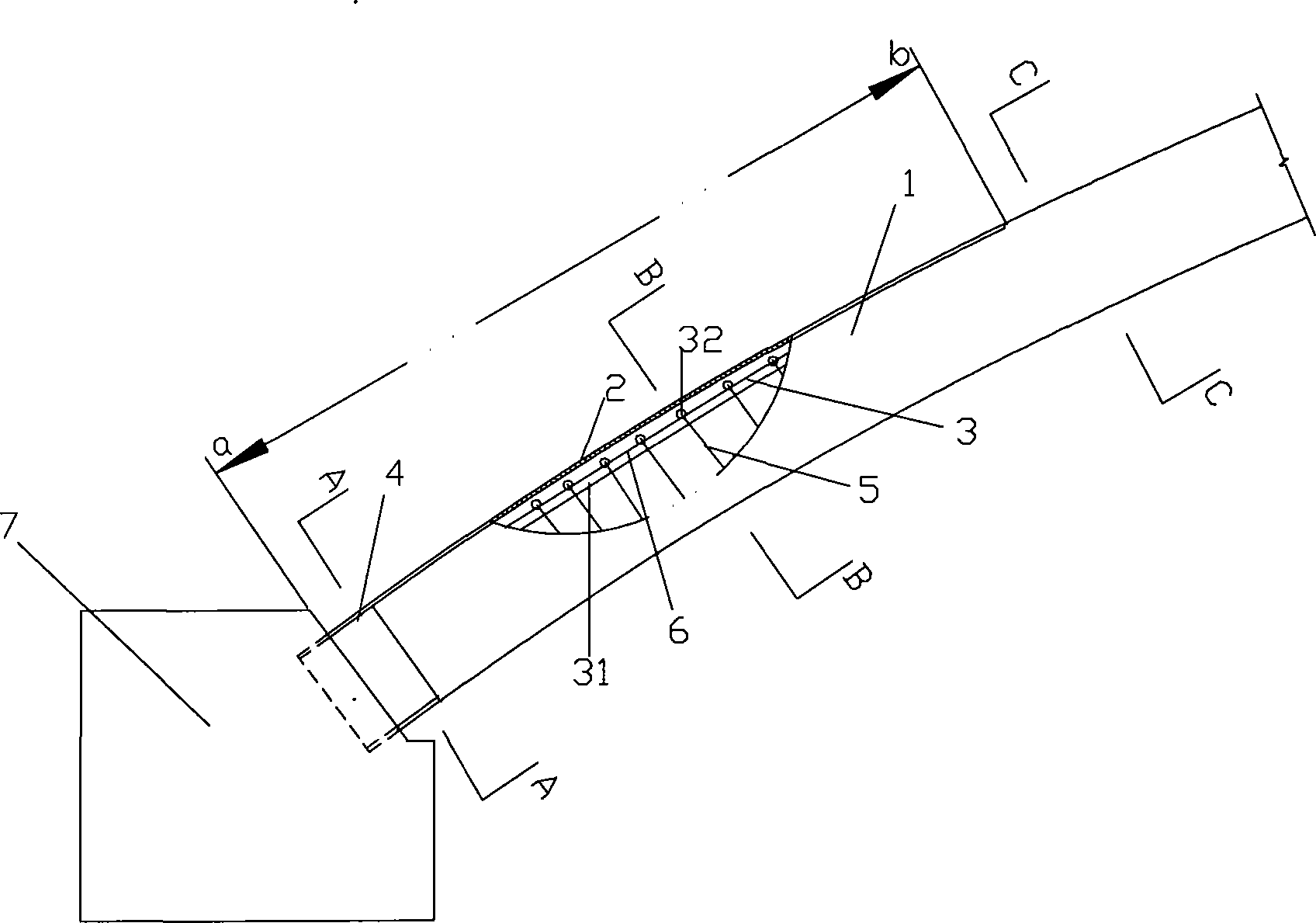

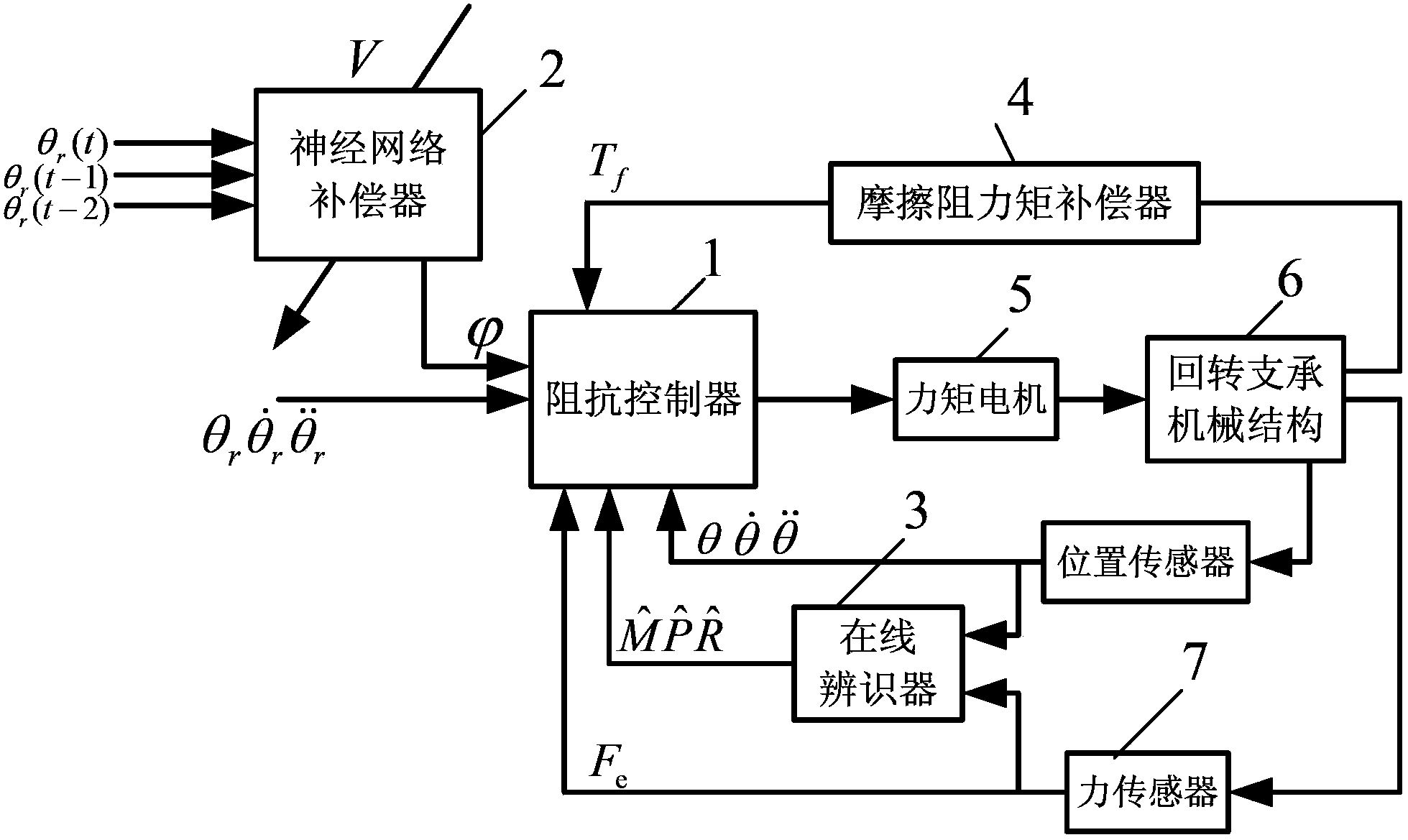

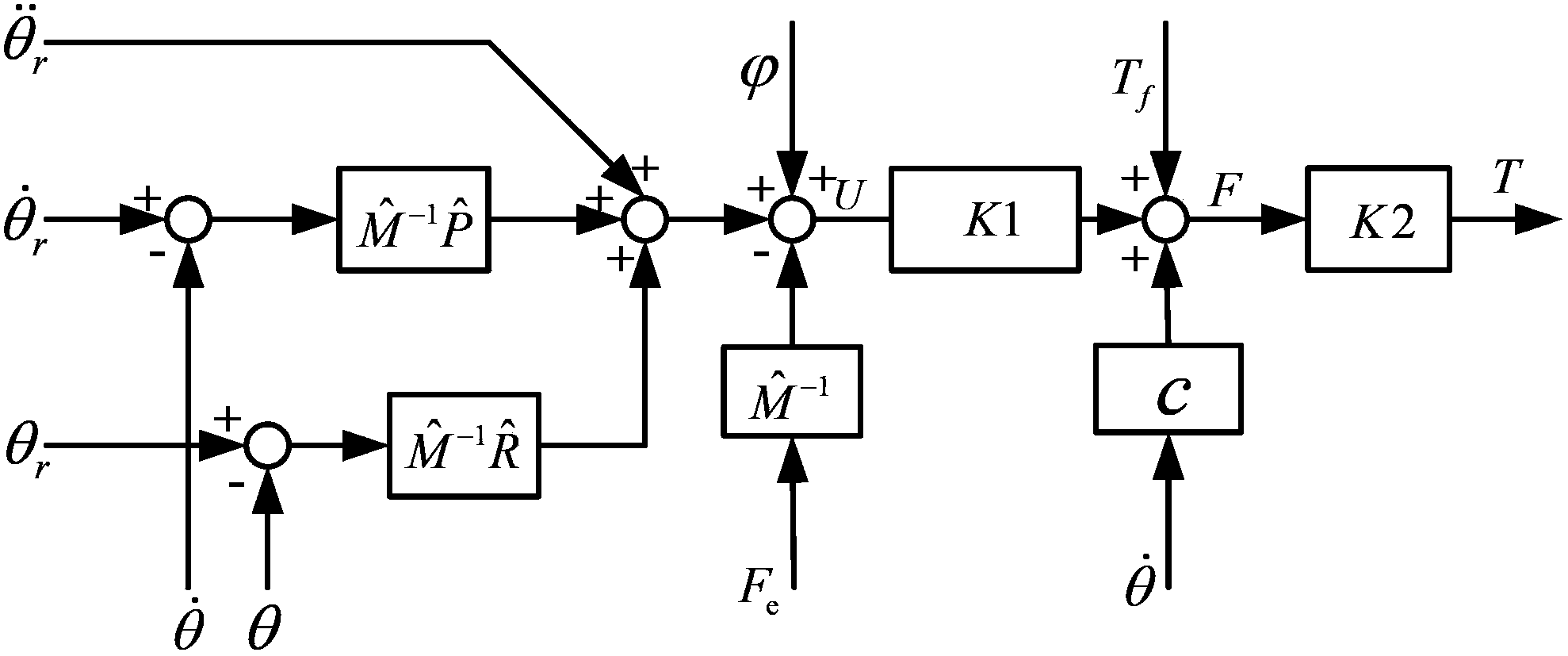

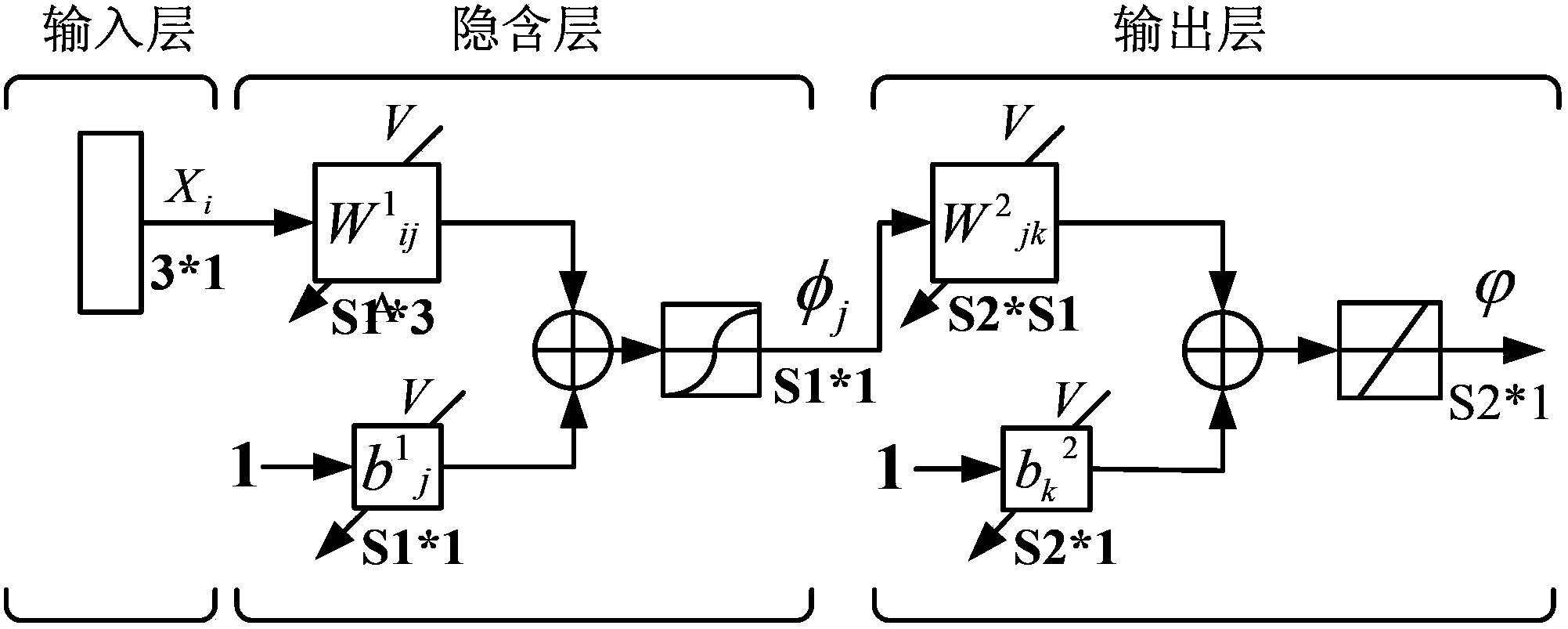

Intelligent movement control method for prolonging service life of slewing bearing

ActiveCN102819219AImplementation locationExtended service lifeAdaptive controlTorque motorElectric machinery

The invention discloses an intelligent movement control method for prolonging service life of a slewing bearing. The intelligent movement control method is characterized by comprising the following steps of: inputting an expected track theta r into an impedance controller (1); measuring interaction force Fe of the tail end of a slewing bearing mechanical structure and an environment through a force sensor (7); inputting a compensation signal of a frictional resisting moment compensator (4) into the impedance controller (1); inputting a reference track theta r(t), theta r(t-1) and theta r(t-2) into a neural network compensator (2); and leading a drive torque signal T obtained by the impedance controller (1) into a torque motor (5), and driving the slewing bearing mechanical structure (6) by the torque motor. According to the intelligent movement control method for prolonging the service life of the slewing bearing, disclosed by the invention, accurate force and position control of the slewing bearing mechanical structure is achieved, therefore, power loss is reduced, the occurrence probability and the development speed of damage are effectively reduced, and the service life is prolonged.

Owner:NANJING UNIV OF TECH +1

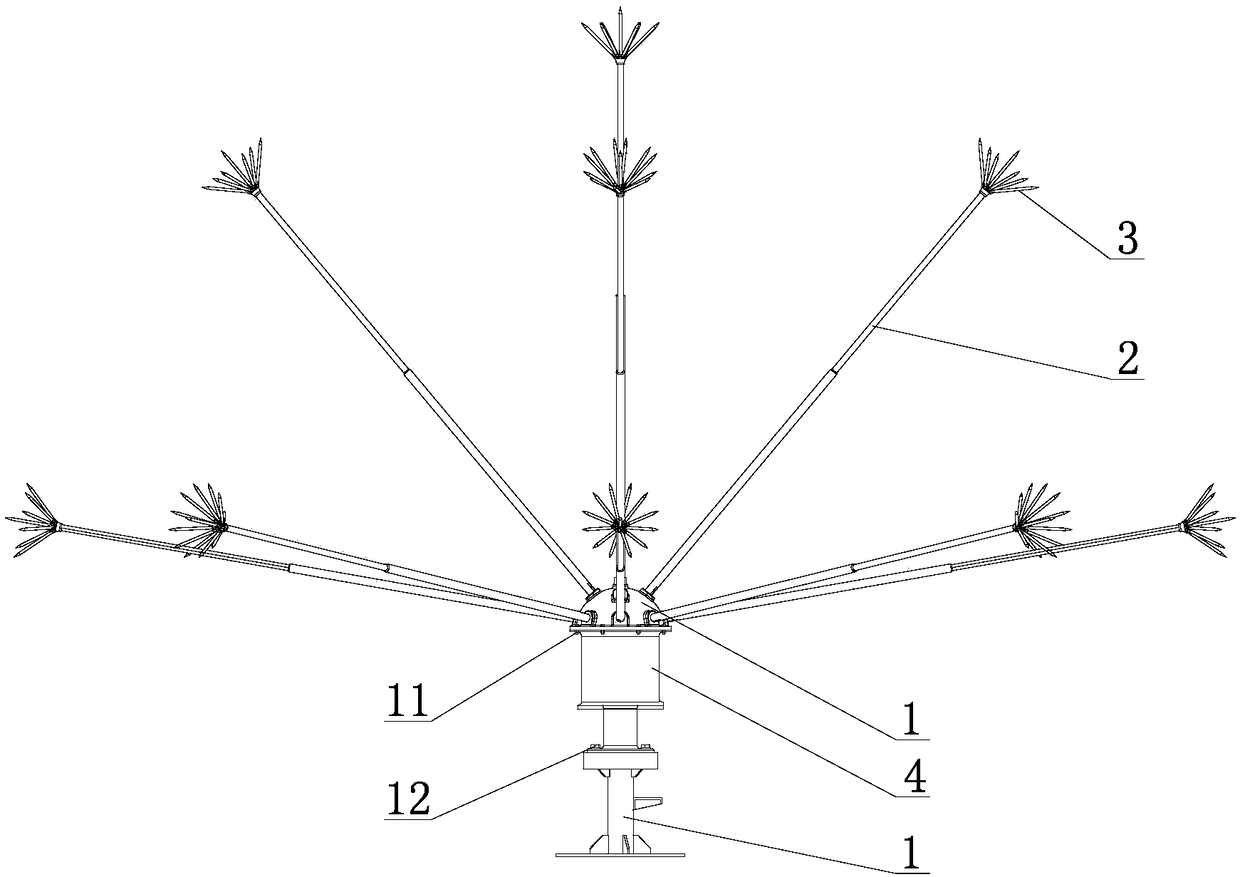

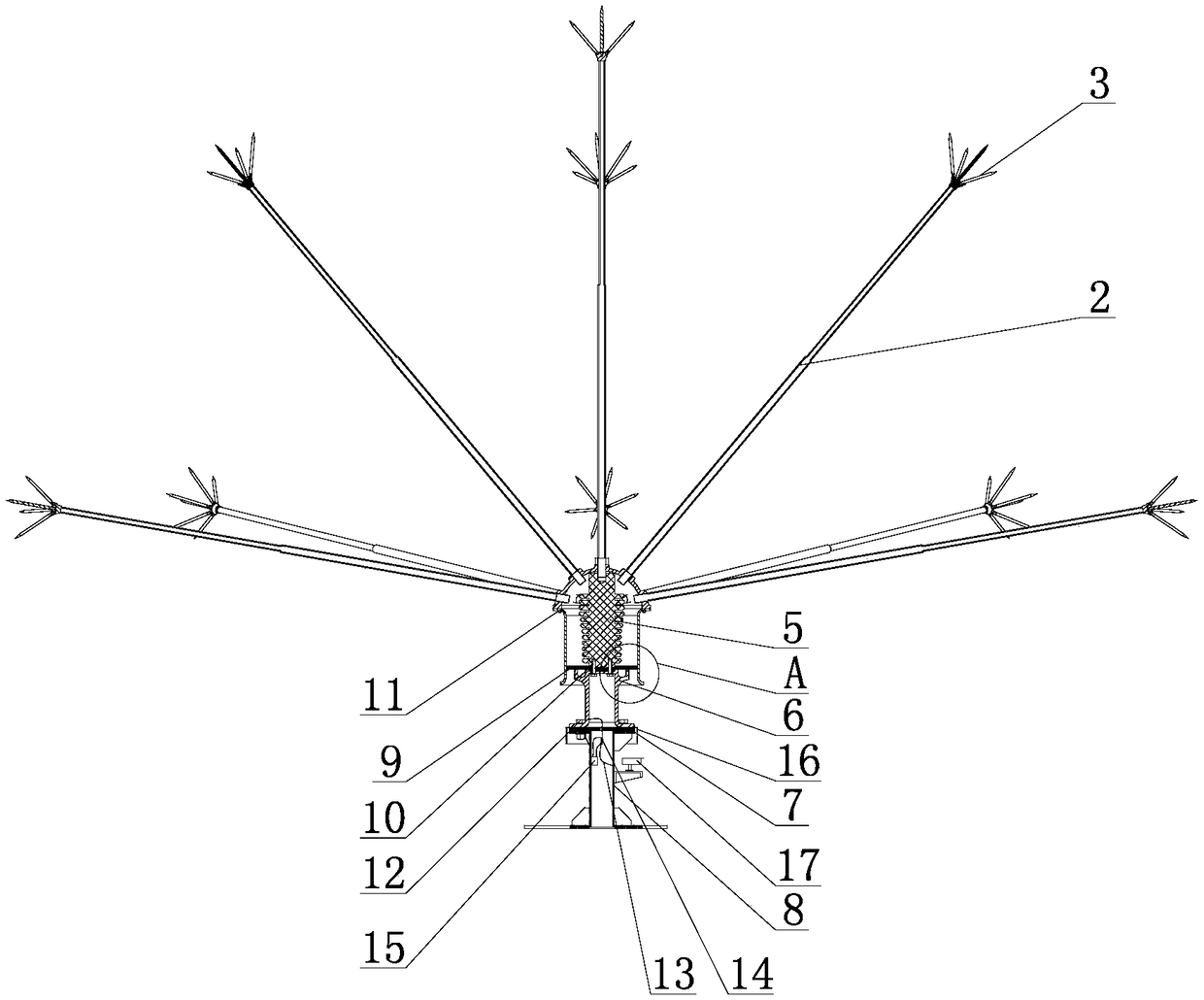

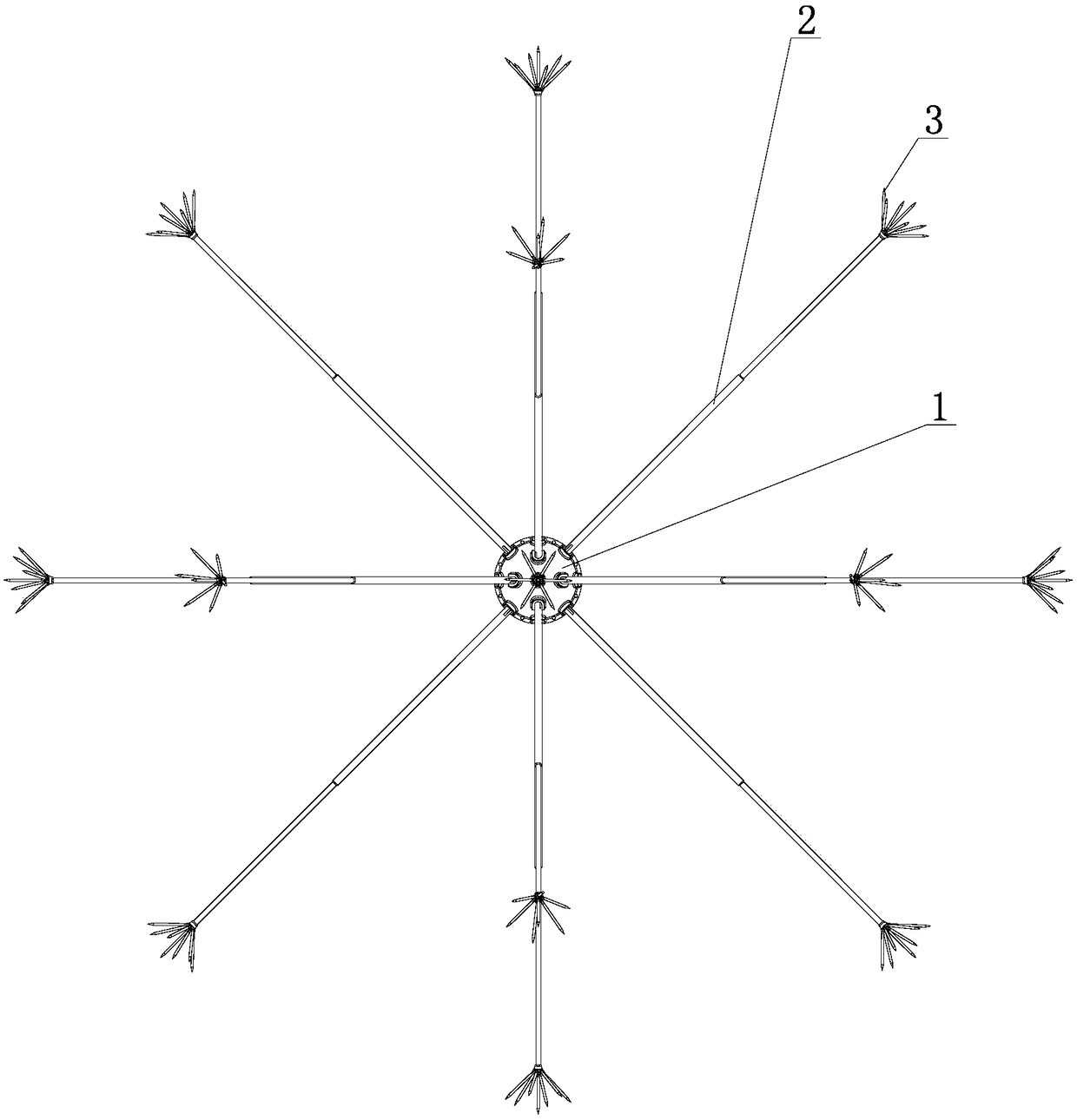

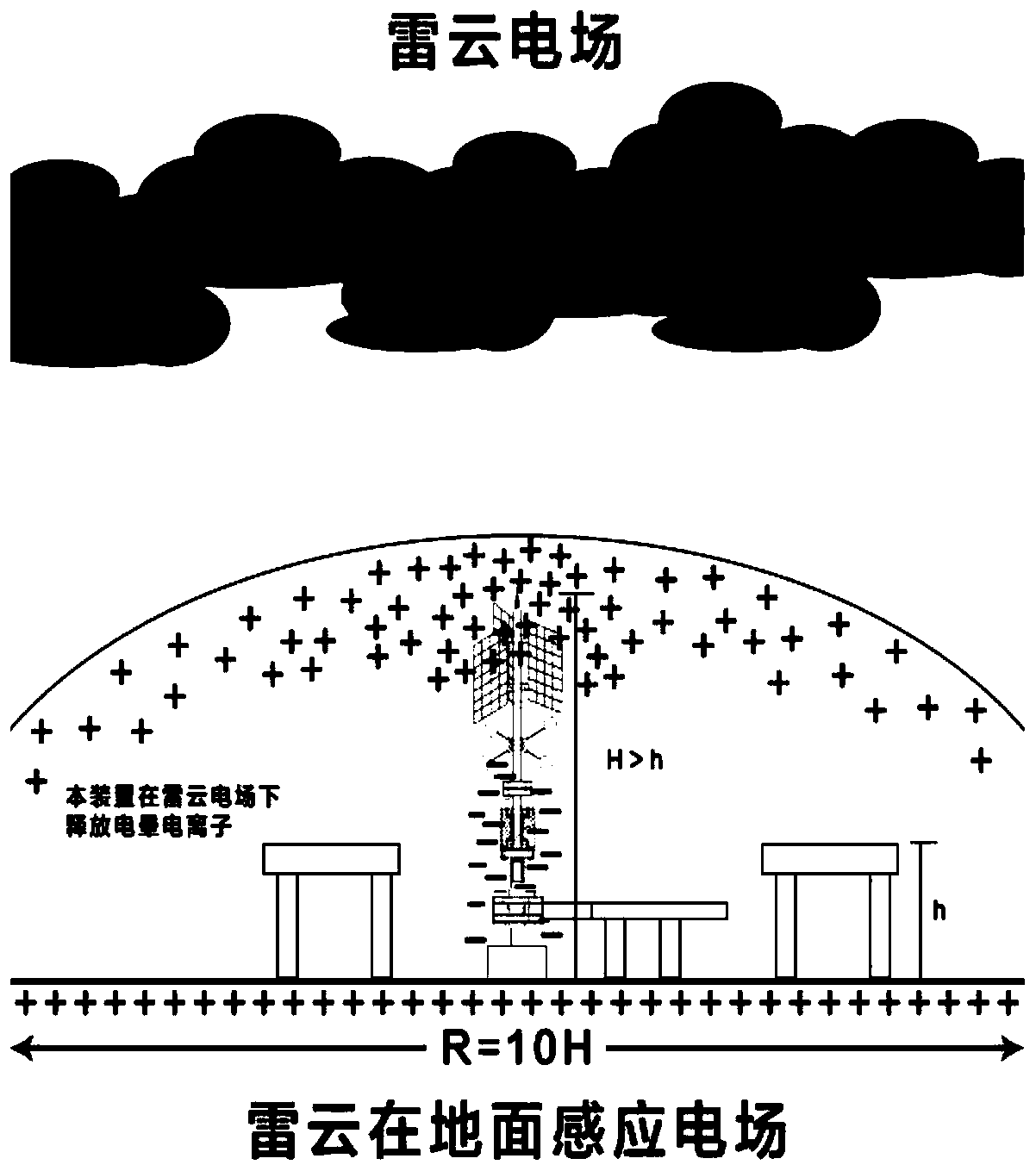

Corona field lightning arrester and lightning arresting method thereof

The invention provides a corona field lightning arrester and a lightning arresting method thereof. The corona field lightning arrester comprises a metal housing. The metal housing is uniformly provided with a plurality of discharge levers at intervals; the upper end of each discharge lever is provided with a plurality of upper discharge electrodes; the lower end of the metal housing is connected with a discharge cylinder; the discharge cylinder at the lower end of the metal housing is internally provided with an insulation support; the upper end of the insulation support is connected with thedischarge lever arranged at the top end of the metal housing; the lower end of the insulation support is connected with a lower discharge electrode; a discharge gap is arranged between the outer wallof the lower discharge electrode and the inner wall of the discharge cylinder; the lower end of the lower discharge electrode is connected with a transition section support through an insulation pad plate; and the lower discharge electrode is connected to the ground through a grounding wire. The corona field lightning arrester has the advantages of reasonable structure design, no need of a power supply, utilization of thundercloud electric field self-excited corona discharge, reliable and stable lightning arresting, no negative impact on the surrounding facilities, easy installation, high windresistance and online monitoring and the like.

Owner:山东中呈防雷科技有限公司

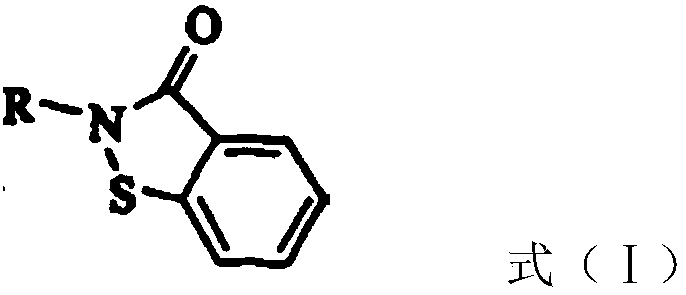

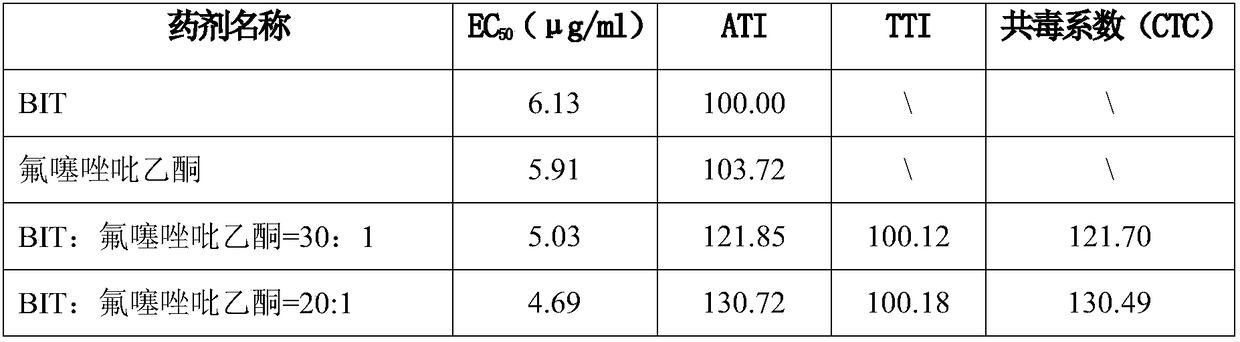

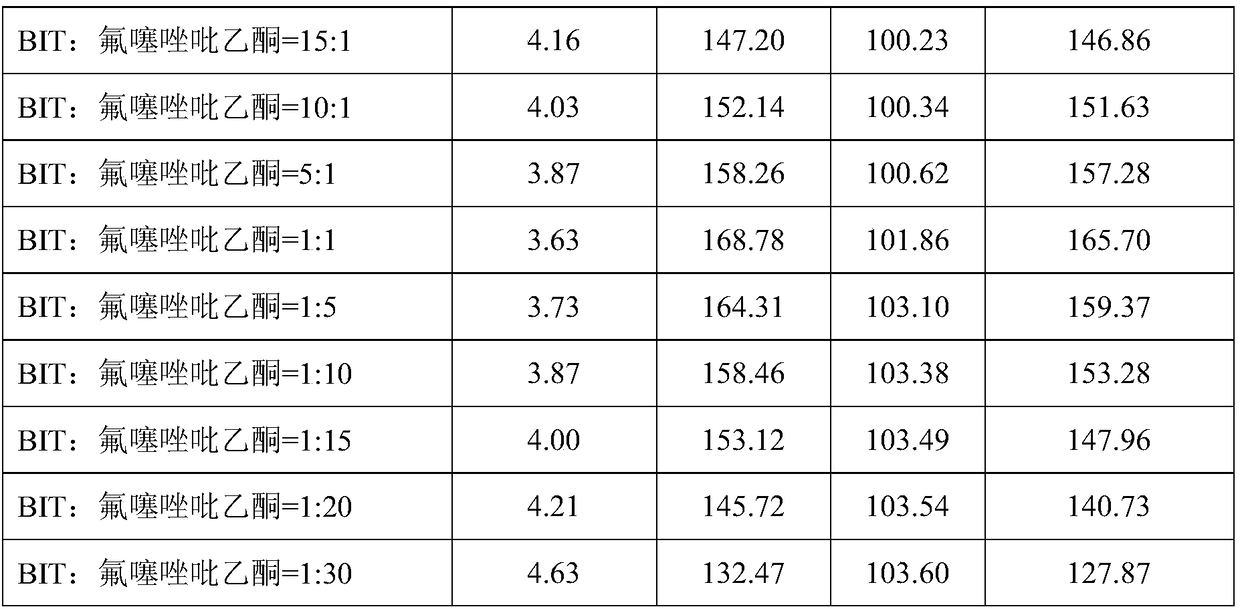

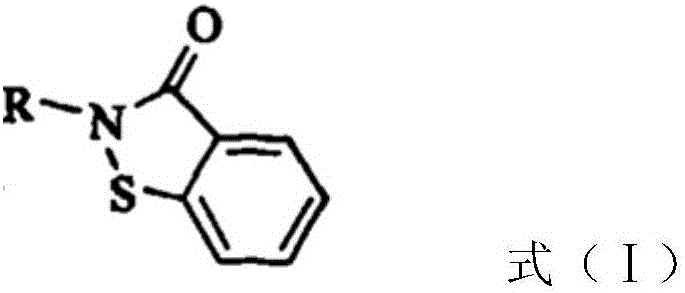

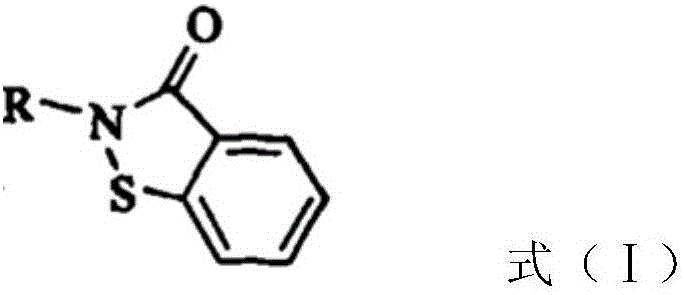

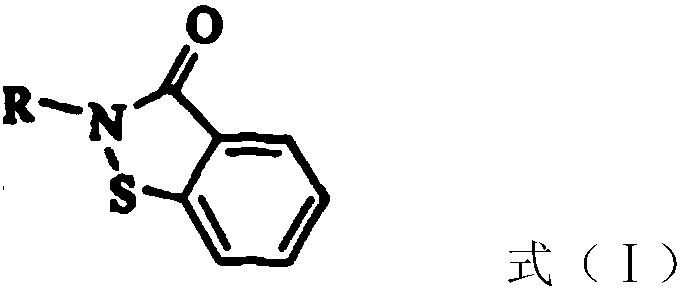

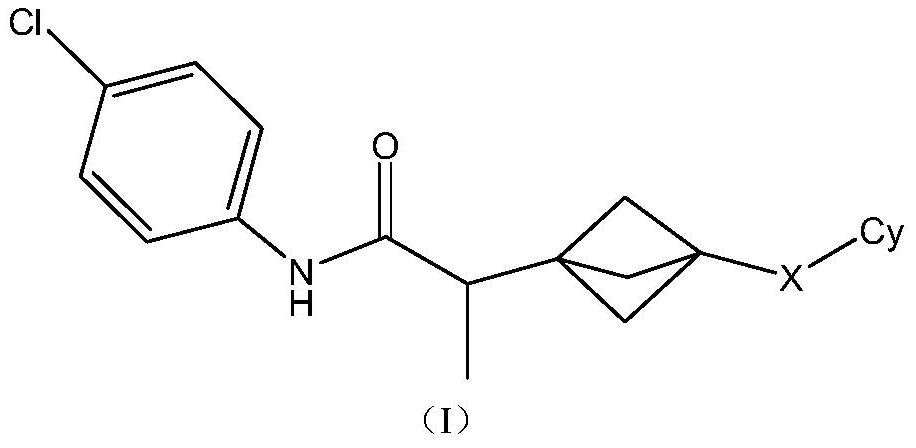

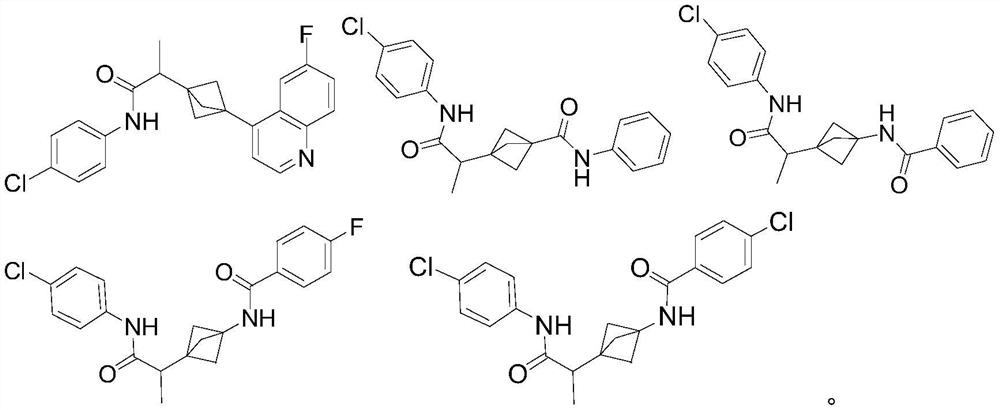

Bactericidal composition comprising benzisothiazolinones and oxathiapiprolin

InactiveCN108338173ASynergistic effect is obviousSignificant synergyBiocideDead animal preservationIsothiazolinoneFungal disease

The invention provides a bactericidal composition containing benzisothiazolinones and oxathiapiprolin, the bactericidal composition contains two active components of A and B, the active component A isa compound with the structure of formula I, the active component B is oxathiapiprolin, and the weight ratio of A to B is 20-1:1-20. The invention also provides a preparation method and application ofthe composition. The test results show that, the bactericidal composition has obvious synergistic effect, more important, the application amount is reduced, and the use cost is reduced. The bactericidal composition can effectively prevent and treat certain bacterial or fungal diseases of crops. By compounding of bactericides of different mechanisms and modes of action, the bactericidal composition has very good effects on expanding the bactericidal spectrum, delaying the fungal and bacterial resistance, improving the control effect and other aspects.

Owner:JIANGSU HUIFENG BIO AGRI CO LTD

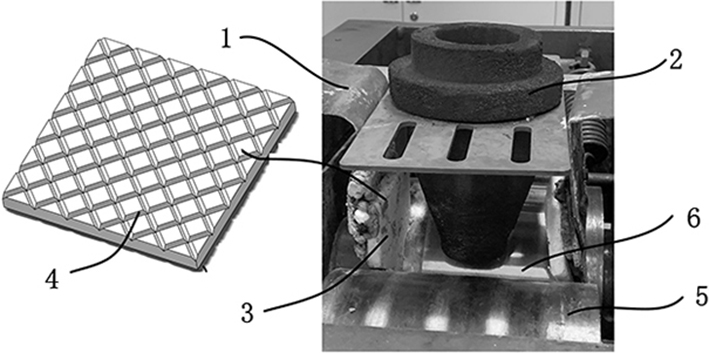

Low-cost consumable molten iron desulphurization mixer and preparation method thereof

The invention discloses a low-cost consumable molten iron desulphurization mixer and a preparation method thereof. The mixer comprises a mixing shaft, and a connecting flange arranged above the mixing shaft, wherein the mixing shaft consists of an internal gas cooling pipe and an external composite mixing shaft core from inside to outside; a plurality of mixing blades are arranged at the lower end of the mixing shaft; and refractory material working liners are applied on the outermost layers of the mixing shaft and the mixing blades. The method comprises the following steps: firstly, a mixing shaft frame and blade frames are prepared; V-shaped anchoring pieces are welded on the metal surfaces of the mixing shaft frame and the blade frames to prepare the composite mixing core; and thermal insulation buffer layers and refractory casting layers cover the metal surfaces of the mixing shaft frame and the blade frames in sequence to obtain the mixer. The comprehensive production cost of the mixer is largely reduced; the recycling value of the mixer after use is largely reduced; the long-distance transporting recovery of the mixer after use and the special recovering utilization of the mixing core are prevented; and the purposes of low cost and consumption of the mixer are achieved.

Owner:武汉钢铁有限公司

Low-cost consumable molten iron desulfurization agitator and preparation method thereof

Owner:武汉钢铁有限公司

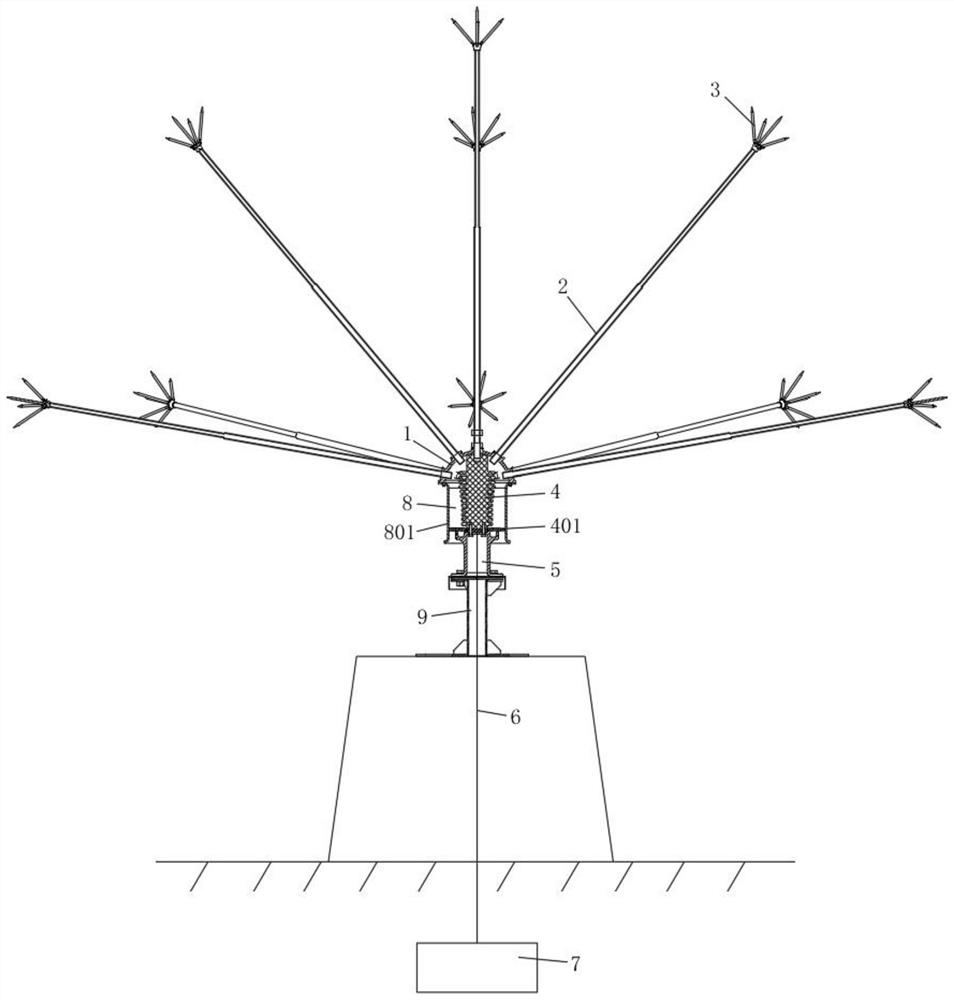

Lightning protection and elimination device for oil well platform

PendingCN111404033AInhibitionSlow down the speed of developmentDischarge by conduction/dissipationCorona dischargeThunderstormElectromagnetic pulse

The invention relates to a lightning protection and elimination device for an oil well platform. The device comprises an electromagnetic receiving net which is used for cutting a magnetic line of force in the atmosphere and can release corona ions under the action of a thunderstorm cloud electric field when thunderstorm cloud is generated, a supporting device which is used for supporting and fixing the electromagnetic receiving net and has a charge conduction effect, a rotating power device which is used for driving the electromagnetic receiving net to rotate along with wind, a thunder eliminating device which is used for effectively converting and / or absorbing the charge energy converted by the electromagnetic receiving net, and a fixing device which is used for fixing the supporting device on an oil well platform. According to the lightning protection and elimination device for an oil well platform provided by the invention, the phenomenon of cloud-to-ground lightning in a protectionarea can be effectively prevented, and meanwhile, the problems of strong electromagnetic pulse radiation, induced voltage, potential counterattack and the like caused by lightning current discharge are also reduced, so that the lightning protection effect is more effectively improved.

Owner:YANGZHOU HUAFENG LIGHTNING PROTECTION NEW TECH CO LTD

Microwave tower passive corona field lightning dispeller

PendingCN111740315AReduced speed and intensity of developmentInhibition of initiationCorona dischargeOvervoltage arrestors using spark gapsPhysicsElectric field

The invention belongs to the technical field of lightning protection, and discloses a microwave tower passive corona field lightning expelling device, which comprises a passive lightning dispeller arranged at the top of a microwave tower, wherein the passive lightning dispeller comprises a metal outer cover of which the bottom end is provided with an opening, the outer wall of the metal outer cover is uniformly provided with a plurality of discharge rods, the inner wall of the opening end of the metal outer cover is provided with an insulating support, the bottom of the insulating support is provided with an electrode, a discharge gap is arranged between the electrode and the inner wall of the metal outer cover, and the electrode is connected with a ground wire. According to the invention,based on the above structure, two-stage discharge under the action of a thundercloud electric field is realized, a passive first-stage discharge corona is generated between the discharge rod and thethundercloud, and a passive second-stage corona discharge is generated between the metal outer cover and the electrode; and a large number of corona ions are generated through the two-stage discharge,and the corona ions diffuse into the air and continuously interact with thundercloud charges, so that the downlink pilot development speed and intensity of thundercloud are effectively weakened.

Owner:山东中呈防雷科技有限公司

Fungicide composition

ActiveCN106212480ASynergistic effect is obviousSignificant synergyBiocideDead animal preservationFungicideMechanism of action

The invention provides a fungicide composition. The composition is prepared from two effective components A and B, wherein the active component A is a structural compound with the formula (I) (please see the formula in the description), the active component B is cyazofamid, and the weight ratio of the two components is 1:30-30:1. The invention further provides a preparation method and application of the composition. An experiment result shows that the fungicide composition has an obvious synergistic effect, and what is more important is that the application amount is decreased, and the usage cost is reduced. The fungicide composition can effectively prevent and control some specific fungus diseases of crops. The application amount of each fungicide is effectively decreased by compounding the fungicides with the different action mechanisms and action modes, and a good effect on fungicidal spectrum expanding, fungal resistance delaying, prevention and control effect improving and the like is achieved.

Owner:ADAMA HUIFENG (JIANGSU) LTD

Bactericide composition

ActiveCN106376578ADelay resistance problemGood prevention effectBiocideDead animal preservationChemistryCrop

The invention provides a bactericide composition. The composition includes an effective component A and an effective component B, the effective component A is a structure compound of formula (I), the effective component B is quinoxyfen, and a weight ratio of the effective component A to the effective component B is 1:(0.1-30). The invention also provides a preparation method of the composition, and a use of the composition. A test result shows that the bactericide composition has the advantages of obvious synergism, reduced application amount and use cost reduction. The bactericide composition can effectively control some specific fungus diseases of crops. Bactericides with different action mechanisms and different action modes are compounded, so the bactericide composition plays a great role in enlargement of the sterilization spectrum, delaying of fungus and bacterium resistance and improvement of the control effect.

Owner:ADAMA HUIFENG (JIANGSU) LTD

Side sealing plate applied to double-roller cast rolling

PendingCN114378267ASlow down the rate of formationSlow down the speed of developmentMetallurgyEngineering

The invention belongs to the field of double-roller cast rolling, and particularly relates to a side sealing plate applied to double-roller cast rolling. Nodulation on the working face of the side sealing plate of the double-roller cast-rolling molten pool is not beneficial to process stability, and at present, reduction of resistance borne by cast-rolled metal passing through the working face of the side sealing plate and / or change of the wettability of the working face of the side sealing plate is a crucial method. The invention provides a side sealing plate applied to double-roller cast rolling.

Owner:SHANDONG UNIV OF TECH

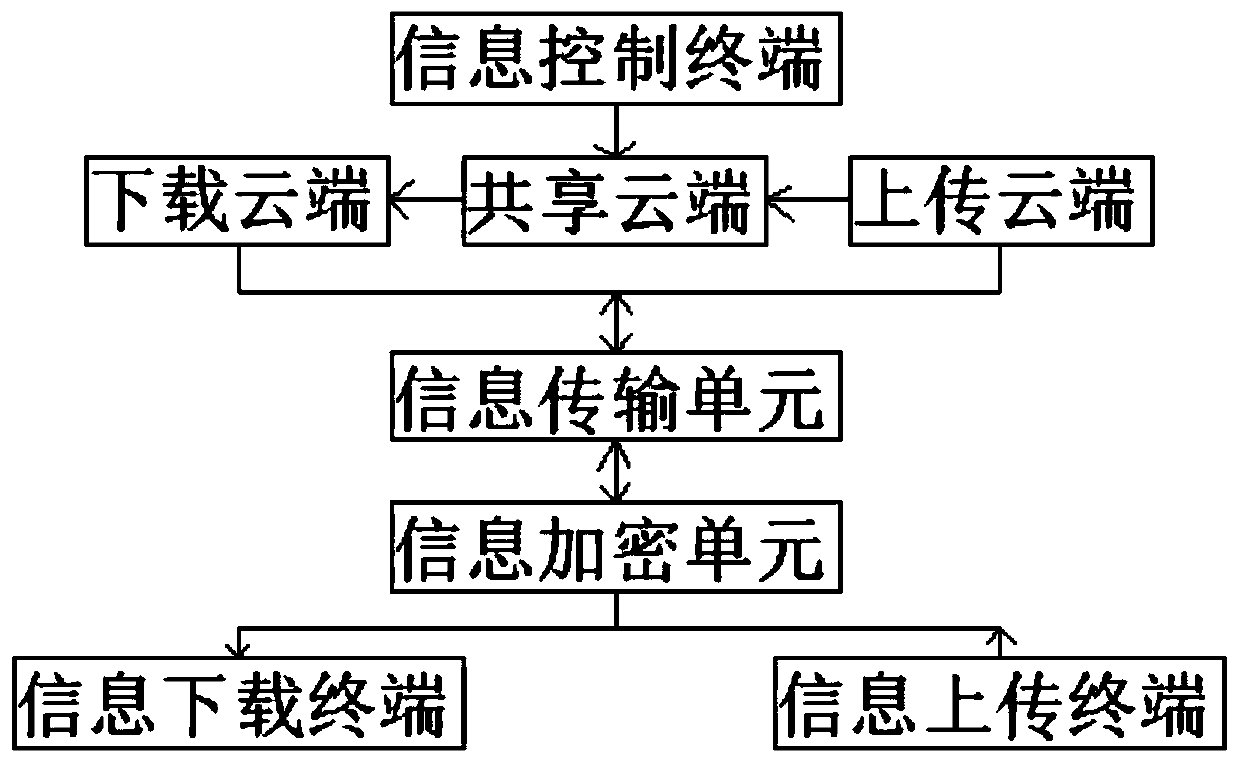

Distributed intelligent economic management system

PendingCN110855712AImprove securityShorten visit timeData processing applicationsDigital data protectionInformation controlInformation transmission

The invention belongs to the technical field of economic management, in particular to a distributed intelligent economic management system which comprises an information control terminal, a downloading cloud, a sharing cloud, an uploading cloud, an information transmission unit, an information encryption unit, an information downloading terminal and an information uploading terminal. The information control terminal wirelessly outputs to the sharing cloud, the sharing cloud wirelessly outputs to the downloading cloud, and the uploading cloud wirelessly outputs to the sharing cloud; the information transmission unit is in wireless input connection with the downloading cloud and is in wireless bidirectional connection with the information encryption unit, the information uploading terminal is in wireless output connection with the information encryption unit, and the information downloading terminal is in wireless input connection with the information encryption unit. According to the present invention, by encrypting the uploading and downloading of the information of each local control end, the information safety degree of the local control ends is improved, at the same time, the open information uploaded to the sharing cloud end can be rapidly downloaded, so that the information access duration is shortened, and the information transmission speed is increased.

Owner:HENAN UNIV OF SCI & TECH

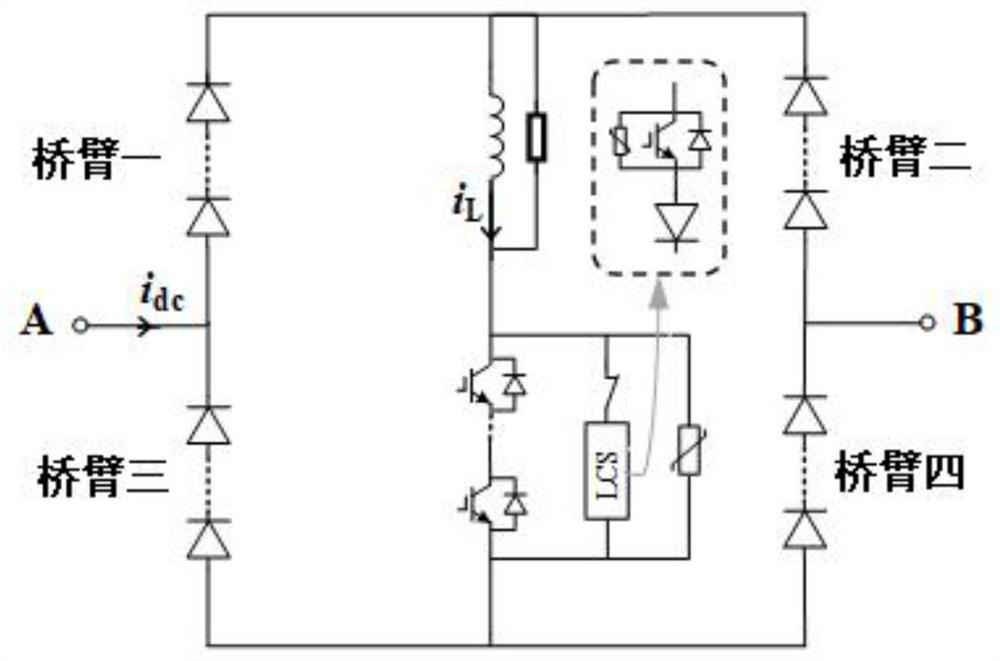

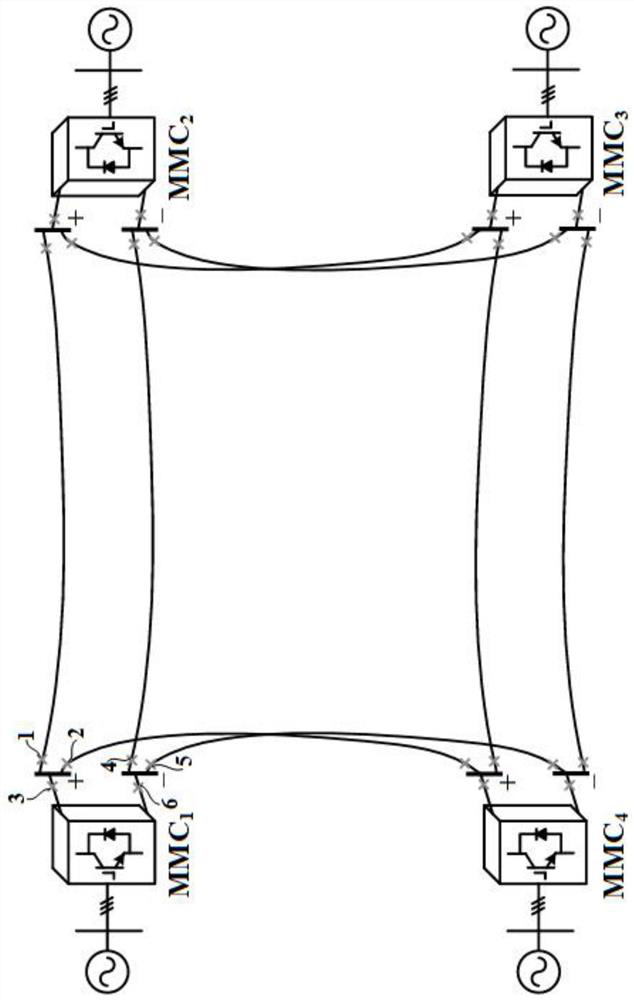

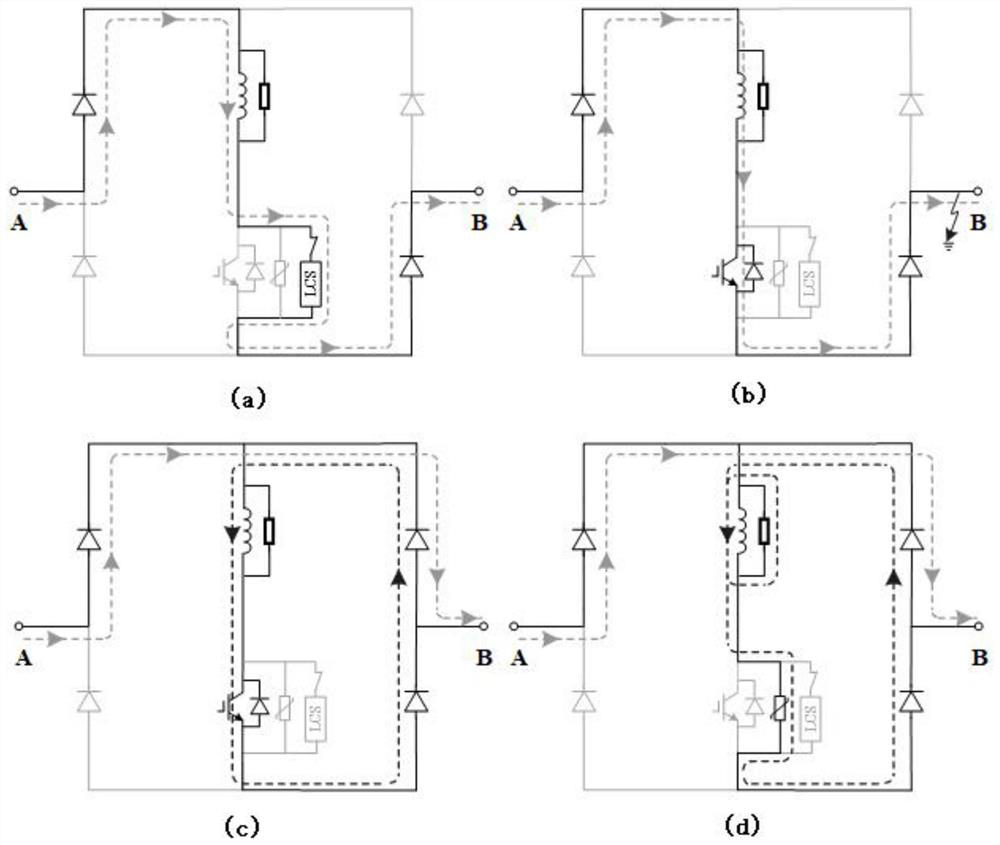

Direct-current fault current limiter suitable for self-cleaning MMC type direct-current distribution network and control method

PendingCN113889984ACooperate effectivelyReliable fault ride-throughElectric power transfer ac networkEmergency protective arrangements for automatic disconnectionHemt circuitsControl theory

The invention discloses a direct-current fault current limiter suitable for a self-cleaning MMC type direct-current distribution network and a control method. The direct-current fault current limiter comprises an H-bridge circuit, a direct-current reactor, a current-limiting resistor, a main circuit breaker and a direct-current line. According to the direct-current fault current limiter working in the normal operation state, when a direct-current fault is detected, an IGBT in a main circuit breaker is immediately conducted, a conduction signal is applied to a rapid mechanical switch, an IGBT in a load branch is locked, fault current is converted from the load branch to the main circuit breaker, and preparation is made for dissipating fault energy; after entering a fault point isolated state, the recovery current limiter supplies power to the whole DC power distribution network. Compared with the prior art, the direct current fault development speed can be delayed, effective cooperation among fault current limiting, protection and current cutoff is achieved, and reliable fault ride-through of the residual network is ensured; and a self-adaptive DC fault current-limiting control strategy is realized.

Owner:TIANJIN UNIV +1

A fungicide composition

ActiveCN106212480BDelayed spawn rateSlow down the speed of developmentBiocideFungicidesFungicideActive ingredient

Provided is a fungicide composition, comprising two active ingredients A and B; the active ingredient A is a compound having a structure shown in formula (I), the active ingredient B is cyazofamid, and the weight ratio between the two ingredients is 1:30-30:1. Also provided are a preparation method for and a use of the composition. Test results show that the above-mentioned fungicide composition has notable synergistic effects. More importantly, a dosage thereof may be reduced which lowers the cost of use. The fungicide composition is effective in preventing and controlling certain specific fungal diseases in crops. Fungicides having different acting mechanisms and modes are compounded, thereby effectively reducing the dosages of individual agents, and contributing to expand a fungicide spectrum, to delay fungus and fungal resistance, and to improve the prevention and control effect.

Owner:ADAMA HUIFENG (JIANGSU) LTD

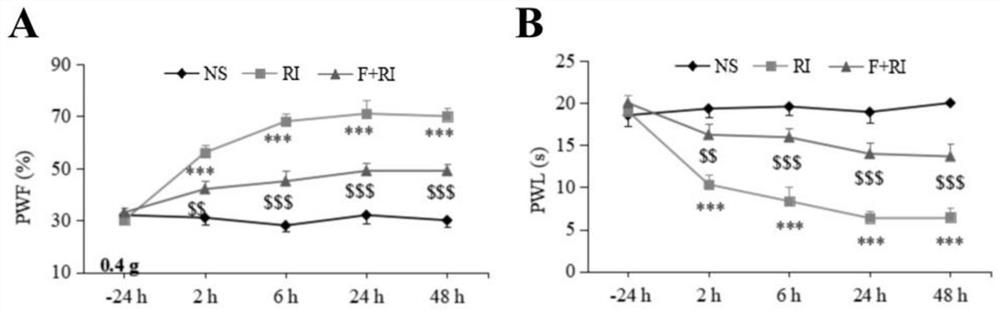

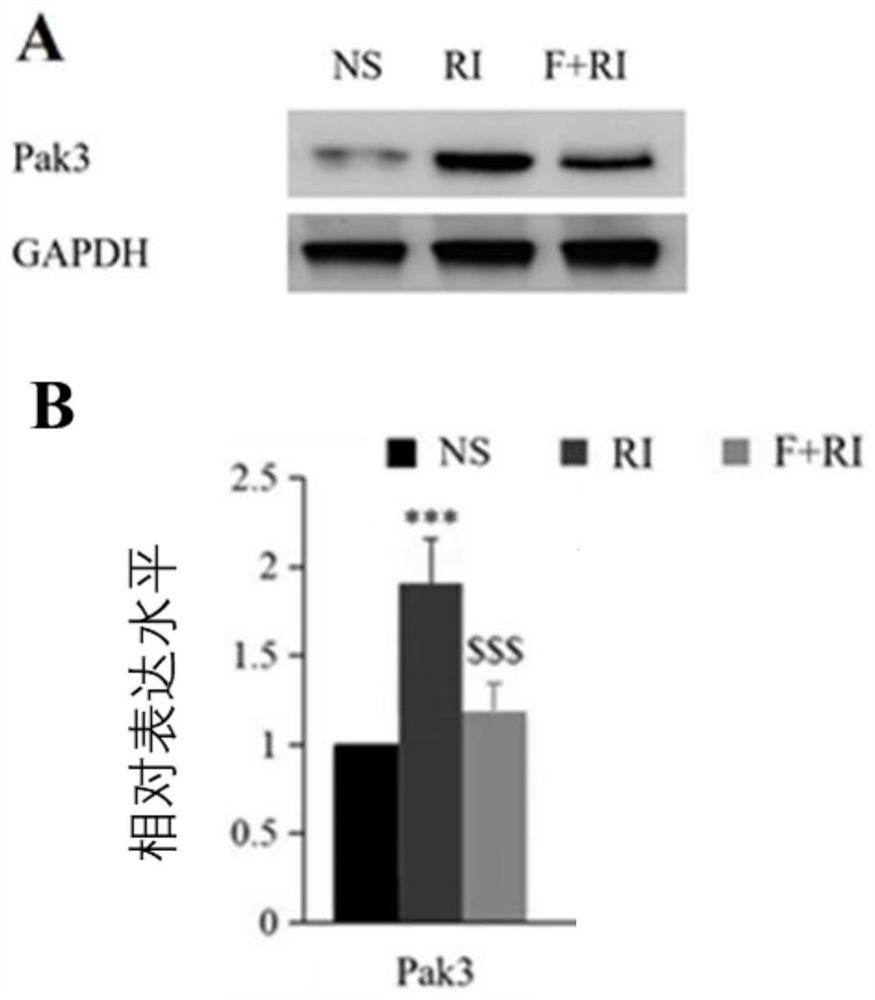

Application of Pak3 inhibitor in treatment of remifentanil-induced incision hyperalgesia

ActiveCN114767864ASlow down the speed of developmentSymptoms improvedOrganic active ingredientsNervous disorderRemifentanilHyperalgesia

The invention discloses an application of a Pak3 inhibitor in treatment of remifentanil induced incision hyperalgesia. Experiments prove that the FRAX597 can be used for inhibiting incision hyperalgesia induced by remifentanil. Therefore, the invention provides a new way for treating remifentanil-induced incision hyperalgesia.

Owner:GENERAL HOSPITAL OF TIANJIN MEDICAL UNIV

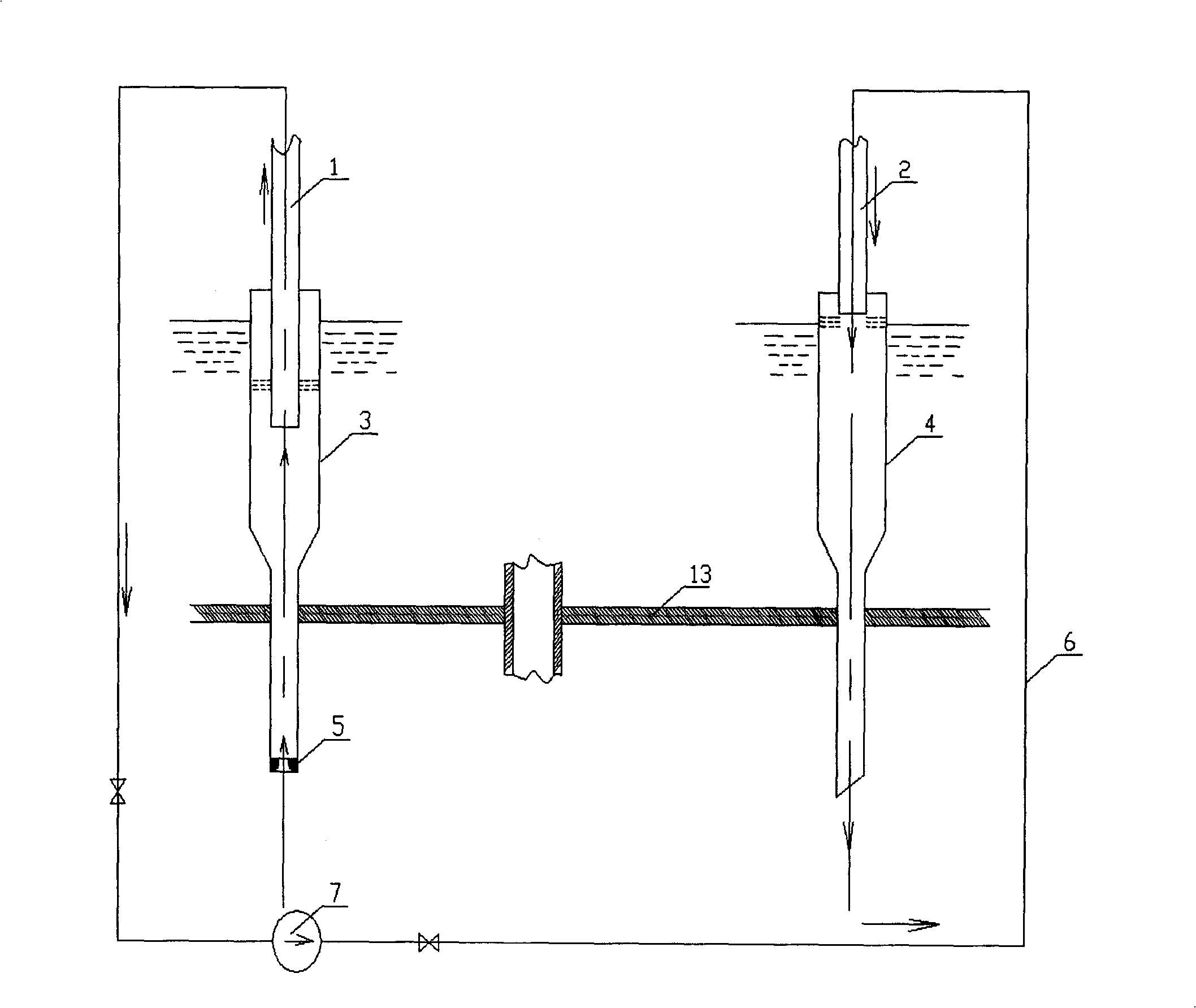

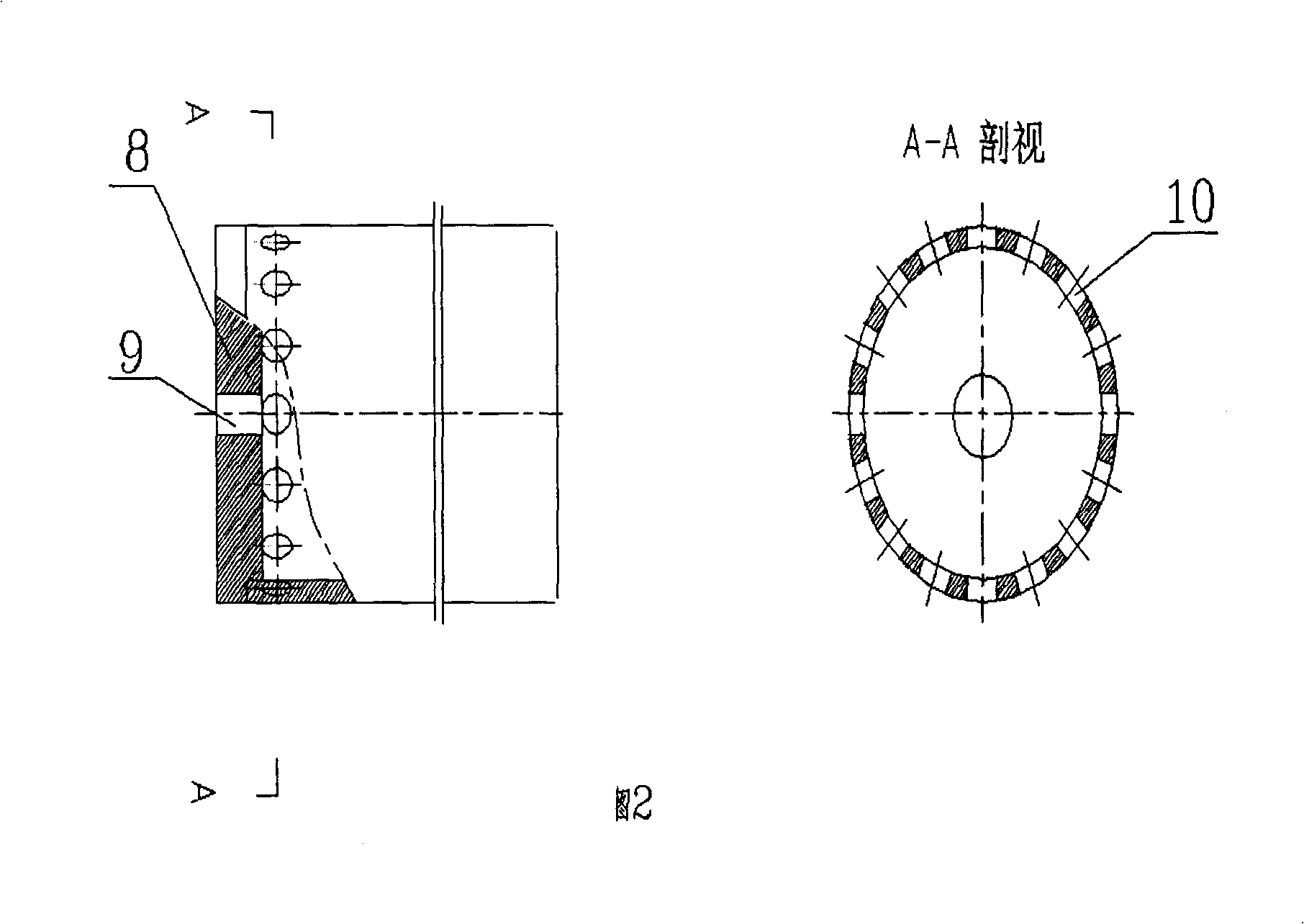

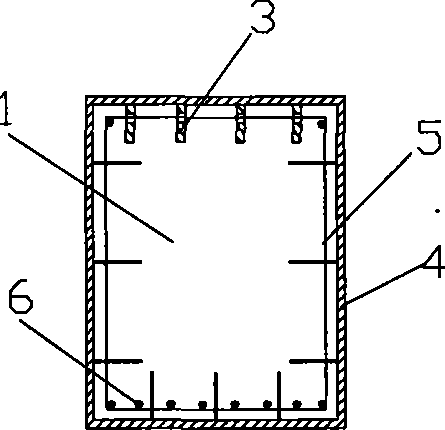

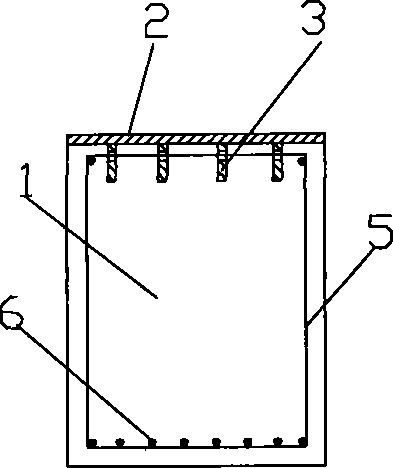

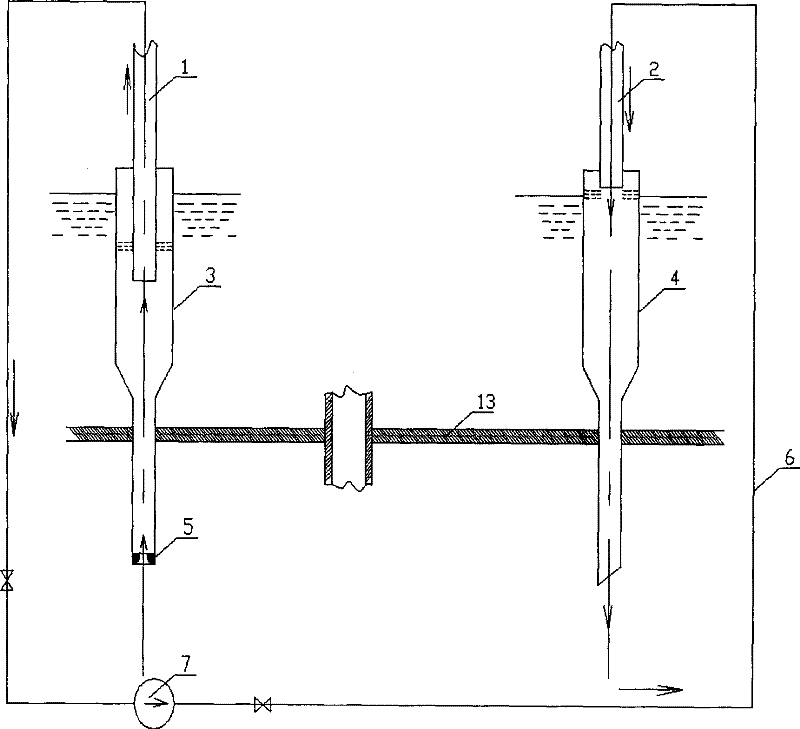

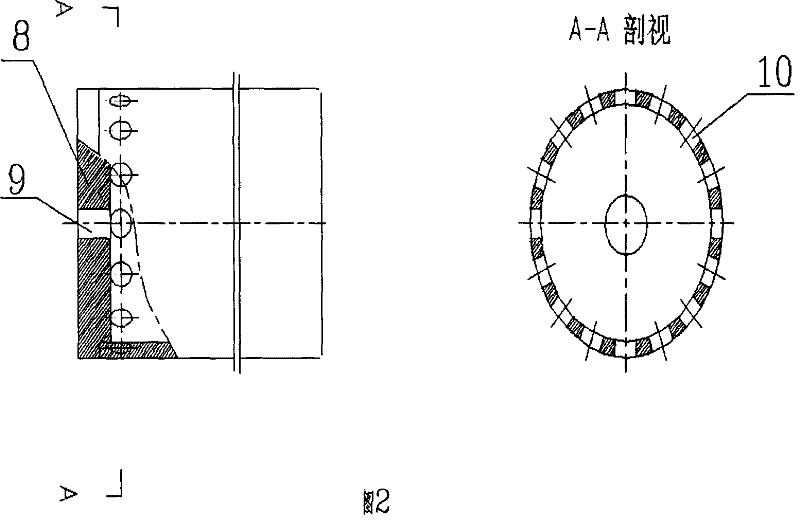

Siphon destroying device

ActiveCN101266843AReduce leakageSolving Complex Two-Phase Flow PhenomenaNuclear energy generationEmergency protection arrangementsSiphonVena contracta diameter

The invention provides a siphon breaking device which has a simple structure, and is safe and reliable. When an out-pile conduit rupture event is happened, the siphon breaking device can reduce sodium leakage and delay developing speed of the event so that operating staff has enough time to process the event. The siphon breaking device comprises: a fetching sodium tube is connected with a circulating pump via the out-pile conduit; the other end of the circulating pump is connected with a return sodium tube via the out-pile conduit; the fetching sodium tube and the return sodium tube are fixed on an isolation board and separately extend into two protective casings in the pile; an inlet orifice plate is arranged on the bottom of the fetching sodium tube; a fracture structure of the protective casing into which the fetching sodium tube extends is a venturi tube and is provided with four mesopores all around; aperture of the inlet orifice plate is 45mm; and elevation of the fetching sodium tube is reduced.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

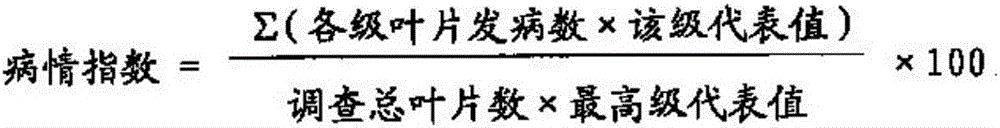

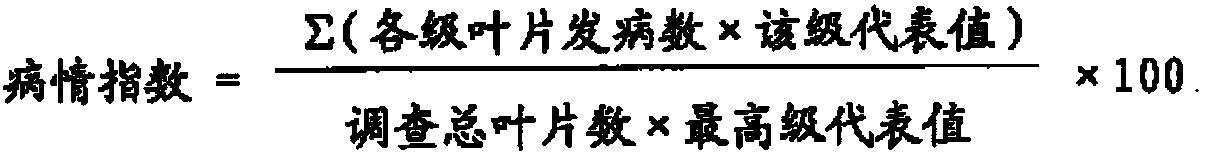

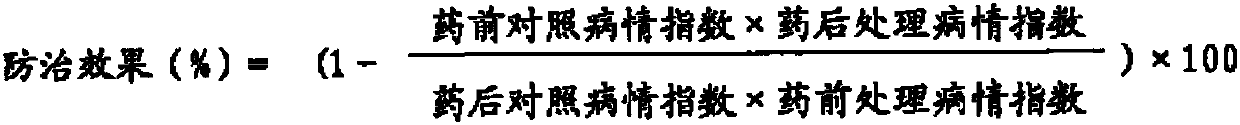

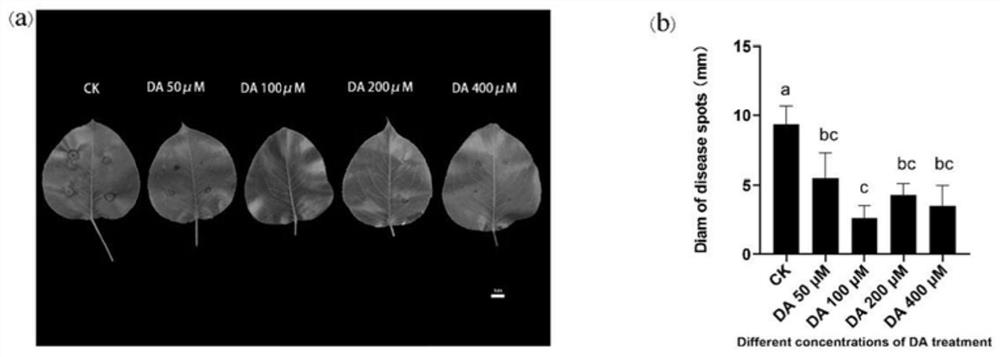

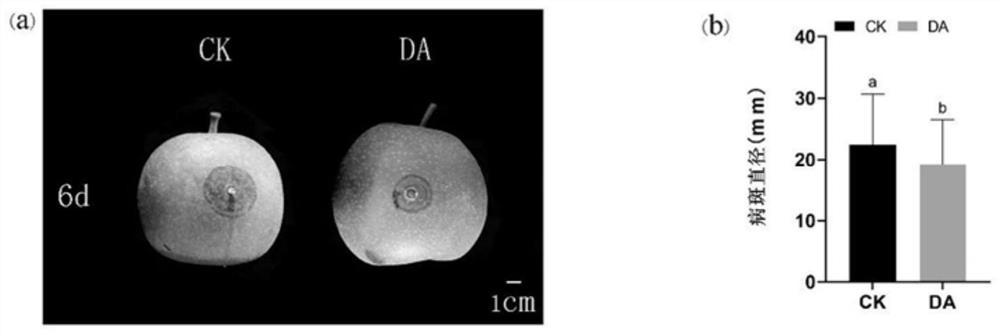

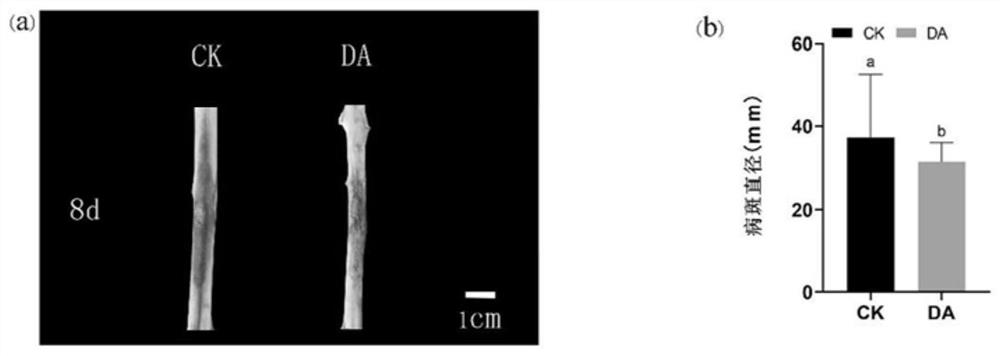

Method for preventing and controlling pear ring spot by using dopamine

PendingCN114303770AIncrease resistanceEnhanced autophagic activityCultivating equipmentsHorticulture methodsBiotechnologyDismutase

The invention belongs to the technical field of fruit and vegetable disease prevention and control, and particularly relates to a method for preventing and controlling pear ring rot by using dopamine, which comprises the following steps: spraying a pear tree body by using a dopamine aqueous solution with the concentration of 50-400 mu M every 15-20 days in a pear fruit swelling period. According to the method, the activity of phenylalanine ammonialyase, superoxide dismutase, peroxidase and peroxidase is improved by spraying dopamine, the ability of removing hydrogen peroxide and superoxide anions in pear trees infected by pathogenic bacteria is improved, the autophagy activity of cells is improved, and the development speed of the diameter of disease spots is delayed; therefore, the occurrence of ring spot is reduced.

Owner:NANJING AGRICULTURAL UNIVERSITY

A kind of aluminum high voltage electric porcelain and its production process

InactiveCN103253926BSmall coefficient of thermal expansionGood arc resistanceClaywaresCalciteHigh pressure

Owner:查府明

Reinforced concrete structure with steel plate reinforcement layer set on partial surface

InactiveCN101245610BImprove tensile propertiesImprove cracking momentArched structuresVaulted structuresReinforced concreteCrack resistance

The invention discloses a reinforced concrete structure, part of the surface of which is provided with a steel plate reinforced layer, comprising a reinforced concrete structure body; the surface of the section bearing tensile stress of the reinforced concrete structure body is poured into an integrated steel plate reinforced layer; the invention can obviously improve the crack resistance bendingmoment of the reinforced concrete structure, enhance the load capacity and ductility and shock resistance capacity of the reinforced concrete structure, restrain the increasing speed of the crack, reduce the width of the crack greatly, and improve the safety and the durability of the reinforced concrete structure effectively.

Owner:CHONGQING JIAOTONG UNIVERSITY

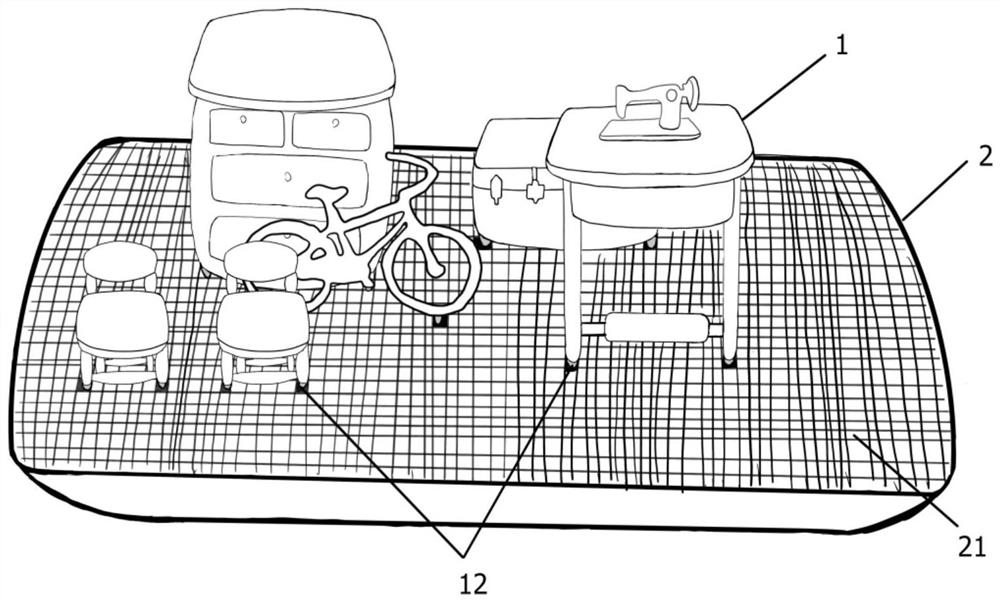

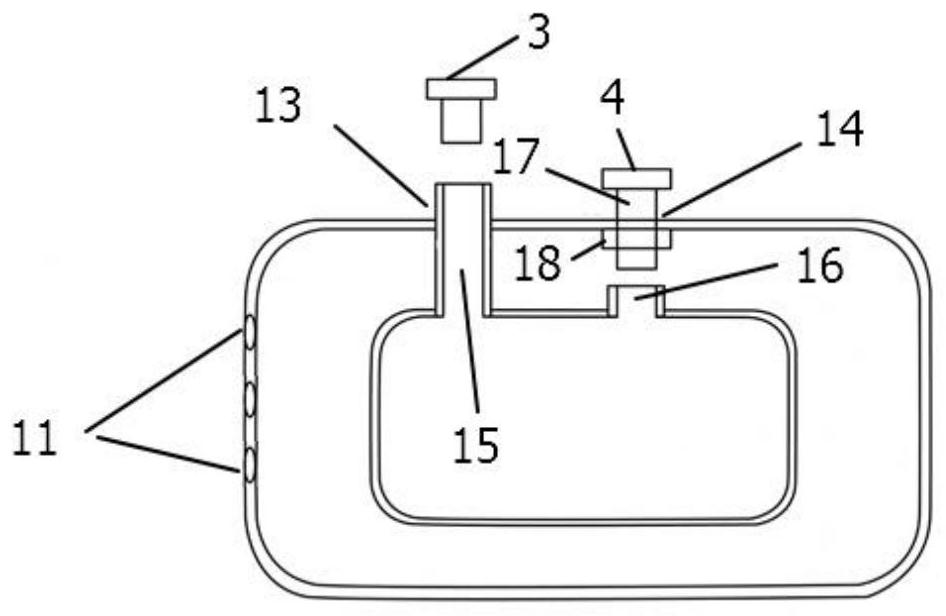

A method of using an educational toy for slowing down dementia in the elderly

ActiveCN109718568BSlow down the speed of developmentPromote recoveryGymnastic exercisingToysPhysical medicine and rehabilitationPhysical therapy

The invention relates to the technical field of daily products, and discloses a using method of puzzle toys capable of relieving elderly dementia. The method comprises the steps that the toys are squeezed to allow the flavors which are stored in the toys to flow out from flavor outlets, the toys are arranged on a bottom plate according to living scenes of designated years in the past, the flavorsare generated by adopting solids or gas materials, the shapes of the toys are conformed to objects of the living scenes of the designated years in the past, the flavors correspond to the characteristics of the toys, and the top face of the bottom plate is uniformly provided with multiple grooves which are used for fixing the toys. The toys have the advantages of simple structures, simple operation, high practicability and low cost, and the method is suitable for being popularized.

Owner:SHANGHAI UNIV OF ENG SCI

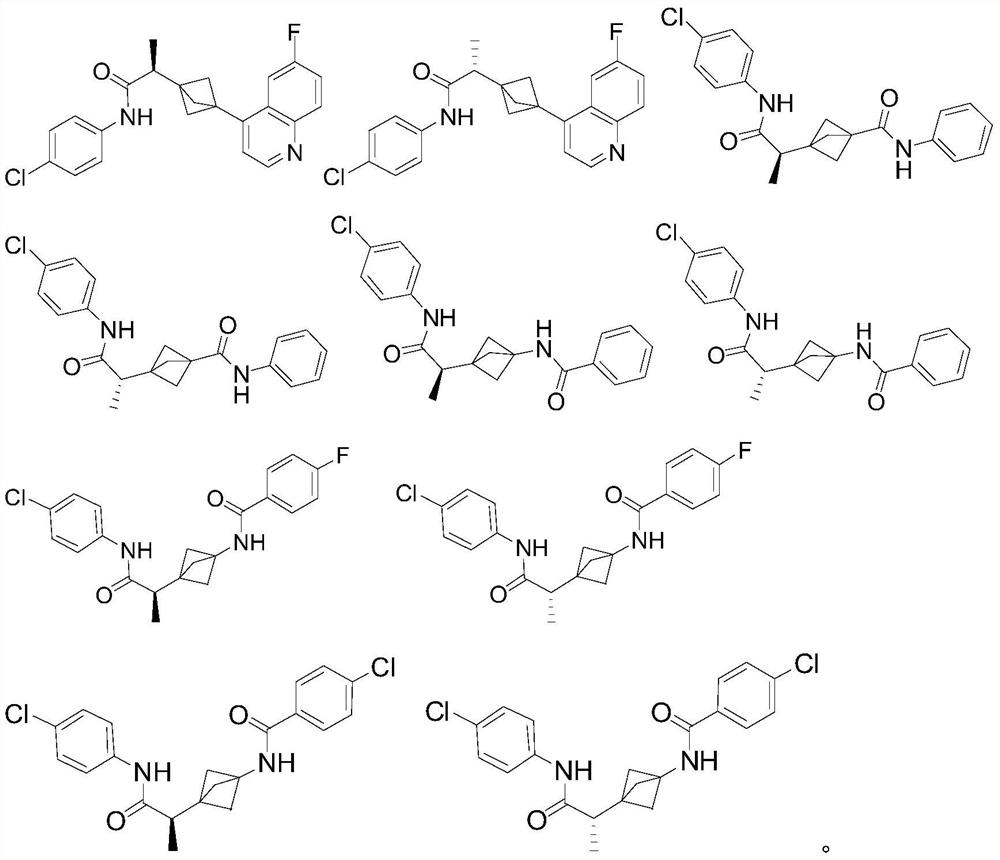

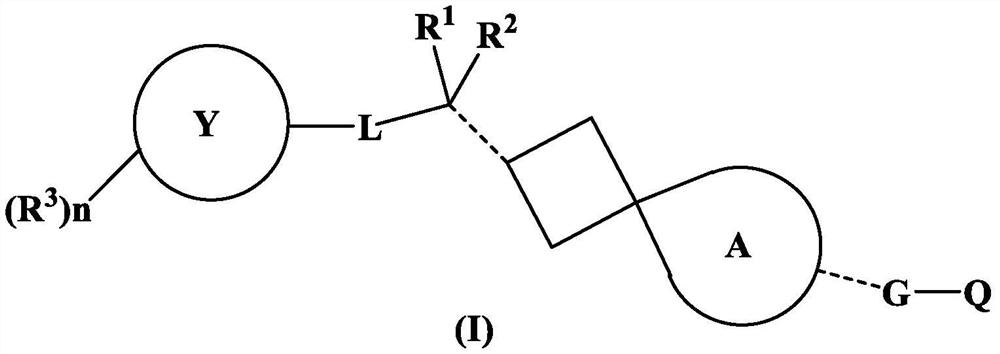

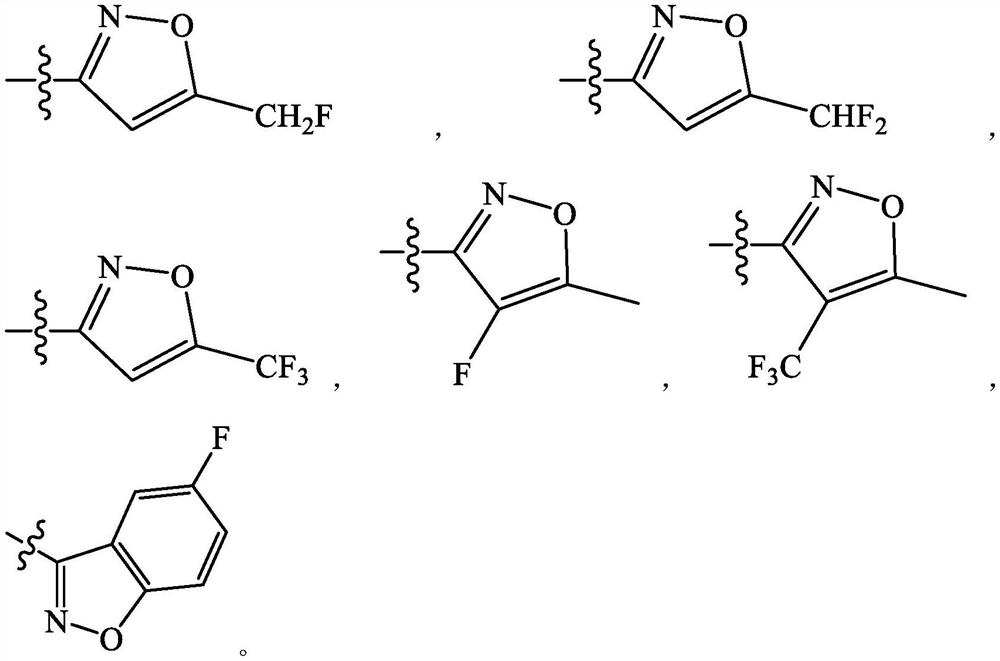

Indoleamine 2,3-dioxygenase inhibitor

InactiveCN112062717ASlow down the speed of developmentPromote healingOrganic chemistryAntipyreticDioxygenase activityDisease

The invention provides a novel compound capable of inhibiting activity of indoleamine 2,3-dioxygenase (IDO), a pharmaceutical composition containing the compound, a preparation method of the compoundand application of the compound in preparation of drugs for treating proliferative diseases, infectious diseases, immune-related diseases and / or inflammatory diseases.

Owner:QILU PHARMA

Spiro compound as indoleamine 2, 3-dioxygenase inhibitor

PendingCN114685341ASlow down the speed of developmentPromote healingAntibacterial agentsOrganic active ingredientsDiseaseBiochemistry

The invention provides a compound which has a spiro structure and can be used as an indoleamine 2, 3-dioxygenase (IDO) inhibitor, a pharmaceutical composition containing the compound, and application of the compound in preparation of drugs for treating proliferative diseases, infectious diseases, immune-related diseases and / or inflammatory diseases.

Owner:QILU PHARMA CO LTD

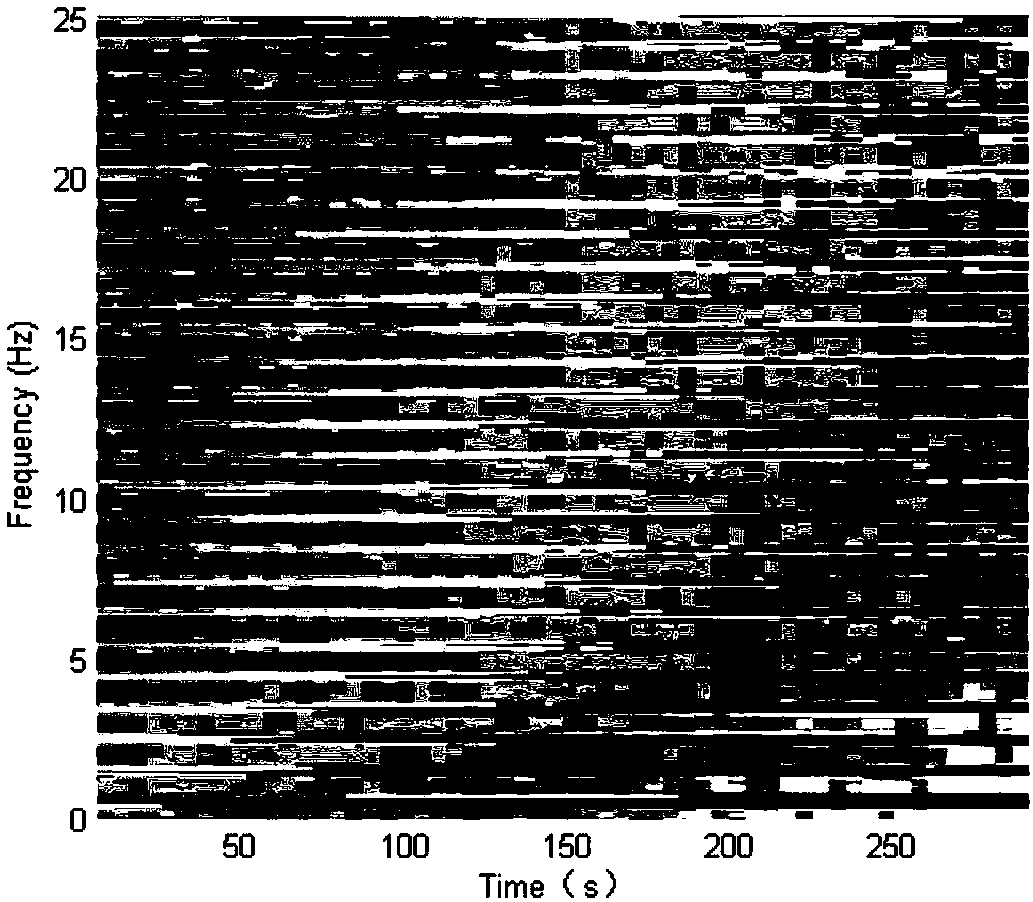

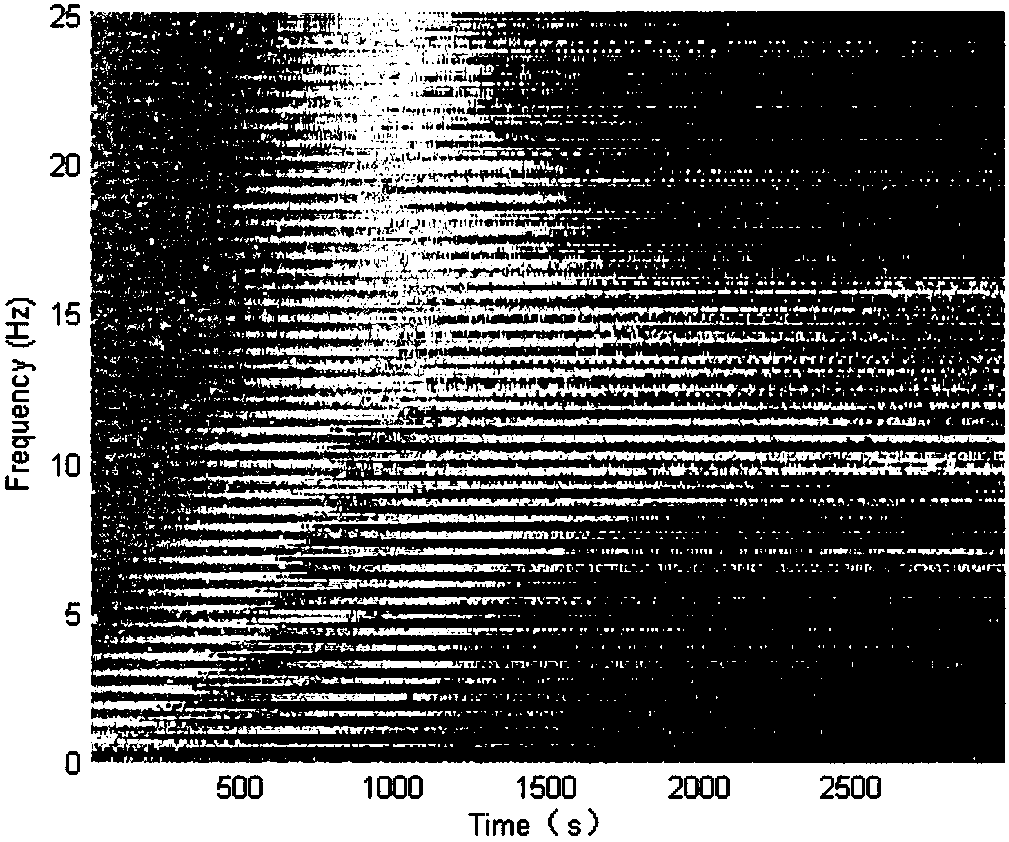

Pipeline structure and method for reducing self-excited vibration of pump system

InactiveCN108149750AReduce self-excited vibrationSlow down the speed of developmentService pipe systemsDesign optimisation/simulationSelf excitedEngineering

The invention discloses a pipeline structure and method for reducing self-excited vibration of a pump system, and provides the pipeline structure for reducing the self-excited vibration of the pump system. The pipeline structure comprises a thin steel pipe, a thick steel pipe and a polyethylene pipe to form a water outlet pipe of the pump system. According to the pipeline structure and method, parameters such as vibration period change, frequency response and the like of the self-excited vibration of the pump system can be obtained, and simultaneously the relationship between obtained data andpipeline parameters is analyzed to provide guidance for designing the pump system, so that the speed of development of the self-excited vibration of the pump system is effectively alleviated, the vibration period of the self-excited vibration is increased, and the vibration frequency at the initial stage of the self-excited vibration is reduced to gain time for prevention of pipe explosion and reduce the risk of the self-excited vibration of the pump system.

Owner:HOHAI UNIV

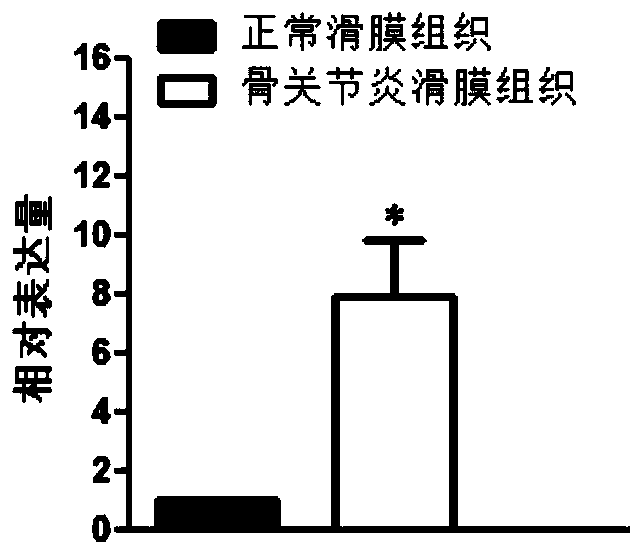

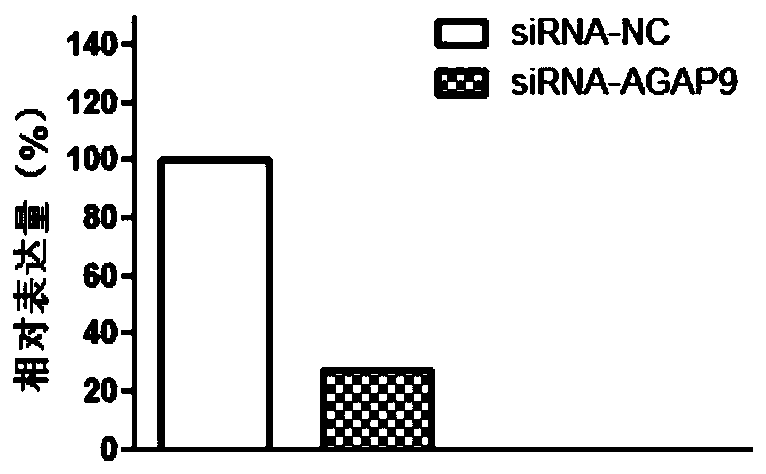

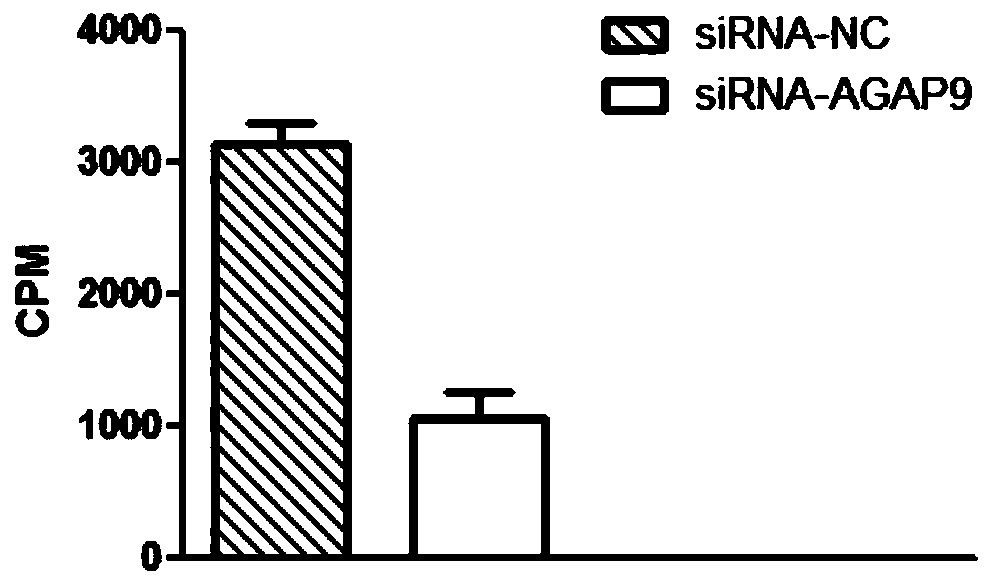

Application of AGAP9 in preparation of osteoarthritis diagnosis product

ActiveCN110499365ASlow down the speed of developmentSymptoms improvedMicrobiological testing/measurementDisease diagnosisBiologyGene

The invention discloses a diagnostic tool for osteoarthritis. The diagnostic tool achieves the purpose of diagnosis by detecting an AGAP9 gene and an expression product of the AGAP9 gene. The study proves that compared with normal synovial tissue, the mRNA expression level of the AGAP9 gene of an osteoarthritis patient is remarkably up-regulated. According to correlation between the AGAP9 gene andosteoarthritis, a kit for diagnosing osteoarthritis can be prepared, and can be widely applied in clinic. Besides, synoviocyte cell proliferation can be inhibited by inhibiting expression of the AGAP9 gene, it is indicated that the AGAP9 gene can be used for researching and developing a drug for treating osteoarthritis, and the research result provides theoretical support for development of a newclinical drug.

Owner:PEOPLES HOSPITAL OF DEYANG CITY

Siphon destroying device

ActiveCN101266843BReduce leakageSolving Complex Two-Phase Flow PhenomenaNuclear energy generationEmergency protection arrangementsSiphonVena contracta diameter

The invention provides a siphon breaking device which has a simple structure, and is safe and reliable. When an out-pile conduit rupture event is happened, the siphon breaking device can reduce sodium leakage and delay developing speed of the event so that operating staff has enough time to process the event. The siphon breaking device comprises: a fetching sodium tube is connected with a circulating pump via the out-pile conduit; the other end of the circulating pump is connected with a return sodium tube via the out-pile conduit; the fetching sodium tube and the return sodium tube are fixedon an isolation board and separately extend into two protective casings in the pile; an inlet orifice plate is arranged on the bottom of the fetching sodium tube; a fracture structure of the protective casing into which the fetching sodium tube extends is a venturi tube and is provided with four mesopores all around; aperture of the inlet orifice plate is 45mm; and elevation of the fetching sodium tube is reduced.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

A method for preparing ni-co nanocomposite multilayer alloy

ActiveCN107034496BEvenly dispersedSlow down the speed of developmentElectrolytic coatingsWear resistantNanoparticle

The invention provides a method of preparing a Ni-Co nano compound multi-layered alloy. The method comprises the following steps of: S1, preparing a Ni-Co nano compound electrolyte; and S2, putting a plating article in the Ni-Co nano compound electrolyte, performing electrodeposition by means of a three current cyclic step change method, taking out the plating article after electrodeposition, washing the plating article thoroughly and naturally airing the plating article. According to the method of preparing the Ni-Co nano compound multi-layered alloy provided by the invention, the obtained plating layer is a multi-layered structure. Nanoparticles are uniformly dispersed, and the invention provides a novel method for electrodepositing preparation of the corrosion-resistant wear-resistant compound multi-layered alloy.

Owner:HOHAI UNIV

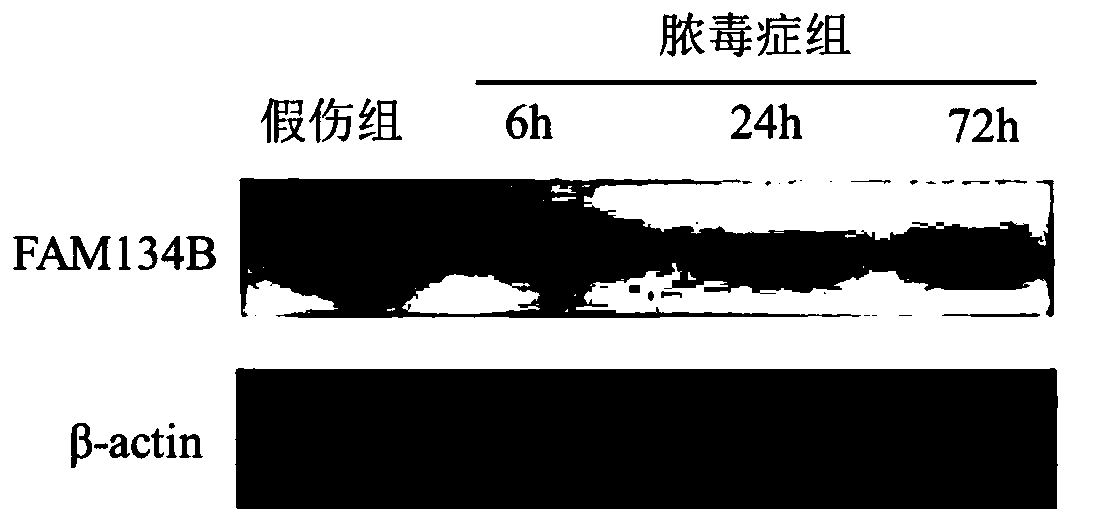

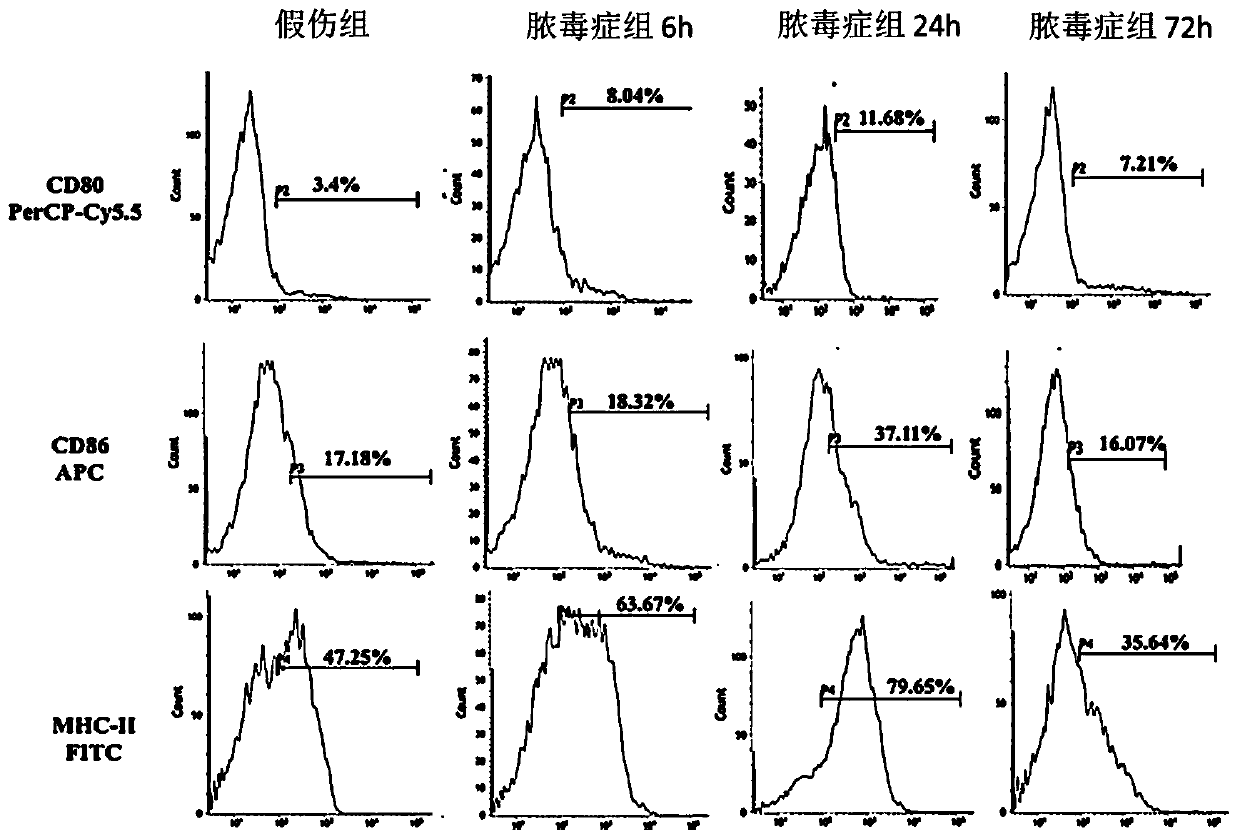

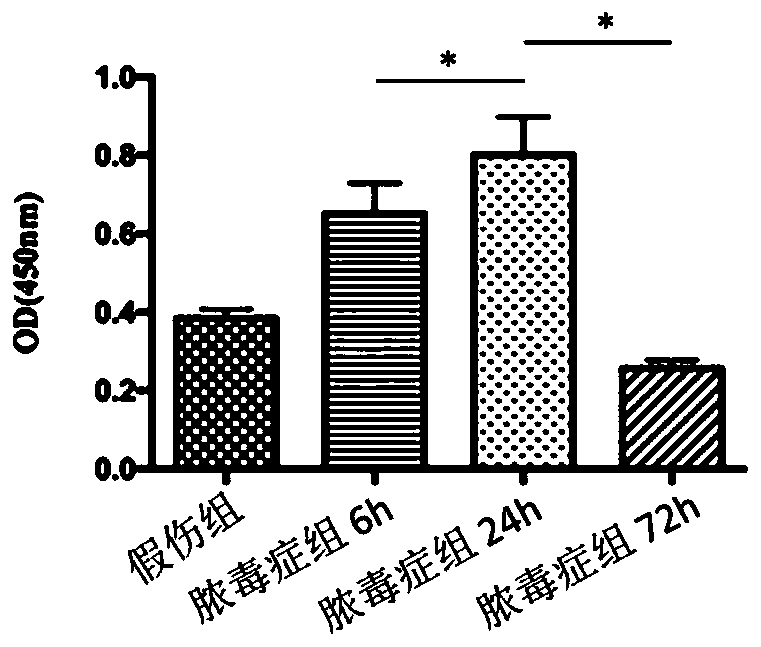

Use of fam134b in the preparation of medicines for treating sepsis

ActiveCN109200289BSlow down the speed of developmentSymptoms improvedAntibacterial agentsCompounds screening/testingIn vivoMolecular marker

The invention discloses a novel use of FAM134B. As proved by experiments in vivo and in vitro, promotion of FAM134B expression can promote the maturation of DC or increase DC activity, thereby realizing the purpose of treating sepsis. In addition, according to the research results of the present invention, those skilled in the art will know that the expression level of FAM134B is correlated with sepsis, and therefore FAM134B can be used as a molecular marker for diagnosis of sepsis. According to the correlation between FAM 134B and DC cells, the invention also provides a method for preparing highly active DC cells in vitro, thereby realizing the industrial production of DC cells.

Owner:FIRST HOSPITAL AFFILIATED TO GENERAL HOSPITAL OF PLA

An intelligent motion control method for prolonging the service life of slewing bearings

ActiveCN102819219BImplementation locationExtended service lifeAdaptive controlElectric machineTorque motor

Owner:NANJING TECH UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![[bumping process] [bumping process]](https://images-eureka.patsnap.com/patent_img/5749955a-dd74-4133-b803-7b01ab7fd782/US20050020050A1-20050127-D00000.png)

![[bumping process] [bumping process]](https://images-eureka.patsnap.com/patent_img/5749955a-dd74-4133-b803-7b01ab7fd782/US20050020050A1-20050127-D00001.png)

![[bumping process] [bumping process]](https://images-eureka.patsnap.com/patent_img/5749955a-dd74-4133-b803-7b01ab7fd782/US20050020050A1-20050127-D00002.png)