Intelligent movement control method for prolonging service life of slewing bearing

A technology of slewing bearing and motion control, which is applied in general control system, adaptive control, control/regulation system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be further described below in conjunction with the accompanying drawings.

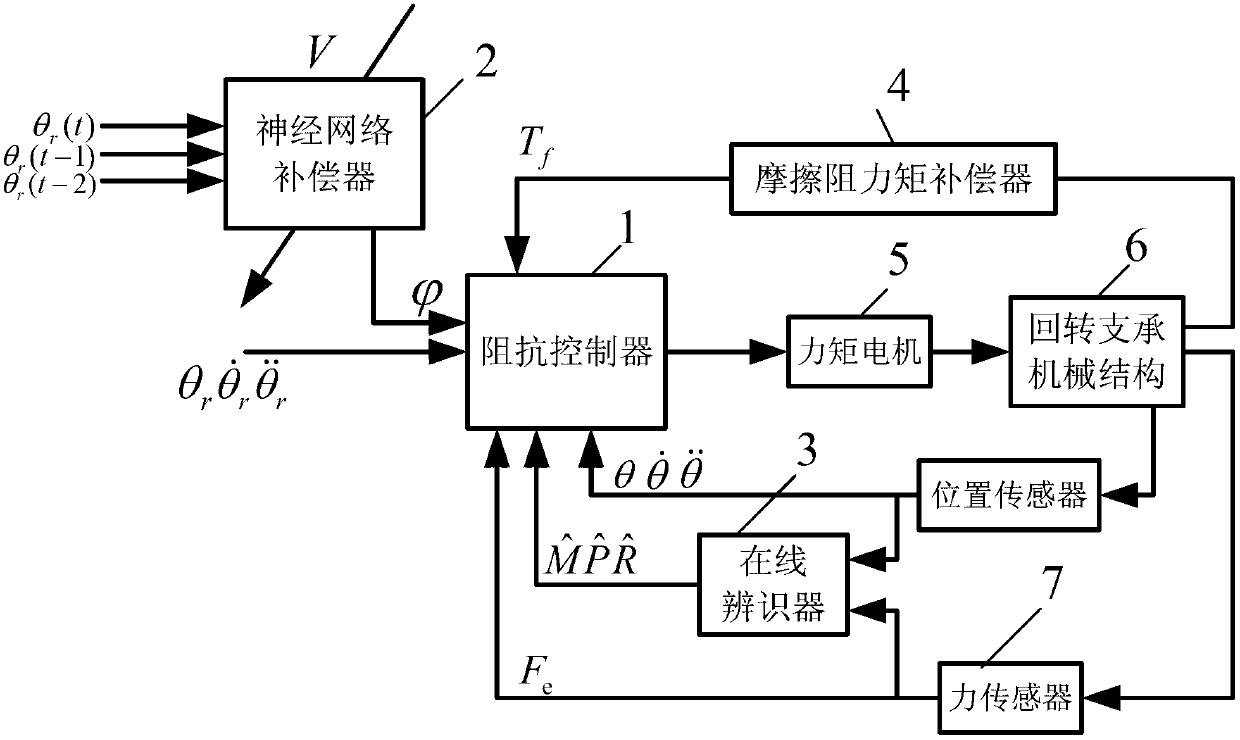

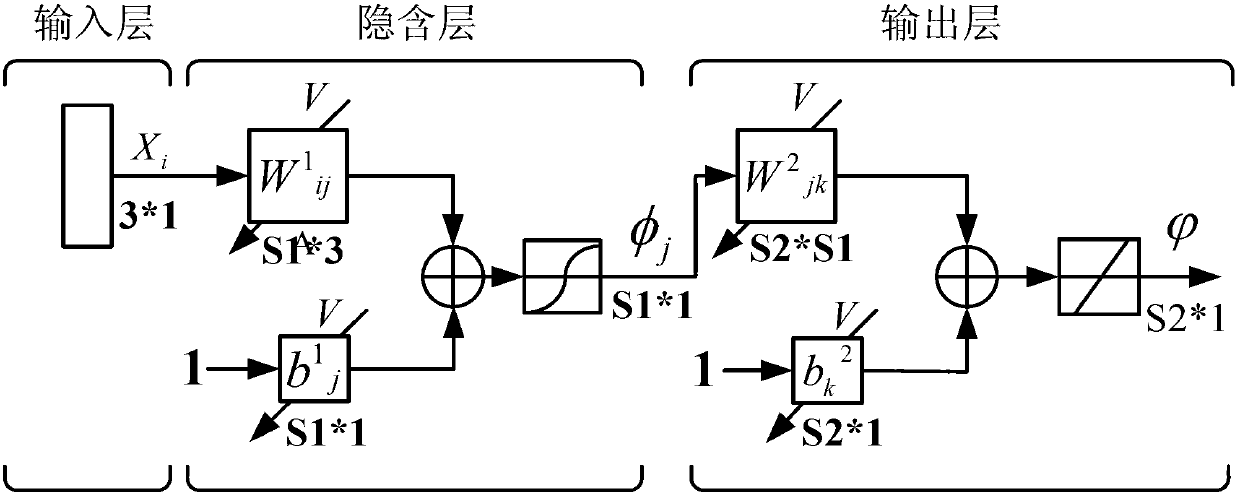

[0062] Such as Figures 1 to 8 , an intelligent motion control method for prolonging the service life of a slewing bearing, comprising the following steps:

[0063] step one:

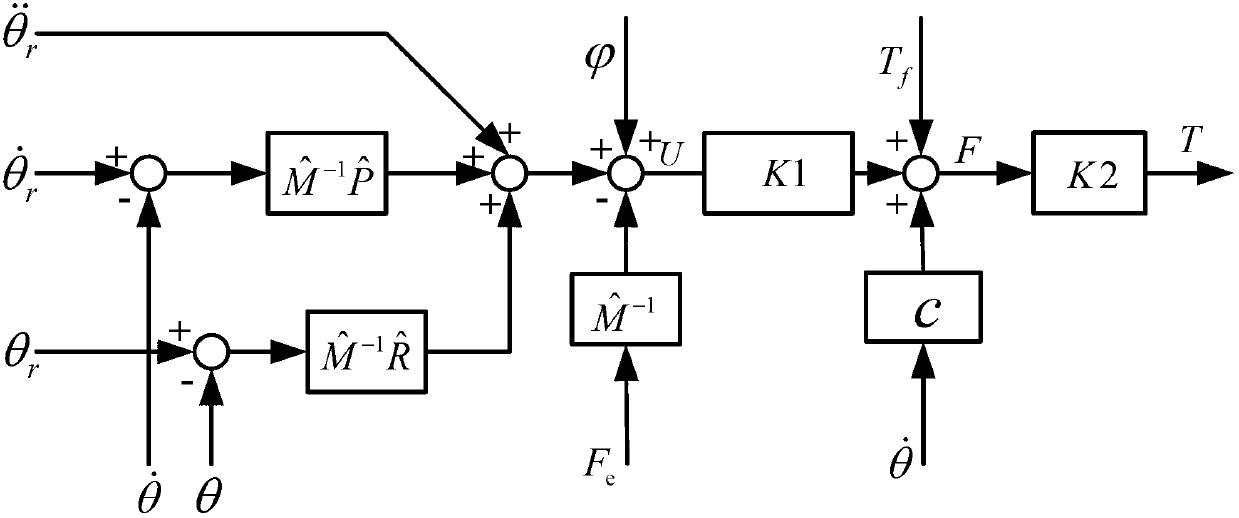

[0064] will expect the trajectory θ r and Input to Impedance Controller 1, where for θ r The differential of , which represents the angular velocity; for The differential of , which represents the angular acceleration.

[0065] Step two:

[0066] Measure the interaction force F between the end of the slewing bearing mechanical structure and the environment through the force sensor 7 e , use the position sensor 8 at the large gear of the slewing bearing to measure the actual angular displacement θ of the slewing bearing, and set F e , θ is imported into the online identifier 3, and the identifier is used to identify the inertial force M, damping coefficient P, and rigidity coefficie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com