Sandwich type structure insulation board production facility

A technology for structural insulation boards and production equipment, which is applied to devices and coatings that apply liquid to the surface, which can solve the problems of limited weighing capacity, low strength of insulation layer, and low bonding efficiency, saving glue, The effect of improving the contact surface and increasing the clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

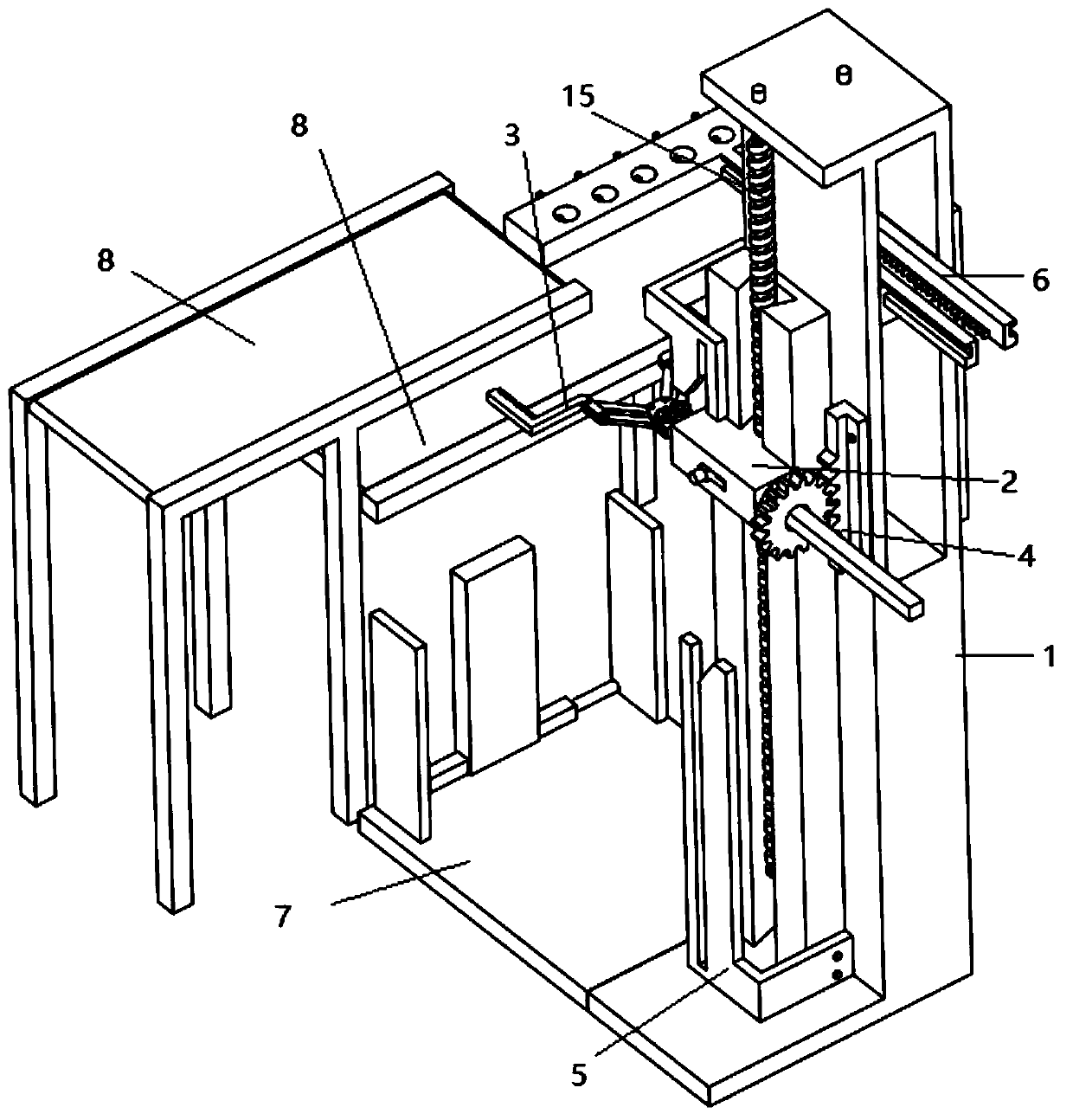

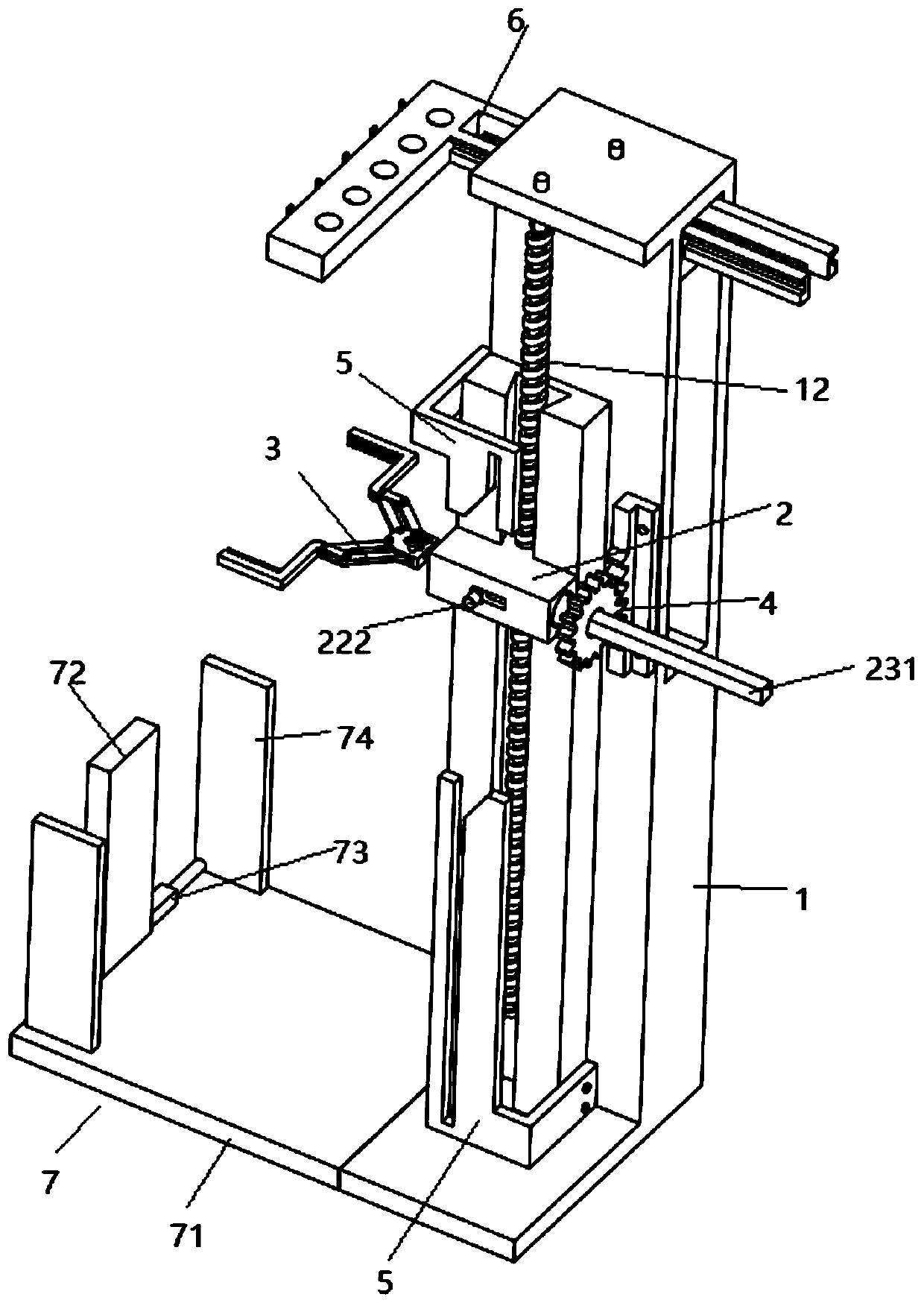

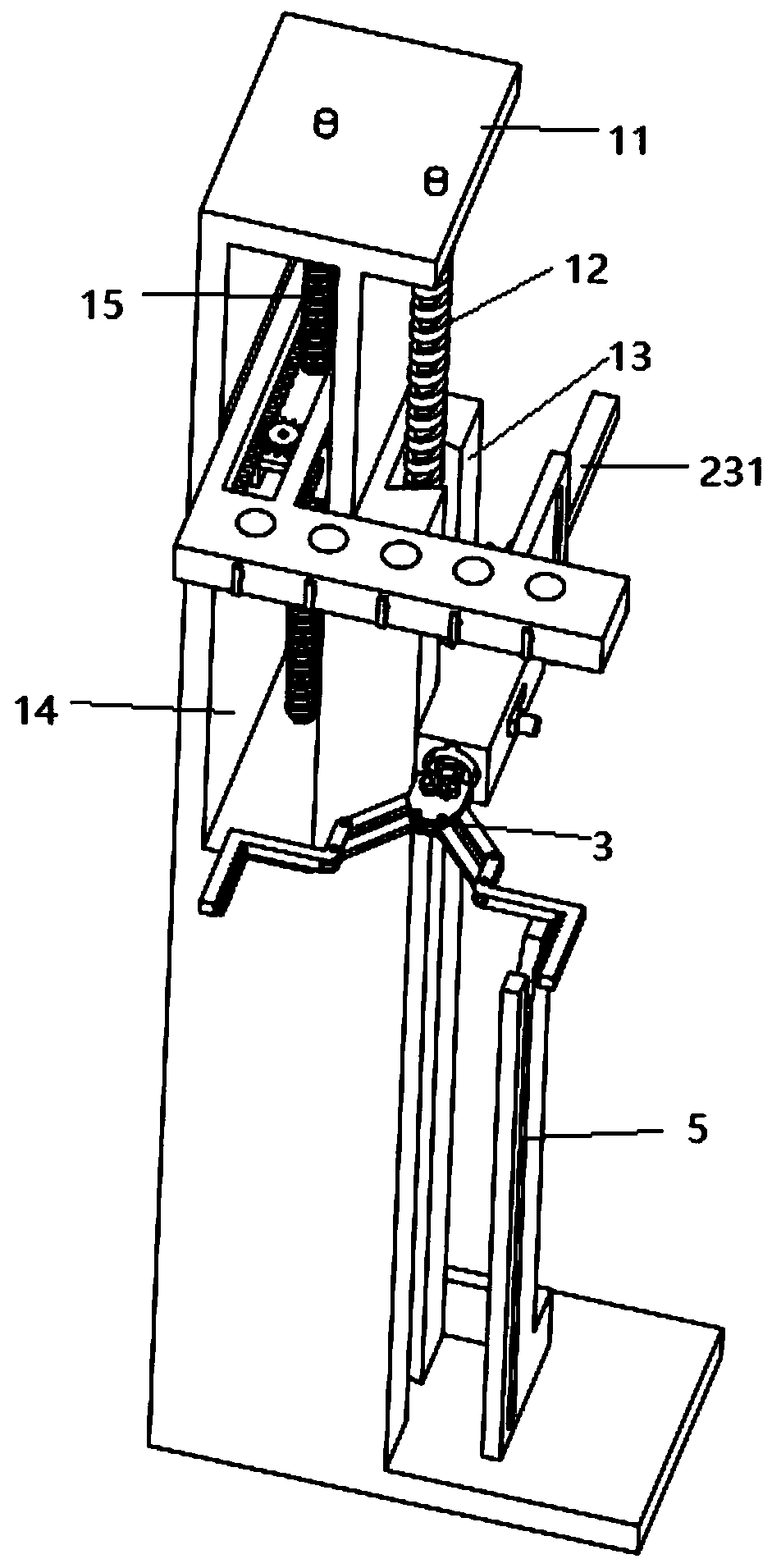

[0032] Attached below Figure 1-8 The specific embodiments of the present invention are described in detail:

[0033] Structural thermal insulation boards usually use foamed thermal insulation materials as the central thermal insulation layer. Due to the low strength of the thermal insulation layer and limited weighing capacity, a layer of plywood is usually bonded on both sides of the thermal insulation layer for support. In the prior art, it is usually directly Through manual bonding, the bonding efficiency is low. In order to improve the bonding efficiency, the present invention provides a production equipment for a sandwich-type structural thermal insulation board, such as Figure 1-3 As shown, it includes a positioning support frame 1, the front side of the positioning support frame 1 is provided with a lifting positioning mechanism 2 that can move up and down, and a clamping mechanism 3 for clamping the middle insulation layer is fixed in the lifting positioning mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com