Camera calibration system and calibration method thereof

A camera calibration and calibration method technology, applied in the camera calibration system and its calibration field, can solve the problems of misoperation, poor calibration flexibility, time-consuming and inconvenient repeated operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

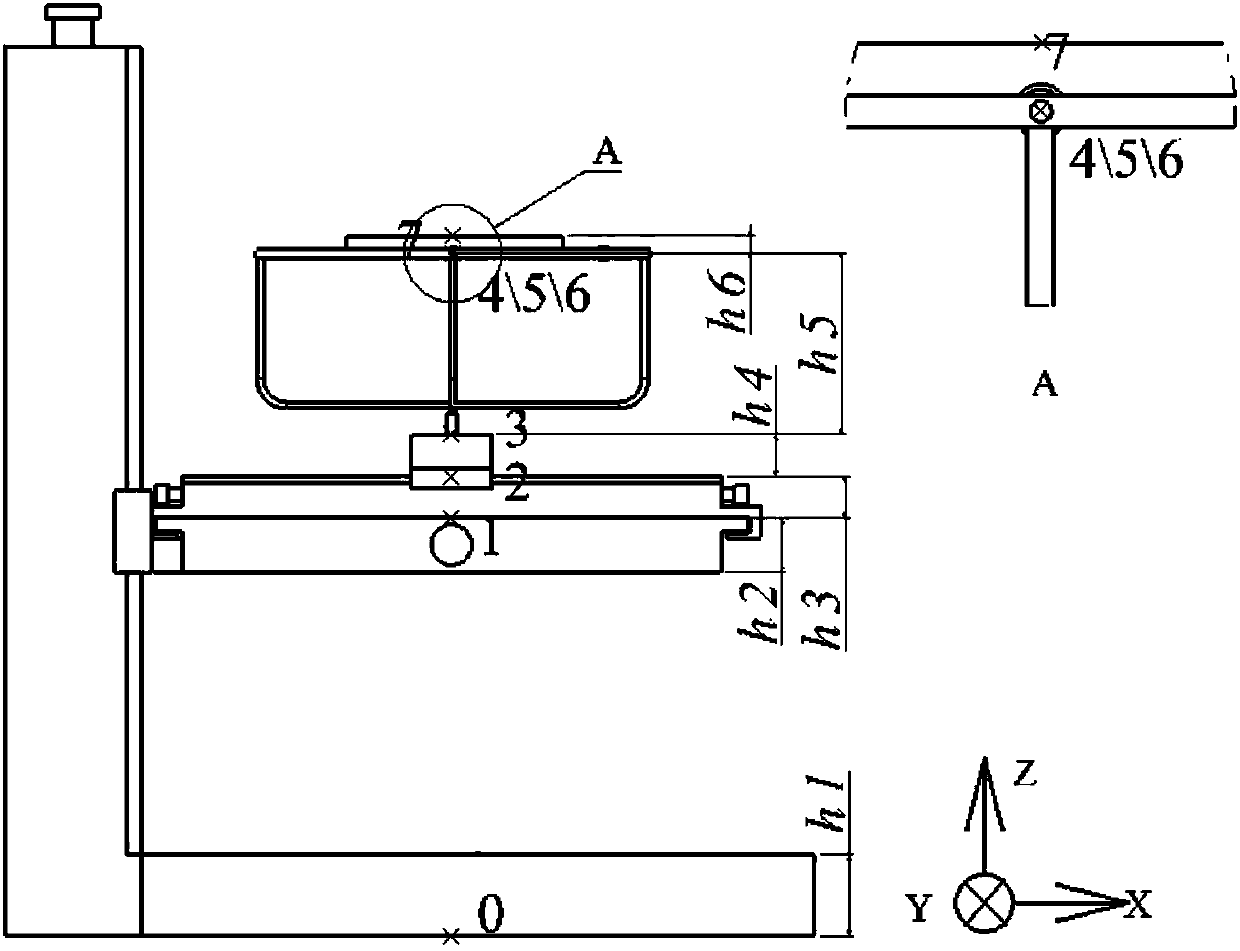

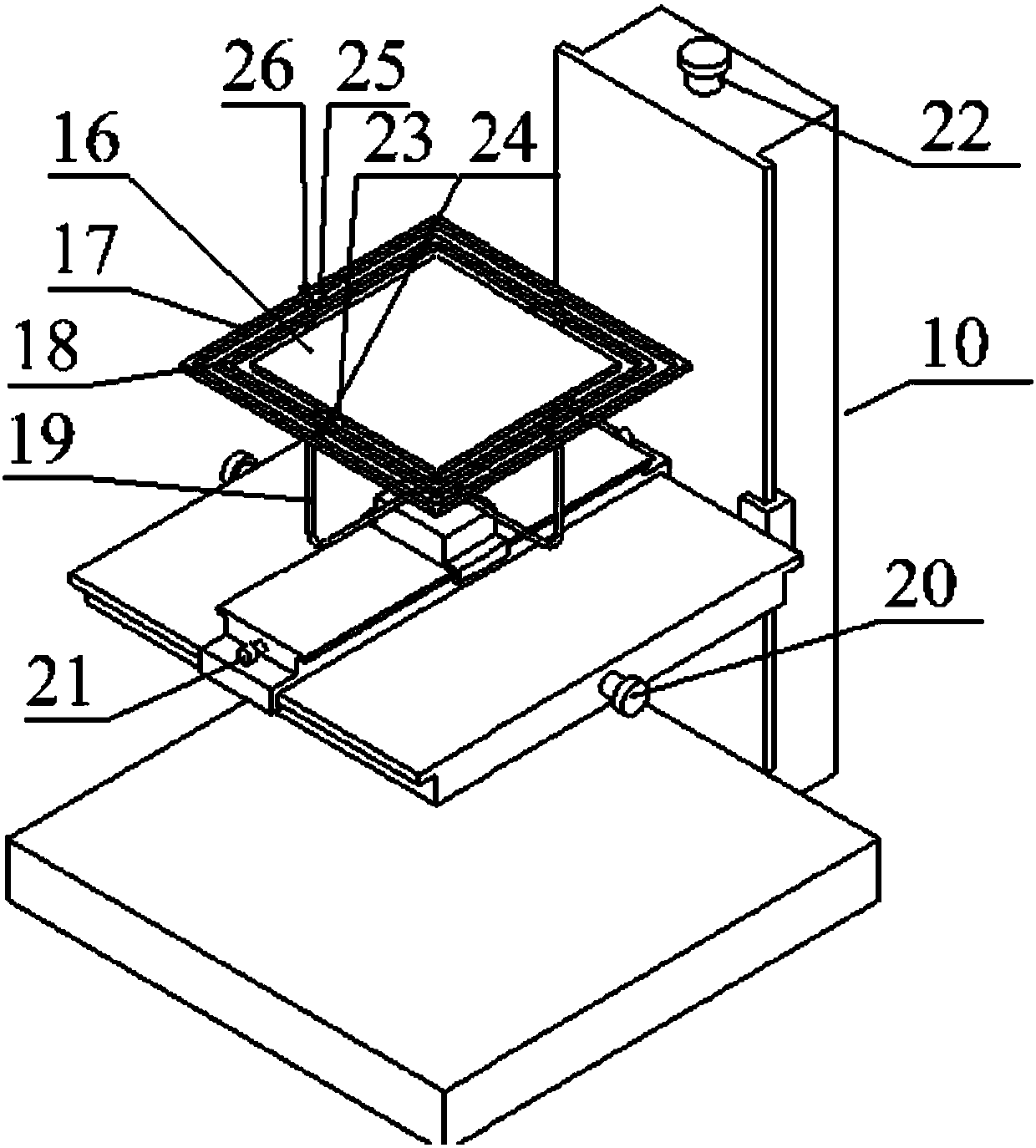

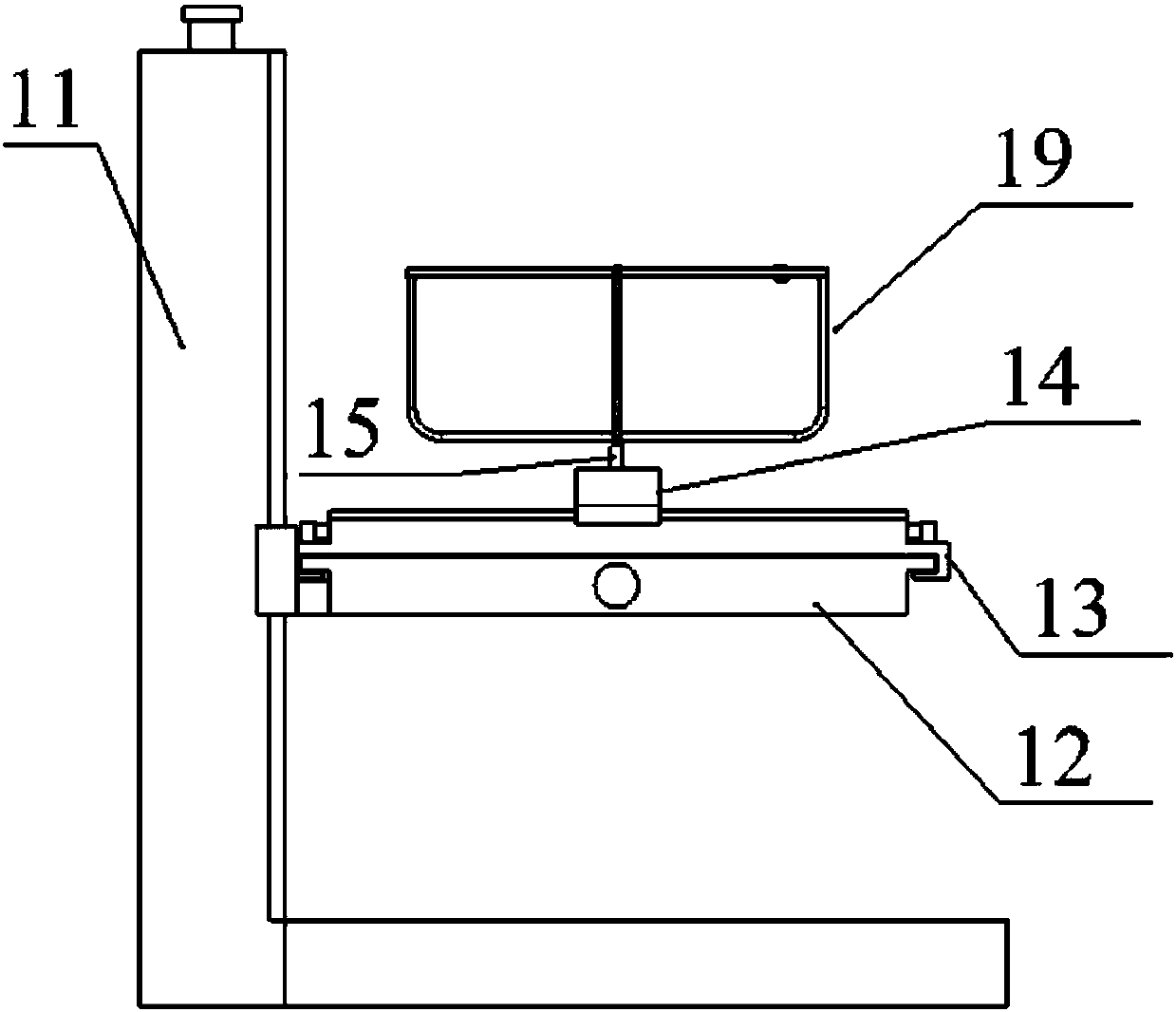

[0087] This embodiment provides a camera calibration system, including a calibration platform, the calibration platform includes an X-axis translation mechanism, a Y-axis translation mechanism, a Z-axis translation mechanism; an X-axis rotation mechanism, a Y-axis rotation mechanism, a Z-axis rotation mechanism and Fixed platform; of which:

[0088] The Z-axis translation mechanism is arranged at the bottom of the entire calibration platform, including the base and the Z-axis movement platform, the Z-axis ball screw and the rotary encoder of the Z-axis translation mechanism; the Z-axis ball screw realizes the Z-axis movement of the platform in the Z direction. The movement of the Z-axis translation mechanism is used to record the rotation times of the Z-axis ball screw through the rotary encoder of the Z-axis translation mechanism, thereby recording the position of the Z-axis moving platform in the Z direction;

[0089] The Y-axis translation mechanism includes a Y-axis mobile...

Embodiment 2

[0101] This embodiment provides a calibration method for a camera calibration system, including any one of the following processes:

[0102] - traditional calibration process;

[0103] - Self-calibration process.

[0104] specifically:

[0105] (1) Traditional calibration method

[0106] The specific steps of Zhang Zhengyou's calibration method using the calibration system provided in Example 1 are introduced here:

[0107] The first step: place the calibration platform 10 at a suitable horizontal position, fix the camera 28 at an appropriate position directly above the calibration platform 10; fix the calibration plate 27 on the fixed platform;

[0108] Second step: adjust the X-axis rotation knob 24 of the X-axis rotation bracket, the Y-axis rotation knob 26 of the Y-axis rotation bracket, and the Z-axis rotation knob of the Z-axis rotation bracket 19, so that the X-axis rotation mechanism rotates the encoder 23, Y The rotation angles of the axis rotation mechanism rotar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com