Side sealing plate applied to double-roller cast rolling

A technology of side sealing plate and sealing plate, which is applied in the field of twin-roll casting and rolling, can solve problems such as the thickness of the speed boundary layer and the wettability of the working face of the side sealing plate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

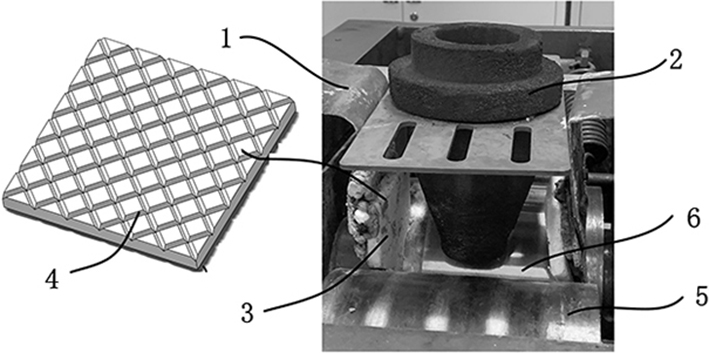

[0015] A side sealing plate applied to twin-roll casting disclosed in Embodiment 1 of the present invention, such as figure 1 As shown, the graphite flow distribution device 2 is preheated to 680 degrees Celsius. The metal to be cast and rolled is aluminum alloy. The copper strip 6 is set for implementing the trace method, and has nothing to do with the invention of this application document.

[0016] Shown in the embodiment of the present invention figure 1 Among them, the working surface 3 of the simple side sealing plate is provided with patterns, and the pattern is a laser-processed prism array structure, and the pattern units are arranged at intervals behind the working surface 3 of the side sealing plate, forming several discontinuous protrusions.

[0017] Shown in the embodiment of the present invention figure 1 Among them, the working surface of the side sealing plate is still as clean as new after working for at most 30 seconds, and the long-term use can be estimat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com