Phosphorus and nitrogen synergistic self-flame retardant environment-friendly wood coating

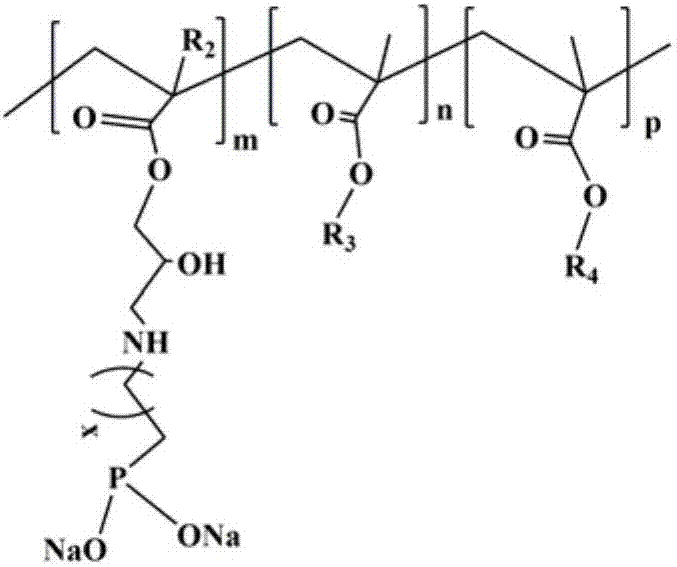

A fire-retardant technology of wood coatings and phosphorus nitrogen, which is applied in fire-resistant coatings, anti-fouling/underwater coatings, paints containing biocides, etc., can solve the problems of reduced flame-retardant performance and uneven dispersion, and achieve the effect of not being free

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A phosphorus-nitrogen synergistic self-flame-retardant acrylic emulsion environmental protection wood coating, the composition is as follows:

[0024] 50.0% of acrylic emulsion of phosphorus nitrogen flame retardant group, 1.0% of polycarboxylic acid type anionic dispersant, 1.0% of pH regulator, 0.1% of silicone defoamer, 0.2% of modified cellulose thickener, alcohol ester ten Two 12.0%, water-based color paste 3.0%, matting powder 5.0%, fungicide 0.2%, deionized water 20.0%, titanium dioxide 7.50%.

[0025] The above-mentioned phosphorus nitrogen synergistic self-flame-retardant acrylic emulsion environmental protection wood coating, the preparation method is as follows:

[0026] a. Preparation of aqueous dispersion: Add deionized water, wetting and dispersing agent, antifreeze agent, defoamer, film-forming aid, thickening rheological agent, bactericide, and matting powder into the dispersion tank according to the specified weight percentage, Stir evenly, add titaniu...

Embodiment 2

[0031] A phosphorus-nitrogen synergistic self-flame-retardant acrylic emulsion environmental protection wood coating, the composition is as follows: 40.0% of acrylic emulsion of phosphorus-nitrogen flame-retardant groups, 2.0% of non-ionic polymer water-based dispersant, 2.0% of pH regulator, fatty acid glyceride Defoamer 0.3%, thickening rheological agent hydrophobically modified alkali-swellable acrylic emulsion 0.2%, film-forming aid polyethylene glycol 200: 10%, hardening agent 2.0%, bactericide 0.2%, deionized water 20.2% , talc powder 12.1%, mica powder 10.0%.

[0032] The above-mentioned phosphorus nitrogen synergistic self-flame-retardant acrylic emulsion environmental protection wood coating, the preparation method is as follows:

[0033] a. Preparation of aqueous dispersion: Add deionized water, wetting and dispersing agent, defoamer, film-forming aid, thickening rheological agent, bactericide, and hardening agent into the dispersion tank according to the specified w...

Embodiment 3

[0037] In this embodiment, the raw material components are shown in the table below, a self-flame-retardant water-based environmental protection coating and its preparation method are as follows: 61.0% acrylic acid emulsion of phosphorus-nitrogen flame-retardant groups, 2.0% non-ionic polymer water-based dispersant, pH Conditioner 1.0%, polyether nonionic surfactant 0.5%, hydrophobic association polyurethane emulsion 0.1%, film-forming aid propylene glycol phenyl ether 15.0%, water-based color paste 5.0%, bactericide 0.5%, deionized water 10.0% %, Kaolin 4.9%.

[0038] The above-mentioned phosphorus nitrogen synergistic self-flame-retardant acrylic emulsion environmental protection wood coating, the preparation method is as follows:

[0039] a. Preparation of aqueous dispersion: Add deionized water, wetting and dispersing agent, defoamer, film-forming aid, thickening rheological agent, and fungicide functional additive into the dispersion tank according to the specified weight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com