A kind of self-flame-retardant aqueous polyurethane emulsion and preparation method thereof

A water-based polyurethane flame-retardant technology, applied in polyurea/polyurethane coatings, anti-fouling/underwater coatings, biocide-containing paints, etc., can solve the problem of harmful coatings, short flame-retardant time, and easy release of flame retardants and other problems, to achieve the effect of long-lasting self-flame retardant performance and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

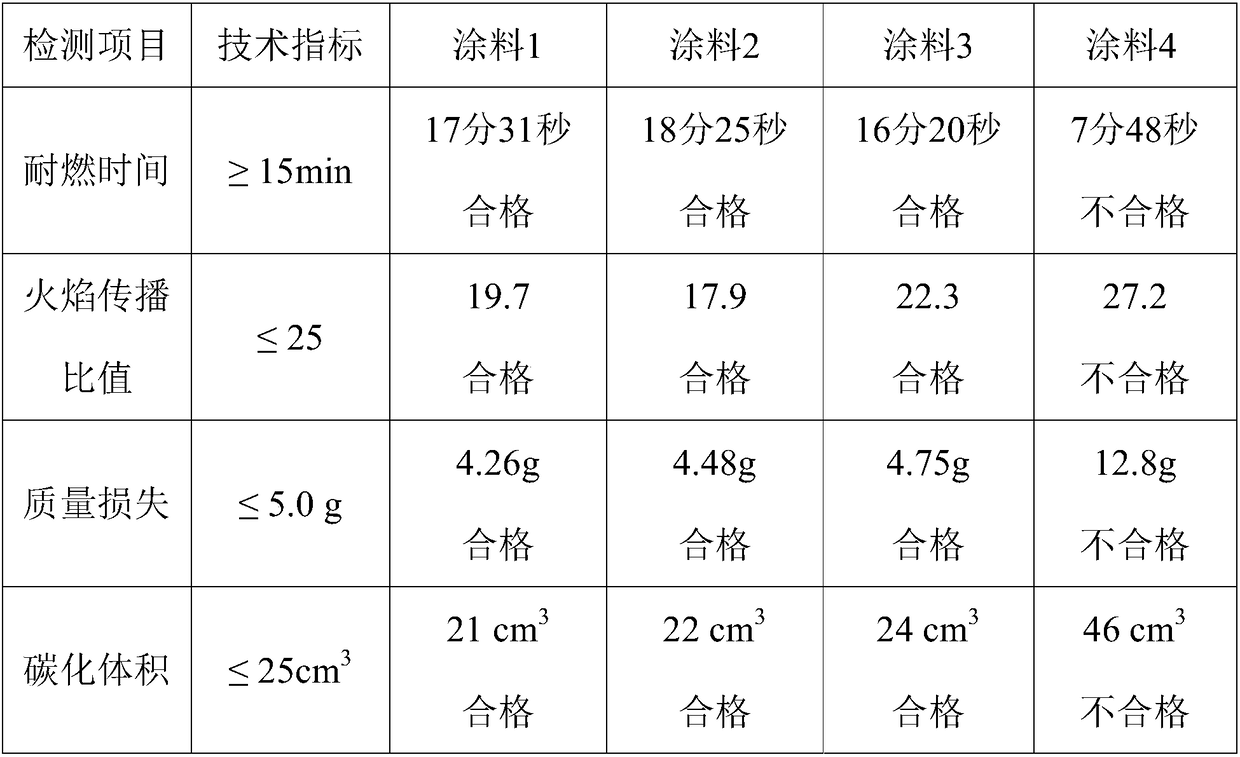

Embodiment 1

[0021] a. 20.0 parts of polytetrahydrofuran ether diol-2000, 2.0 parts of dimethylol propionic acid, 15.0 parts of bromotoluene diisocyanate, and 20.0 parts of dibromotoluene diisocyanate were stirred at 600r / min under nitrogen protection for 80 ℃ for 2 hours, until the measured -NCO content reaches the theoretical value specified by titration with di-n-butylamine-toluene solution;

[0022] b. Keeping other conditions in a constant, cool down the system to 80°C, add 30.0 parts of butanone, then add 2.0 parts of 1,4-butanediol and 0.02 parts of dibutyltin dilaurate, and then use di-n-butyl Amine-toluene solution was used to measure the -NCO content, when the -NCO content reached the theoretical value, the bromine-modified polyurethane prepolymer was obtained;

[0023] c. Maintain the above speed, cool down the reaction system prepared in step b to 35°C, add 2.0 parts of neutralizing agent triethylamine, and neutralize for 3 minutes; then add 80.0 parts of water, then increase t...

Embodiment 2

[0025] a. 15.0 parts of polybutylene adipate diol-1500, 10.0 parts of polypropylene oxide ether diol-2100, 6.0 parts of dimethylol propionic acid, 30.0 parts of trichlorodiphenylmethane diisocyanate , under the condition of stirring at 300r / min, under the protection of nitrogen, react at 80°C for 2h, and react until the measured -NCO content reaches the theoretical value specified by titration with di-n-butylamine-toluene solution;

[0026] b. Keep other conditions in a constant, cool the system down to 60°C, add 50.0 parts of acetone, then add 10.0 parts of 1,6-hexanediol and 0.1 part of dibutyltin dilaurate, and then use di-n-butylamine -Toluene solution measures -NCO content, when -NCO content reaches theoretical value, promptly obtains bromine-modified polyurethane prepolymer;

[0027] c. Maintain the above speed, cool down the reaction system prepared in step b to 45°C, add 5.0 parts of neutralizing agent triethylamine, and neutralize for 10 minutes; then add 150.0 parts ...

Embodiment 3

[0029] a. React 20.0 parts of polycaprolactone diol, 3.2 parts of dimethylolpropionic acid, and 20.0 parts of tribromodiphenylmethane diisocyanate at 500 r / min under nitrogen protection at 90°C for 2 hours. Until the measured -NCO content reaches the theoretical value specified by di-n-butylamine-toluene solution titration;

[0030] b. Keep other conditions in a constant, cool the system down to 70°C, add 30.0 parts of N-methylpyrrolidone, then add 3.0 parts of trimethylolpropane and 0.04 parts of dibutyltin dilaurate, and then use dibutyltin dilaurate The n-butylamine-toluene solution was used to measure the -NCO content, and when the -NCO content reached the theoretical value, the bromine-modified polyurethane prepolymer was obtained;

[0031]c. Maintain the above speed, cool down the reaction system prepared in step b to 40°C, add 3.0 parts of neutralizing agent triethylamine, and neutralize for 8 minutes; then add 120.0 parts of water, then increase the speed to 1200r / min,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com