Fines co-feed for maintaining efficient reactor hydrodynamics

A technology of fine powder and reaction system, applied in organic chemistry, biological raw materials, chemical instruments and methods, etc., can solve the problems of loss of effectiveness, inefficiency, and poor operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

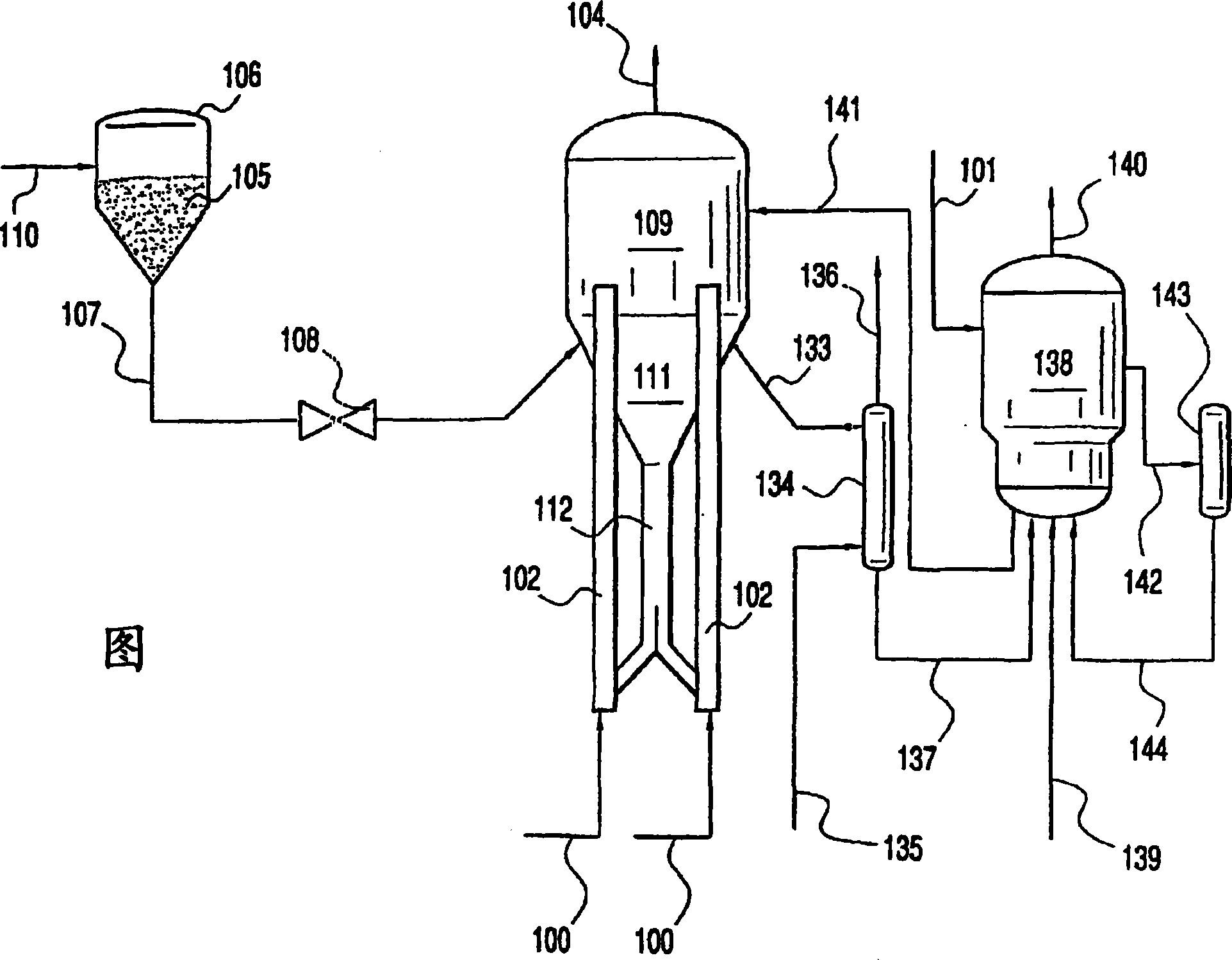

Image

Examples

Embodiment Construction

introduce

[0018] The present invention provides a method for maintaining a desired particle size distribution in a reaction system for converting oxygenates to olefins (OTO). Loss of catalyst fines from such reaction systems can lead to undesired fluidization and hydrodynamic characteristics. In one embodiment, the present invention involves replacing lost catalyst fines with less reactive co-catalyst particles. Additionally or alternatively, the reaction system includes a catalyst regenerator, and the co-catalyst particles enhance regeneration within the catalyst regenerator. By adding less reactive co-catalyst particles to the reaction system, the desired fluidization characteristics and hydrodynamics can be maintained without affecting the overall (or main catalyst's) performance and product selectivity. The present invention also relates to populations of catalyst particles having a desired particle size distribution well suited to achieve desired fluidization and hydro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com