Reinforced concrete structure with steel plate reinforcement layer set on partial surface

A reinforced concrete and reinforced layer technology, applied in the field of reinforced concrete structures, can solve problems affecting structural safety and durability, reduce structural rigidity and durability, increase section size, etc., to reduce control section size, reduce Crack width, effect of increasing joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

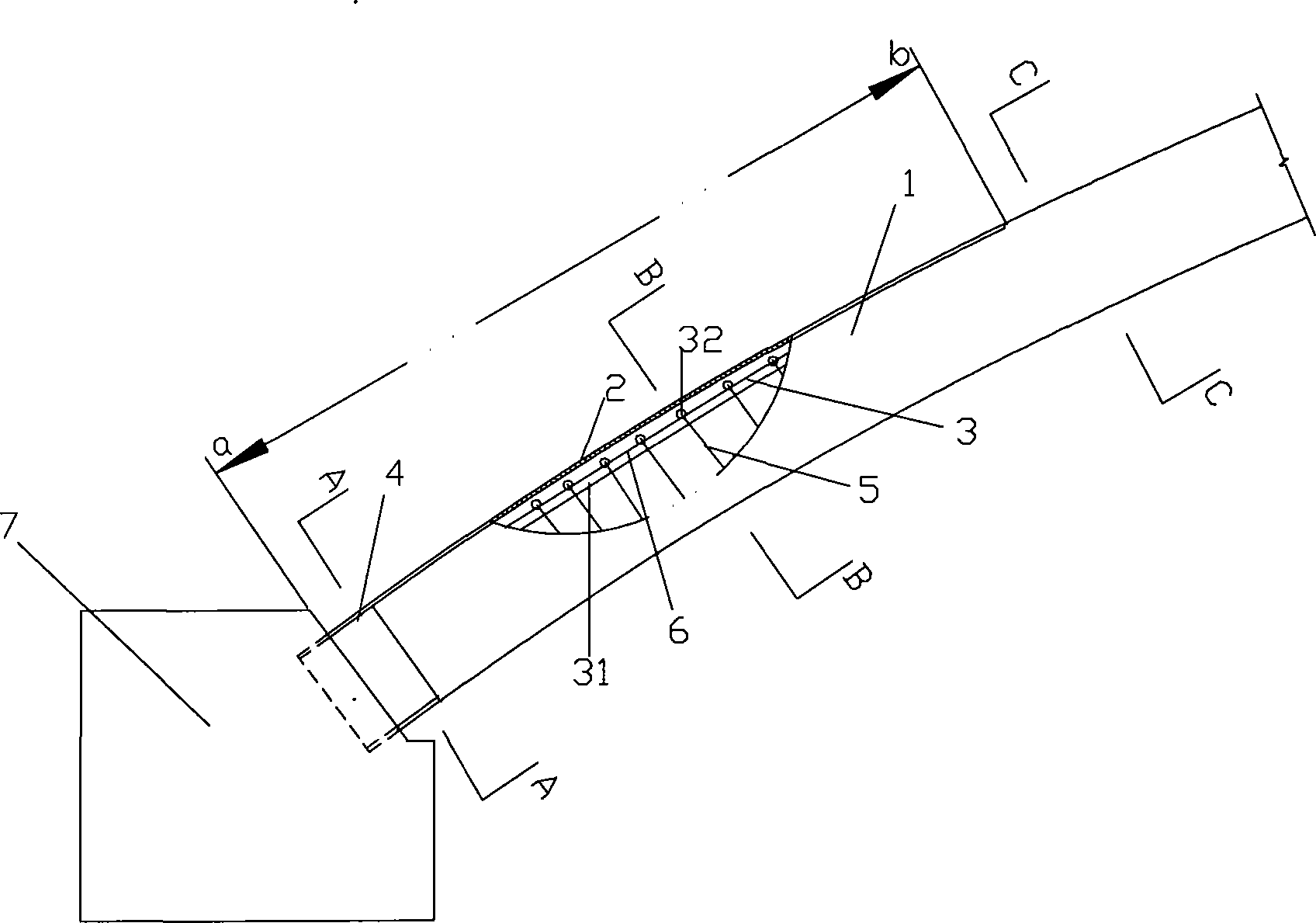

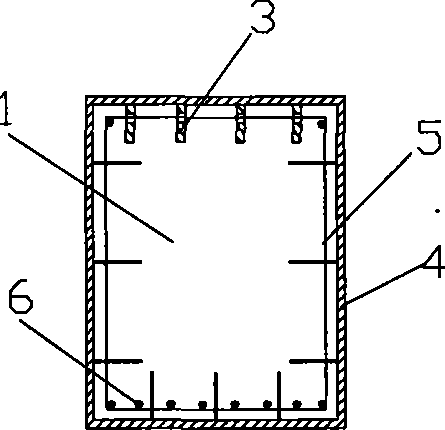

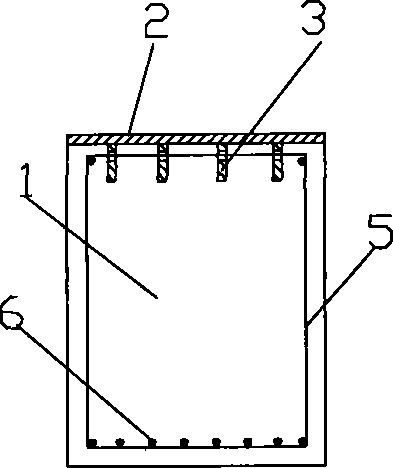

[0026] figure 1 It is a structural schematic diagram of Embodiment 1 of the present invention, figure 2 for figure 1 View along A-A direction, image 3 for figure 1 View along B-B direction, Figure 4 for figure 1 Sectional view along C-C direction, Figure 5 It is a schematic diagram of the force analysis of the invention embodiment 1, as shown in the figure: the reinforced concrete structure of the partial surface of the present embodiment is provided with a steel plate reinforcement layer as an arch rib, including a reinforced concrete arch rib 1, a stirrup 5 poured in the arch rib and a longitudinal The steel bar 6 is poured on the upper surface of the reinforced concrete arch rib 1 that bears the tensile stress, and the steel plate reinforcement layer 2 is cast as a whole; the lower end of the steel plate reinforcement layer 2 is fixedly connected with the abutment 7 through the steel box 4, and the steel box 4 Enclosed around the root of the reinforced concrete ar...

Embodiment 2

[0031] Image 6 Schematic diagram of the second embodiment of the present invention, Figure 7 for Image 6 Sectional view along D-D direction, Figure 8 for Image 6 Sectional view along E-E direction, Figure 9 for Image 6 Sectional view along F-F direction, Figure 10 It is a schematic diagram of the force analysis of the second embodiment of the invention, as shown in the figure: the reinforced concrete structure with a steel plate reinforcement layer on the local surface of this embodiment is a continuous beam structure, including a reinforced concrete continuous beam structure 1, and a stirrup 5 poured in the continuous beam structure and the longitudinal steel bar 6, the upper surface of the continuous beam structure at the upper surface of the continuous beam structure 1 that bears the tensile stress on the upper part of the reinforced concrete continuous beam structure 1 is poured to form a steel plate reinforcement layer 2, and the two ends of the steel plate r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com