Siphon destroying device

A siphon and sodium tube technology, applied in the field of additional flow adjustment devices, can solve the problems of cavitation of circulating pump, large leakage of sodium, deterioration of heat transfer, etc., and achieve the effects of slowing down the development speed, reducing leakage and reducing accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

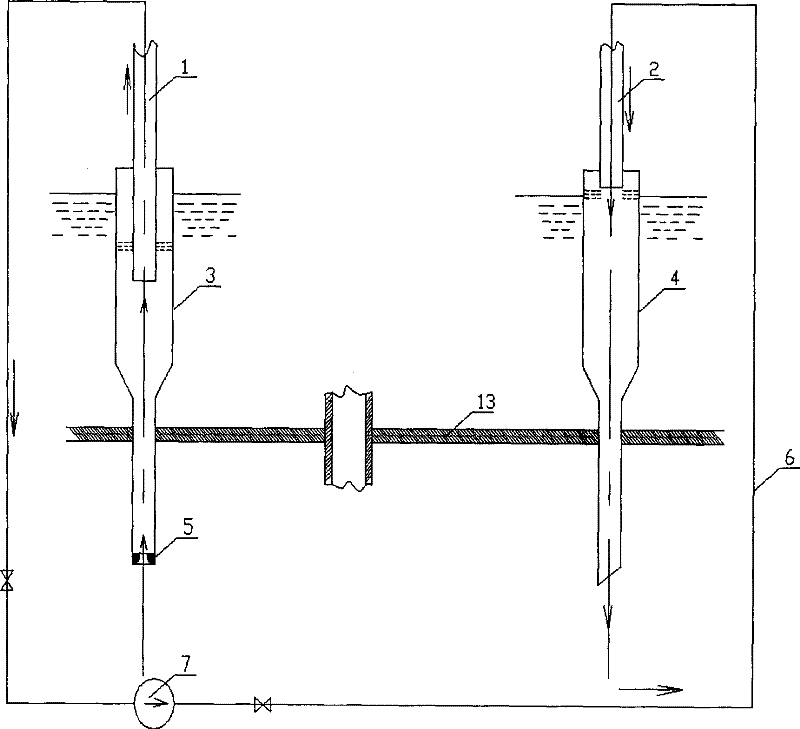

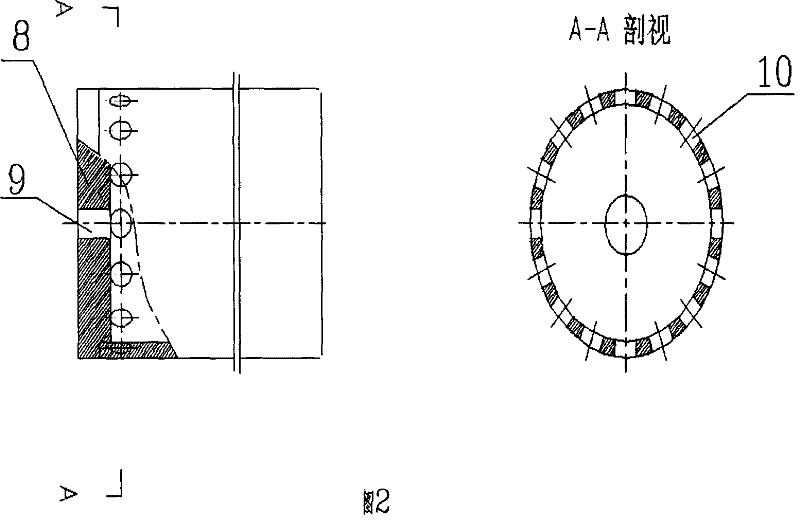

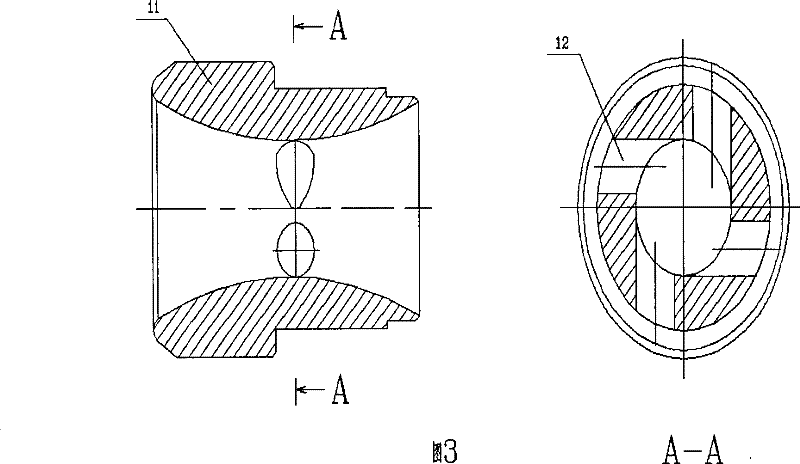

[0013] The device comprises that the sodium extraction pipe 1 is connected with the circulation pump 7 through the external pipeline 6, and the other end of the circulation pump 7 is connected with the sodium return pipe 2 through the external pipeline 6, and the sodium extraction pipe 1 and the sodium return pipe 2 are respectively fixed on the isolation plate 13, the sodium extraction pipe 1 extends into the protective sleeve 3 in the pile, the sodium return pipe extends into the protective sleeve 4, the inlet orifice 5 is located at the lower end of the sodium extraction pipe 1, and the sodium extraction pipe 1 extends The fracture structure of the inserted protective sleeve 3 is a Venturi tube 11 with a throat diameter of 50mm, and four 20mm middle holes 12 are opened around it. The aperture of the inlet orifice 5 is 45mm. Lower the elevati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com