Concentrated solution backflow circulating type membrane separation equipment and method thereof

A technology for concentrated liquid and membrane separation, applied in semi-permeable membrane separation, chemical instruments and methods, membrane technology, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

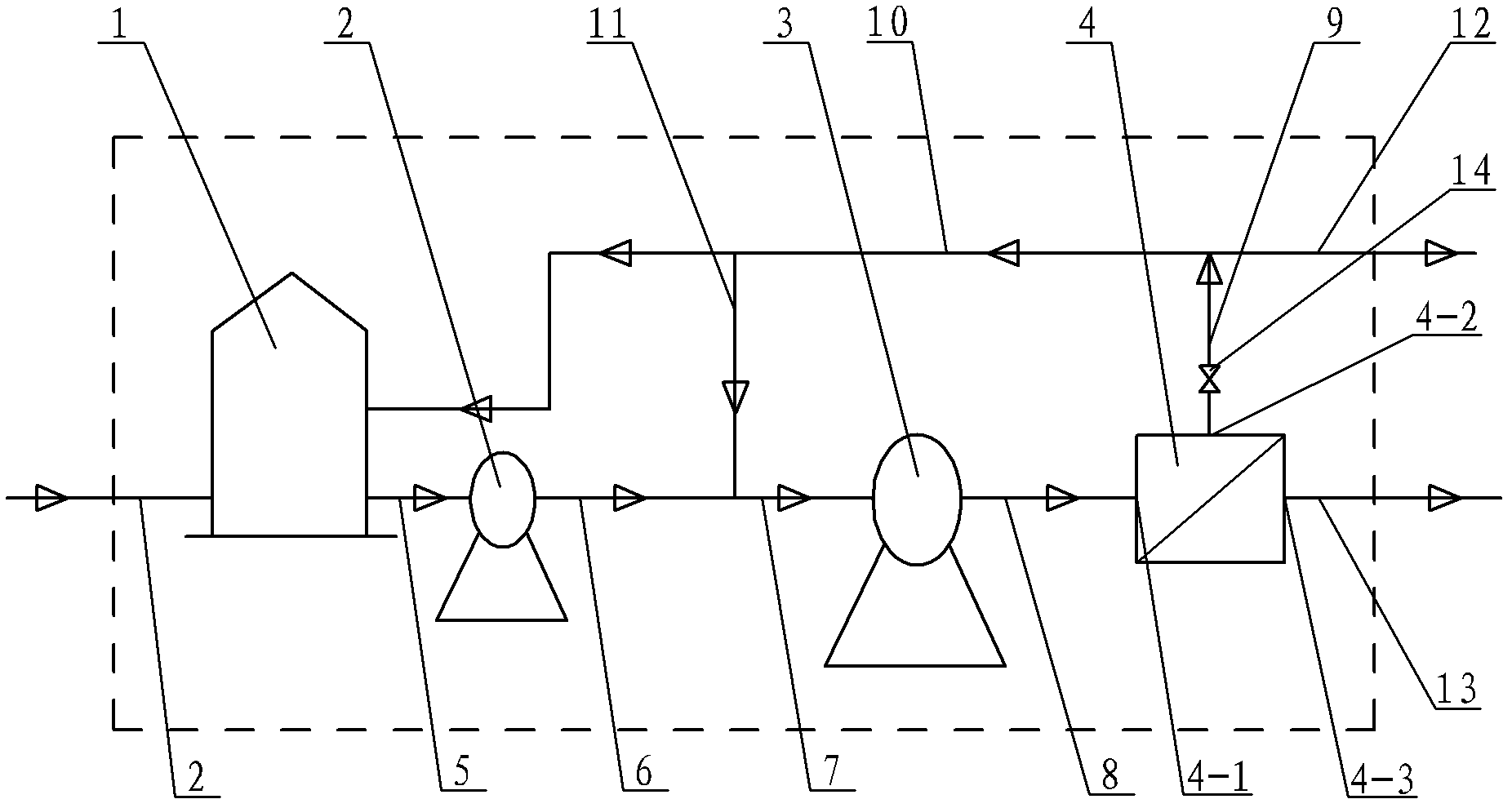

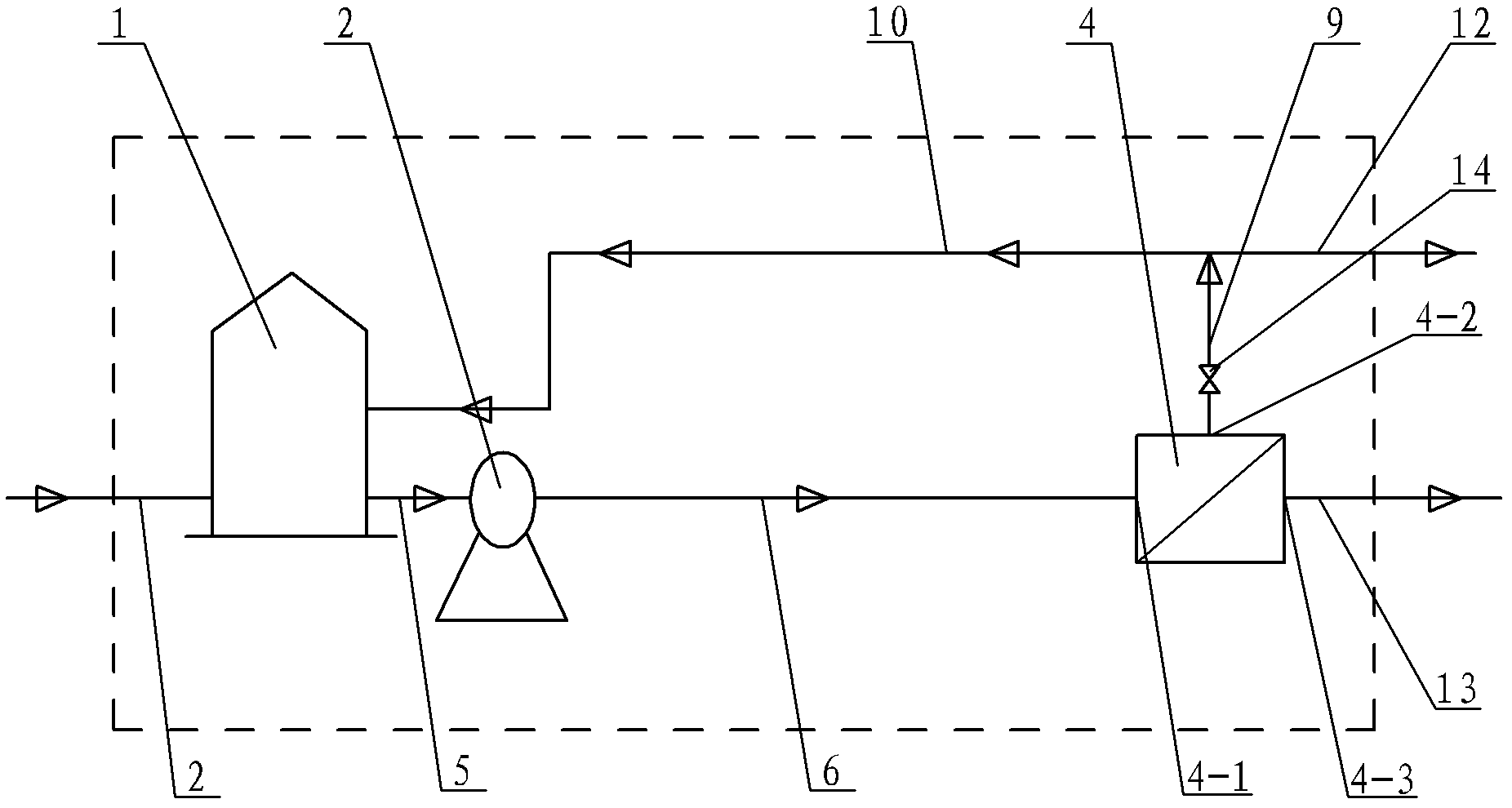

[0010] Specific implementation mode one: combine figure 1 Describe this embodiment, the concentrated liquid reflux circulating membrane separation equipment of this embodiment includes a buffer water tank 1, a feed pump 2, a circulation pump 3, a membrane module 4, a feed pump suction pipe 5, a feed pump pressure pipe 6, a circulation Pump suction pipe 7, circulation pump pressure pipe 8, concentrate delivery pipe 9, return pipe 10, circulation pipe 11, concentrate discharge pipe 12 and permeate output pipe 13, the input end of the feed pump 2 passes through the feed pump suction pipe 5 is connected to the buffer water tank 1, the output end of the feed pump 2 is connected to the suction pipe 7 of the circulation pump through the pressure water pipe 6 of the feed pump, the input end of the circulation pump 3 is connected to the suction pipe 7 of the circulation pump, and the output end of the circulation pump 3 is connected to the suction pipe 7 of the circulation pump. The i...

specific Embodiment approach 2

[0011] Specific implementation mode two: combination figure 1 To describe this embodiment, the inner diameter of a single tubular membrane in the membrane module 4 of this embodiment is 0.1 mm to 50 mm, and the membrane pore diameter of the tubular membrane is 0.001 μm to 10 μm. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0012] Specific implementation mode three: combination figure 1 To illustrate this embodiment, this embodiment and the concentrated liquid backflow circulation type membrane separation equipment further include a back pressure valve 14 installed on the concentrated liquid delivery pipe 9 . Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com