A continuous membrane treatment method for alkali press liquid in viscose fiber production process

A production process, viscose fiber technology, applied in the field of viscose fiber production, can solve the problems of affecting the filtration effect, reducing the net liquid flux, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The principles and features of the present invention will be described below, and the exemplified examples are intended to be construed as limiting the scope of the invention.

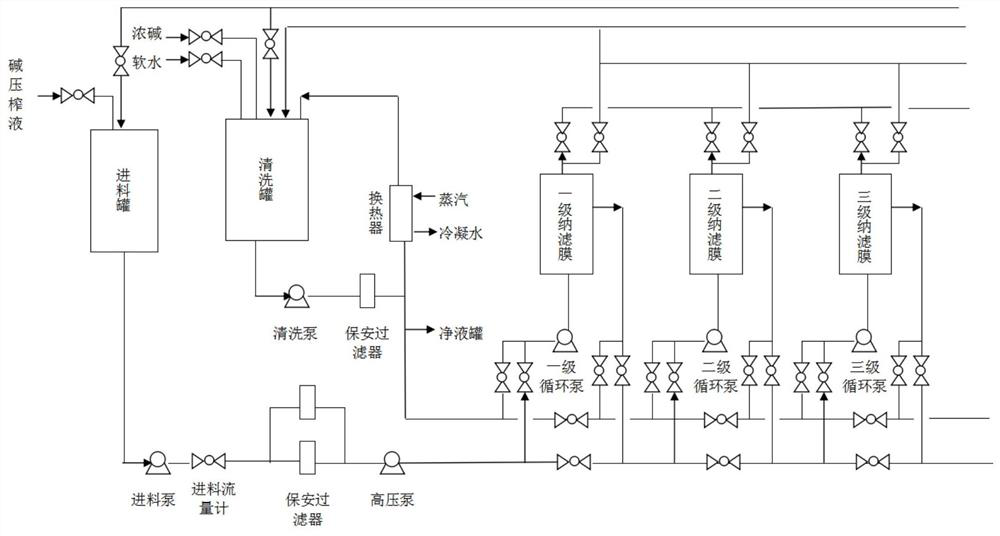

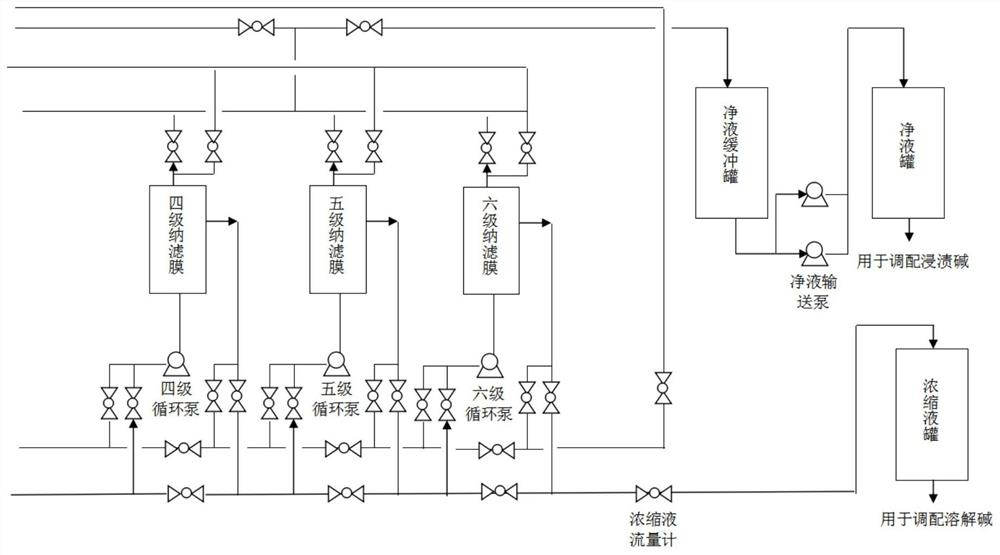

[0033] In the present invention figure 1 Right pipeline figure 2 The upper and lower lines of the left side corresponds to the drawings, that is, the structure of the continuous film treatment apparatus for the alkali pressing liquid for the production process of viscose fibers, because the entire drawings are large, so the dismantling Two parts to show clear.

[0034] The present invention relates to a continuous film treatment method for alkali pressing liquid during viscose fibers, including the following steps:

[0035] (1) The prepare is added to the feed tank, and the alkali pressure juice in the set range is added, and the spare is stored.

[0036] (2) Feeding, an alkali pressure liquid in the feed tank into the nanofiltration membrane system, including a multi-stage nanofiltration membrane a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com