Continuous membrane treatment method for alkali pressed liquid in viscose fiber production process

A production process and viscose fiber technology, applied in the field of viscose fiber production, can solve the problems of reduced net liquid flux, easy fouling and attenuation of nanofiltration membranes, and achieve improved utilization, reduced cleaning times, and extended service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The principles and features of the present invention are described below, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

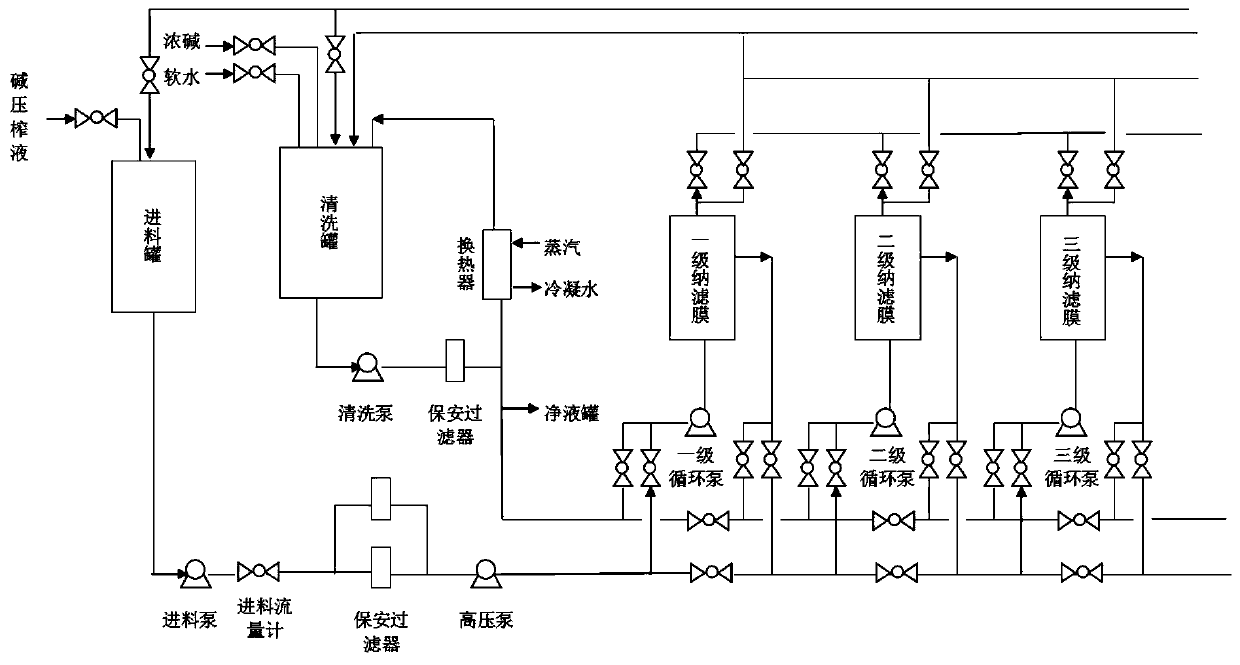

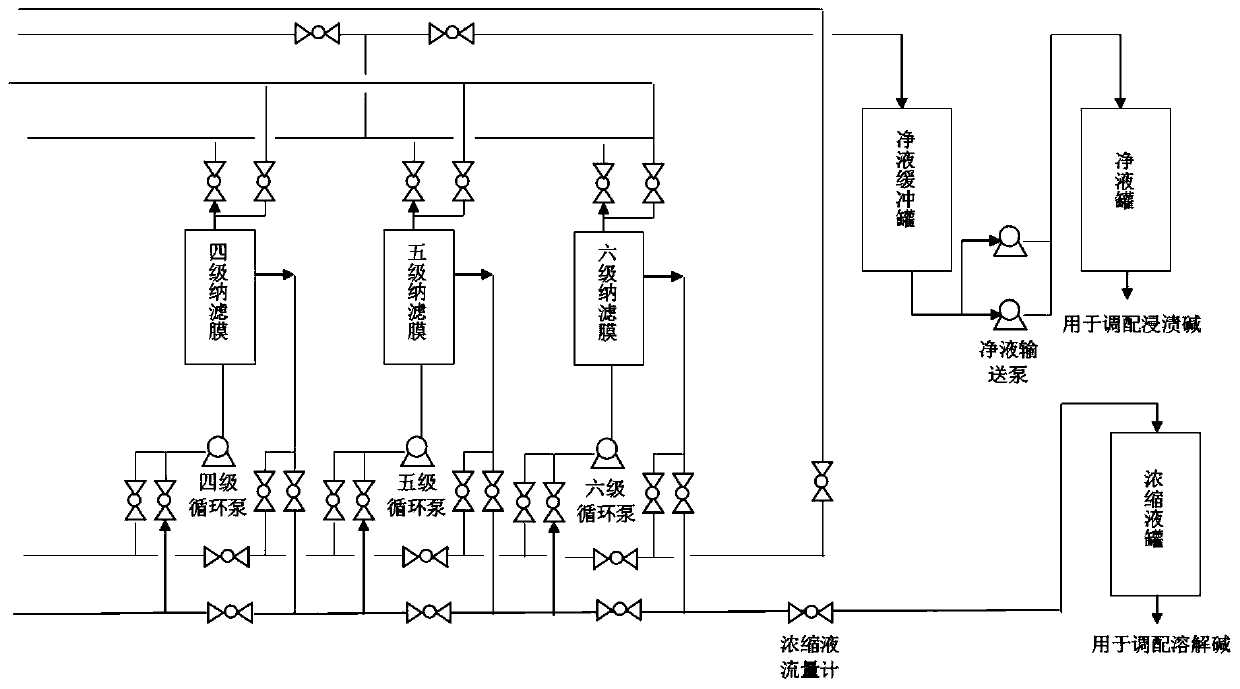

[0033] In the present invention figure 1 The pipeline on the right and the figure 2 The pipelines on the left are connected up and down correspondingly, and spliced into a drawing of an overall structure, which is a schematic structural diagram of the continuous membrane treatment device for alkali squeeze liquid in the production process of viscose fiber. Because the whole drawing is relatively large, it is disassembled into Two parts to show clearly.

[0034] The invention relates to a continuous membrane treatment method for alkali press liquid in viscose fiber production process, comprising the following steps:

[0035] (1) prepare the material, add the alkali squeeze liquid in the setting range value in the feed tank, store for subsequent use;

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com