Dishwasher spray mechanism

A technology of a dishwasher and a spray arm, which is applied to the washing machine/rinsing machine of tableware, the parts of washing machine/rinsing and rinsing machine of tableware, cleaning equipment, etc., and can solve the problems of low cleaning efficiency, spray pressure and flow rate of spray liquid Small size, large number of nozzles, etc., to achieve the effect of strong cleaning ability, high cleaning efficiency and large liquid flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

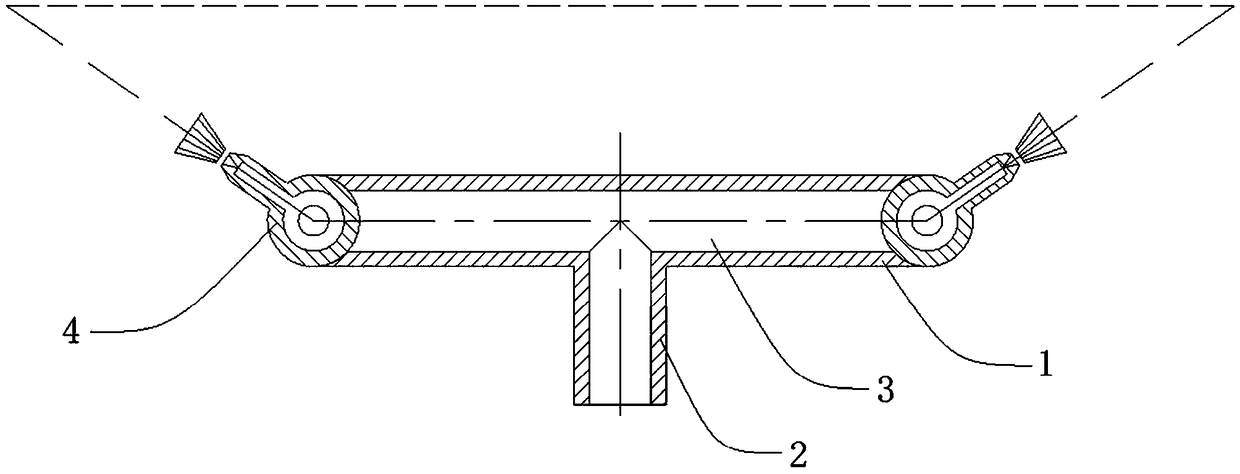

[0025] Such as figure 1 As shown, this embodiment includes:

[0026] A spray arm 1, the spray arm 1 is connected with a rotating rod 2 and is provided with a water-passing cavity 3;

[0027] The high-pressure nozzle 4 communicates with the water-passing cavity 3; the high-pressure nozzle 4 is rotatably arranged relative to the spray arm 1;

[0028] The rotating rod 2 drives the spray arm 1 to rotate.

[0029] The spray arm 1 is arranged symmetrically with respect to the rotation axis of the rotating rod; the number of the high-pressure spray nozzles 4 is two, which are arranged at both ends of the spray arm 1 .

[0030] The high-pressure nozzle 4 is selected to use a fan-shaped nozzle or a self-rotating nozzle.

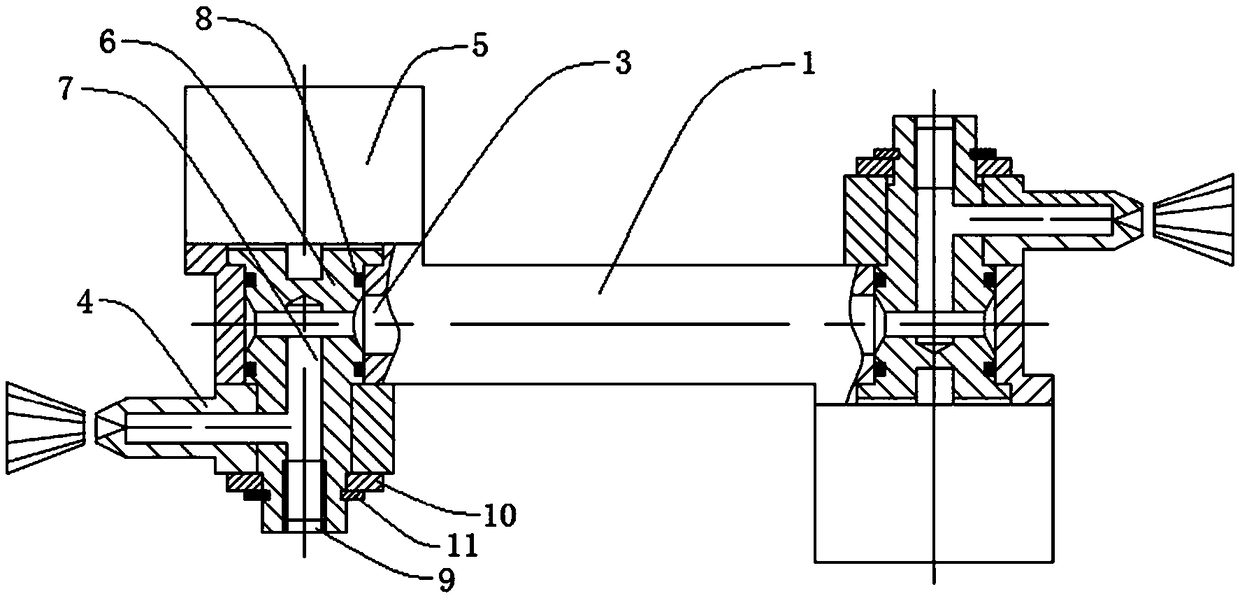

[0031] Such as figure 2 As shown, the high-pressure nozzle 4 is connected to the rotary motor 5, and the swing angle range of the high-pressure nozzle is adjustable; of course, the high-pressure nozzle 4 can also be fixed, and by selecting a nozzle with a large a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com