Oil filling and discharging valve seat

A technology of oil discharge valve and oil valve, which is applied in the field of machinery, can solve the problems of reduced flow rate at the oil discharge port, reduced oil discharge space, thick bottom of the oil discharge, etc., to achieve increased liquid flow, increased size, and good sealing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

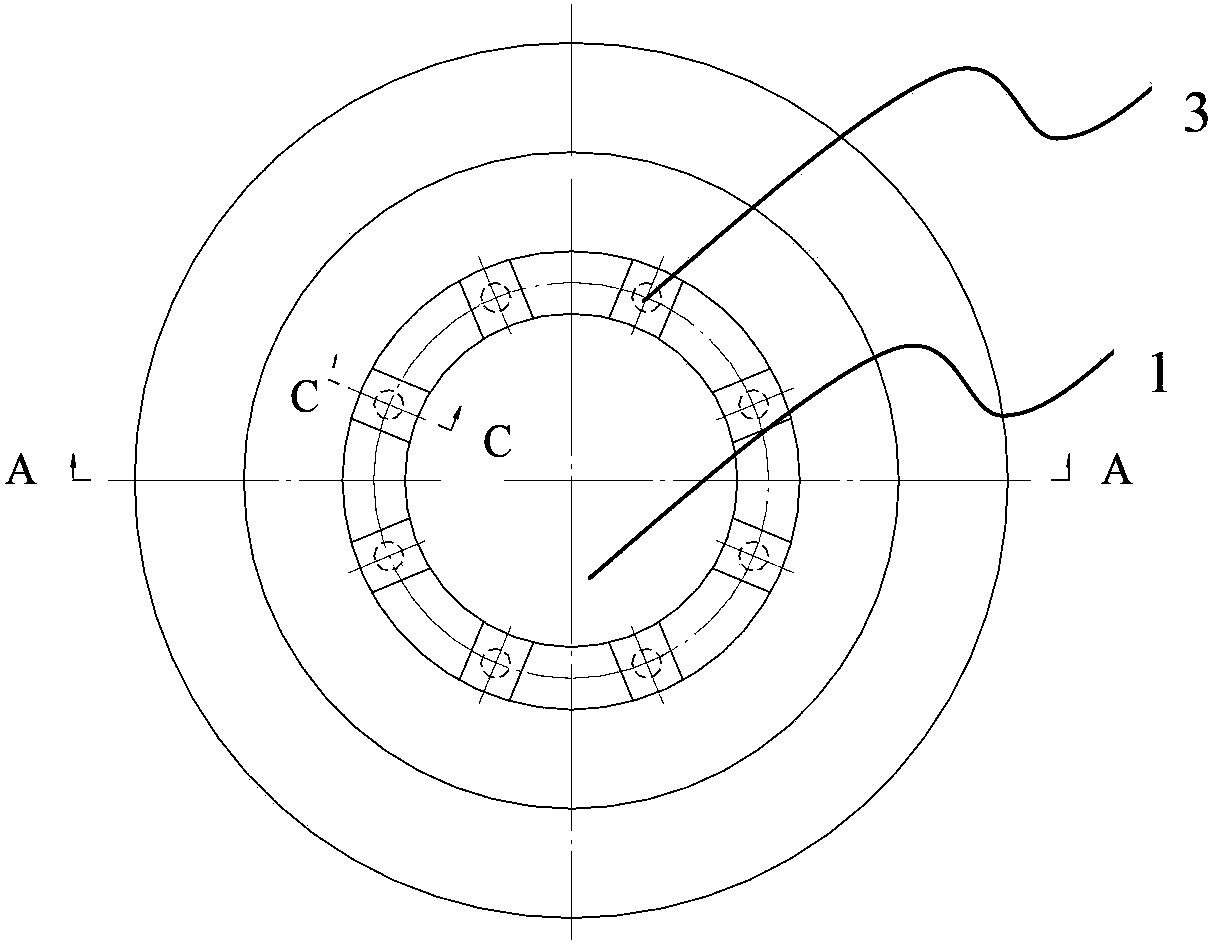

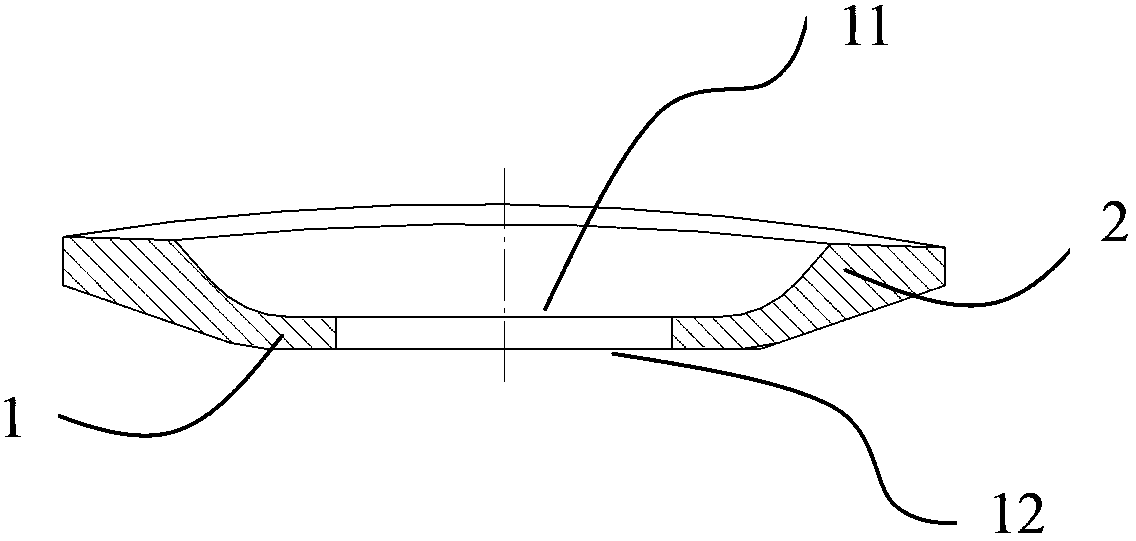

[0019] The theoretical basis of the present invention is that the oil discharge valve seat will be connected with the tank body on the one hand, and will be connected with the lower discharge valve on the other hand. The part connected with the tank body requires high rigidity, but the part connected with the unloading valve needs to increase the size of the oil discharge port as much as possible to increase the flow rate, so the cross section of the oil discharge valve seat is thin at the bottom and thick at the top.

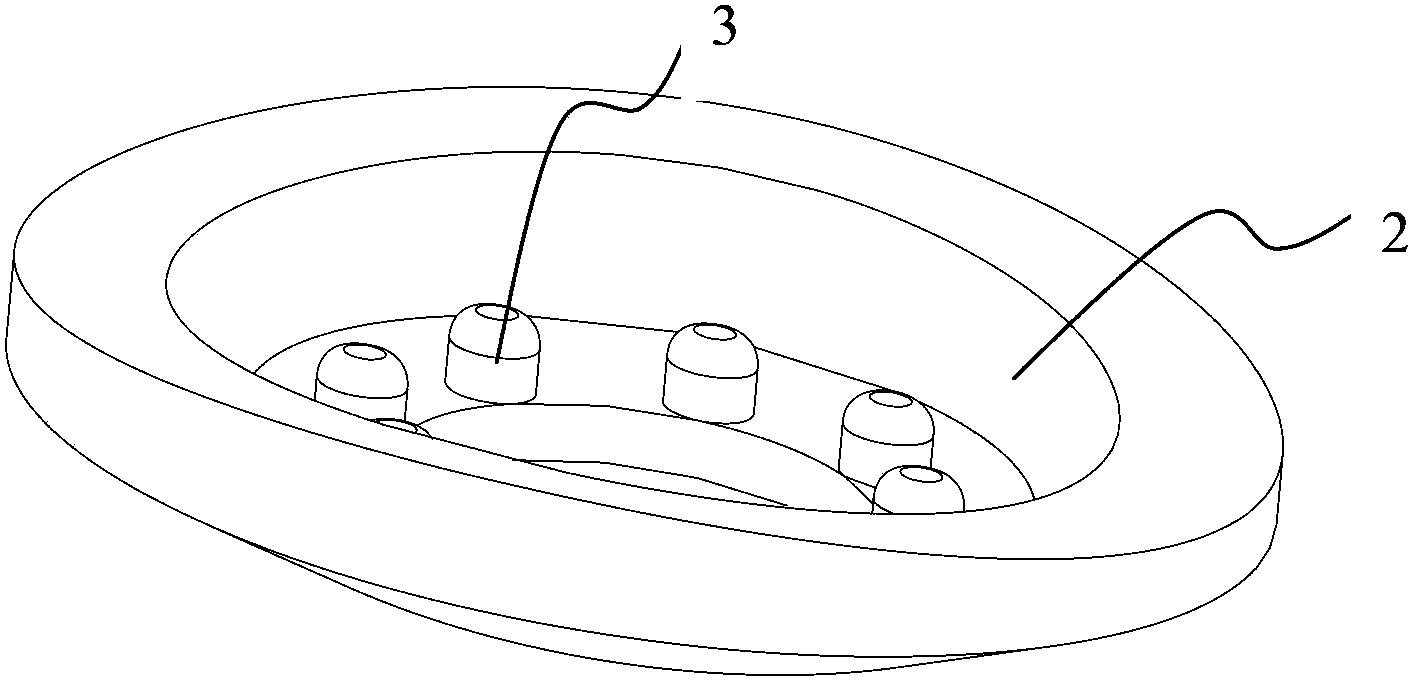

[0020] see figure 1 , figure 2 , image 3 as well as Figure 4 , the present invention provides an oil filling and draining valve seat, the oil filling and draining valve seat includes a bottom 1 of the oil filling and draining valve seat and an oil filling and draining valve seat root 2 extending upward from the edge of the bottom 1 of the oil filling and draining valve seat, for Ensure that the oil discharge port is as large as possible, thereby eliminati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com