Valve body blank

A valve body, blank technology, applied in valve details, valve device, valve shell structure and other directions, can solve the problems of insufficient hydraulic pressure, small flow, and many materials, and achieve the effect of large liquid flow, material saving, and high promotion value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further illustrate the present invention, describe in detail below in conjunction with accompanying drawing:

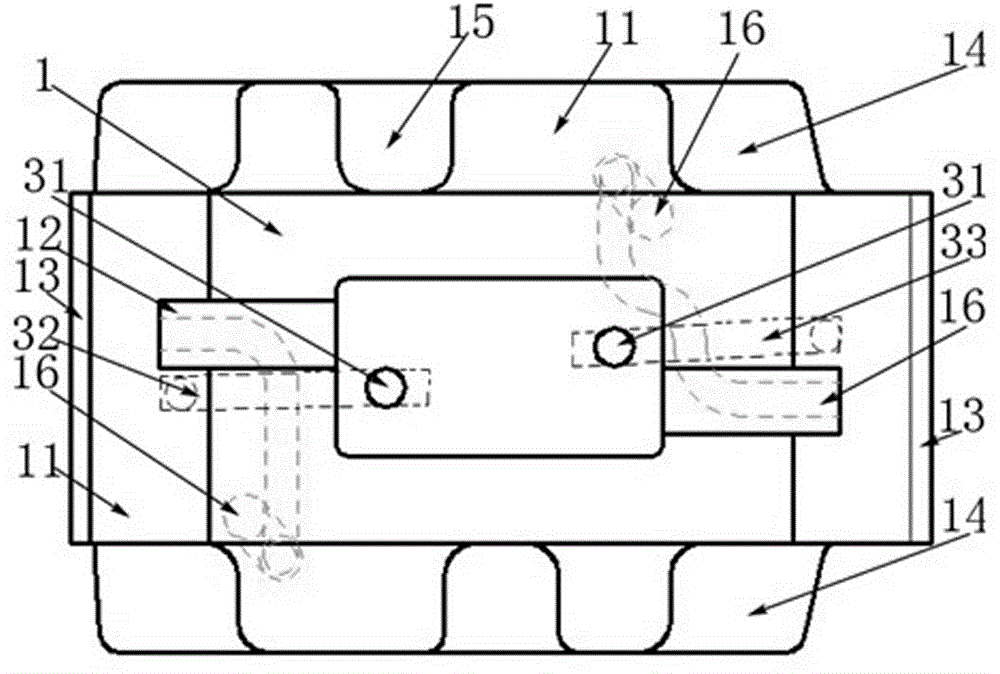

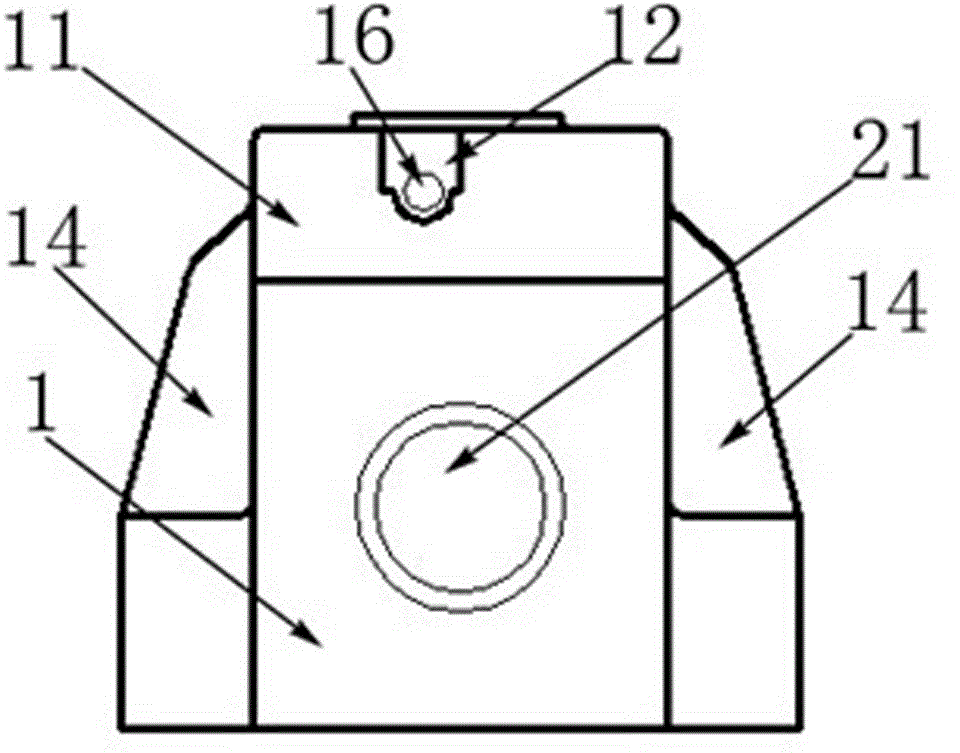

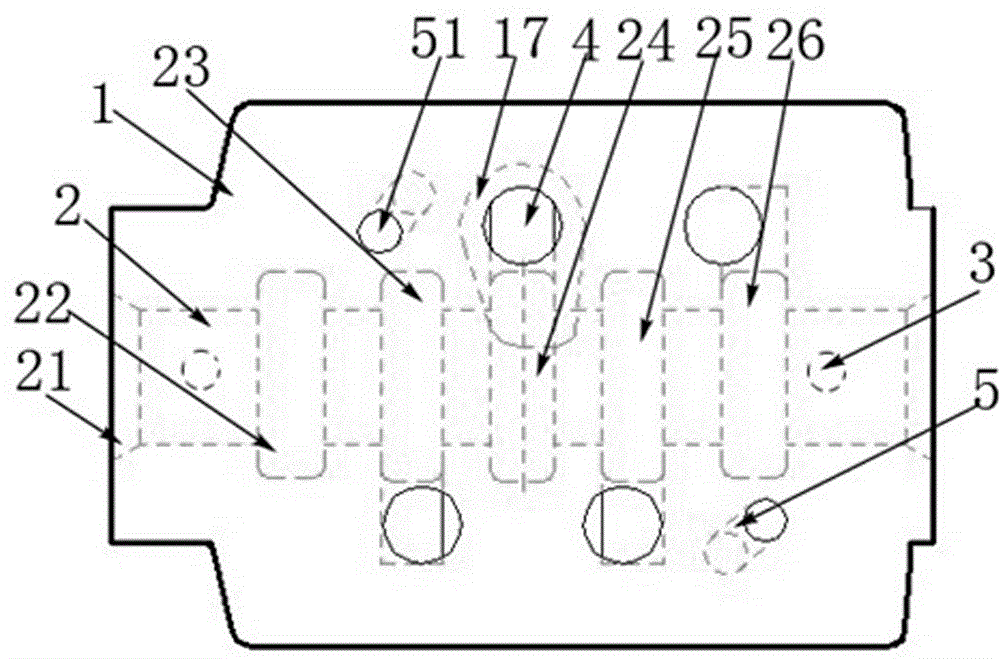

[0021] Referring to the figure below, a valve body blank 1 has a flow channel cast inside it. The flow channel includes a main flow channel 2, a control flow channel 3 and an oil inlet flow channel 4. The main flow channel 2 is located in the middle of the valve body and runs through the valve body horizontally. The flow channel 3 is located above the main channel 2, that is, the upper end of the valve body, and the oil inlet channel 4 is located below the main channel 2, that is, the lower end of the valve body. The four corners of the upper end of the valve body blank 1 are slope surfaces 11, and the upper end two There is a rectangular protrusion 12 in the middle of the slope surface 11 on both sides of the short corner, and there is a section of platform 13 on the edge of the slope surface 11, and there are '∟' grooves 14 on both sides of the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com