Patents

Literature

38results about How to "Increase inlet pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

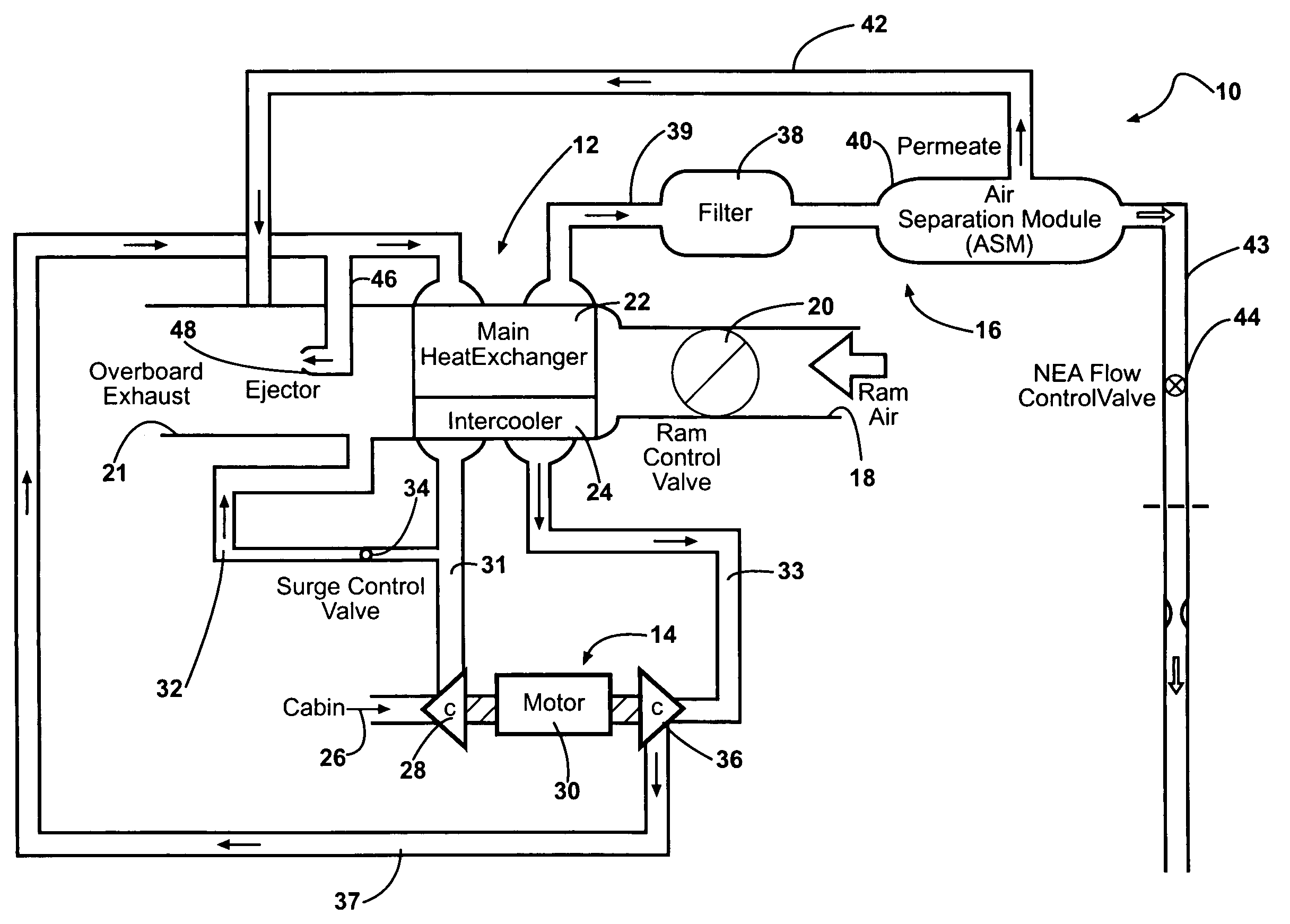

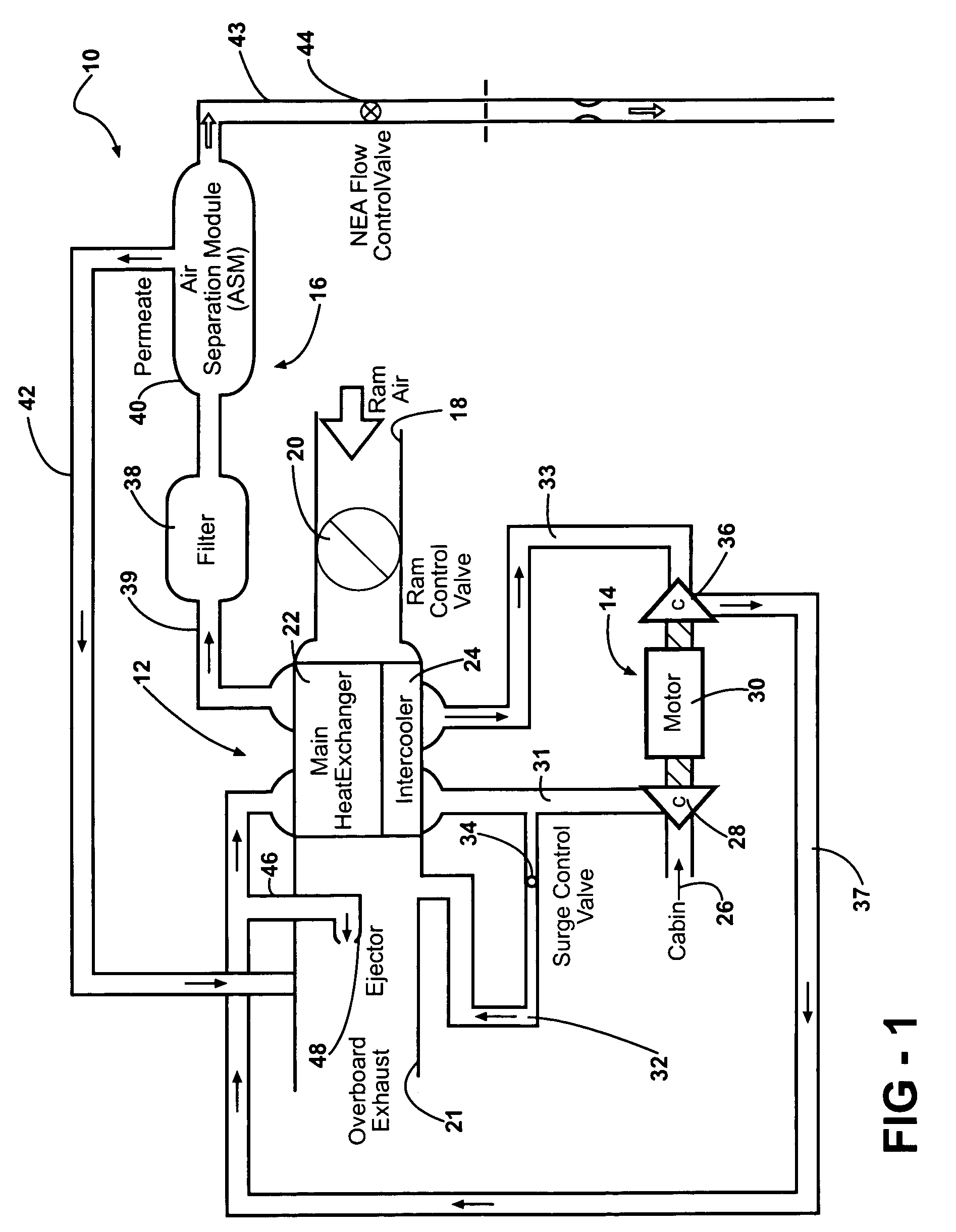

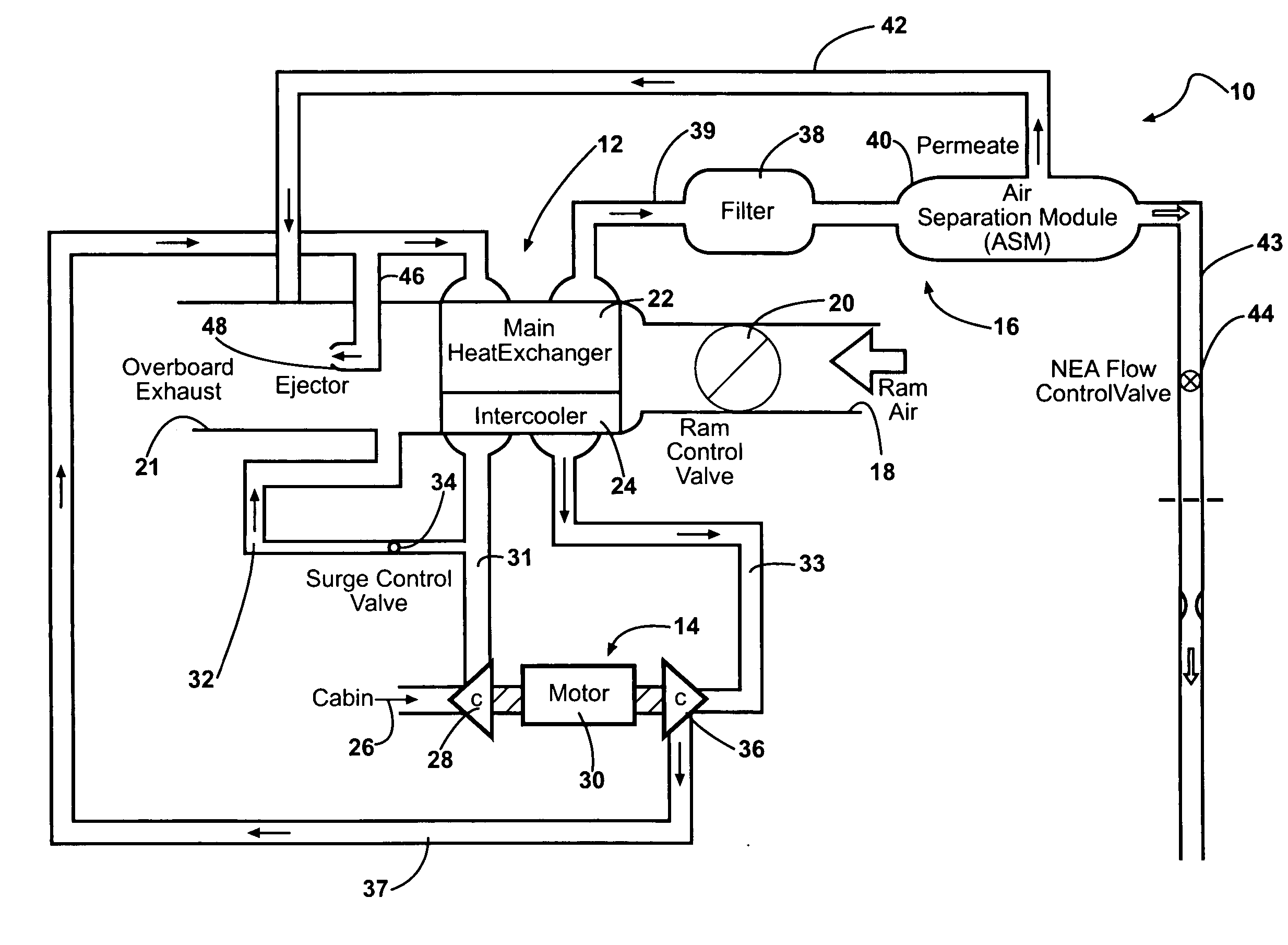

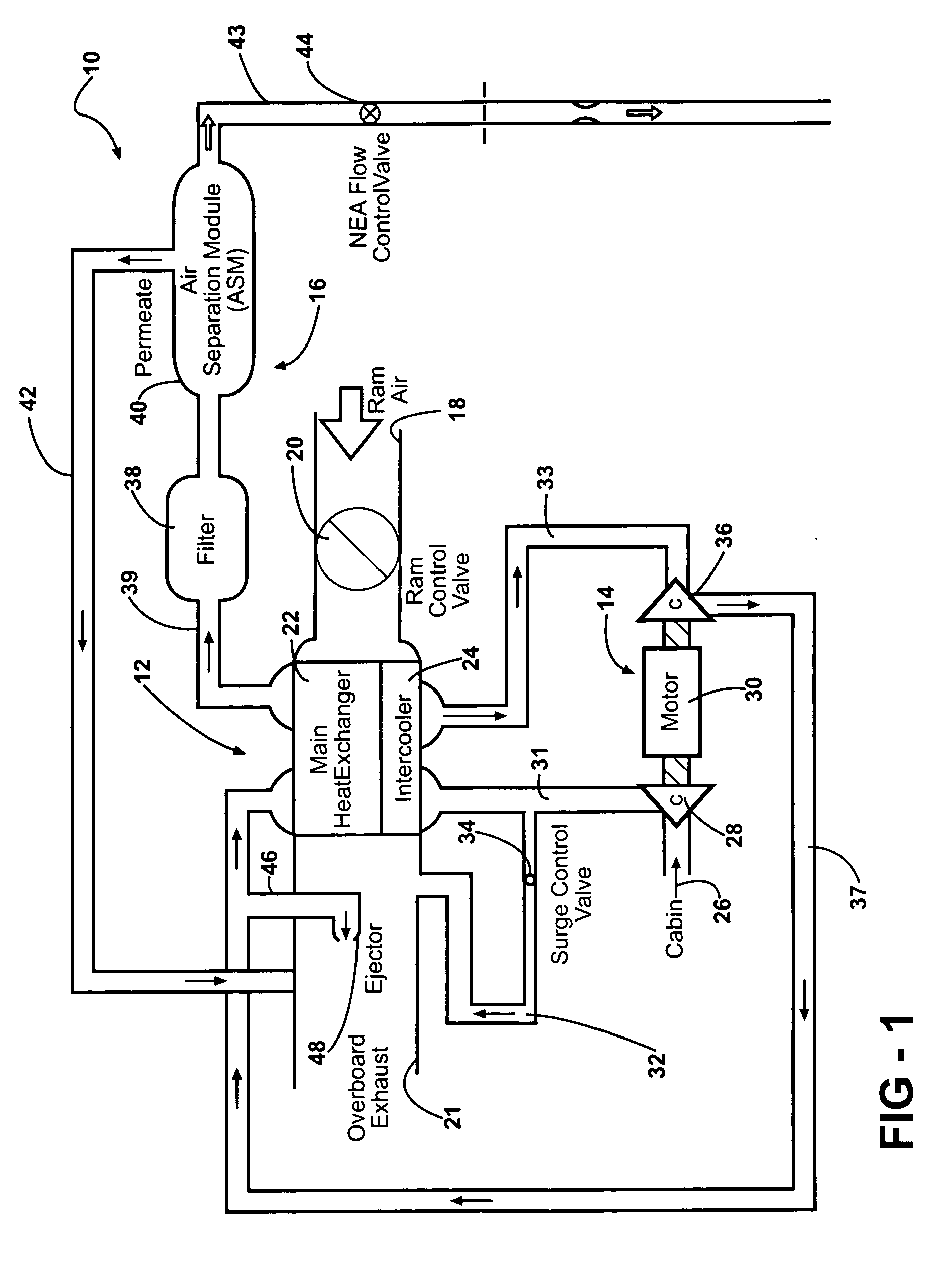

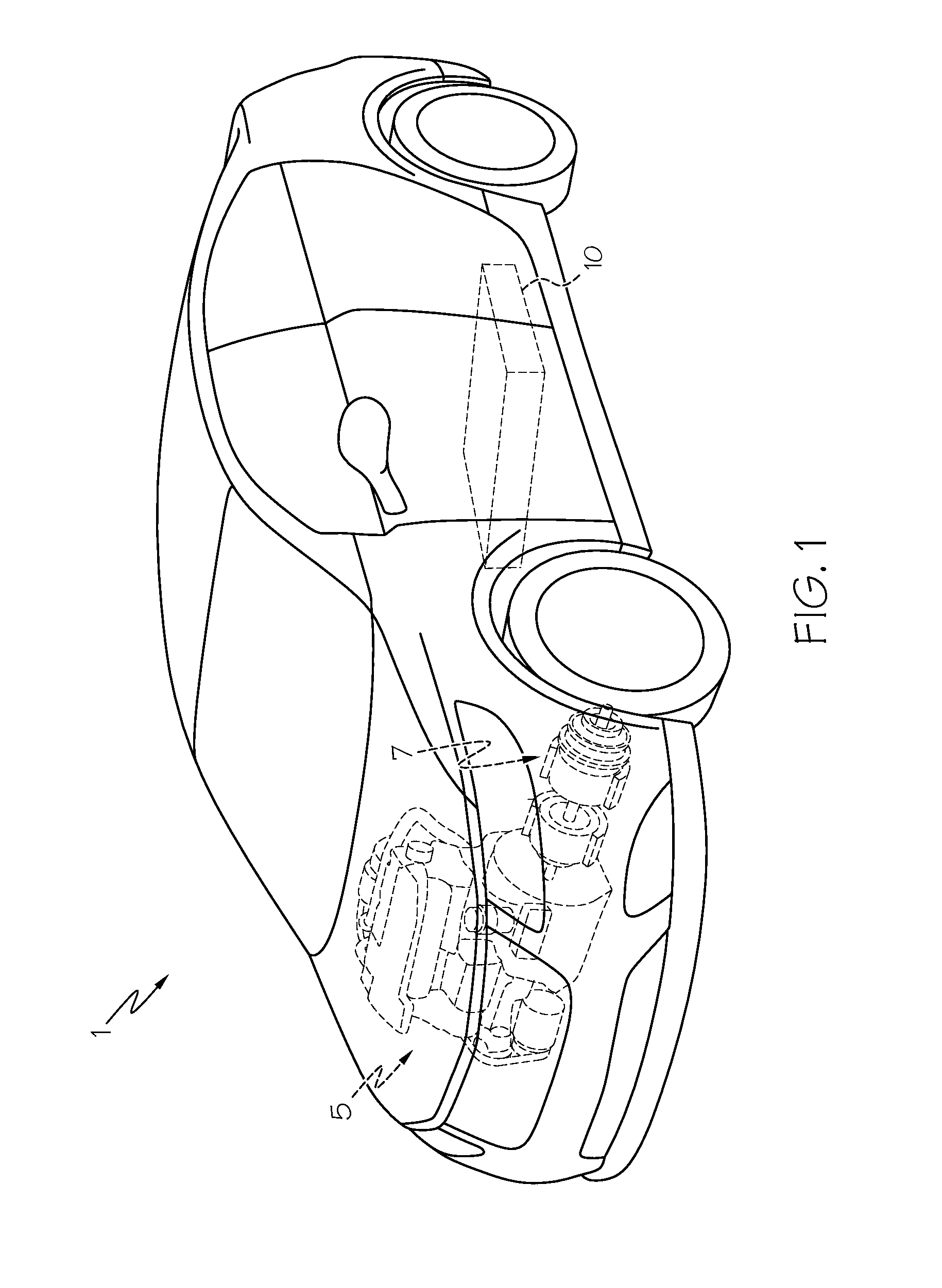

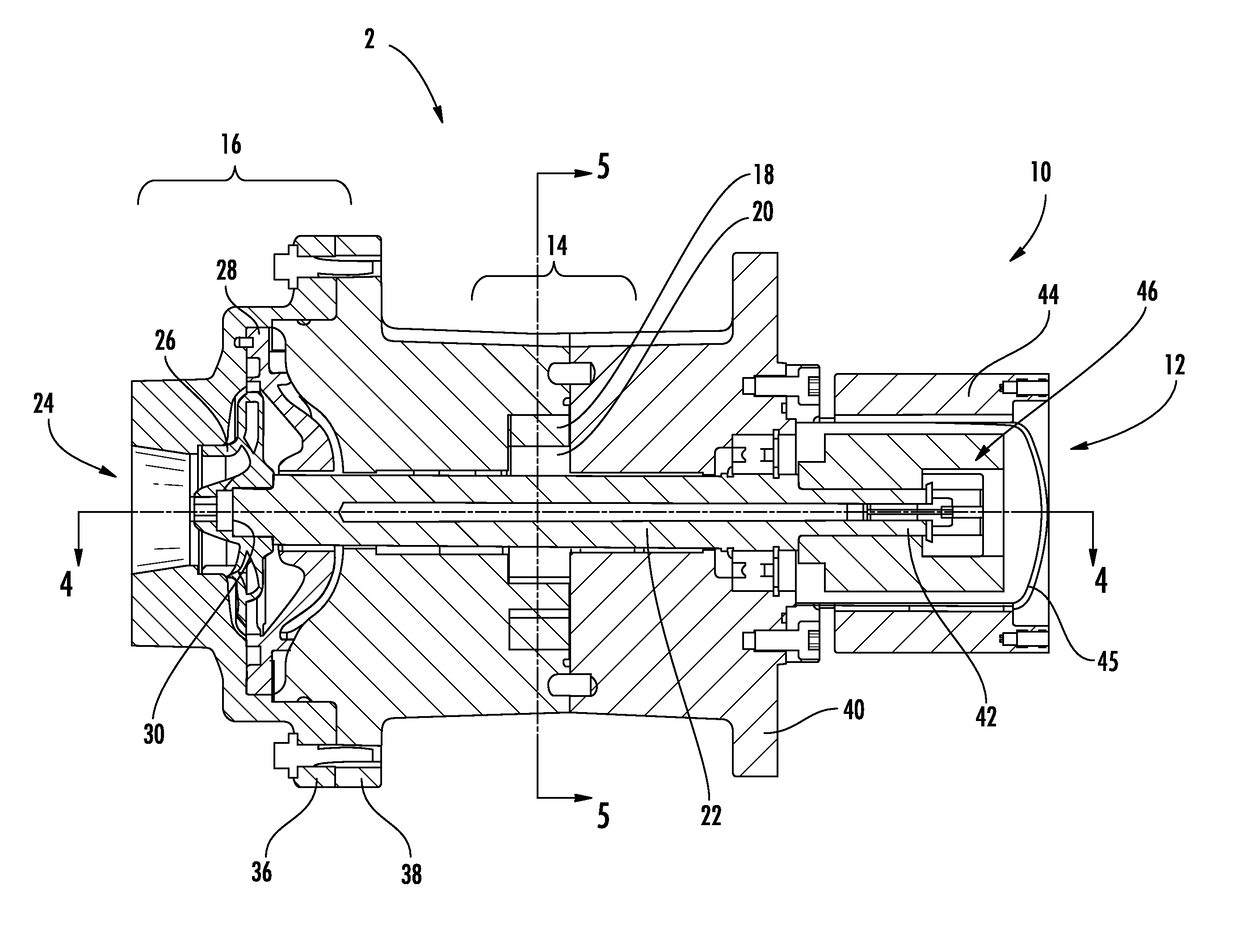

On-board inert gas generation system

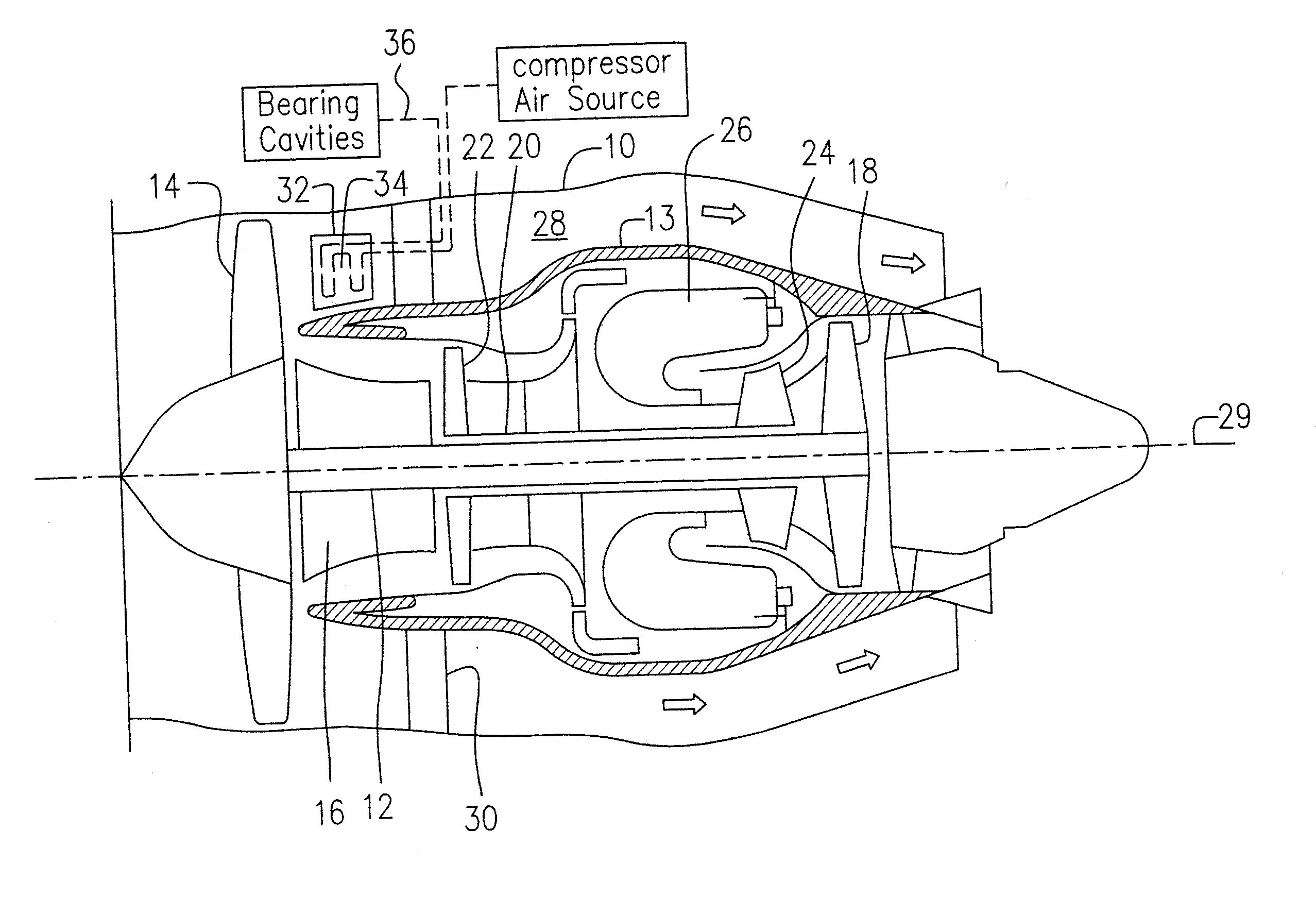

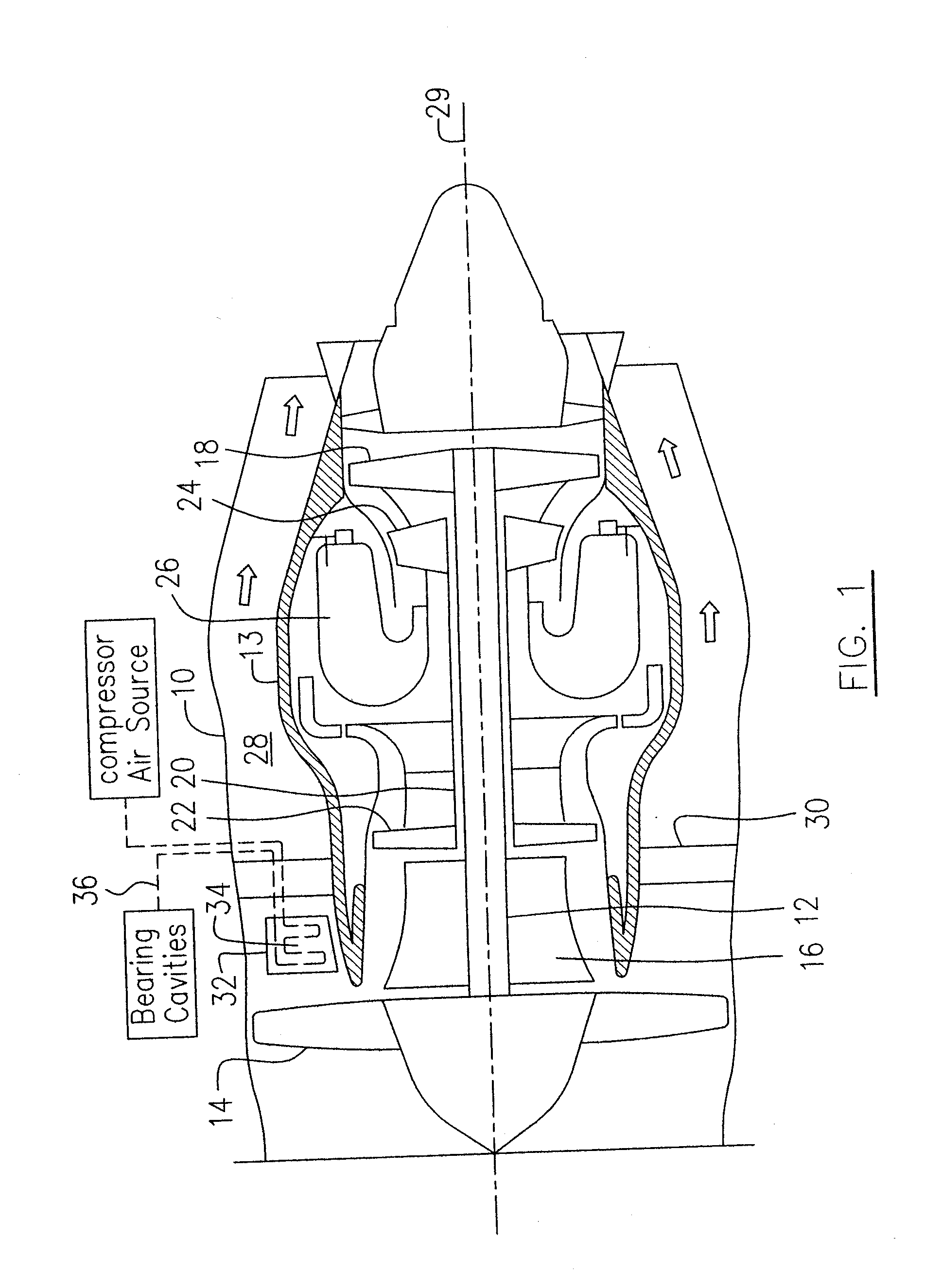

ActiveUS7273507B2Increase inlet pressureIncrease airflowCombination devicesAuxillary pretreatmentOn boardInlet pressure

An on-board inert gas generation system provides first and second compressors in fluid communication with one another. The second compressor includes an inlet and an outlet. The inlet is in fluid communication with the first compressor. The second compressor is the final compressor stage of the system. An air separation module is fluidly connected to the outlet of the second compressor by a passageway. A vent passage is arranged between the outlet and the air separation module for venting fluid between the outlet and air separation module. The vent passage enables the flow from the second compressor to be increased thereby increasing compressor efficiency and increasing the inlet pressure to the air separation module, which enables use of a smaller air separation module.

Owner:HAMILTON SUNDSTRAND CORP

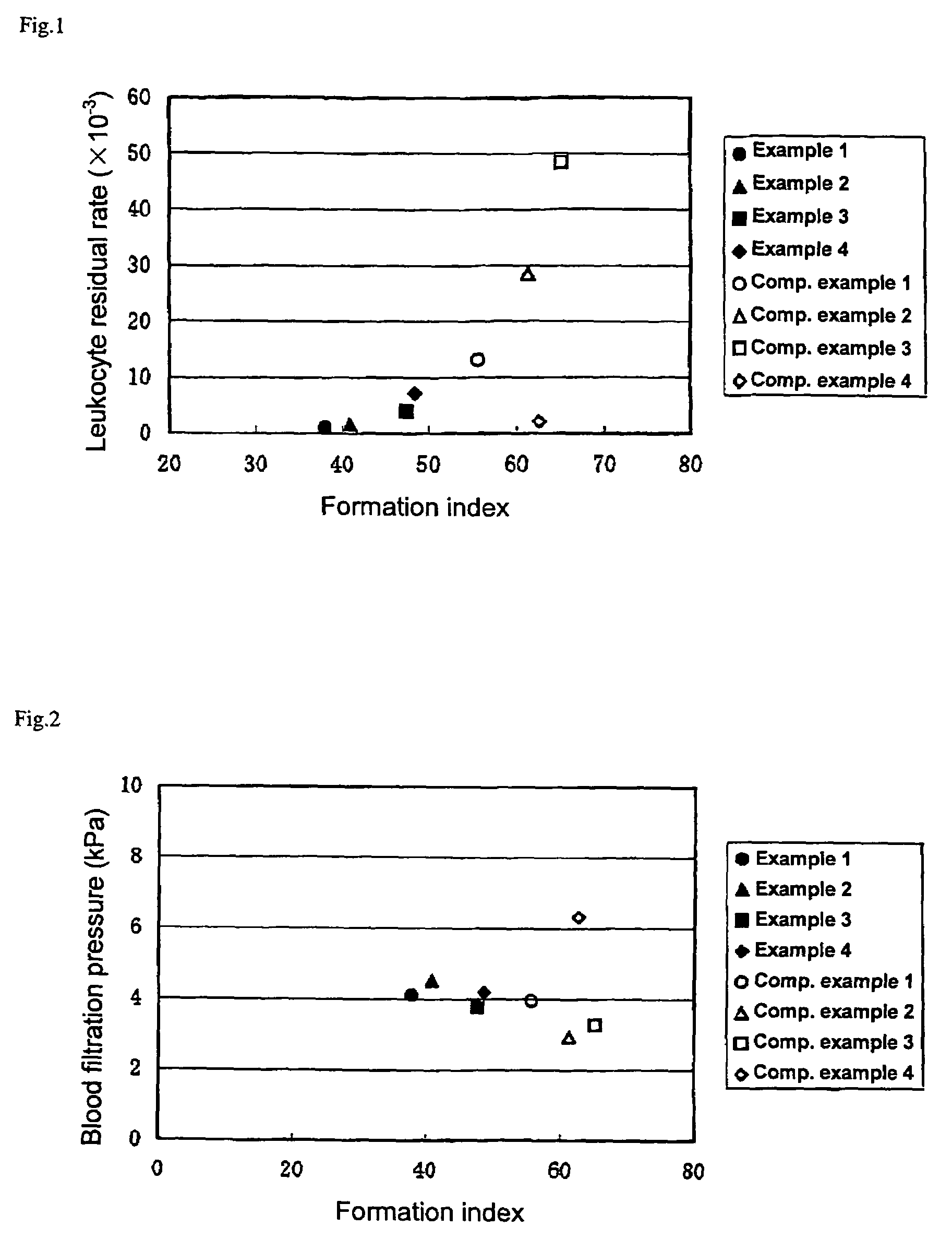

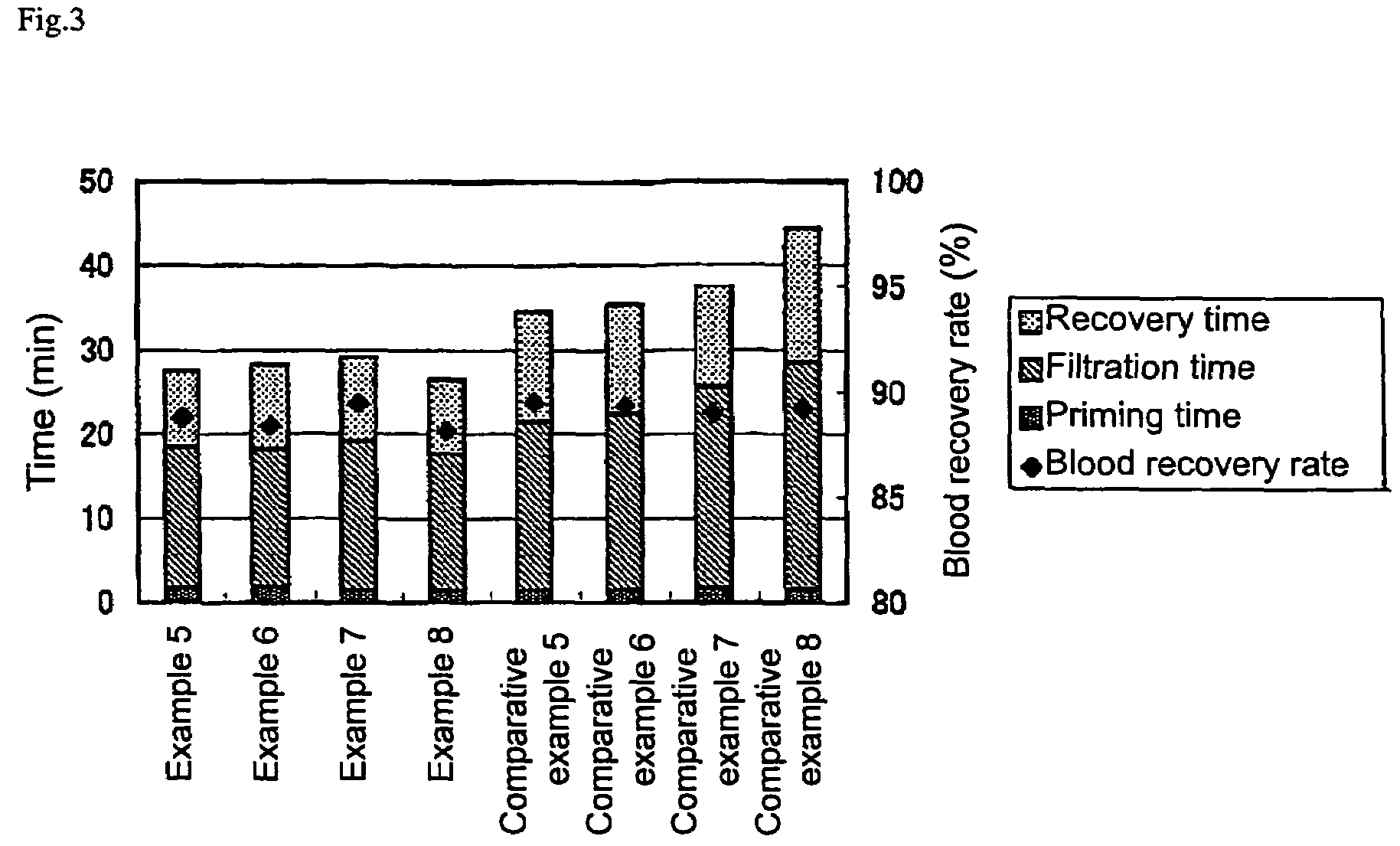

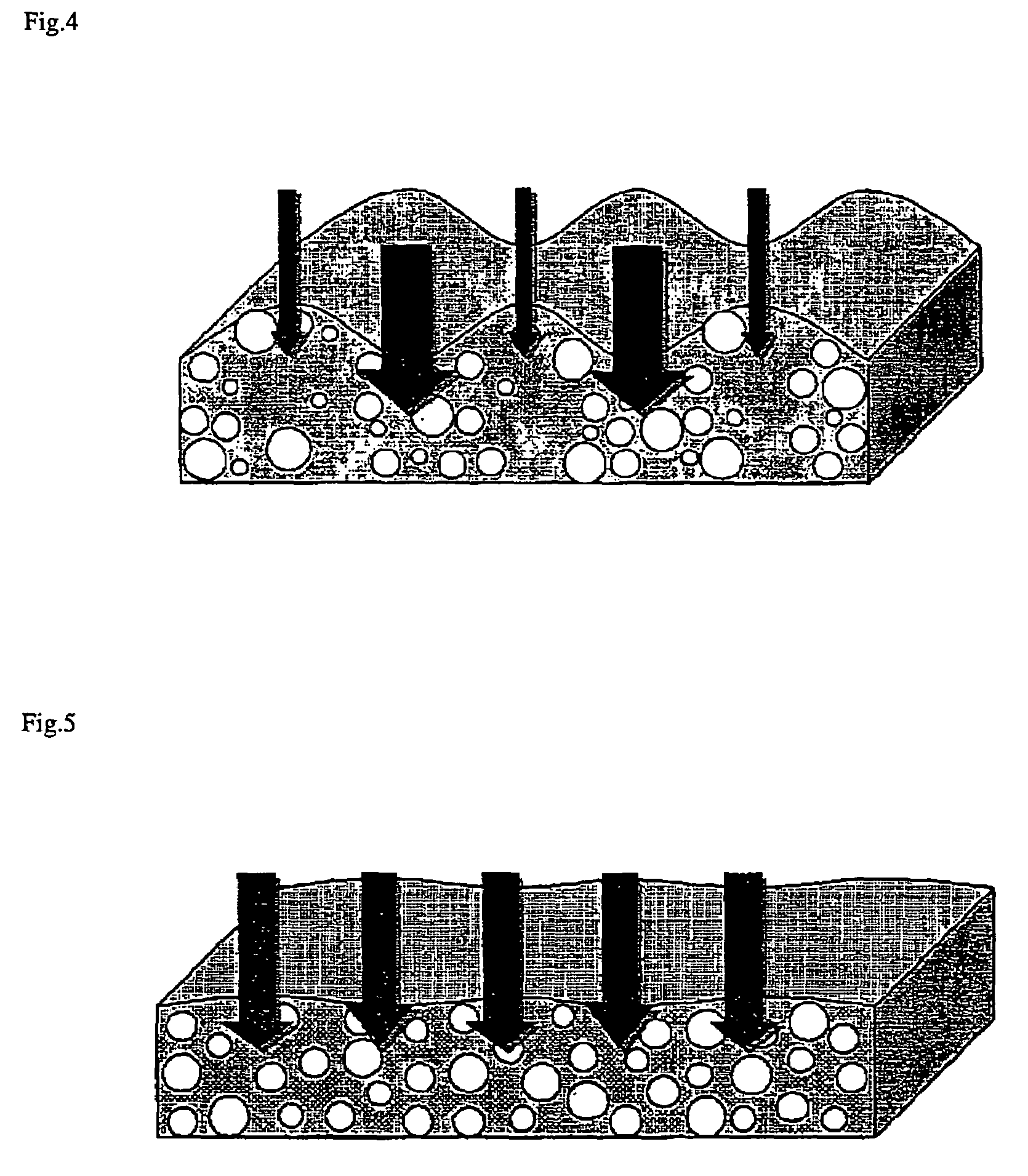

Method for removing leukocytes, leukocyte-removing filter and utilization thereof

ActiveUS7591954B2Good removal effectShorten fermentation timeSemi-permeable membranesOther blood circulation devicesFiltrationWhite blood cell

A method for removing leukocytes, whereby leukocytes can be removed at a higher level of performance in a short filtration time without clogging. A method comprising passing a leukocyte-containing liquid through a filter for removing leukocytes made of a nonwoven fabric having an average fiber diameter of from 0.3 to 3.0 μm, and thus removing the leukocytes from the leukocyte-containing liquid, to give a leukocyte-free liquid, characterized by using a nonwoven fabric having a formation index (y) of 50 or less corresponding to a thickness of 0.3 mm; use of a leukocyte removal filter therefore; and the leukocyte removal filter.

Owner:ASAHI KASEI MEDICAL CO LTD

On-board inert gas generation system

ActiveUS20060117956A1Increase inlet pressureIncrease efficiencyCombination devicesLiquid degasificationAir separationEngineering

An on-board inert gas generation system provides first and second compressors in fluid communication with one another. The second compressor includes an inlet and an outlet. The inlet is in fluid communication with the first compressor. The second compressor is the final compressor stage of the system. An air separation module is fluidly connected to the outlet of the second compressor by a passageway. A vent passage is arranged between the outlet and the air separation module for venting fluid between the outlet and air separation module. The vent passage enables the flow from the second compressor to be increased thereby increasing compressor efficiency and increasing the inlet pressure to the air separation module, which enables use of a smaller air separation module.

Owner:HAMILTON SUNDSTRAND CORP

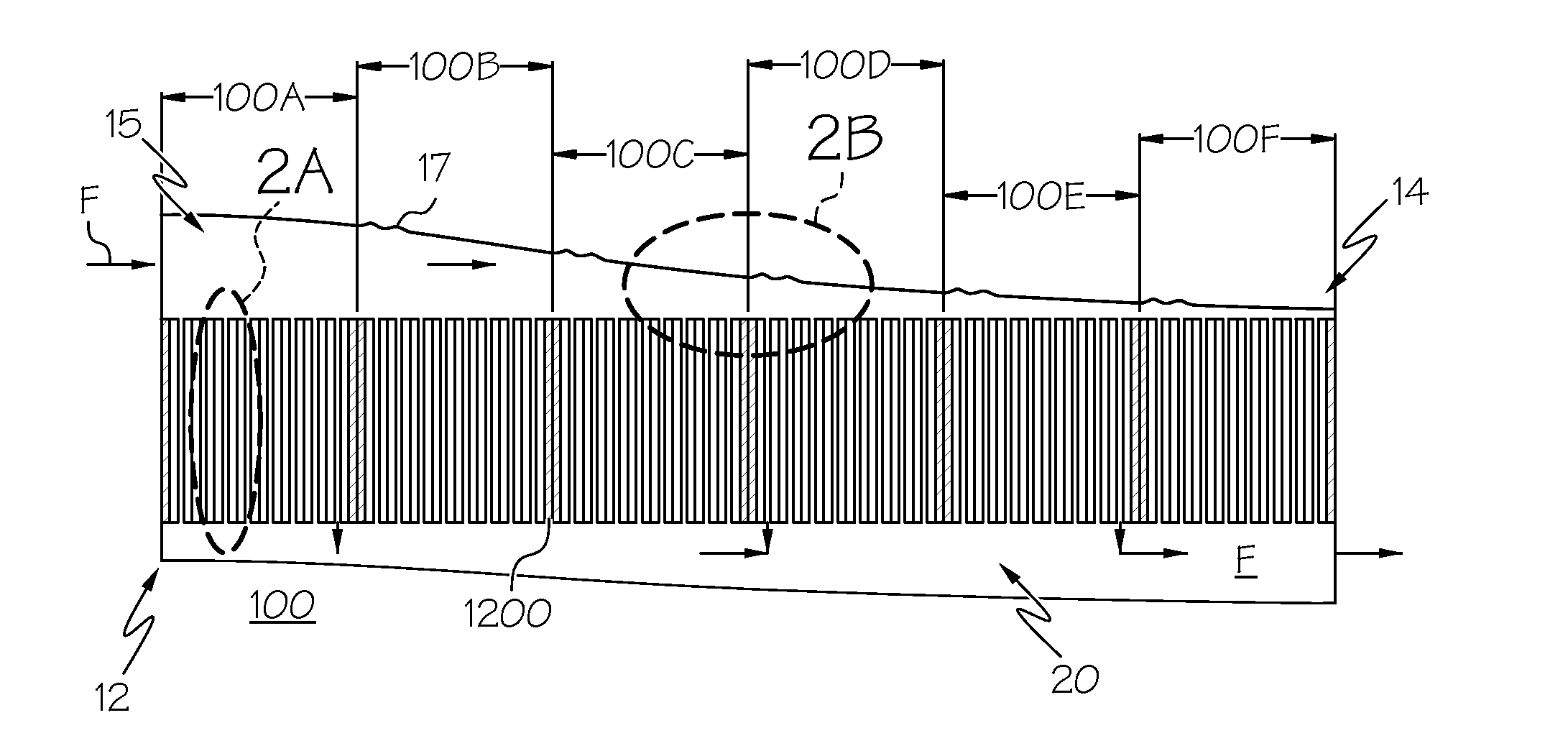

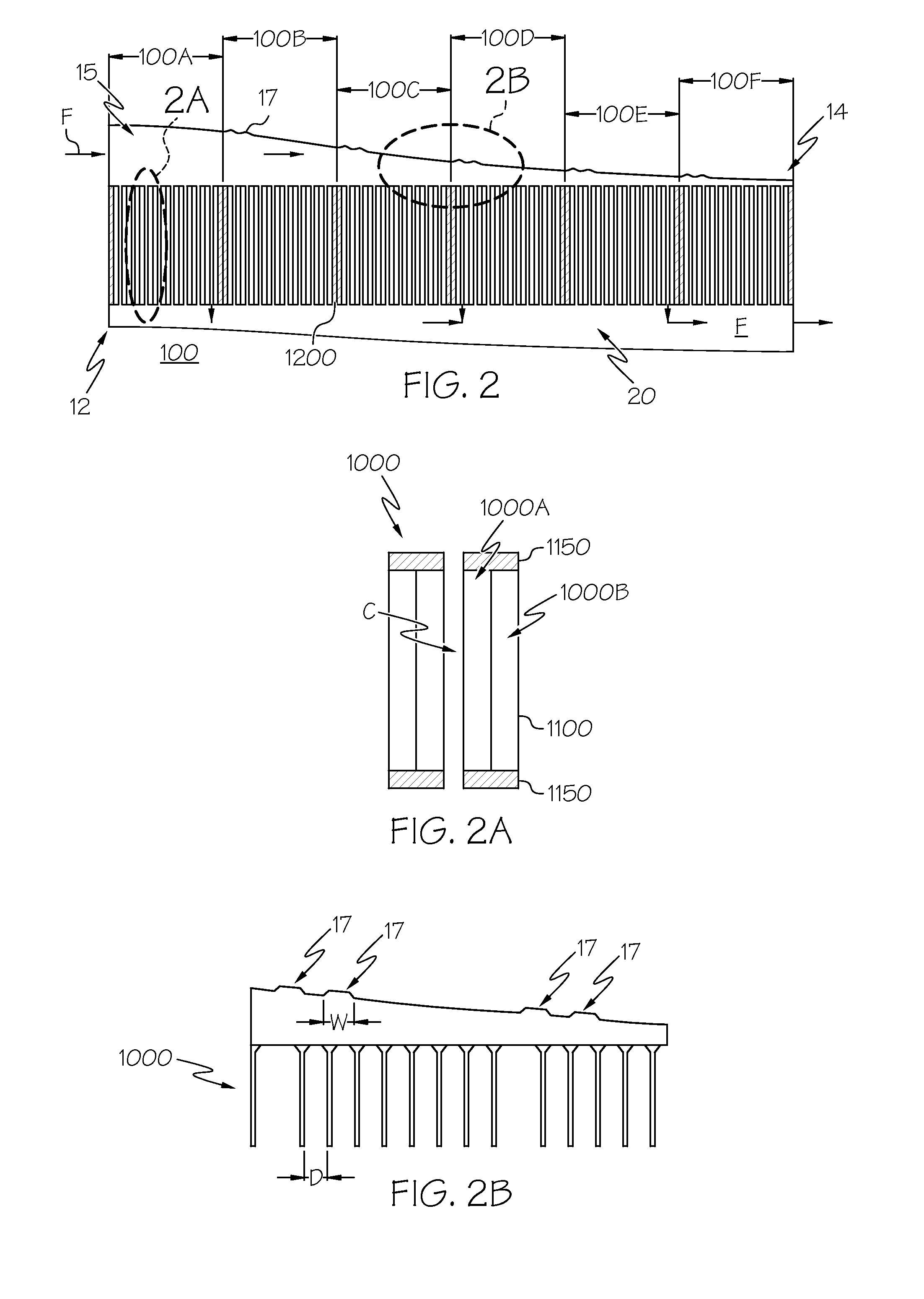

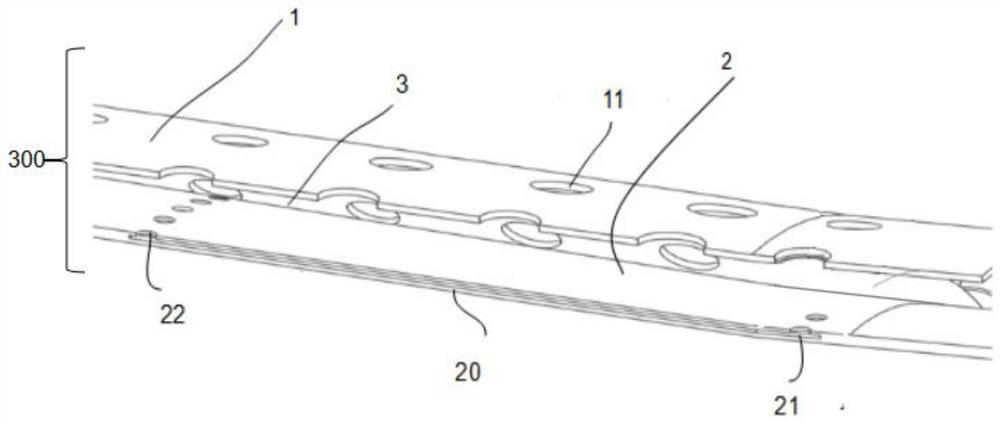

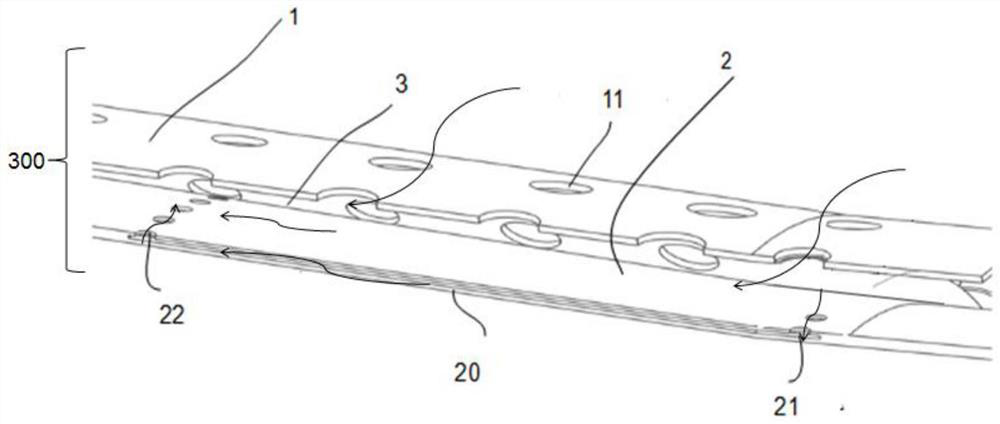

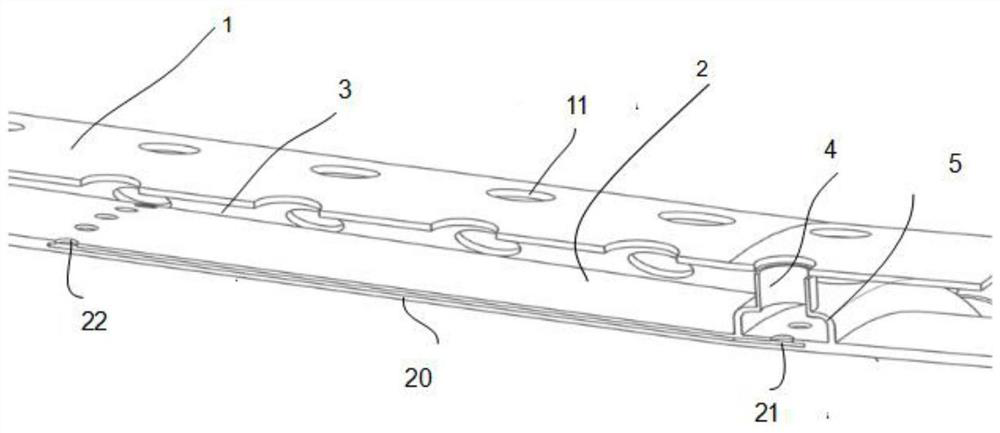

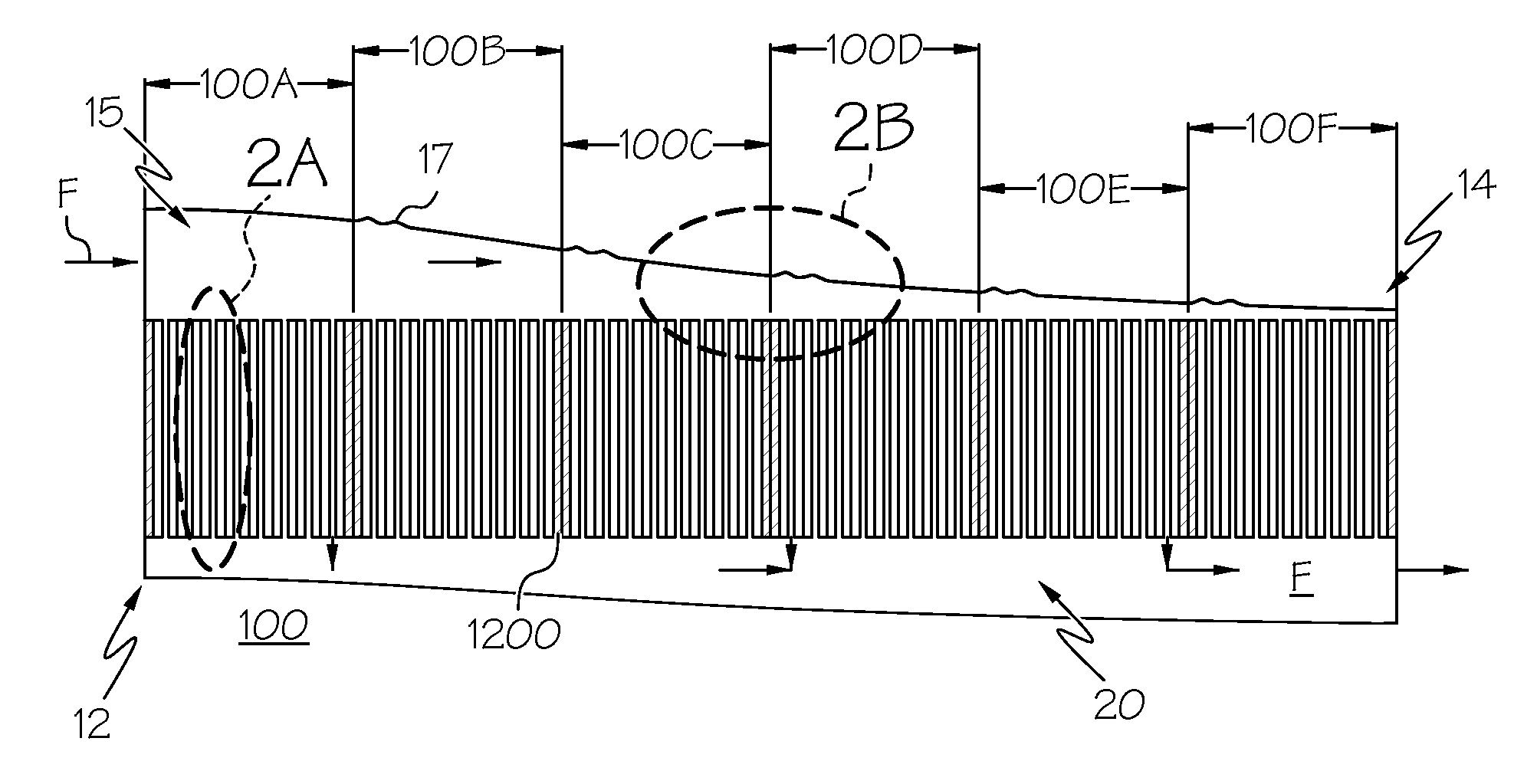

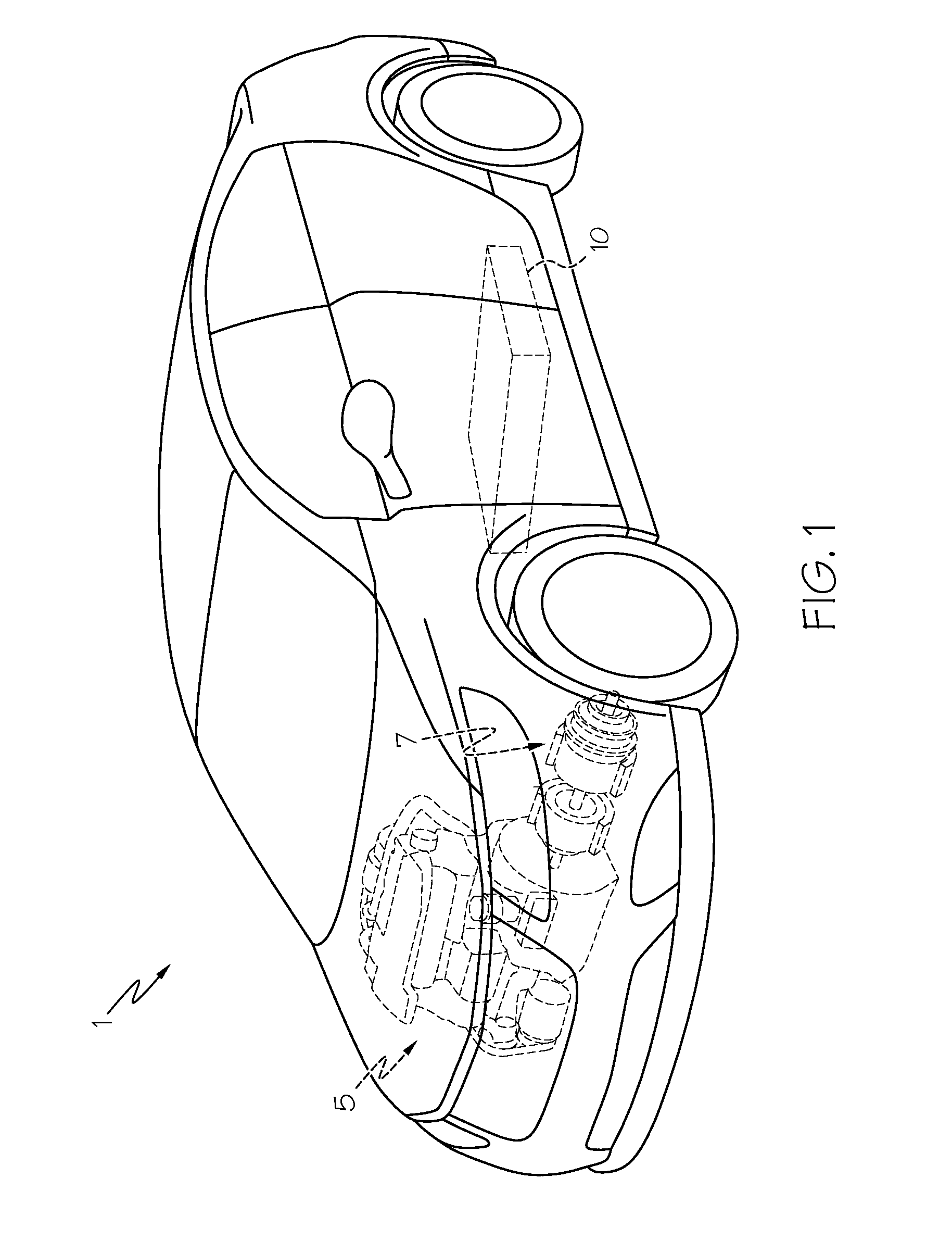

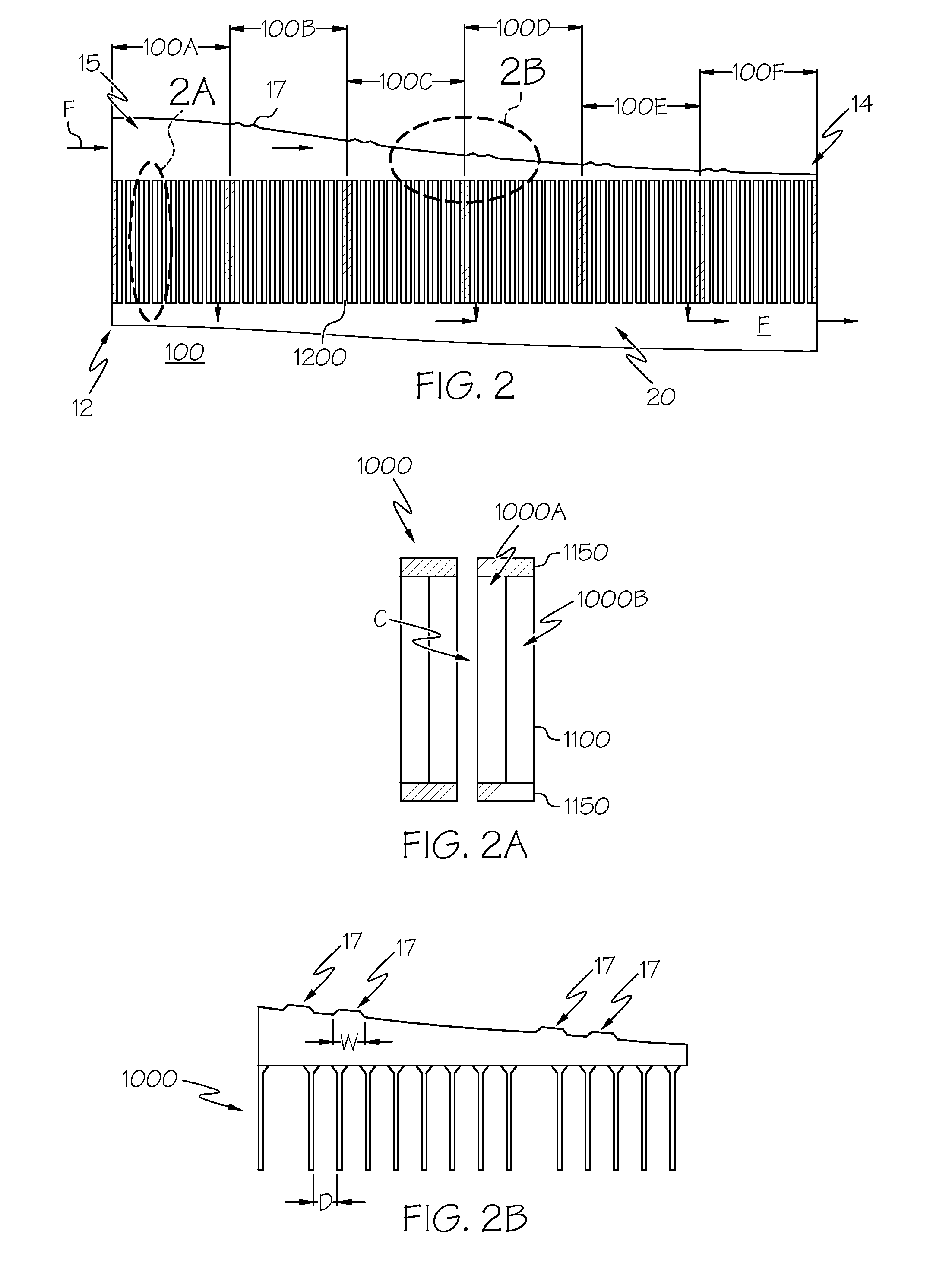

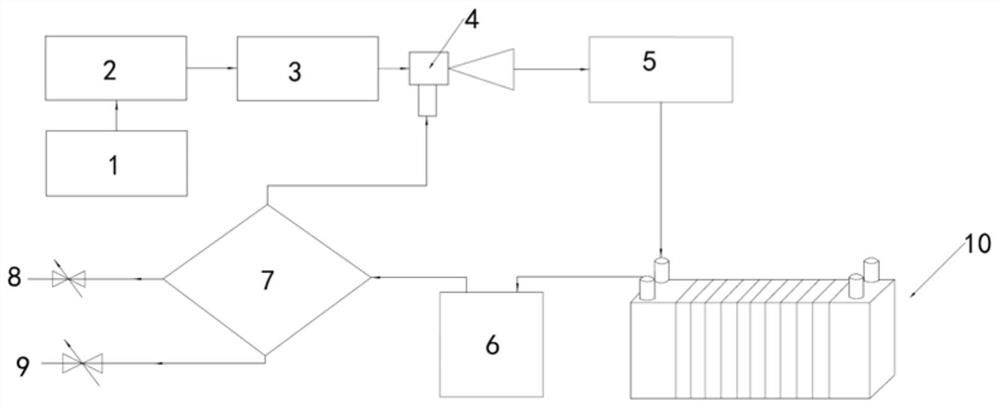

Flow uniformity of air-cooled battery packs

ActiveUS20150210184A1Improve pressure effectDistribution moreHybrid vehiclesElectric devicesCooling channelEngineering

A battery pack and method of cooling a battery pack. In one form, the battery pack is an assembly made up of numerous battery cells arranged within numerous modules. Cooling channels that receive cooling fluid from a ducted supply are placed between adjacent cells or cooling plates within each of the modules. The ducted supply includes beads or related area-increasing undulations that are designed to improve both the stiffness of the ducting as well as the uniformity of the flow rates of individual cooling channels within each of the modules. In one form, the pressure-enhancing beads are placed in an inlet portion of the ducting that is adjacent a forward portion of one or more of the sequentially-encountered modules in order to promote a more equitable distribution of the cooling fluid between the various cooling channels within each of the modules.

Owner:GM GLOBAL TECH OPERATIONS LLC

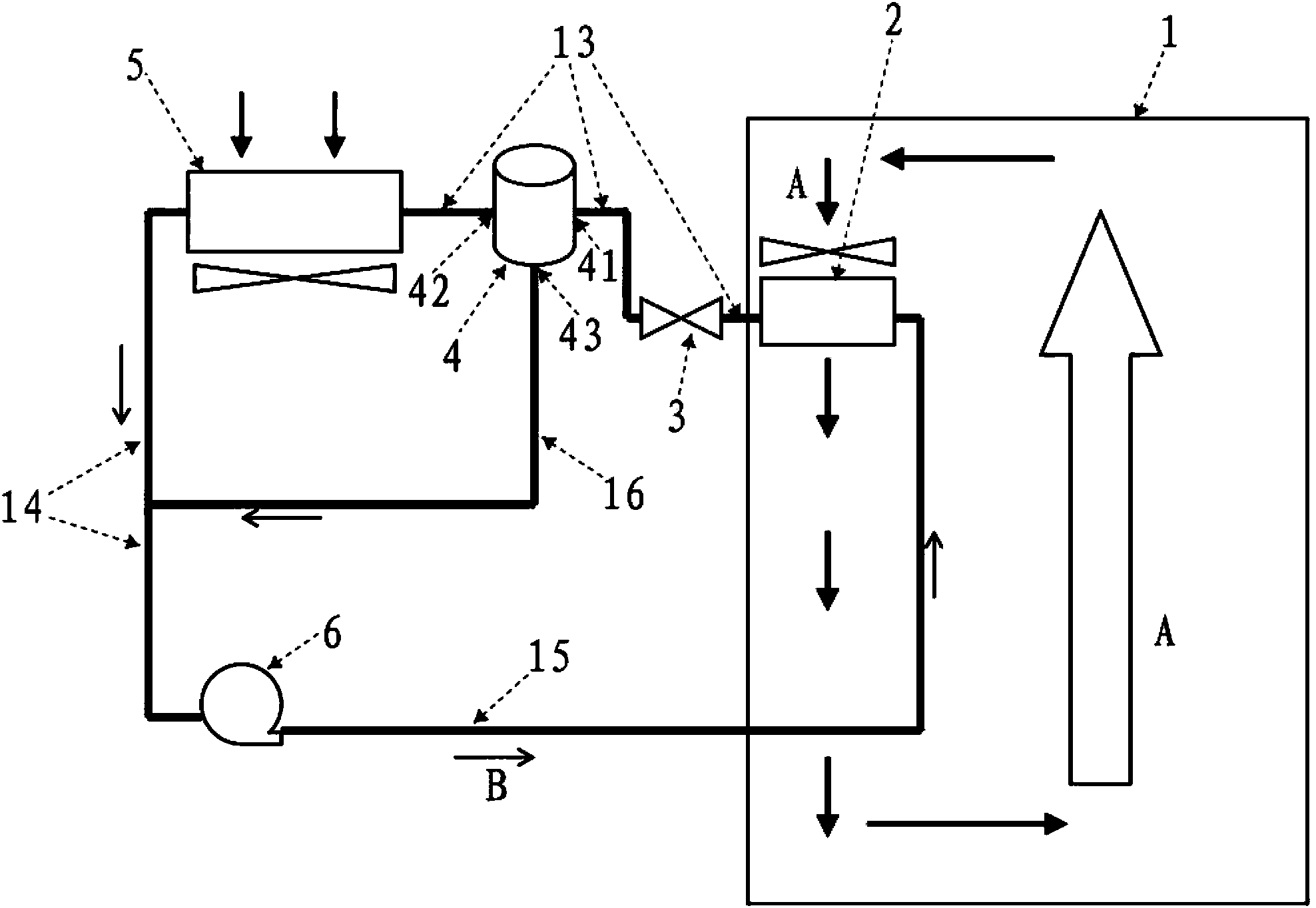

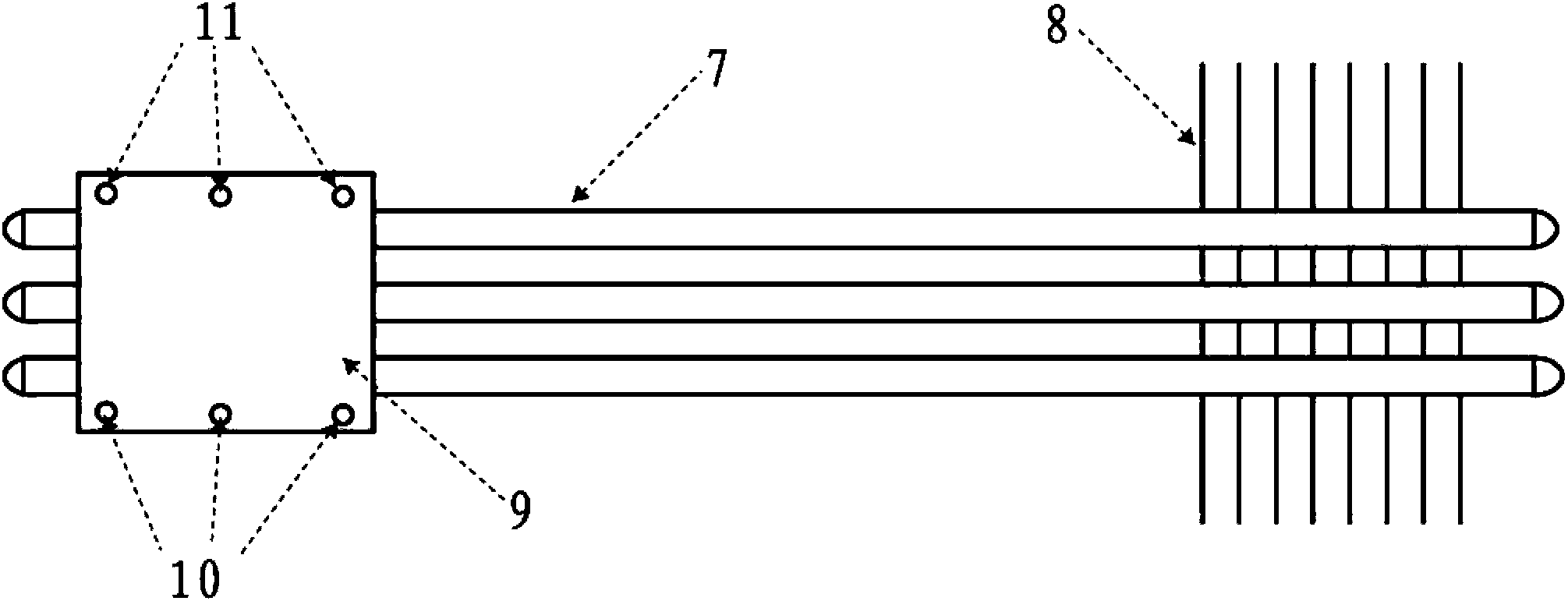

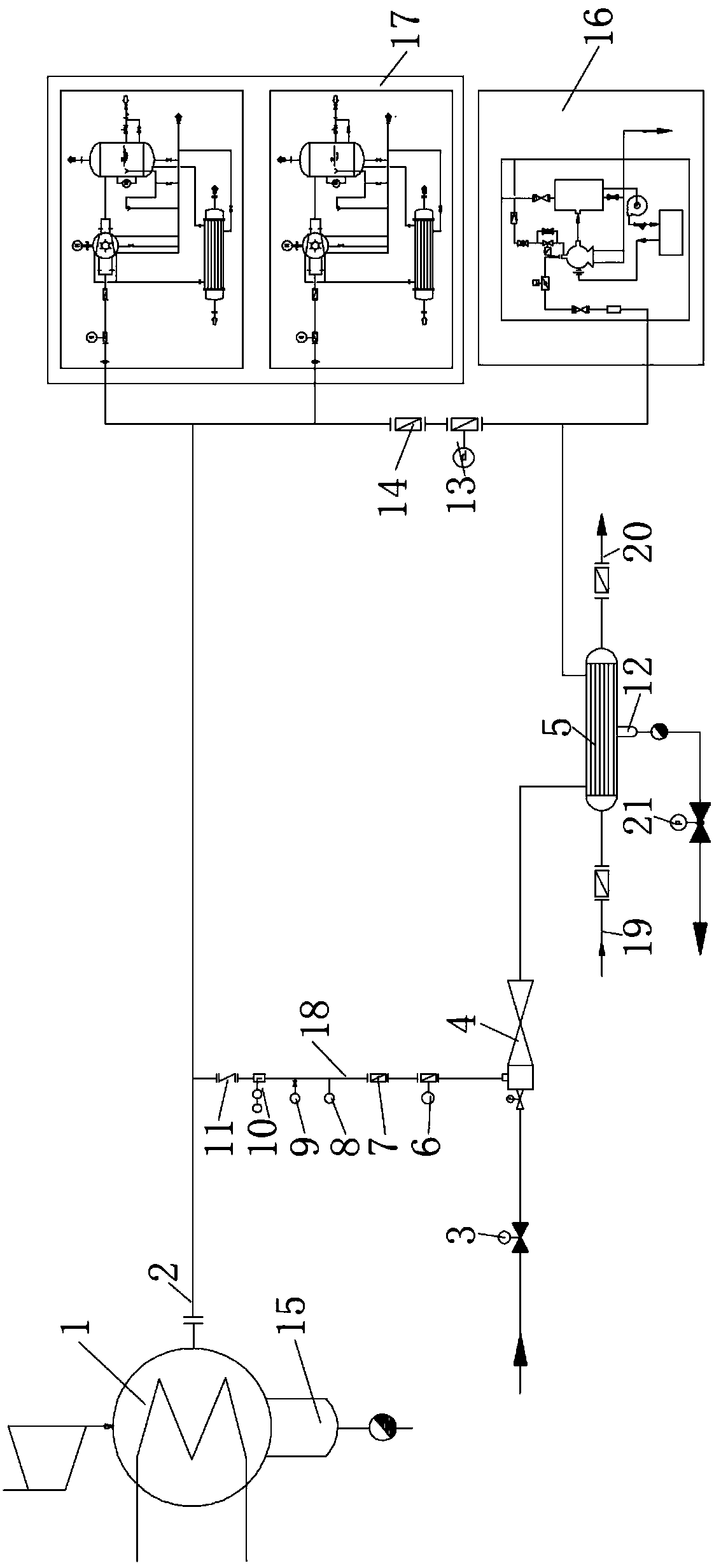

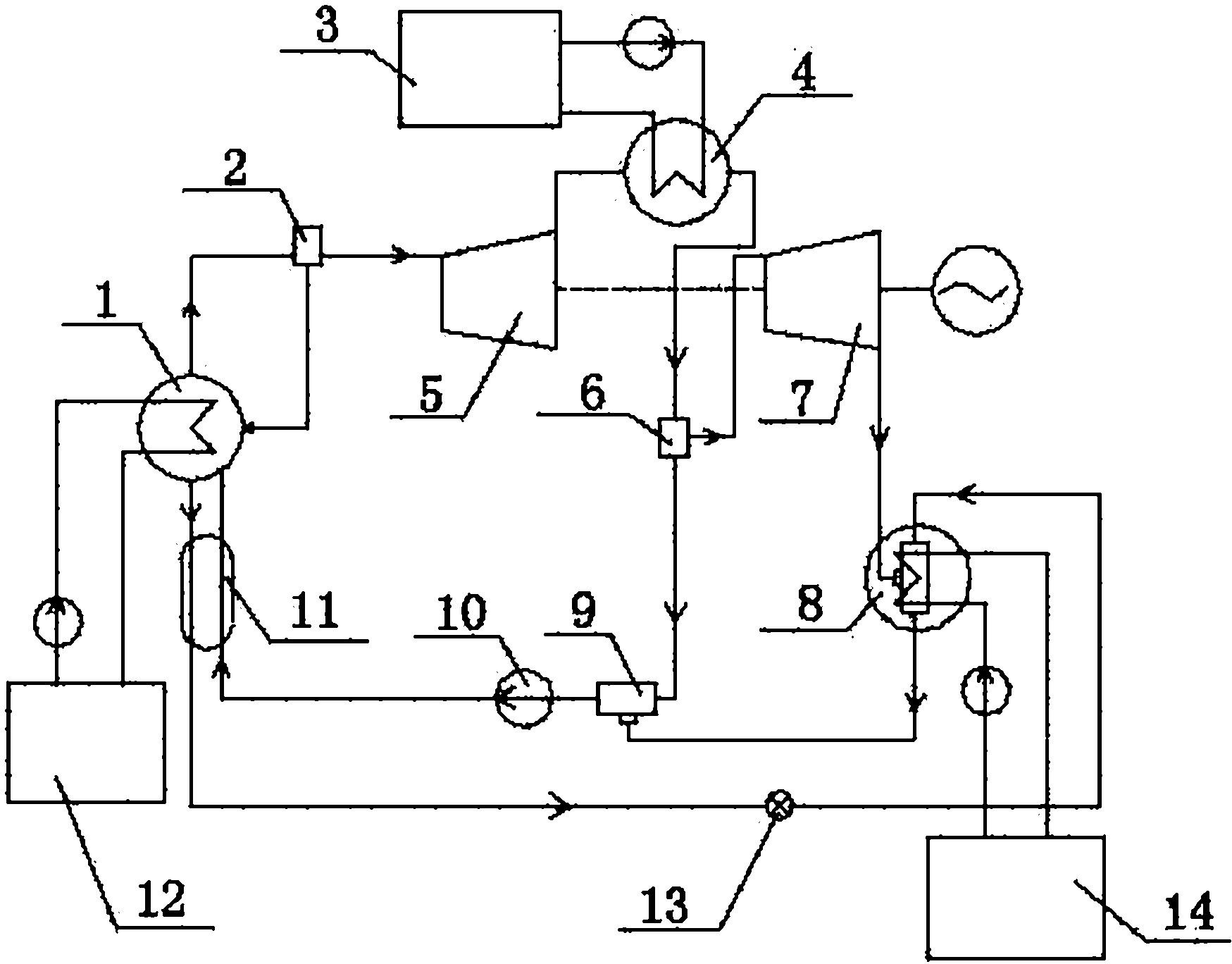

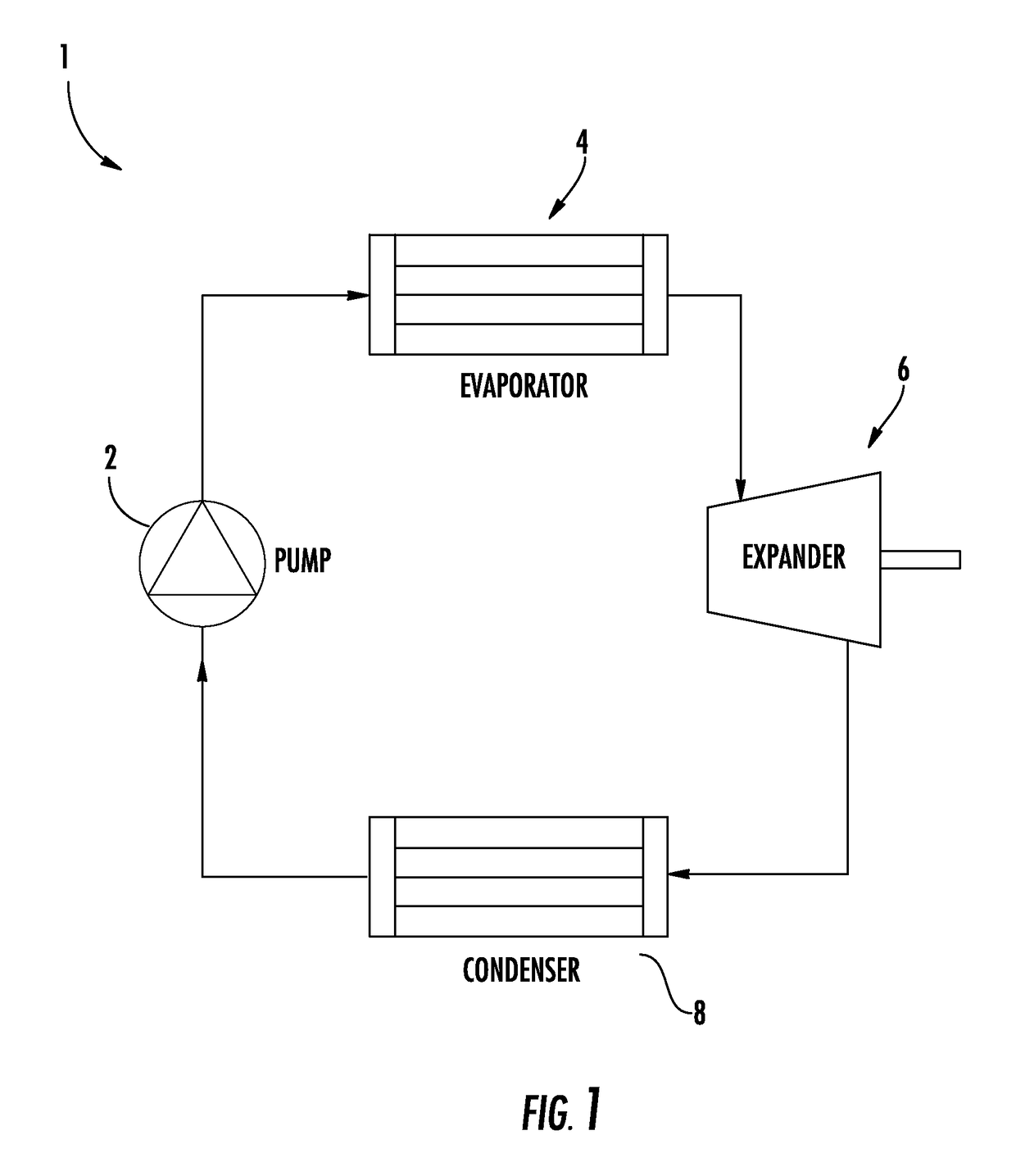

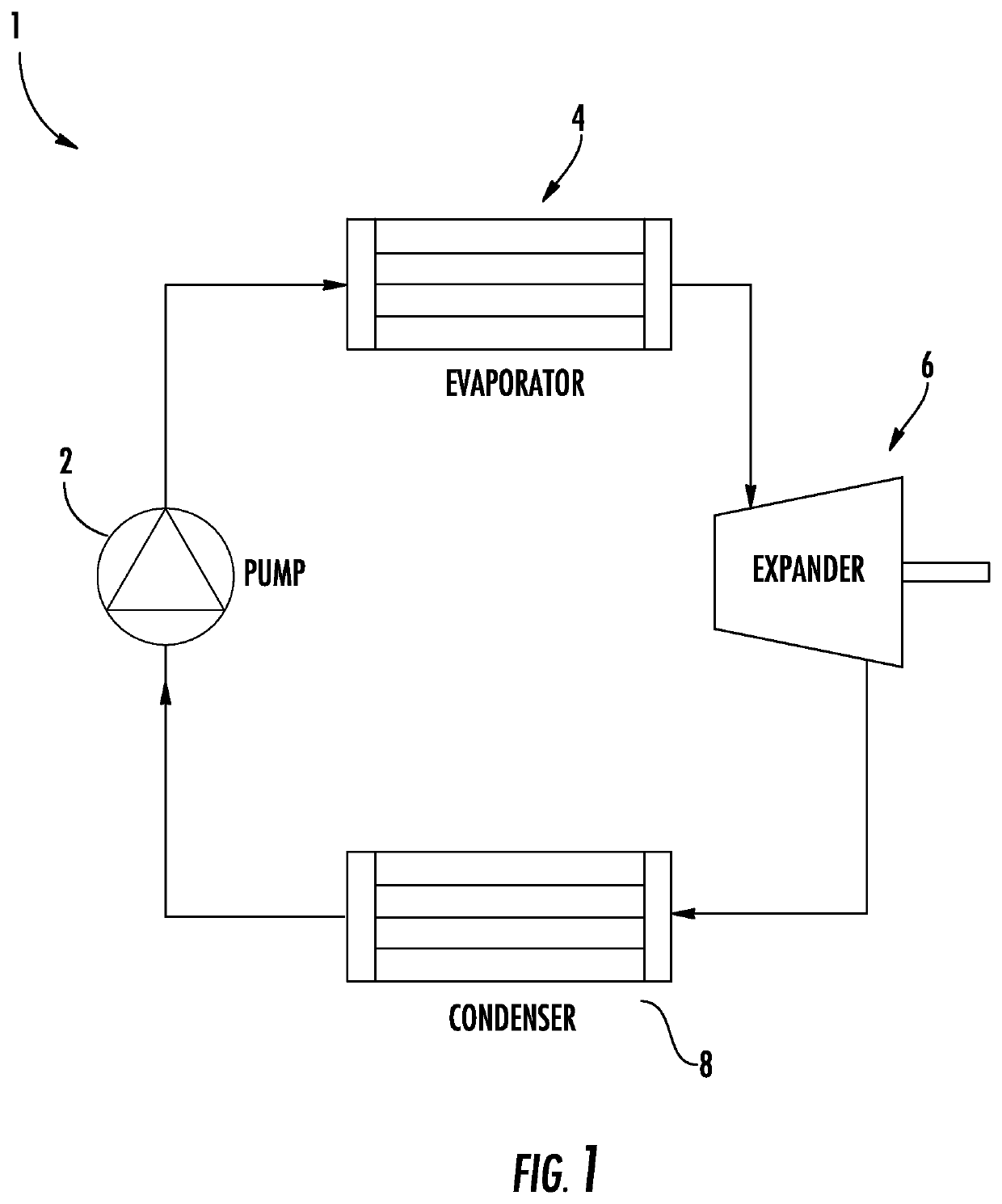

Liquid phase-change heat transfer type pumping cooling system with booster pump

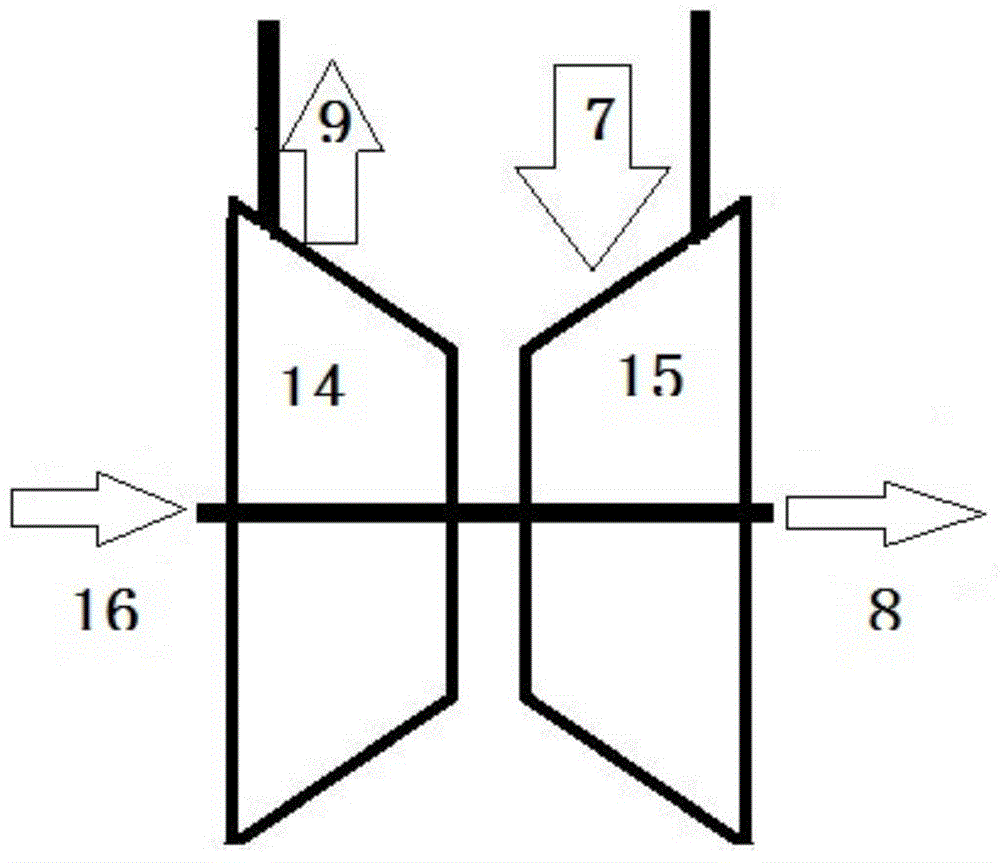

InactiveCN103424018AImprove cooling effectIncrease inlet pressureIndirect heat exchangersRefrigeration componentsEngineeringHeat pipe

The invention discloses a liquid phase-change heat transfer type pumping cooling system which comprises an evaporator system (2), a liquid feeding pump (6), a condenser (5), a pipeline system and a booster pump (3). The evaporator system (2) is arranged in electrical equipment (1); the liquid feeding pump (6) is used for feeding liquid to the evaporator system (2); cooling media can evaporate in the evaporator system (2) to generate steam; the condenser (5) is used for condensing the steam exhausted from the evaporator system so as to generate single-phase liquid; the booster pump (3) is arranged in the pipeline system at an outlet of the evaporator system and is used for reducing the evaporating pressure and increasing the condensing pressure simultaneously. The evaporator system (2) can comprise one evaporator or a plurality of evaporators, each evaporator comprises heat pipes (7) and a heat exchanger (9), the evaporator system is used for dissipating heat by the evaporators to cool the electrical equipment, and the heat is generated in the electrical equipment. The liquid phase-change heat transfer type pumping cooling system has the advantage that the electrical equipment with distributed heat sources can be cooled by the cooling system efficiently.

Owner:SCHNEIDER ELECTRIC IND SAS

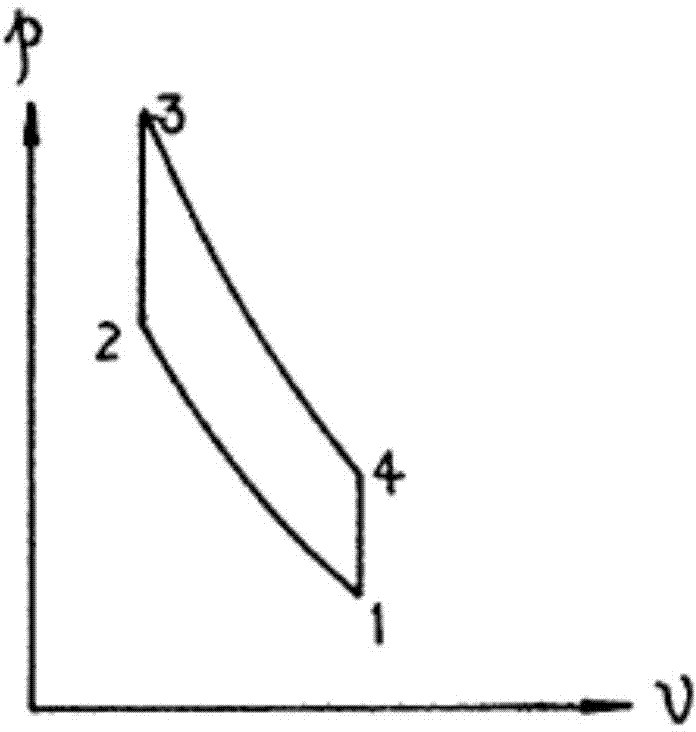

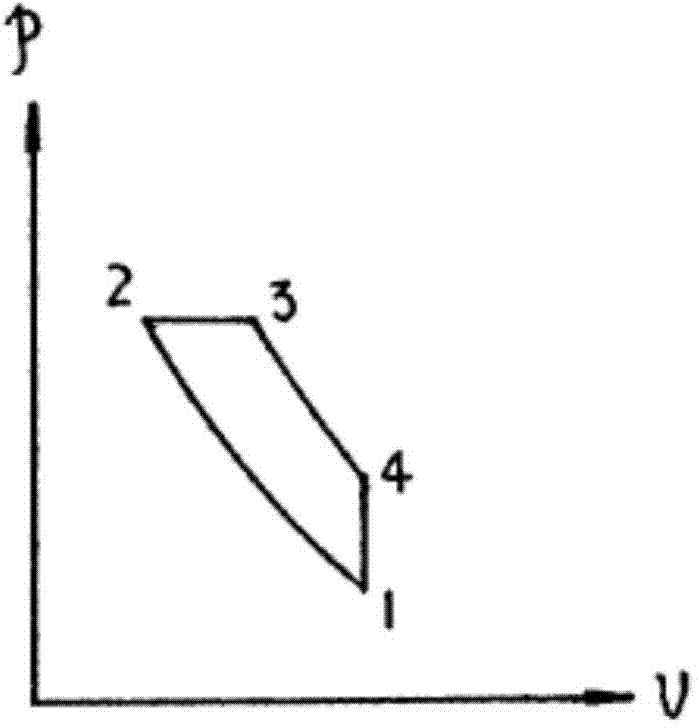

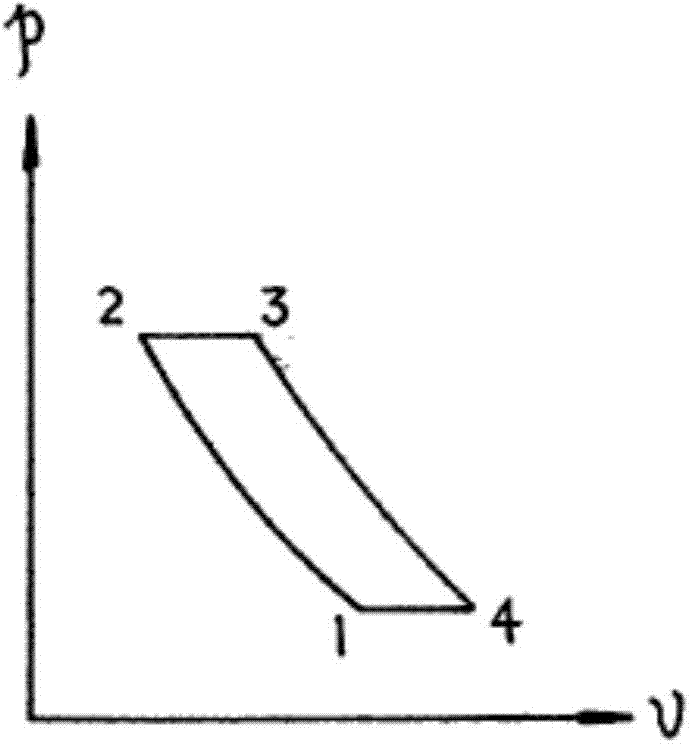

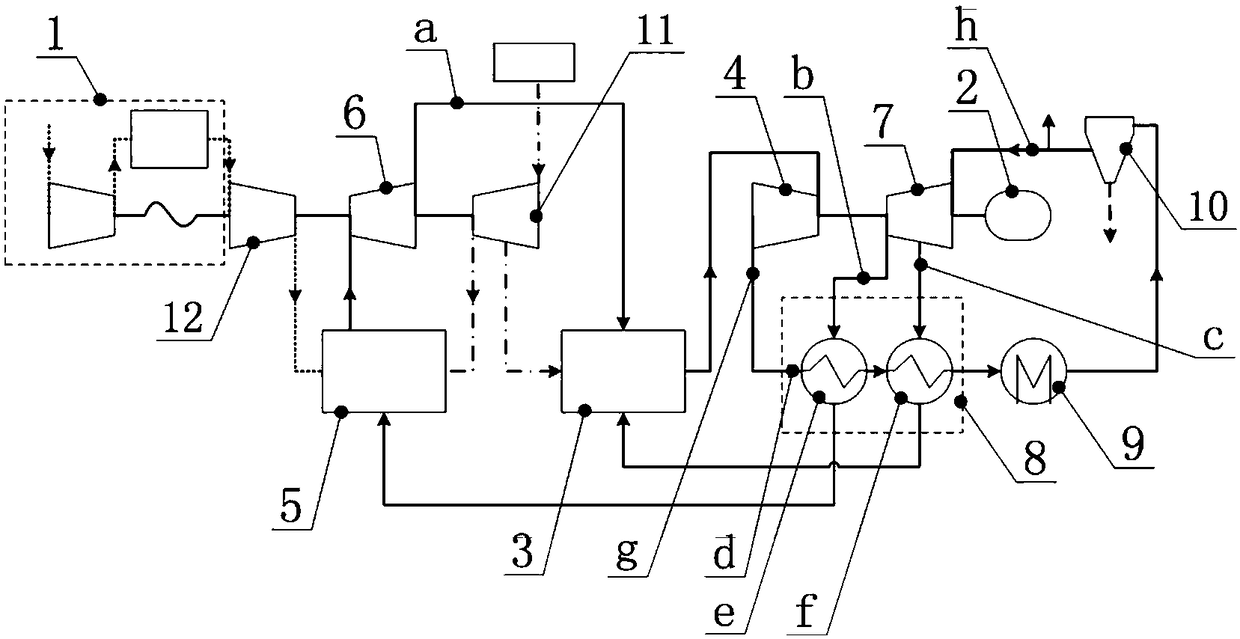

Semi-closed type timing constant-volume thermodynamic circulation method and system of prime motor

ActiveCN103883399AReduced Compression Power ConsumptionReduce fresh working fluid temperatureInternal combustion piston enginesGas turbine plantsThermal dilatationPrime mover

The invention provides a semi-closed type timing constant-volume thermodynamic circulation method and a semi-closed type timing constant-volume thermodynamic circulation system of a prime motor. The thermodynamic circulation method comprises six processes, namely multi-compression-stage intercooling, countercurrent heat exchanging, timing constant-volume burning, adiabatic expansion, aftercooling, and carbon dioxide and water removal. Heat-power conversion is achieved in the thermodynamic circulation. In the process of multi-compression-stage intercooling, compression power consumption is lowered; in the process of countercurrent heat exchanging, the enthalpy of an expanded working medium is recovered to participate in thermodynamic circulation; the process of timing constant-volume burning effectively inhibits the generation of harmful pollutants such as HC, CO, PM and NOx; in the process of adiabatic expansion, complete expansion for working is achieved; in the process of aftercooling, the working medium is further cooled to the environment temperature and the expansion ratio in the process of adiabatic expansion is enhanced; in the process of carbon dioxide and water removal, the carbon dioxide and the water generated in the process of timing constant-volume burning are removed; the remaining work mediums participate in the next thermodynamic circulation. By the method and the system, the direction is defined for designing a high-efficiency low-pollutant-emission and high-performance prime motor in the future.

Owner:GREEN ENERGY HIGH TECH GRP +5

Air cooler system for gas turbine engines

ActiveUS20130291554A1Increase inlet pressureEngine manufactureEngine fuctionsEngineeringGas turbines

A buffer air cooler system for gas turbine engines disposed in a bypass duct of the engine, includes a housing for containing the buffer air cooler therein and an inlet portion attached to the housing. In one embodiment, the inlet portion has a double-skin configuration in at least one region of a top, bottom and sides of the inlet portion.

Owner:PRATT & WHITNEY CANADA CORP

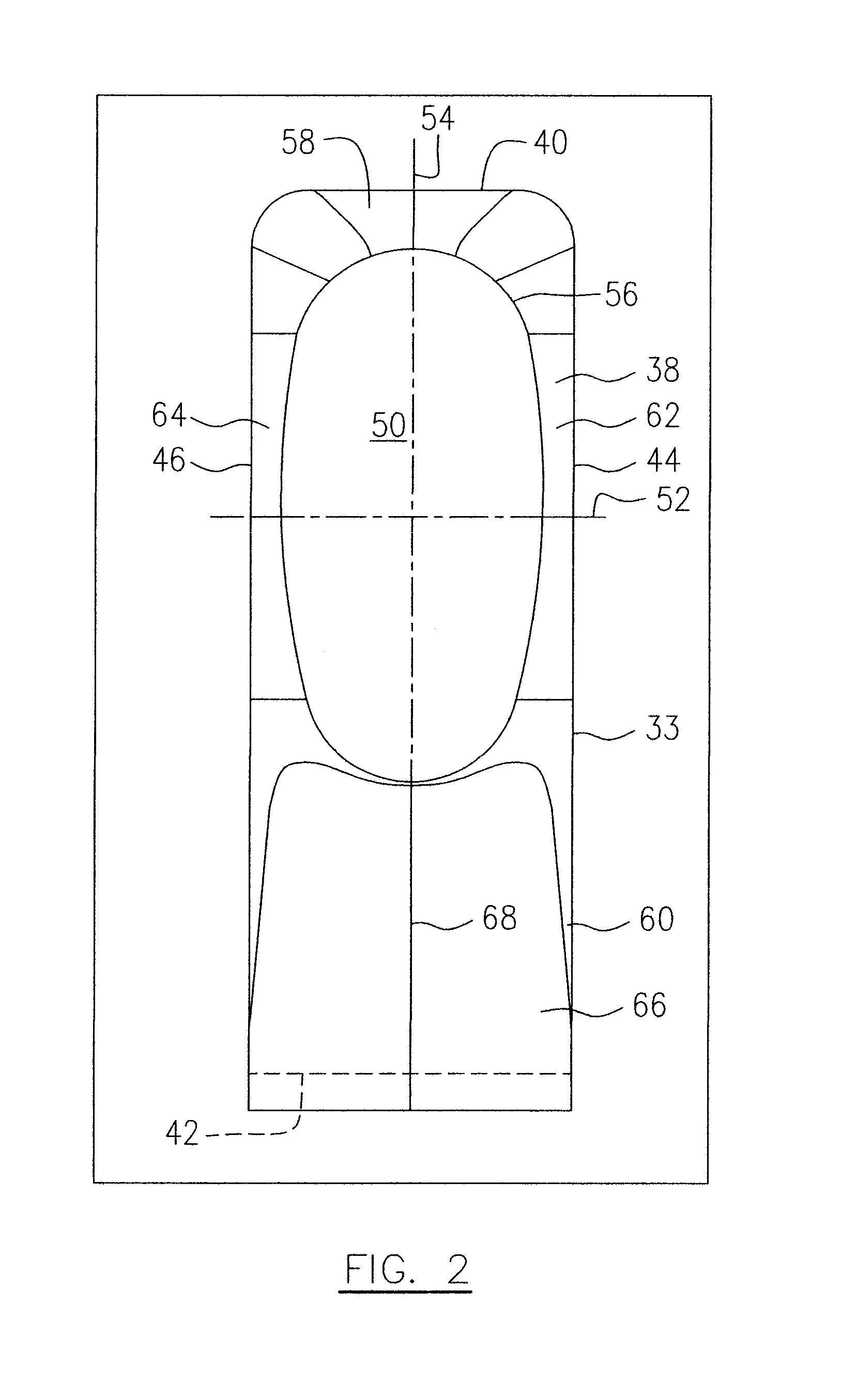

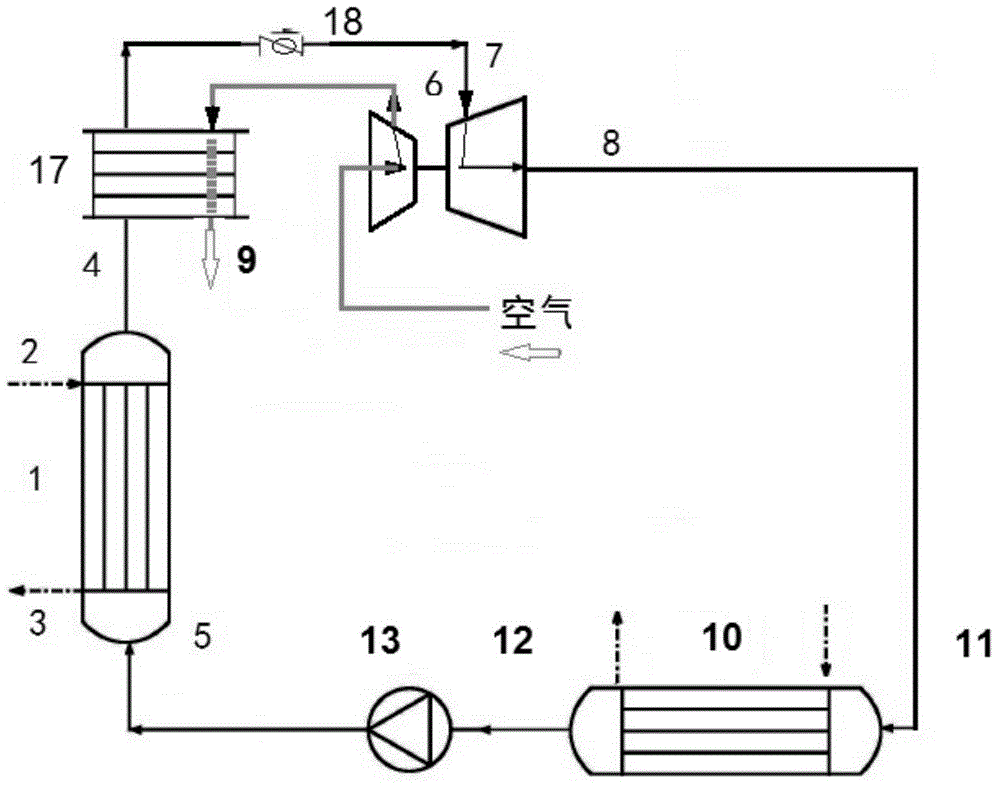

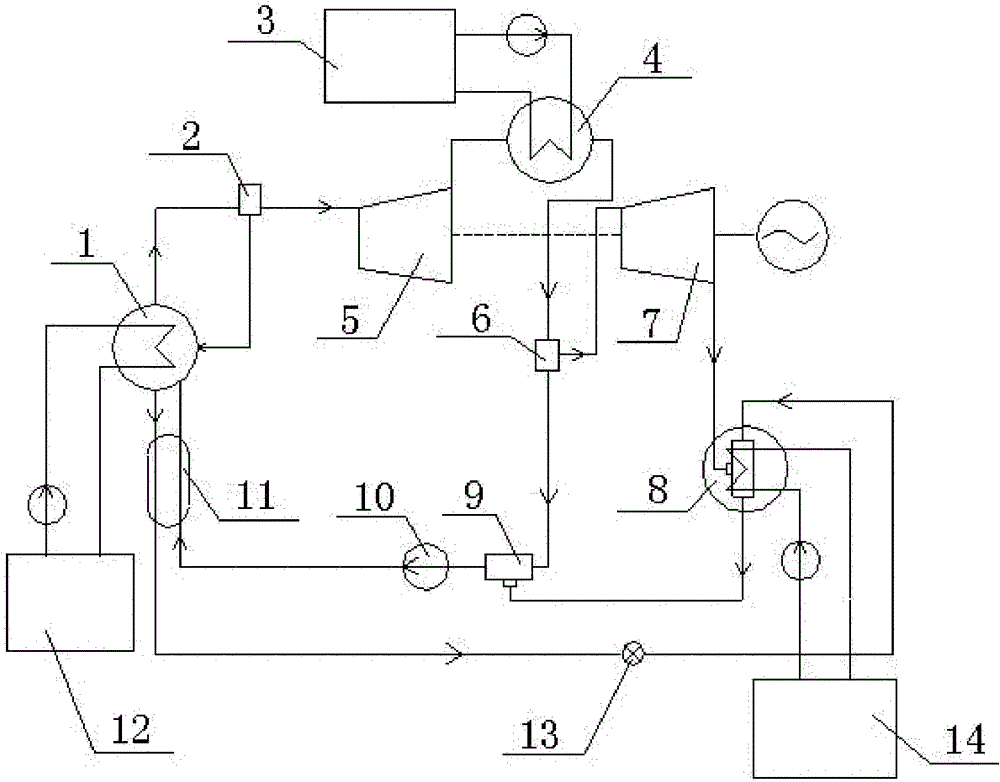

Solar-driven pressurized jet refrigeration system

ActiveCN112629066AIncrease inlet pressureGuaranteed uptimeMechanical apparatusCompression machines with non-reversible cycleIntermediate heat exchangerCollector device

The invention discloses a solar-driven pressurized jet refrigeration system, and relates to the field of refrigeration systems. In an existing solar pressurization jet refrigeration system, the heat exchange temperature difference of an intermediate heat exchanger is large, further improvement of system performance is affected, and a large amount of irreversible throttling losses exist. The solar-driven pressurized jet refrigeration system comprises a solar heat collector, a first water pump, a heat storage water tank, a second water pump, a generator, a steam ejector, a condenser, a working medium pump, a two-phase ejector, a gas-liquid separator, an expansion valve, an evaporator and a scroll compressor. The scroll compressor is arranged at the inlet of the two-phase ejector, so that the pressure of a driving fluid inlet can be effectively improved, throttling loss recovery is realized, the pressure of a secondary fluid inlet of the steam ejector is improved, the performance of the steam ejector is improved, abnormal work is avoided, and the solar energy utilization rate and the system operation stability are improved; and the scroll compressor, the steam ejector and the two-phase ejector jointly bear the compression effect of a refrigerant, so that the power consumption is reduced, and the system energy efficiency is improved.

Owner:浙江省送变电工程有限公司 +2

Internal combustion engine, lubricating system and machine oil sump strainer

ActiveCN106050356AHigh trafficIncrease pressurePressure lubricationLubricant mounting/connectionExternal combustion engineInlet pressure

Owner:WEICHAI POWER CO LTD

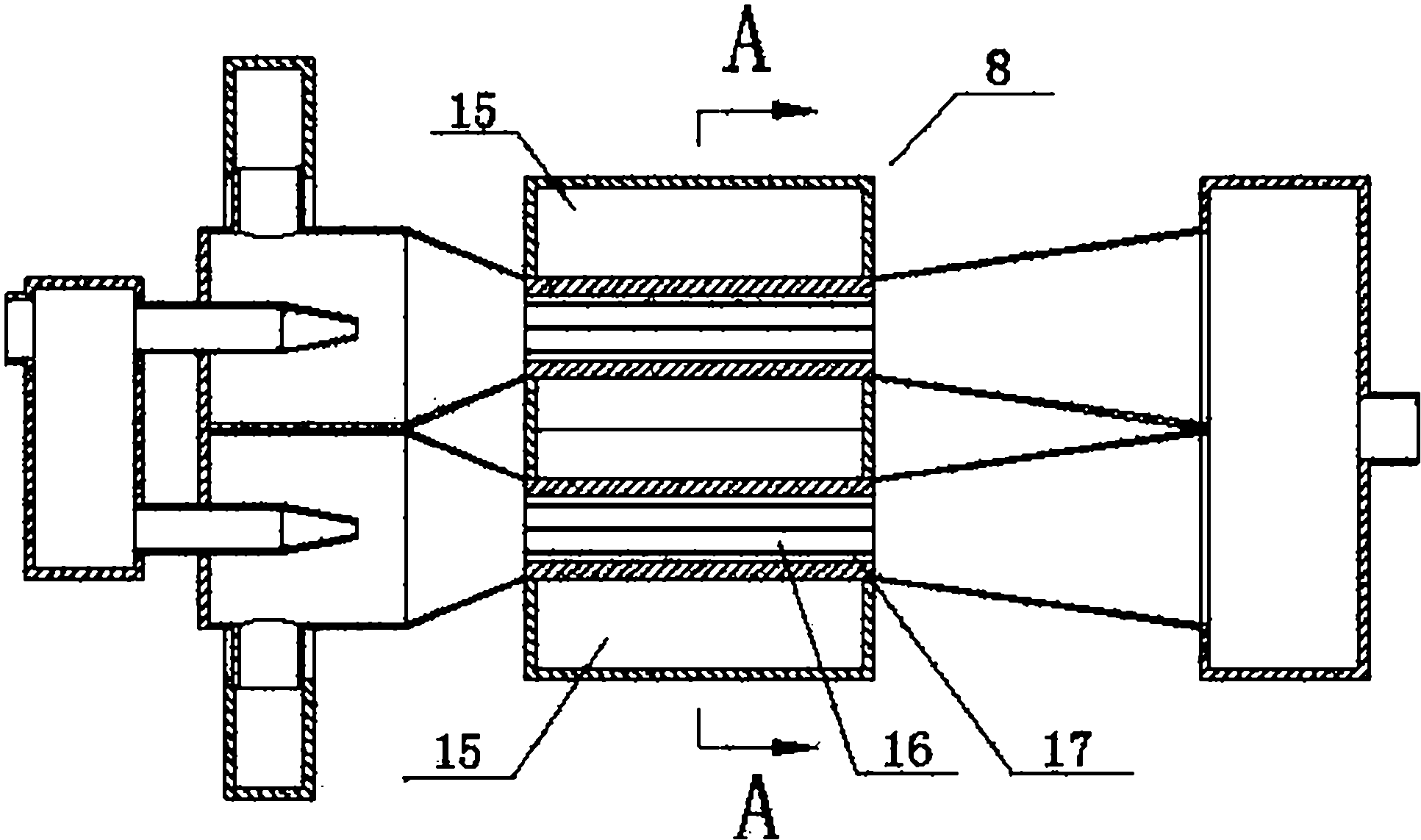

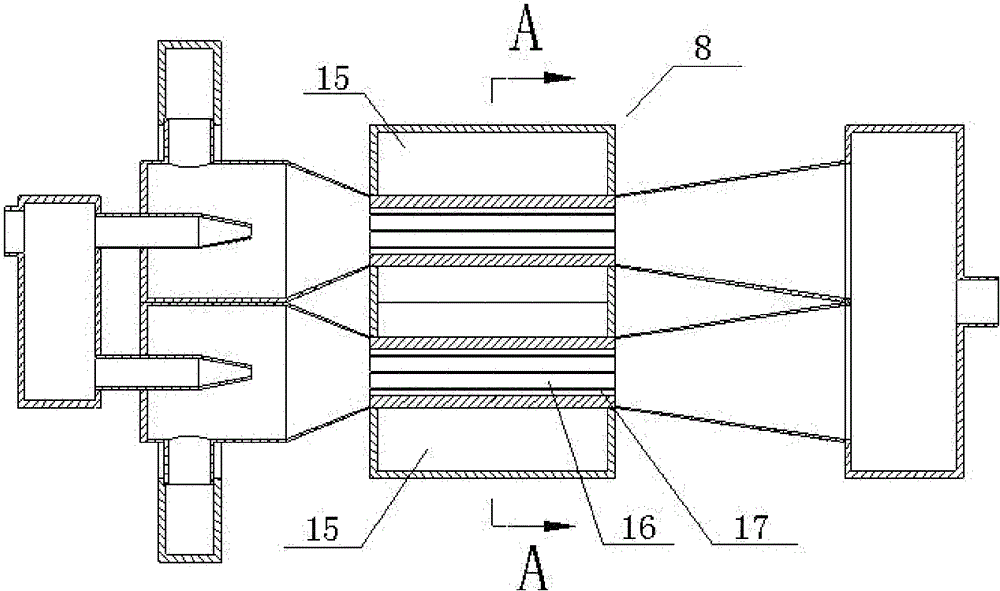

ORC compressed air preparation device and method

ActiveCN104612771ARaise the inlet temperatureIncrease inlet pressureSteam regenerationInlet temperatureEvaporator

The invention relates to a medium-and-low temperature heat recovery technology, and provides an ORC compressed air preparation device and method. The device comprises an evaporator, a secondary heat exchanger, a turbine coaxial integrated machine, a condenser and a working medium pump. The turbine coaxial integrated machine is formed by coaxially and directly connecting a turbine expander with a turbine compressor, the turbine expander is used for doing work by expansion, and the turbine compressor is used for preparing compressed air. All the devices are connected through pipelines. The outlet end of the working medium pump is connected with a working medium inlet of the evaporator, and a working medium outlet of the evaporator is connected to a working medium inlet of the turbine expander through the secondary heat exchanger. A working medium outlet of the turbine expander is connected to the inlet end of the working medium pump through the condenser. A compressed air outlet of the turbine compressor is connected to a compressed air inlet of the secondary heat exchanger. Medium-and-low temperature waste heat recovery is achieved through ORC, the compressed air is directly prepared, the inlet temperature and pressure of the expander are increased through compression heat recovery, and the recovery efficiency of waste heat energy is greatly improved.

Owner:沈天昱

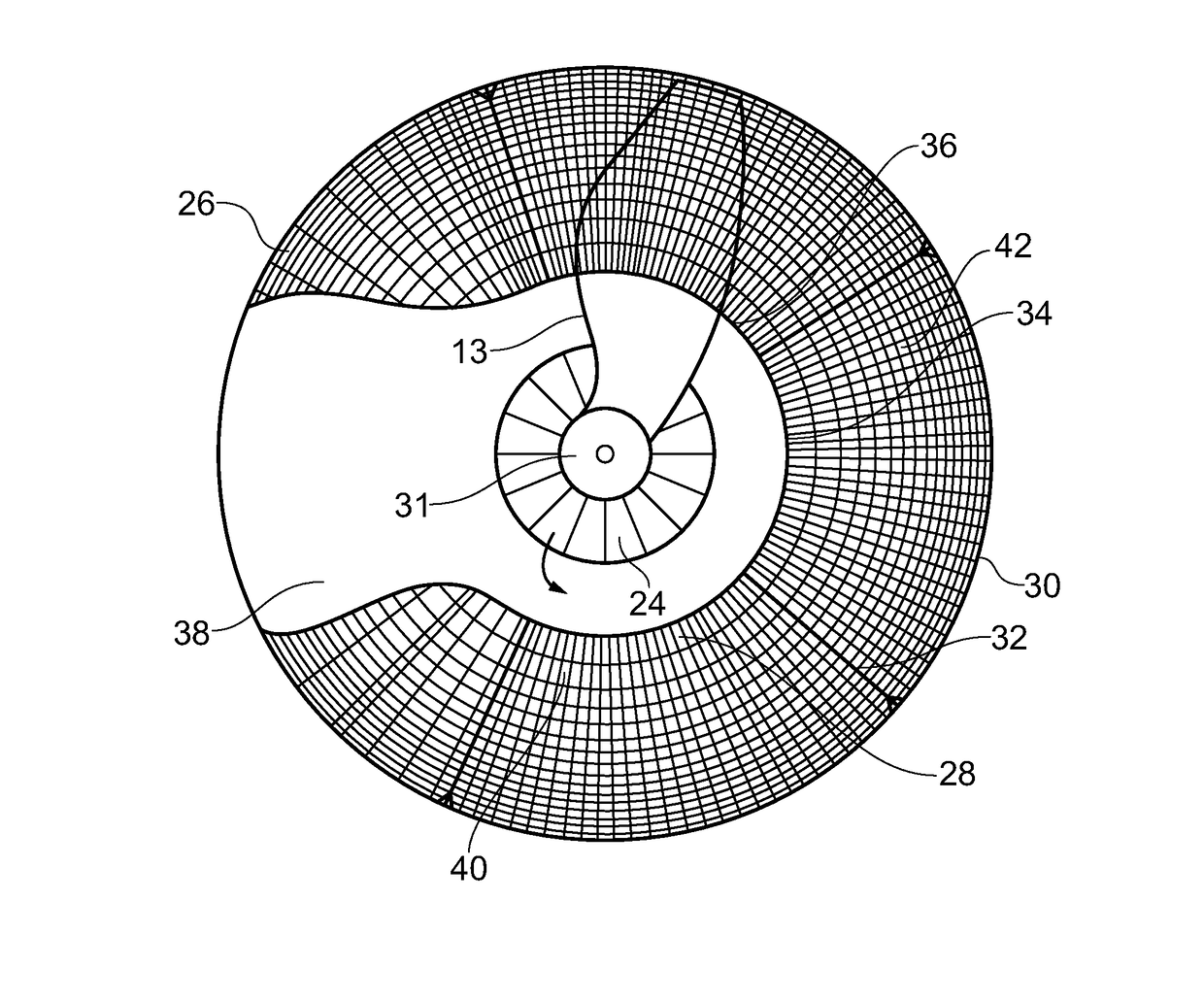

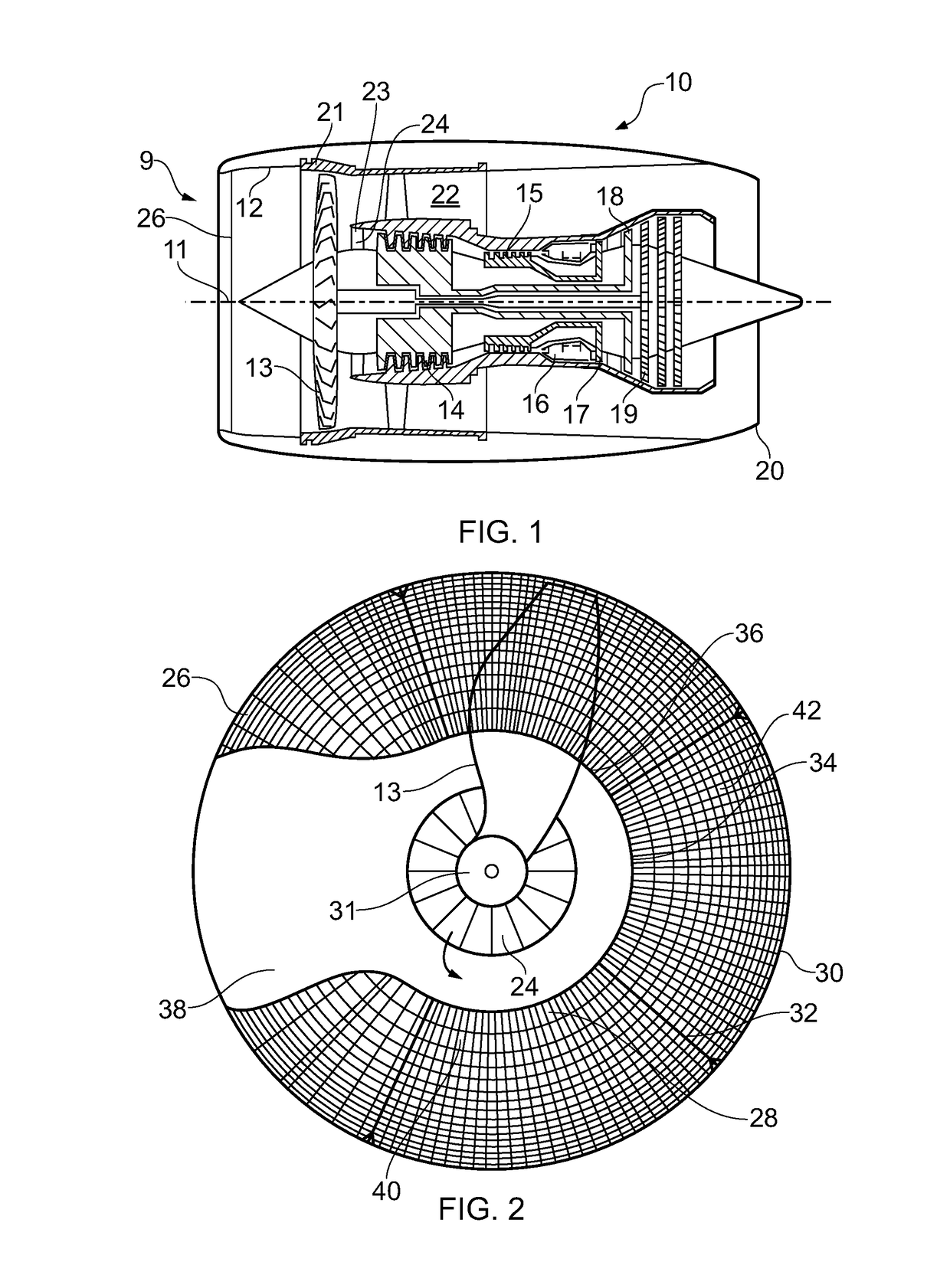

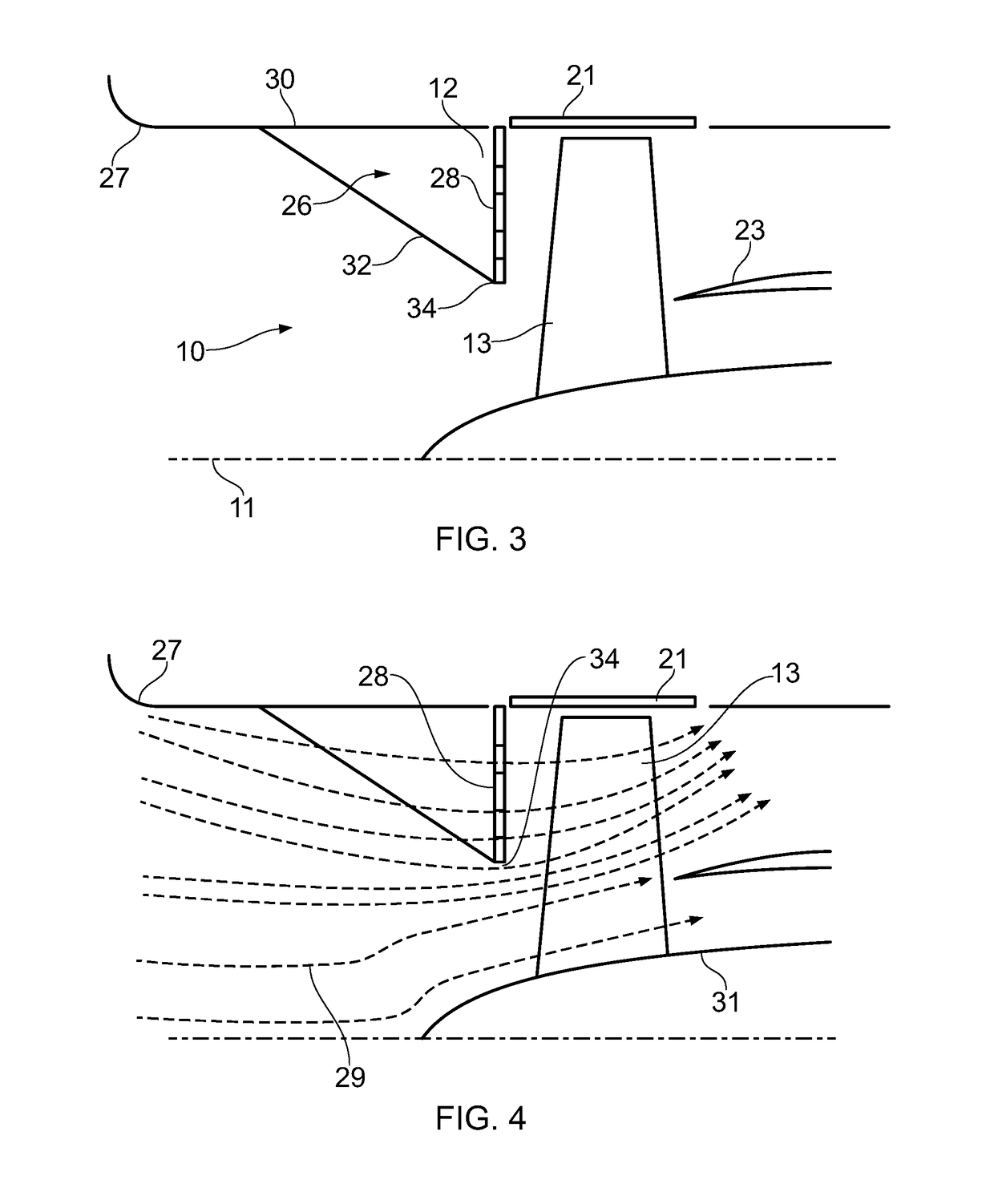

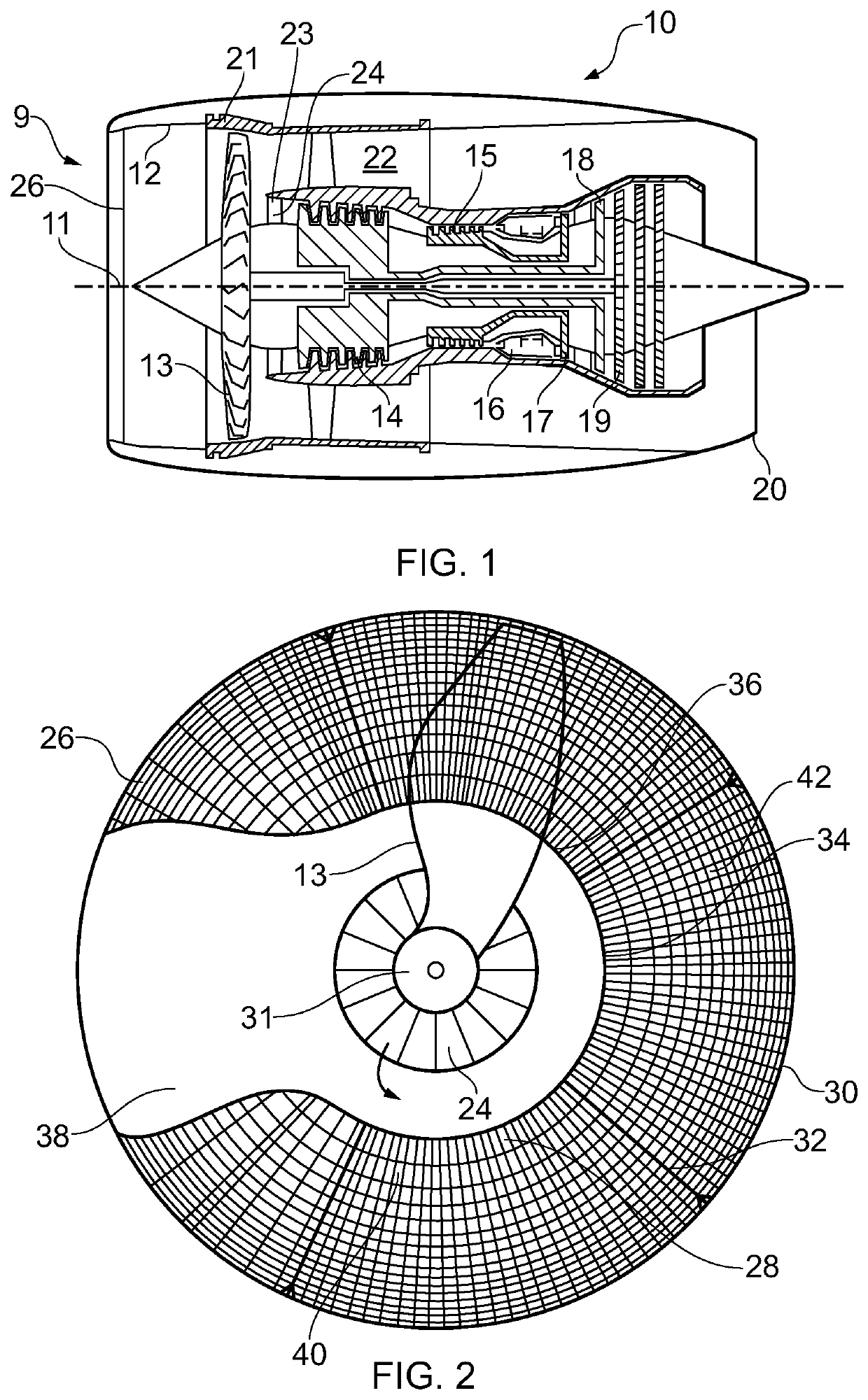

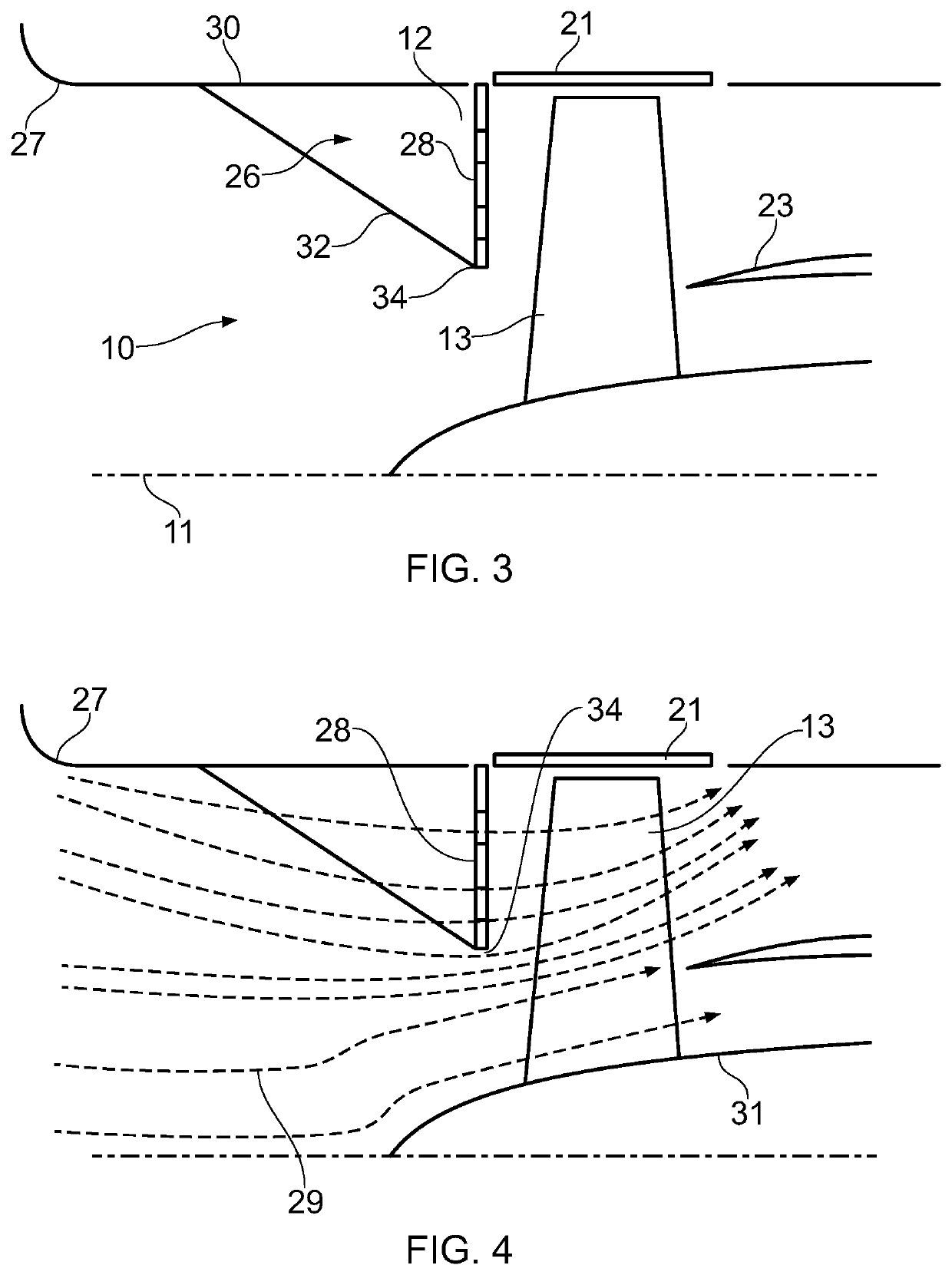

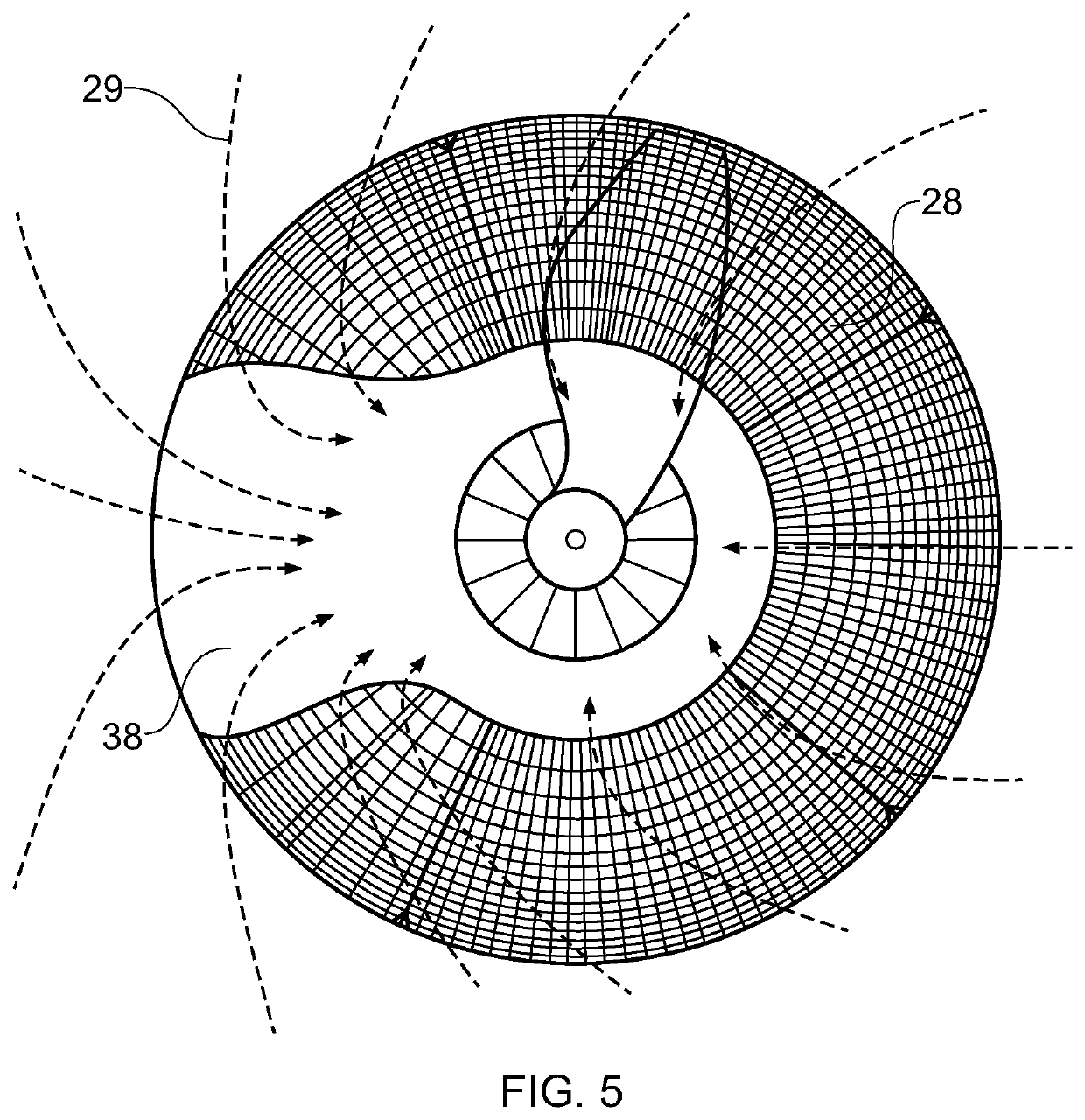

Gas turbine engine arrangement

ActiveUS20180245514A1Increase speedReduce power levelEngine fuctionsGas turbine plantsRadial positionTurbine

A gas turbine engine arrangement comprising a gas turbine engine and an inlet screen. The gas turbine engine comprises an engine core comprising an inlet having a radial extent extending from an engine longitudinal axis to a first radial position, and a fan duct comprising an inlet having a radial extent extending from the first radial position to a fan casing, the inlet screen comprising an at least part annular porous grid radially extending across at least part of the radial extent of the fan duct inlet, and not extending across any substantial part of the radial extent of the core inlet.

Owner:ROLLS ROYCE PLC

Combustion chamber laminate and combustion chamber

PendingCN113091092AAdd cooling structureImprove cooling effectContinuous combustion chamberCombustion chamberEngineering

The invention discloses a combustion chamber laminate which comprises an outer layer wall and an inner layer wall, and the outer layer wall and the inner layer wall jointly form an interlayer channel. A plurality of impact cooling holes are formed in the outer layer wall. The inner layer wall is provided with a laminate inflow hole, a laminate channel and a laminate outflow hole. First airflow flows into the interlayer channel from the impact cooling holes of the outer layer wall to form impact cooling on the inner layer wall, and flows in the upstream direction along the interlayer channel. Second airflow flows into the interlayer from the impact cooling holes of the outer layer wall, flows into the laminate channel through the laminate inflow hole, flows in the upstream direction along the laminate channel, flows out from the laminate outflow hole, enters the interlayer channel to be converged with the first airflow and flows to an inlet of a combustion chamber. According to the combustion chamber laminate and the combustion chamber, the cooling performance of a combustion chamber flame tube or a transition section is improved.

Owner:CHINA UNITED GAS TURBINE TECH CO LTD

Energy-saving type vacuum device

ActiveCN107560451AGuaranteed energy savingIncrease inlet pressureSteam/vapor condensersVacuum pumpingIsolation valve

The invention relates to an energy-saving type vacuum device. The energy-saving type vacuum device comprises a condenser, a condenser hot well, a steam condensing mother pipe, a first water ring vacuum pump system, a steam condensing branch pipe, a steam condensing pipeline check valve, a steam condensing pipeline flow meter, a steam condensing pipeline pressure transmitter, a steam condensing pipeline thermal resistor, a steam condensing pipeline isolating valve, a steam condensing pipeline pneumatic valve, a power steam adjusting valve, a steam ejector, a tubular heat exchanger, a steam trap, a hydrophobic pneumatic valve, a contact pneumatic valve, a contact isolation valve and a second water ring vacuum pump. According to the energy-saving type vacuum device, the first water ring vacuum pump system is replaced by the tubular heat exchanger and the small-power second water ring vacuum pump, thus the vacuum of the condenser can be maintained and provided, the condenser is guaranteedto be in the optimum working condition, the influence of environmental temperature changes is avoided, stable pumping capacity of the condenser is kept all the time, the vacuum degree of the condenseris improved, the power generation coal consumption of a unit is reduced, the operation power consumption of a vacuum pumping system is reduced, operation of the system equipment is reliable and safe,the maintenance workload is small, the cavitation phenomenon is avoided, and the phenomena of high noise and vibration are avoided.

Owner:WUHAN EDW PUMP & VALVE

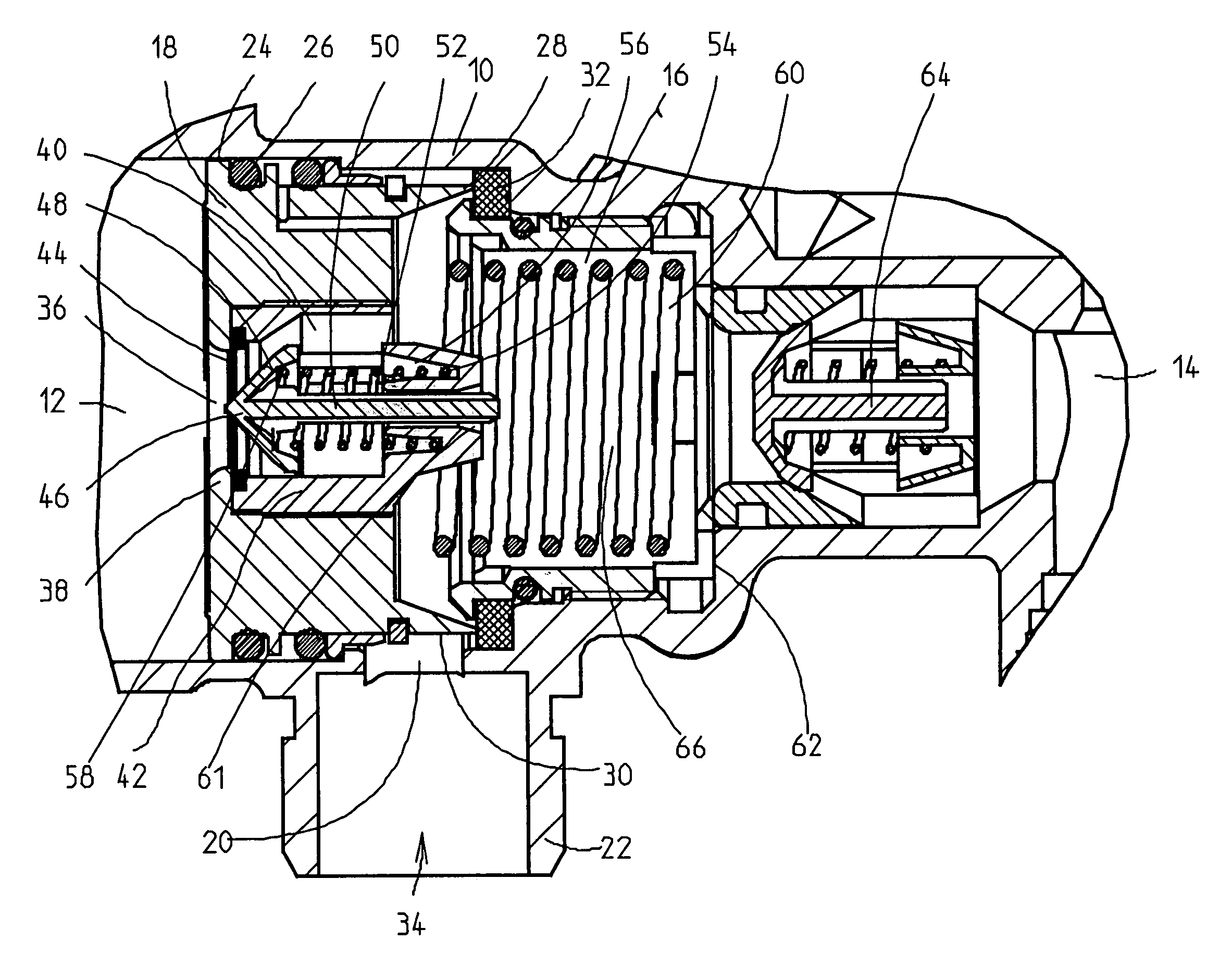

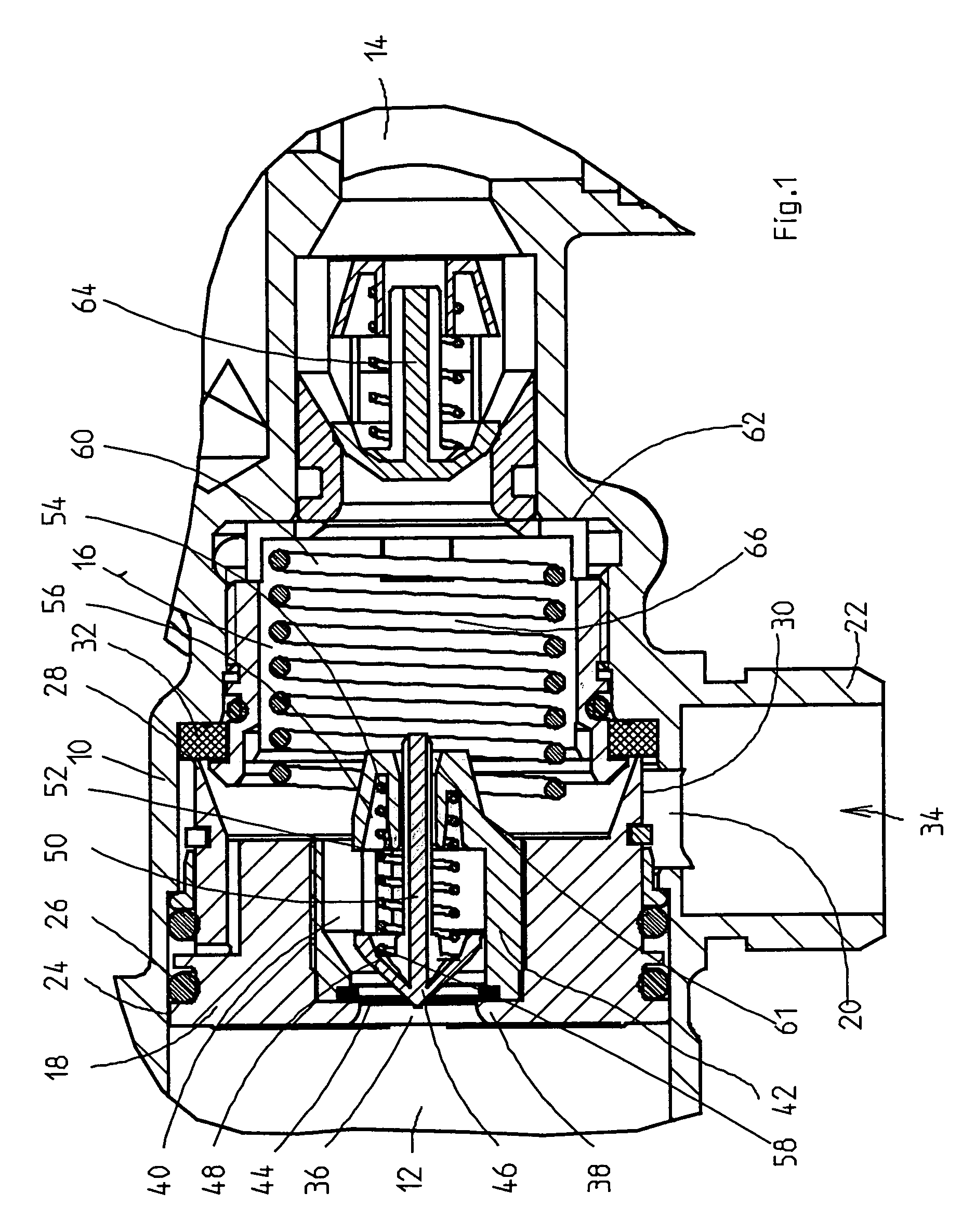

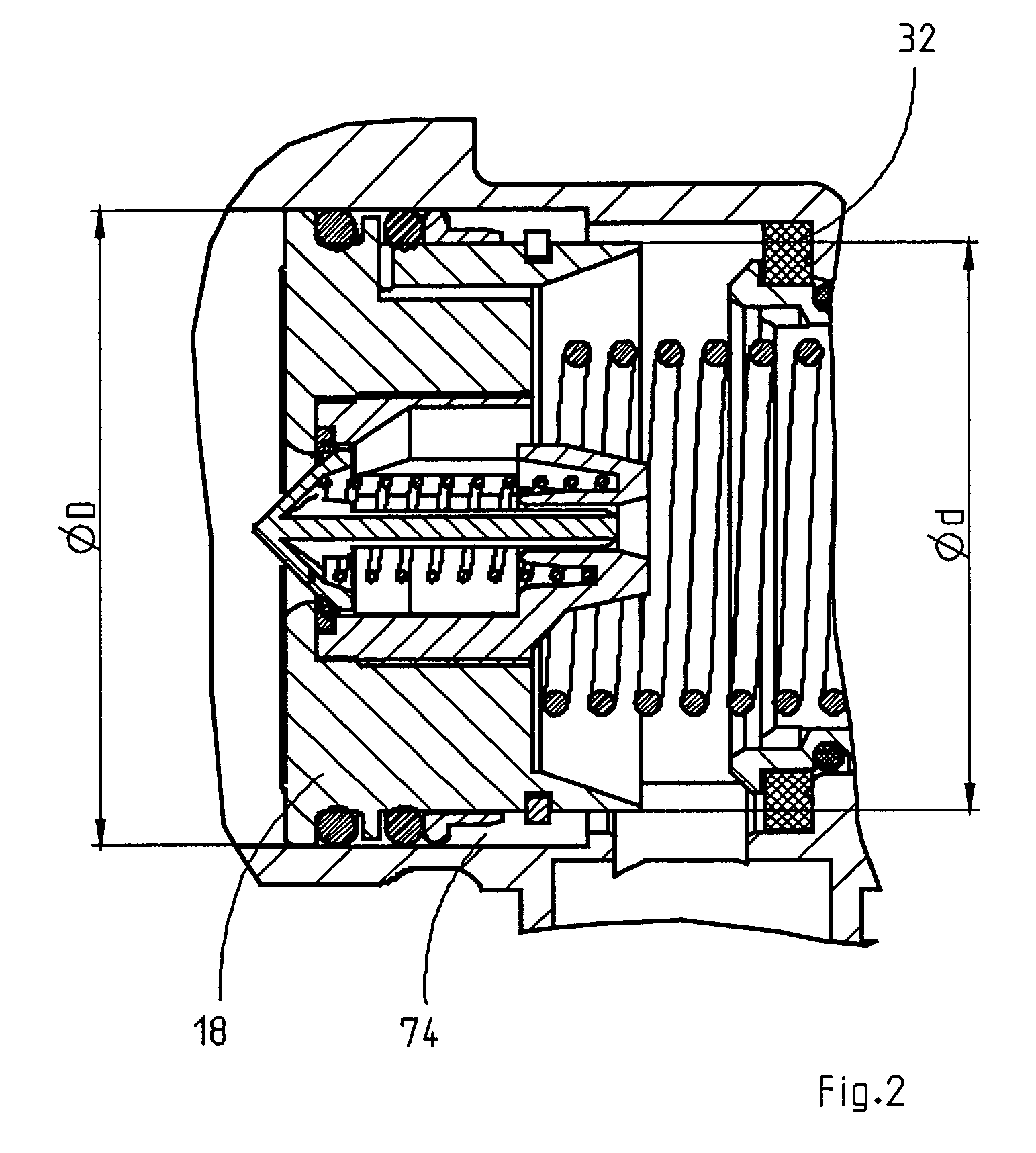

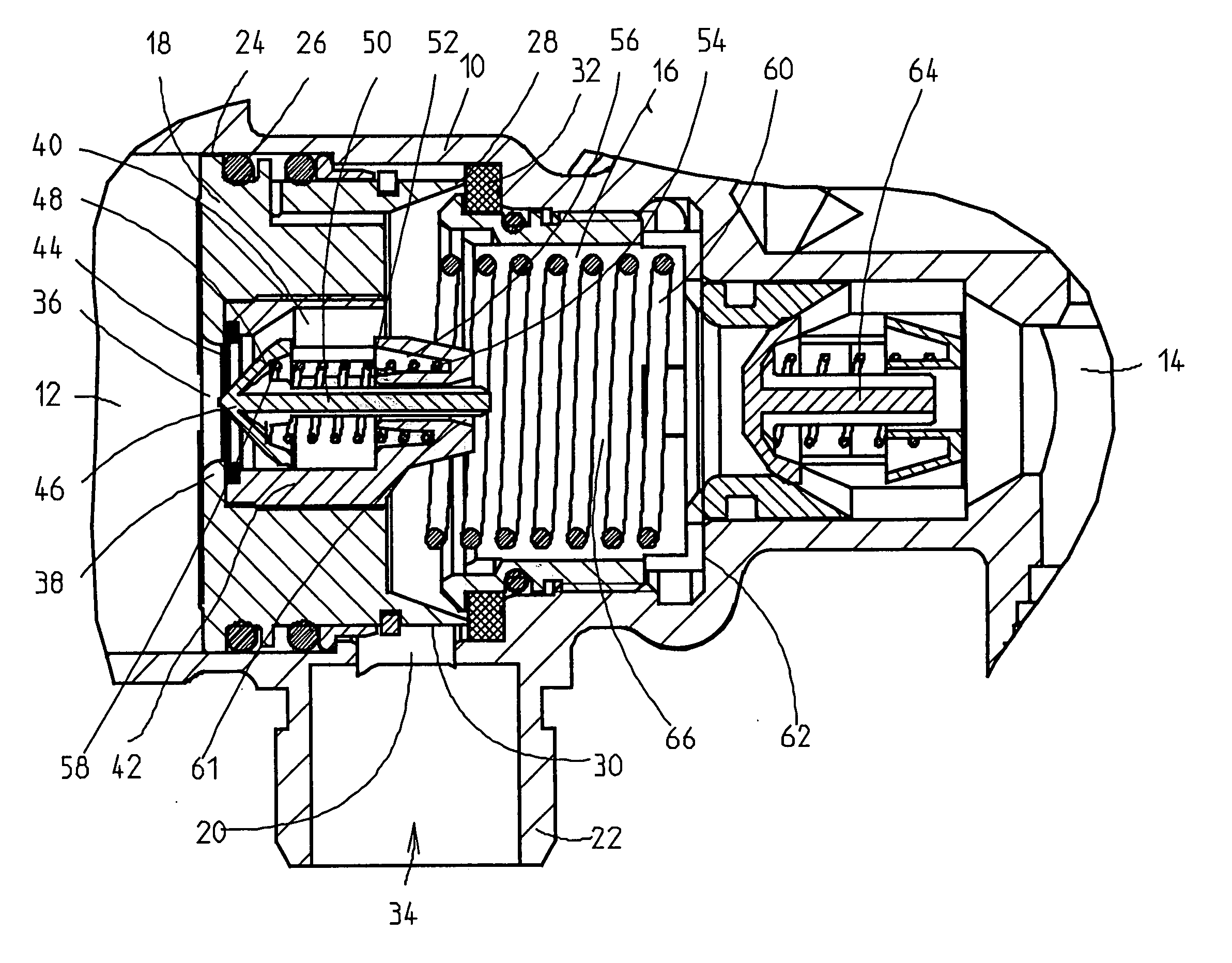

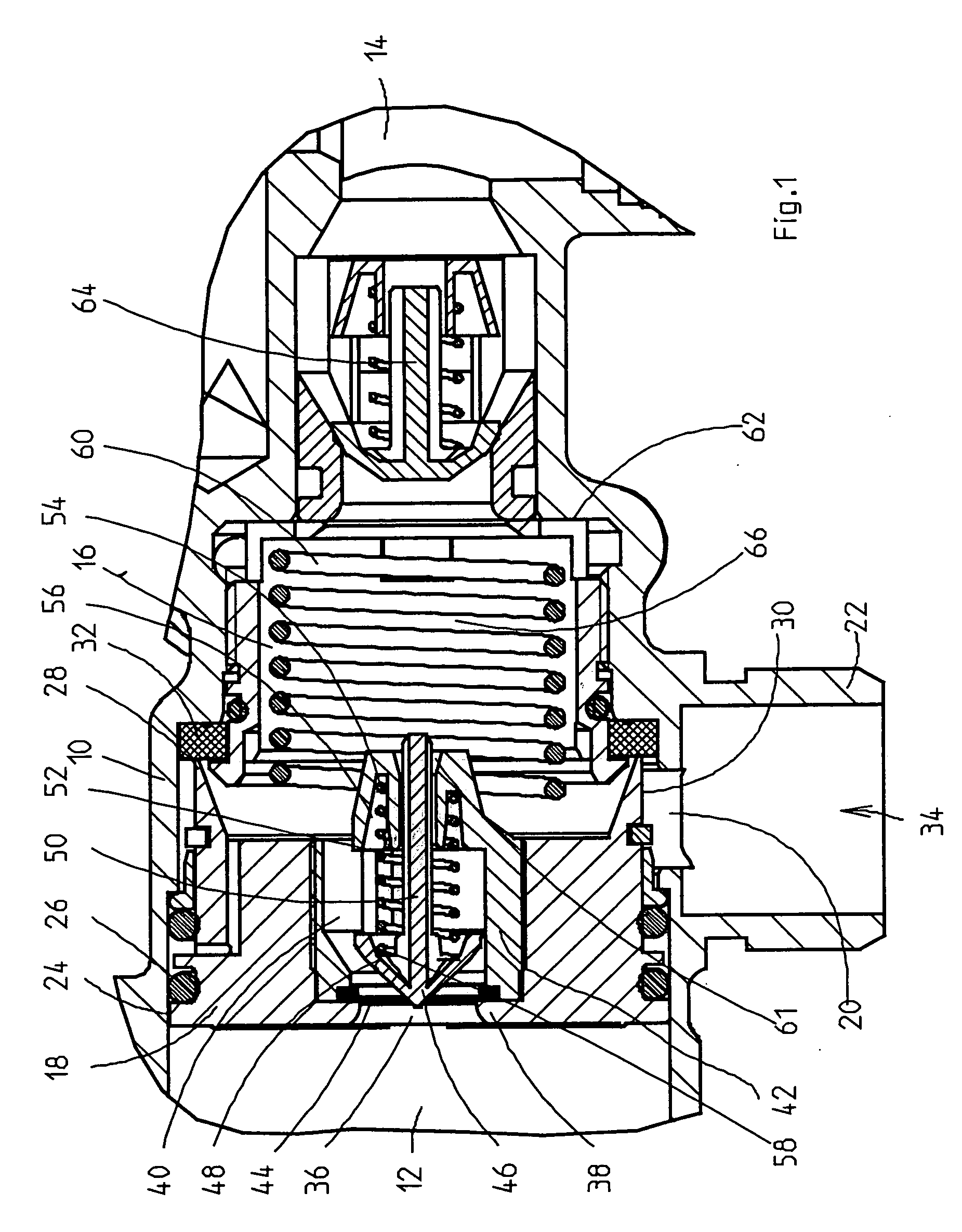

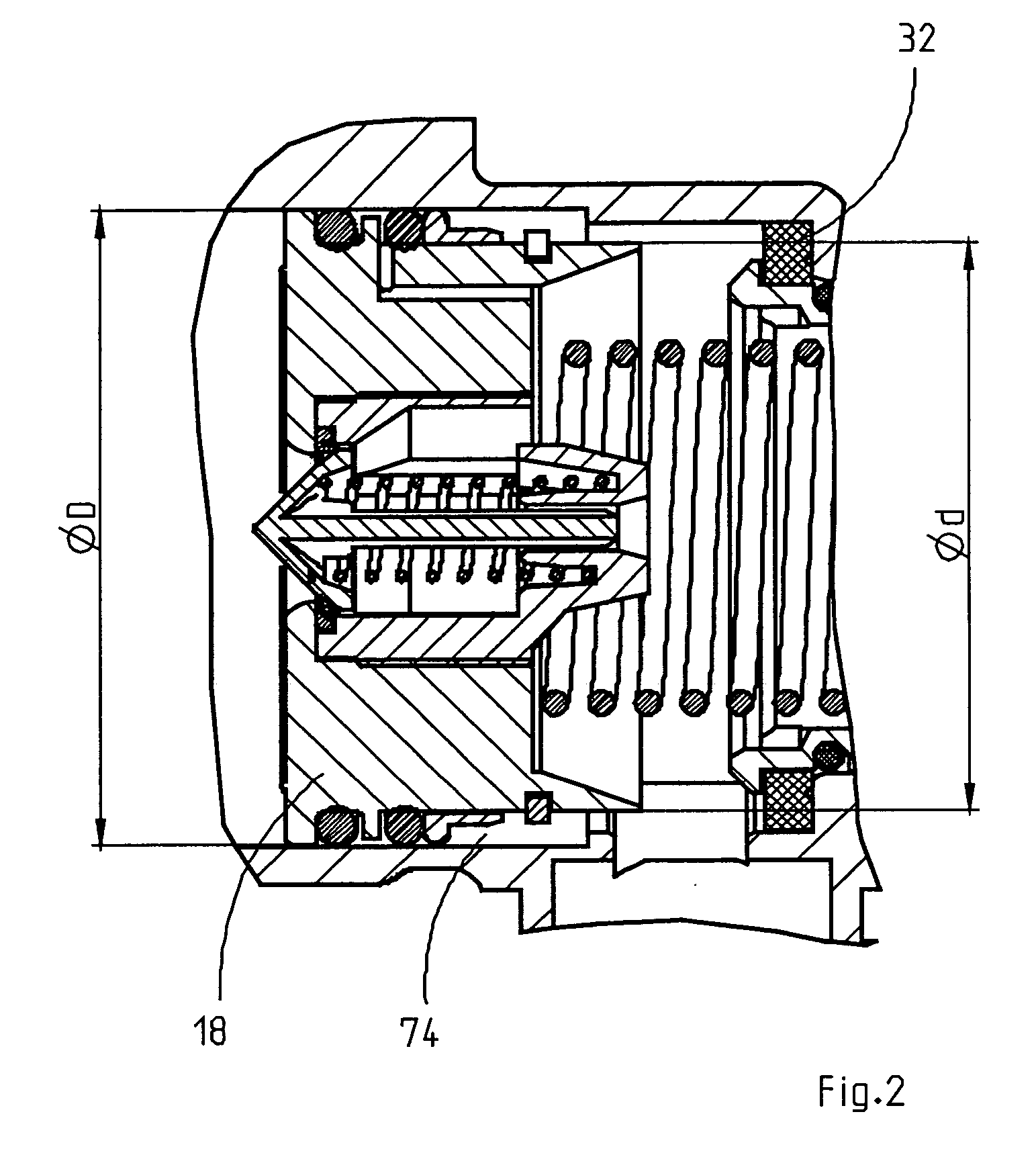

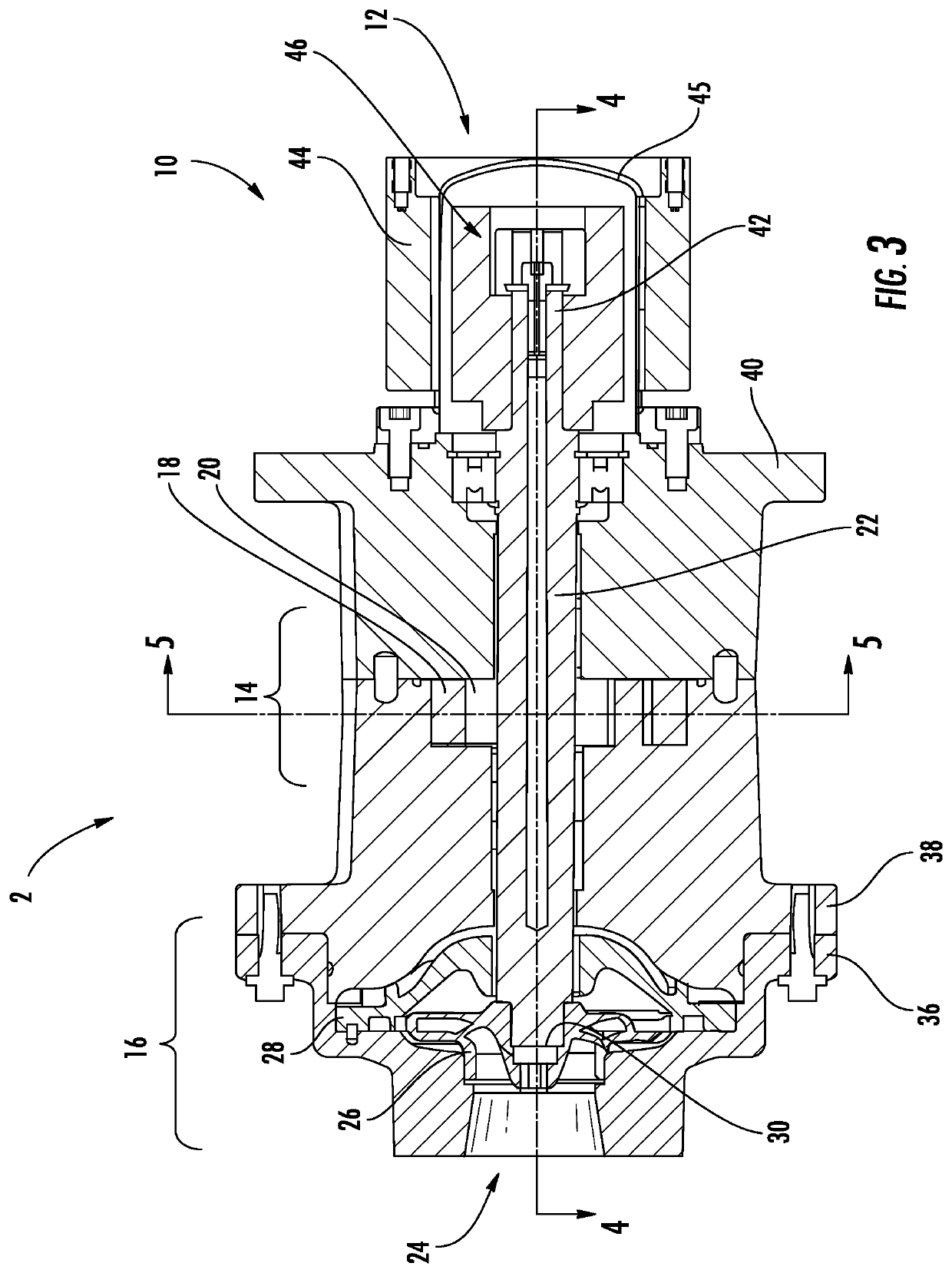

Pipe disconnector with increased sealing power

ActiveUS7575016B2Increase tightening forceIncrease powerLighting and heating apparatusCheck valvesEngineeringInlet pressure

A system disconnector for disconnecting an upstream liquid system providing an inlet pressure from a downstream liquid system by a release valve (34) in response to a pressure drop between the systems, includes an upstream backflow preventer (40), a downstream backflow preventer (64) and a release valve body piston (18) arranged between the backflow preventers (40, 64). A pressure difference between the inlet pressure and a middle pressure between the backflow preventers (40,64) counteracts a spring (60) biasing the release valve body in the opening direction, the release valve body (18) having an effective pressurized surface (d) smaller than the surface effective for the inlet pressure. A hollow space (74) defined by the release valve body is connected to the middle pressure (66). A shiftable seat (76) provided in hollow space (74), is movable with respect to the release valve body to a fixed stop (84) upstream of the valve seat (32).

Owner:HANS SASSERATH GMBH & CO KG

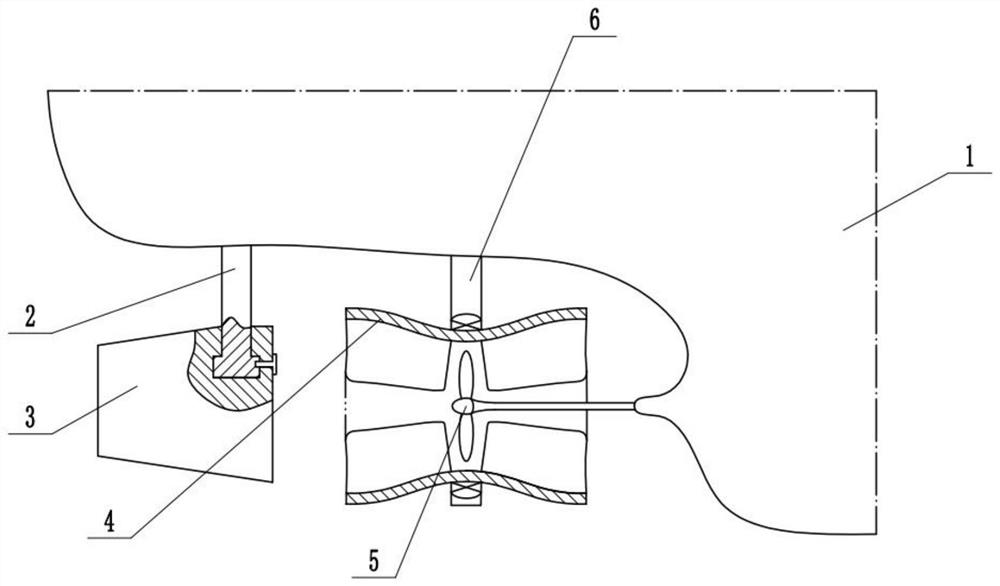

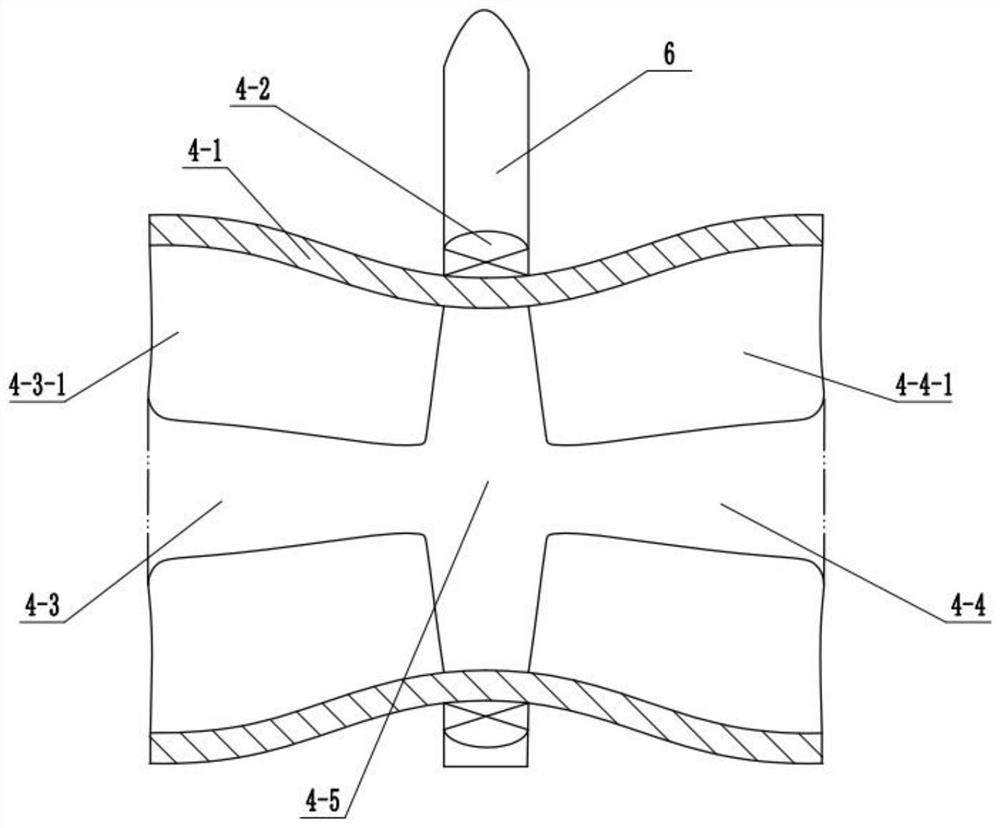

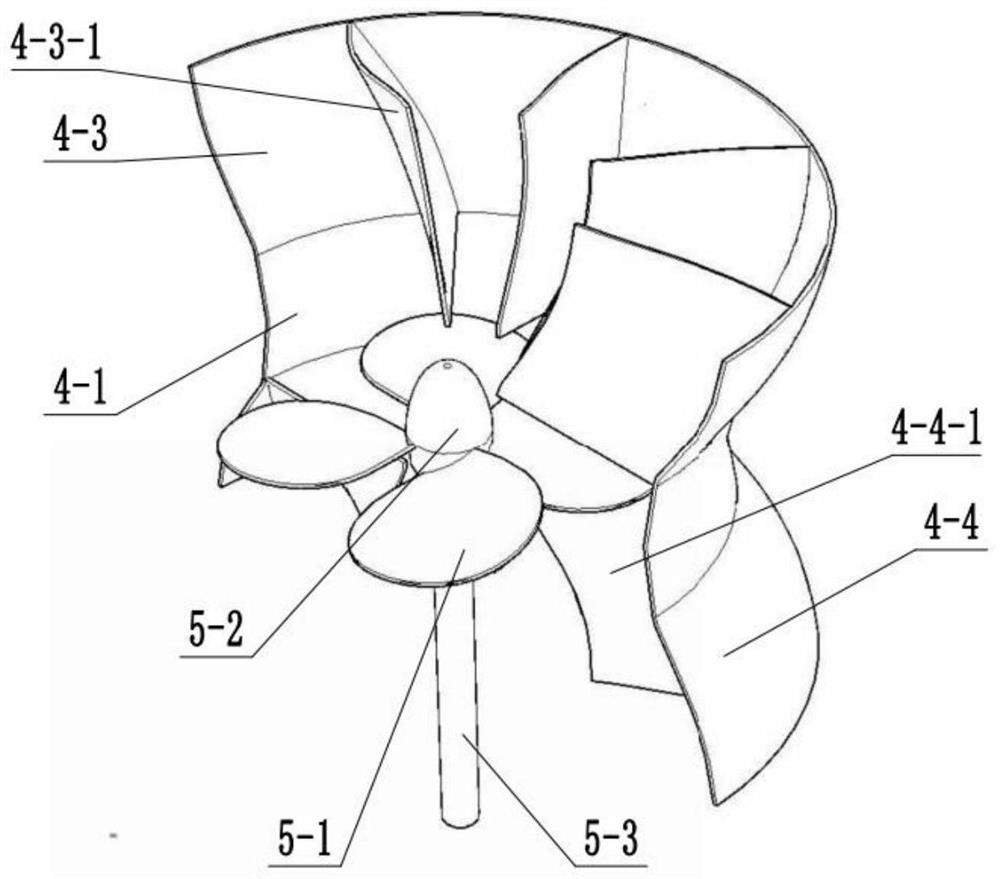

Propeller turbocharging device

PendingCN114313185AIncrease water pressureIncrease inlet pressurePropulsive elementsDrive shaftTurbine blade

The invention belongs to the technical field of ship engineering and fluid mechanics, and particularly relates to a propeller turbocharging device. Comprising a ship body, a steering rudder driving rod is installed on the ship body, a steering rudder is fixedly installed at the lower end of the steering rudder driving rod, a support and a propeller assembly are further installed on the ship body, a fairing assembly is installed on the support, and one side of the propeller assembly is located in the fairing assembly. The propeller blade hub is driven to rotate through the propeller blade transmission shaft, the propeller blades are driven to rotate through the propeller blade hub, water flow is driven to flow through the propeller blades, and then the ship body is pushed to move forwards through the counter-acting force of the water flow. Tangential and radial velocity components in the wake flow of the propeller are extracted through a turbine area and turbine blades, and the energy is applied to increase of the water inlet pressure of the propeller. The turbine area can be driven by the wake flow area to actively provide kinetic energy and increase the water pressure at the front end of the propeller; and the direction of the ship body can be controlled through the steering rudder.

Owner:TIANJIN RES INST FOR WATER TRANSPORT ENG M O T

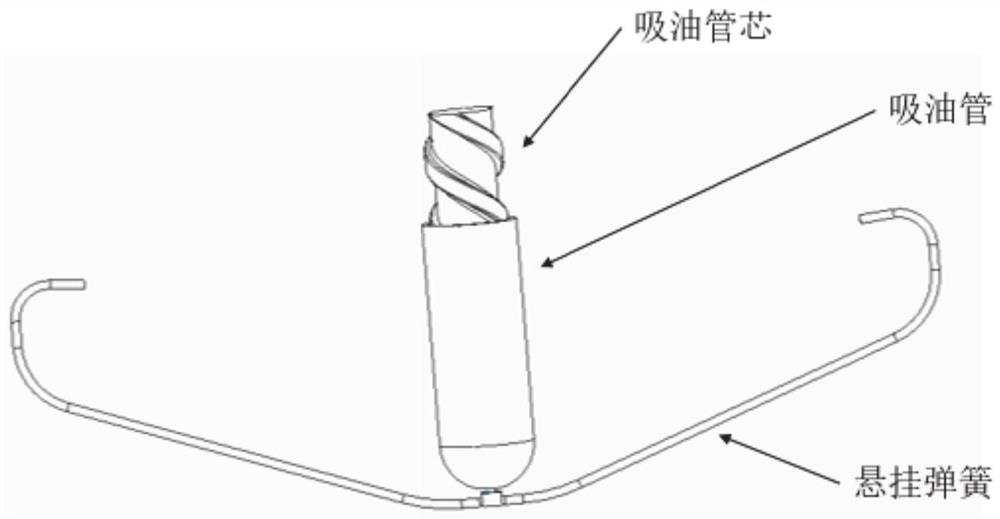

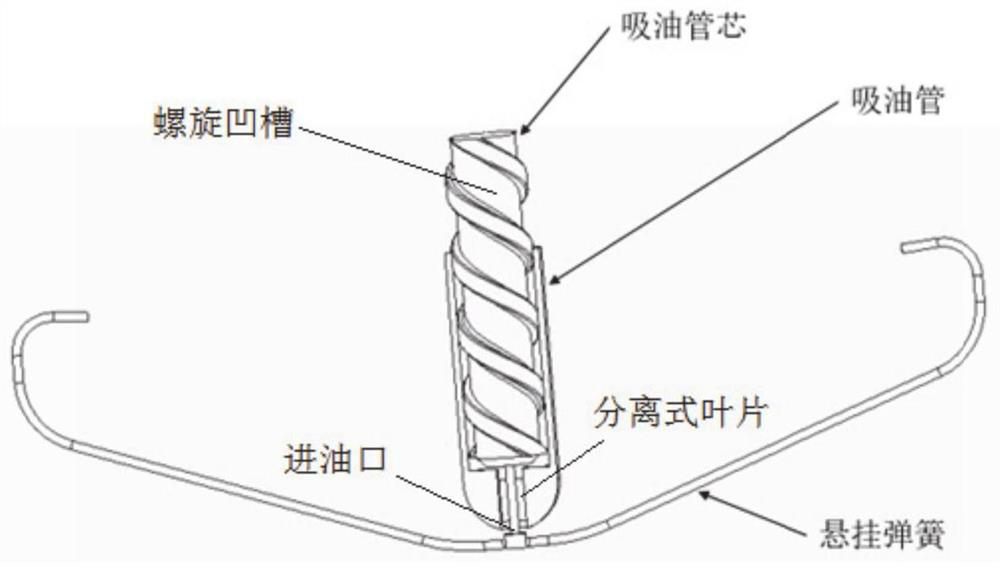

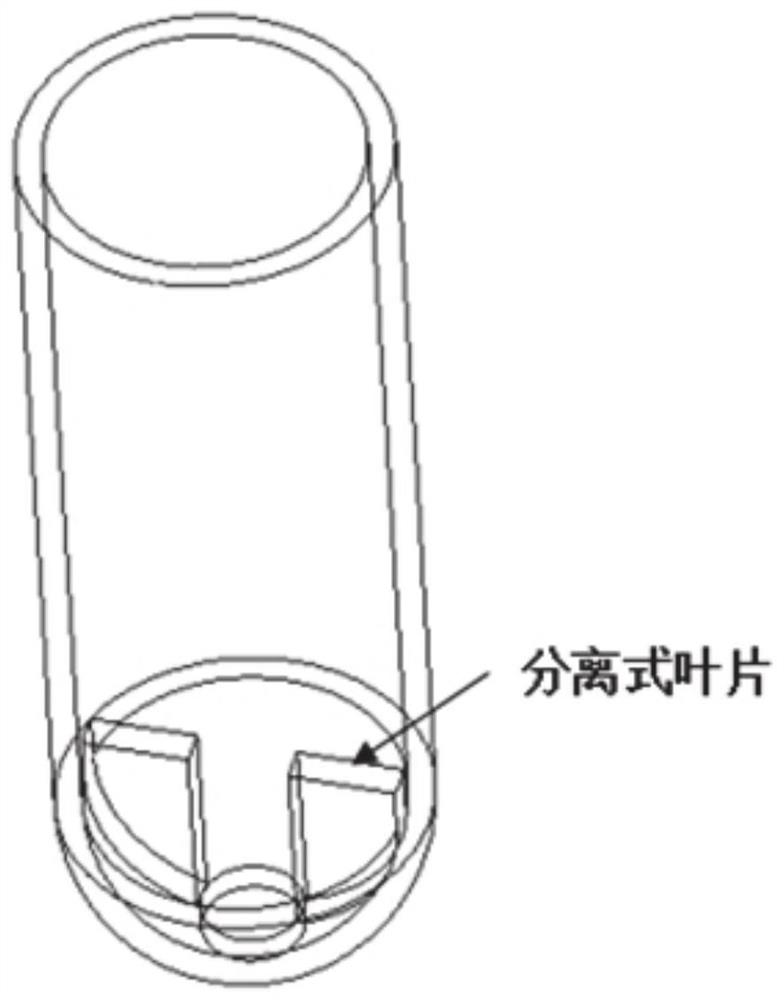

Centrifugal supercharging type spiral oil pump, compressor and heat exchange equipment

InactiveCN111677649AAvoid blockingFlow area effectPositive displacement pump componentsLubricating pumpsOil separationCentrifugal force

The invention provides a centrifugal supercharging type spiral oil pump, a compressor and heat exchange equipment. The oil pumping amount of the compressor oil pump under the conditions of low rotating speed, high oil temperature and low viscosity can be increased. The spiral oil pump comprises an oil suction pipe and an oil suction pipe core arranged in the oil suction pipe, wherein a spiral groove is formed in the surface of the oil suction pipe core in the axis direction from bottom to top, an oil inlet is formed in the bottom of the oil suction pipe, separation type blades which do not shield the oil inlet are arranged on the periphery of the oil inlet and fixedly connected with the inner wall of the oil suction pipe, and the oil suction pipe and the oil suction pipe core can rotate relatively to realize oil pumping. The separation type blades rotate to stir entering oil to generate strong centrifugal force when the oil suction pipe rotates, and meanwhile, the separation type blades are arranged to avoid blocking of the blades to the oil inlet, the oil inlet amount is increased, and therefore the oil pumping capacity is further improved, the oil pumping capacity of a compressoroil pumping system under the low-rotating-speed and high-temperature conditions is improved, and the oil pump is suitable for the variable frequency compressor.

Owner:QINGDAO WANBAO COMPRESSOR

Pipe disconnector with increased sealing power

ActiveUS20070079873A1Increase tightening forceIncrease powerLighting and heating apparatusCheck valvesBackflow prevention deviceEngineering

A system disconnector for physically disconnecting an upstream liquid system from a downstream liquid system by means of a release valve (34) in response to a pressure drop between the upstream and downstream liquid system, with an upstream backflow preventer (40), a downstream backflow preventer (64) and a release valve body (18) in the form of a piston which is, regarding the flow, arranged between the backflow preventers (40, 64), an inlet pressure of the upstream liquid system upstream from the upstream backflow preventer (40), a middle pressure in a middle pressure space (66) between the release valve body (18) and the downstream backflow preventer (64) and an outlet pressure of the downstream liquid system downstream of the downstream backflow preventer (64), wherein a pressure difference between the inlet pressure and the middle pressure counteracts a spring (60) biasing the release valve body in the opening direction and wherein the release valve body (18) has an effective pressurized surface (d) which is smaller than the surface effective for the inlet pressure whereby a hollow space (74) is defined by the release valve body and the hollow space is connected to the middle pressure space (66) wherein a shiftable seat (76) adapted to be moved in the moving direction of the release valve body is provided in the hollow space (74), movable with respect to the release valve body up to a casing fixed stop (84) which is arranged in the flow direction upstream of the valve seat (32) of the release valve (34).

Owner:HANS SASSERATH GMBH & CO KG

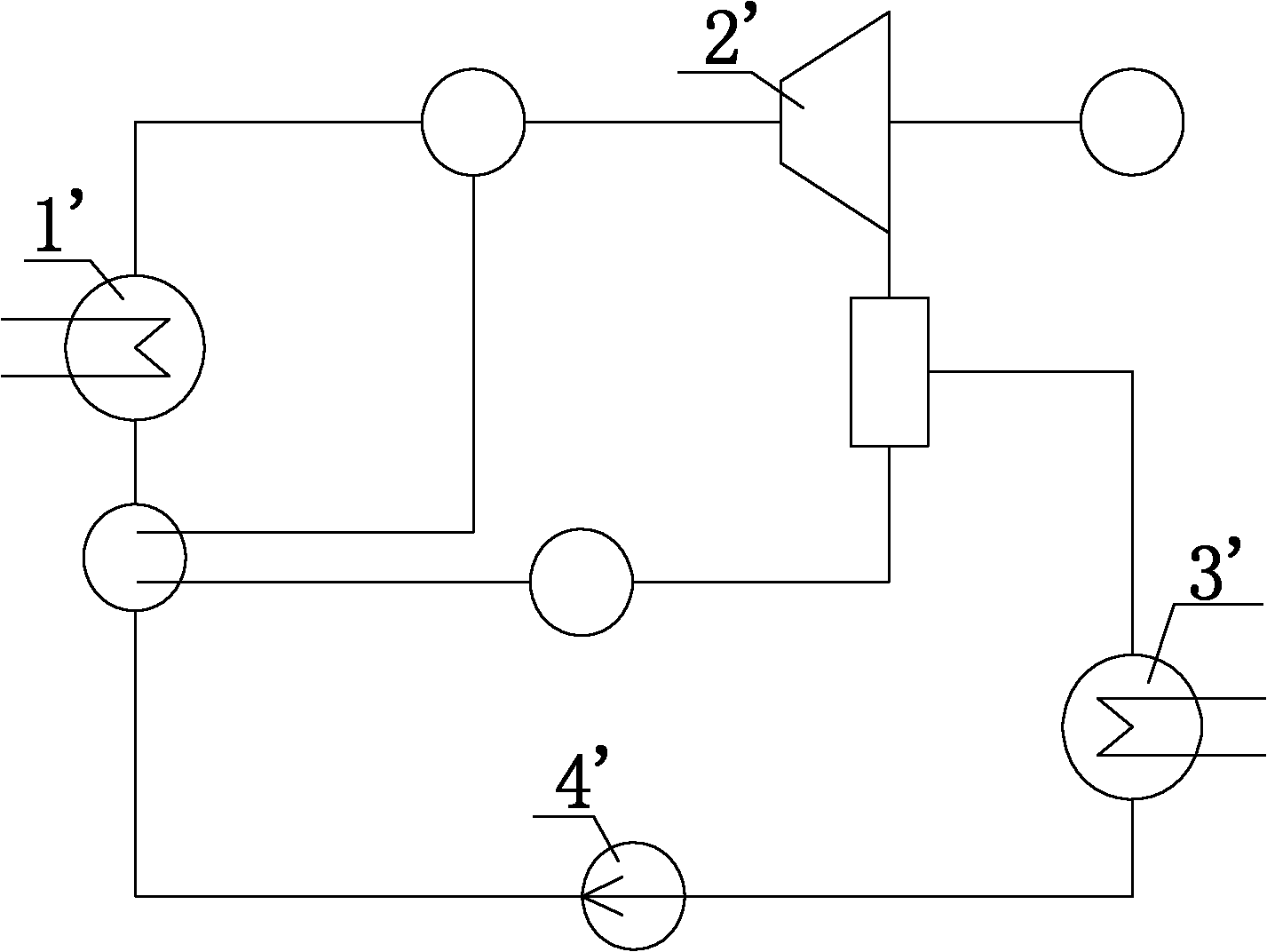

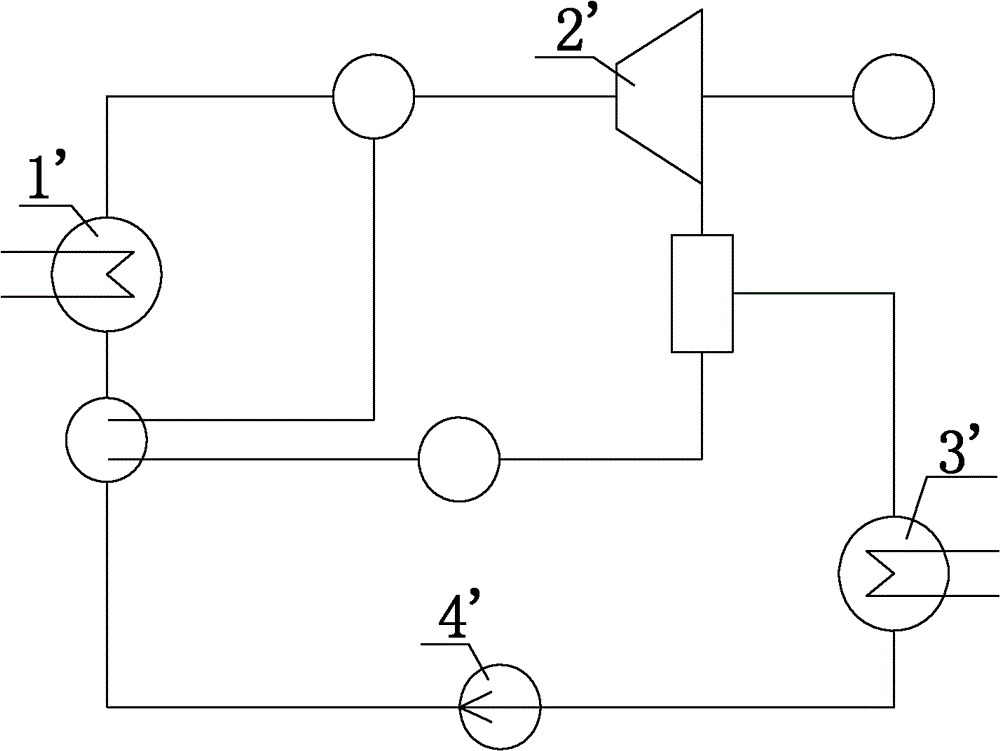

Ammonia water reheating-injecting power absorption circulation system driven by temperature difference of seawater

InactiveCN102116274AIncrease inlet pressureReduce power consumptionMachines/enginesMechanical power devicesWorking fluidVapor–liquid separator

The invention relates to the field of working by using temperature difference of seawater, in particular to an ammonia water reheating-injecting power absorption circulation system driven by the temperature difference of the seawater. The system comprises a generator, gas-liquid separators and a steam turbine, wherein the steam turbine comprises a primary steam turbine and a secondary steam turbine. The gas channel outlet of the generator is communicated with an inlet of the primary steam turbine through the gas-liquid separator I. The outlet of the primary steam turbine is communicated with an inlet of a reheater through a pipeline. The outlet of the reheater is communicated with the gas-liquid separator II through a pipeline. The liquid outlet of the gas-liquid separator II is communicated with a working fluid inlet of a secondary injector through a pipeline. The gas outlet of the gas-liquid separator II is communicated with an inlet of the secondary steam turbine through a pipeline. The outlet of the secondary steam turbine is communicated with a gas inlet of an injecting absorption heat exchanger through a pipeline. The first outlet of the injecting absorption heat exchanger is communicated with a gas sucking inlet of the secondary injector through a pipeline. The outlet of the secondary injector is communicated with inlets of a solution pump and a solution heat exchanger through pipelines. By virtue of the system, the circulation efficiency is greatly improved.

Owner:OCEAN UNIV OF CHINA

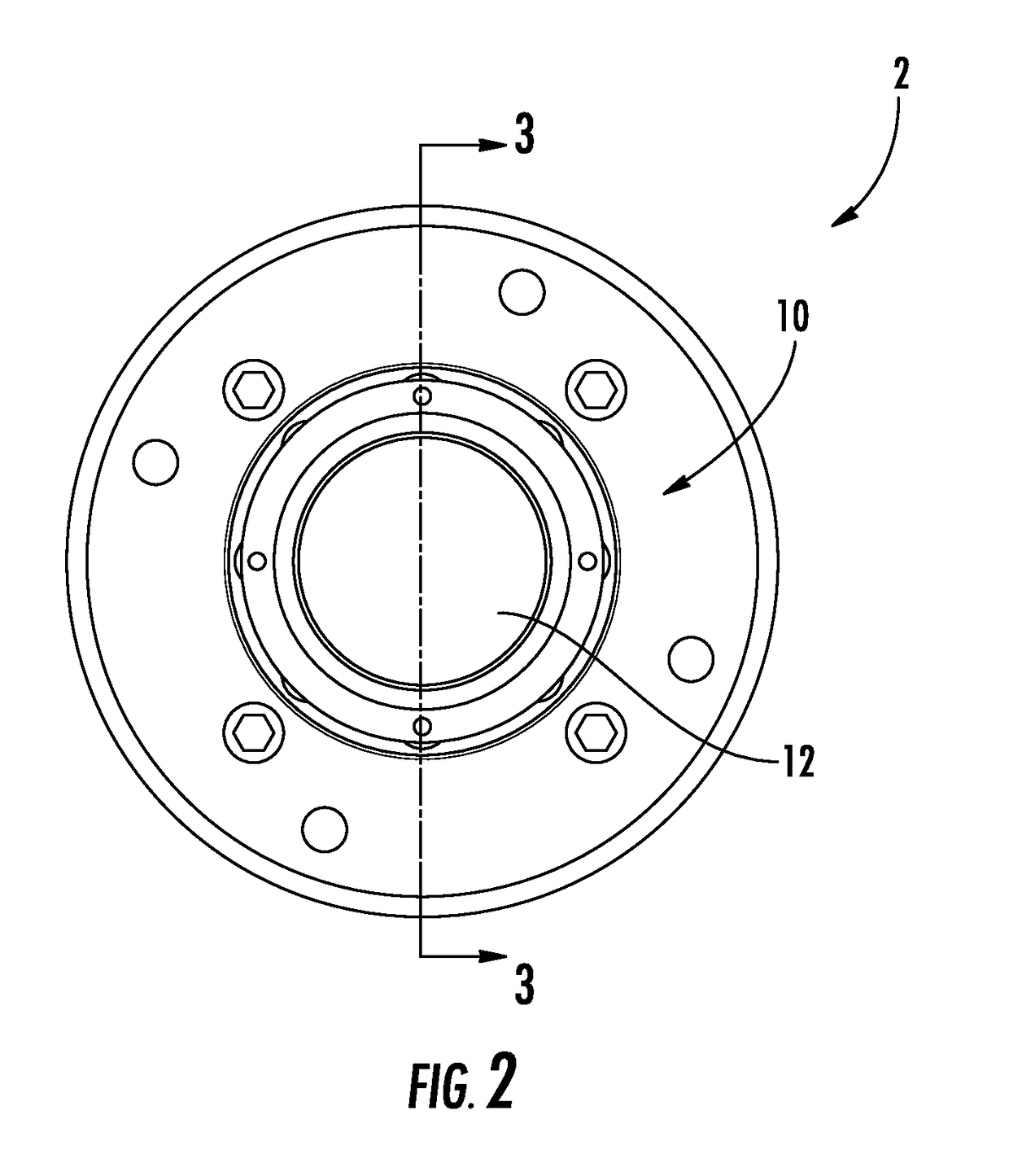

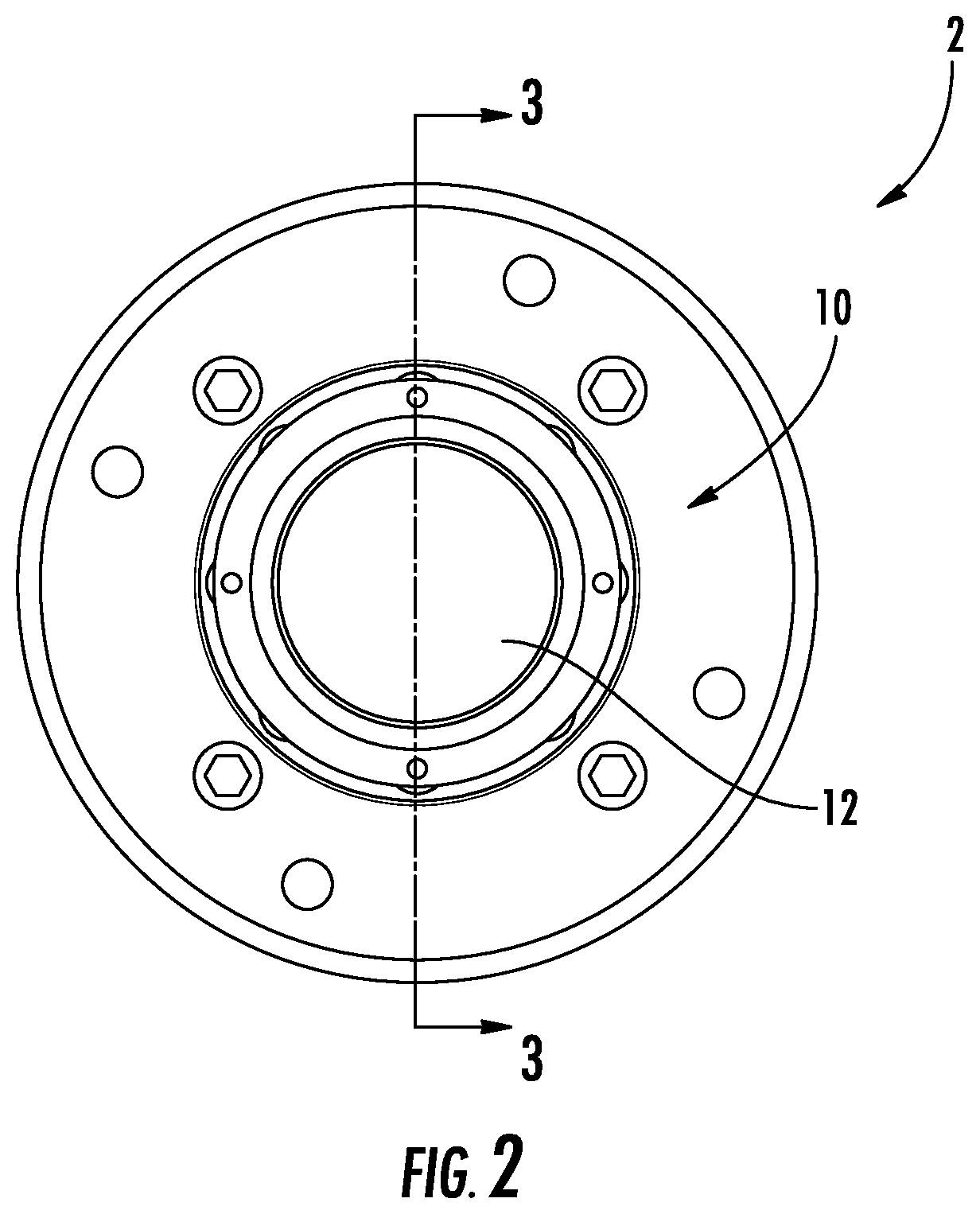

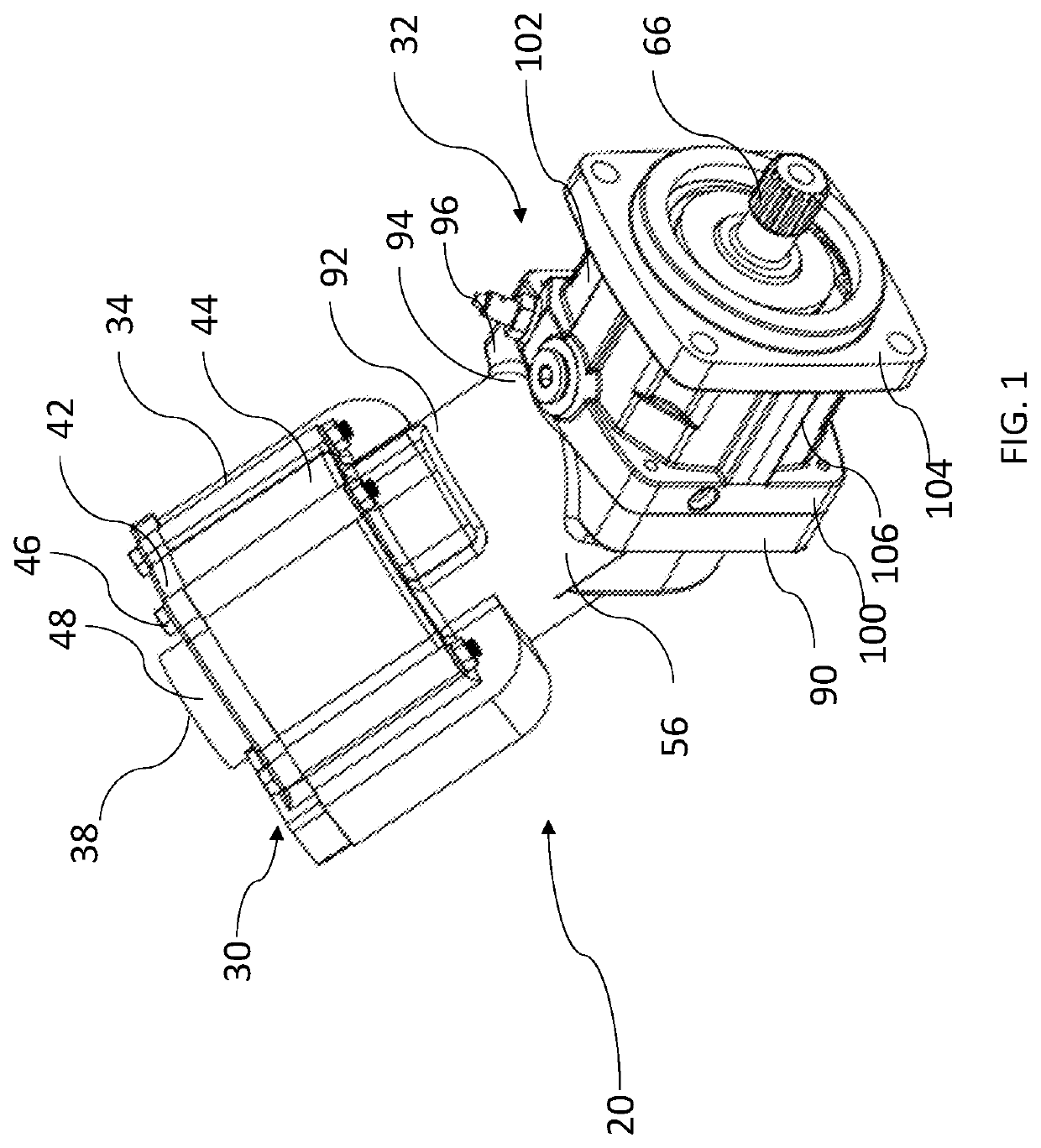

Dual integrated organic working fluid pump

ActiveUS20170211577A1Easy for cavitationIncrease inlet pressureRotary piston pumpsRotary/oscillating piston combinationsWorking fluidDrive shaft

A pump includes a housing, a drive shaft, a centrifugal pump portion having an impeller, and a gear pump portion having first and second gears. The impeller and one of the first and second gears are mounted to the drive shaft to drive the centrifugal pump portion and the gear pump portion at the same rotational speed. The gear pump can be a crescent internal gear (CIG) pump. The drive shaft can be rotated by a magnetic drive. The drive shaft can include a longitudinal bore in fluid communication with a cavity in the magnetic drive and with a discharge of the centrifugal pump portion to circulate working fluid through the magnetic drive to cool the drive. An impeller can be coupled to an inlet of the centrifugal pump portion.

Owner:CIRCOR PUMPS NORTH AMERICA LLC

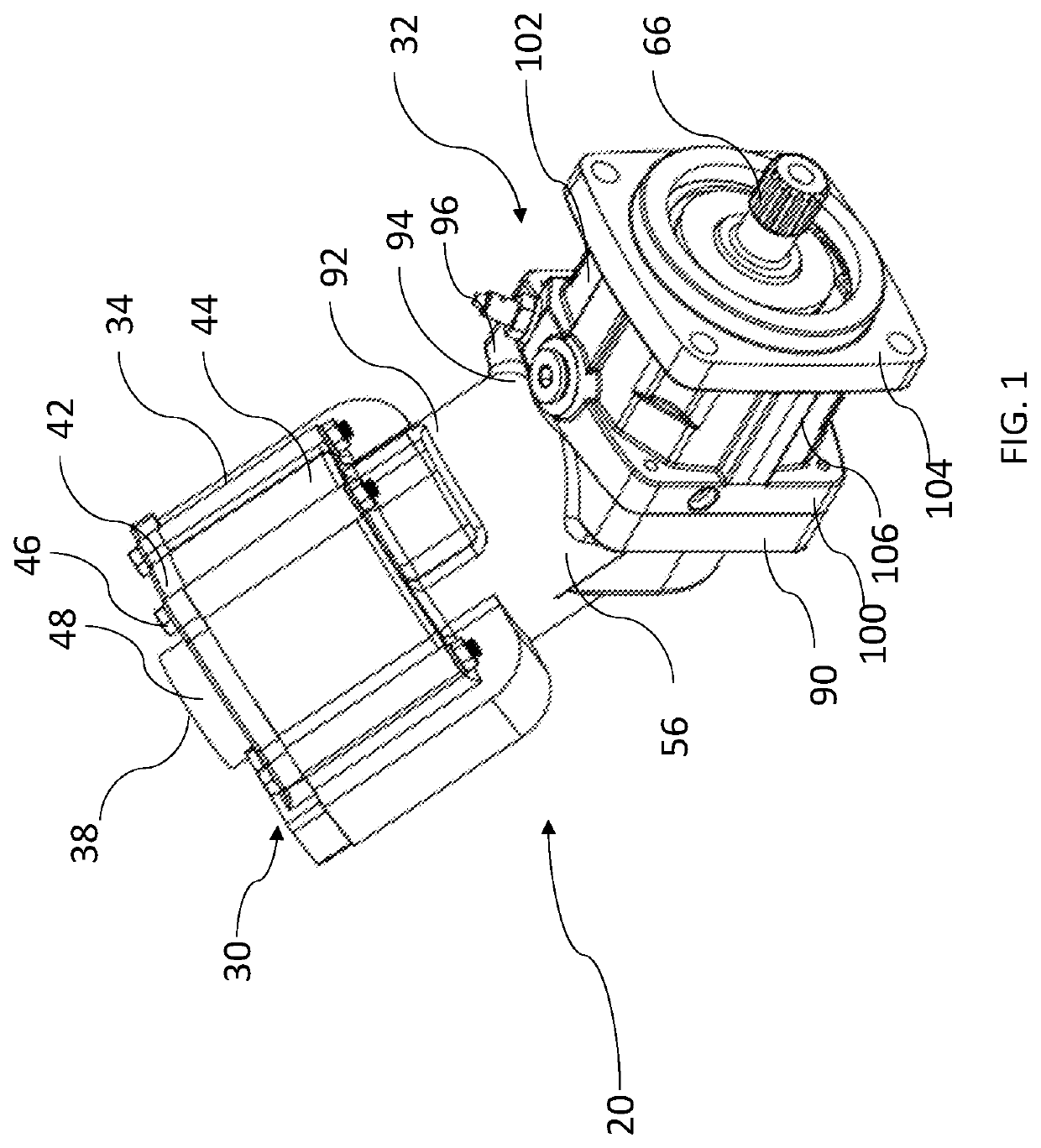

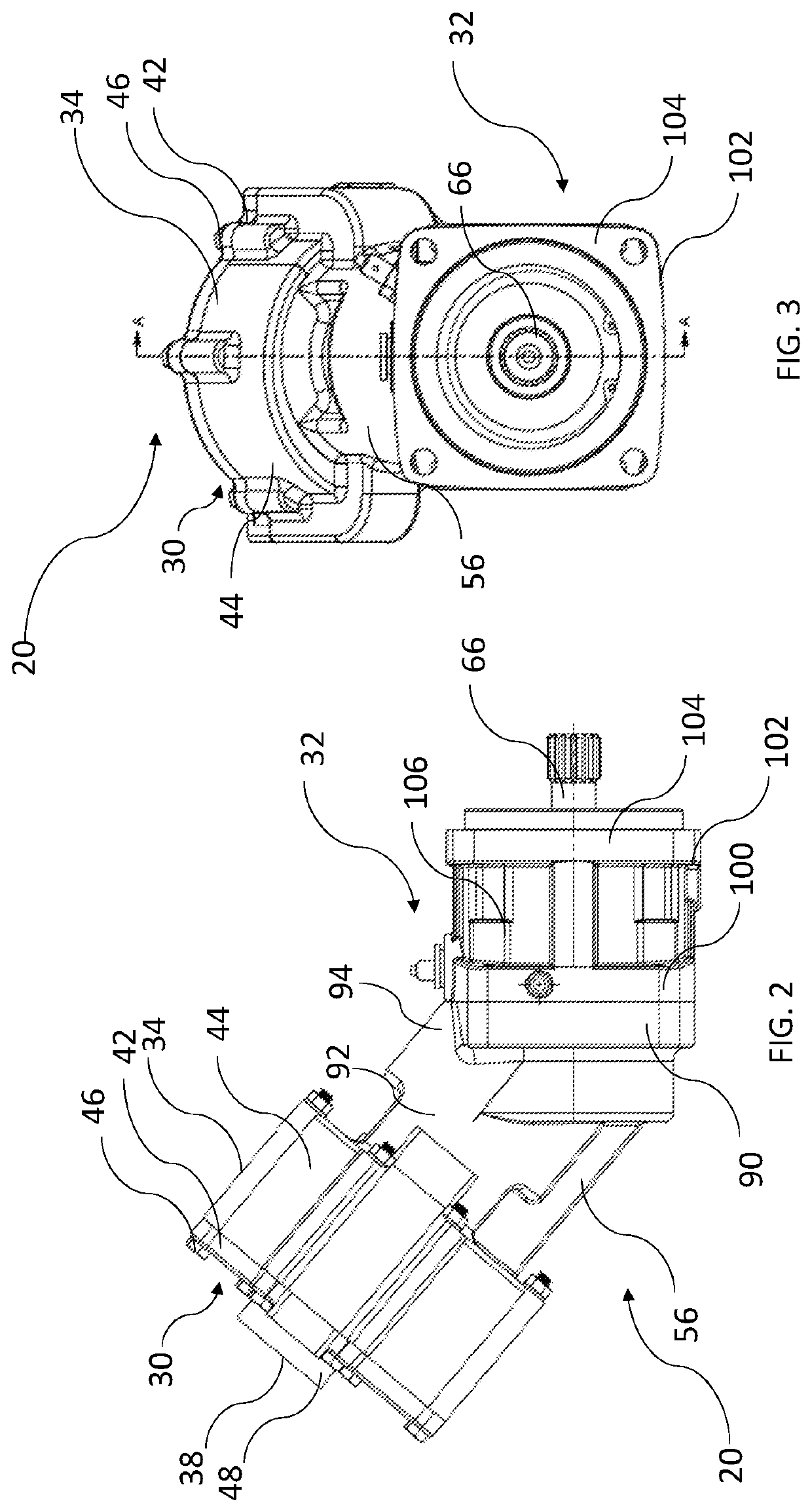

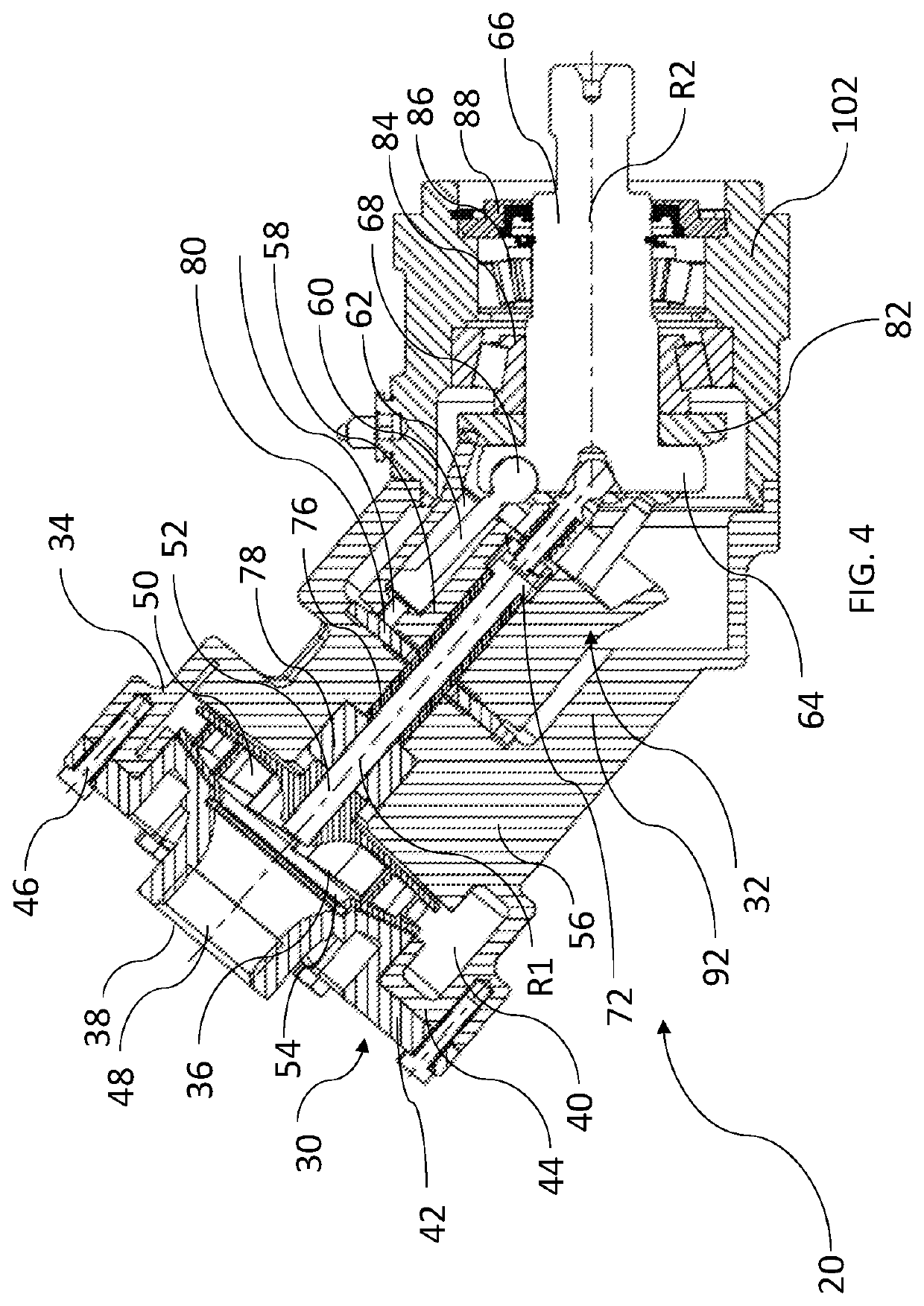

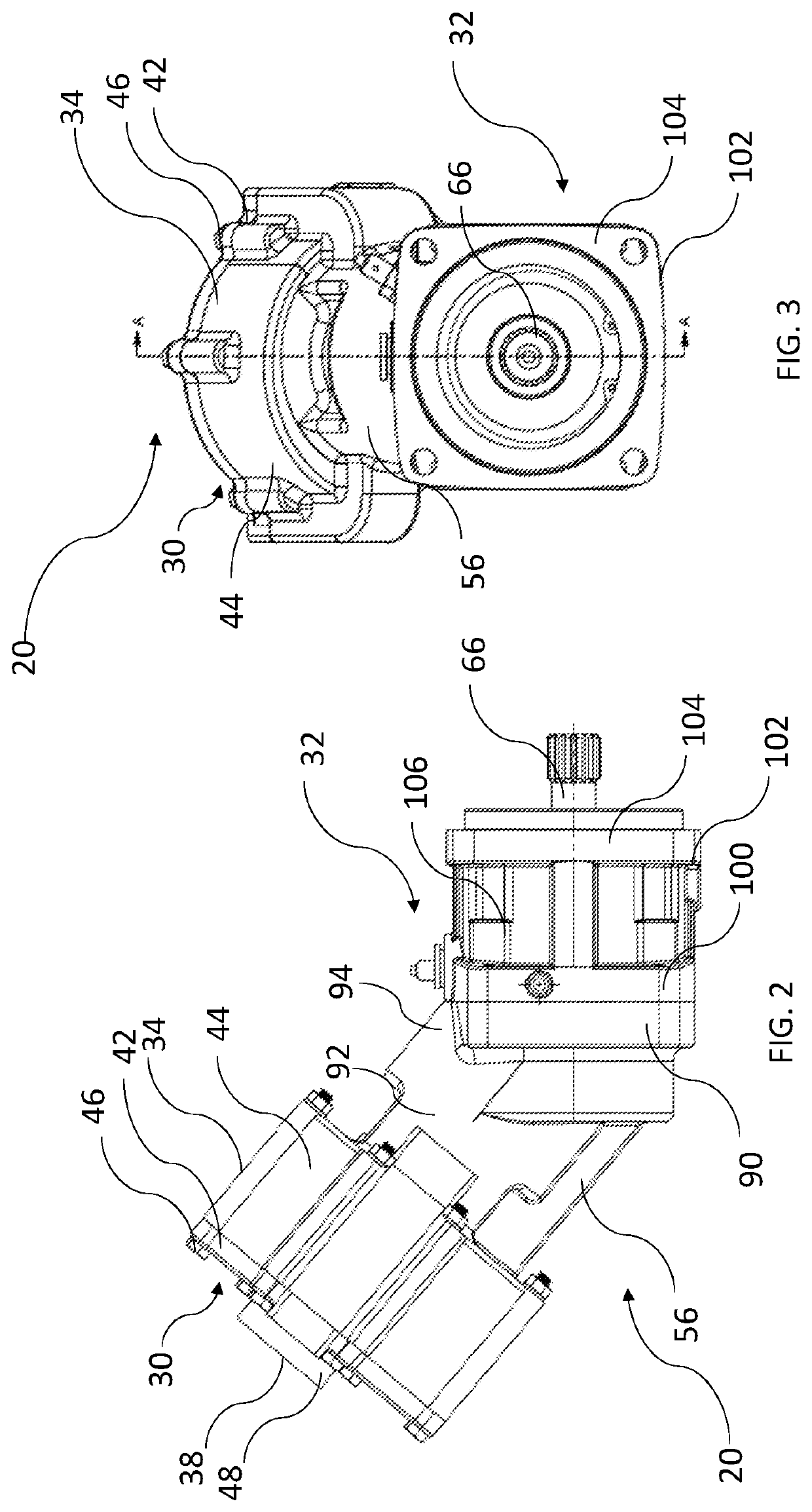

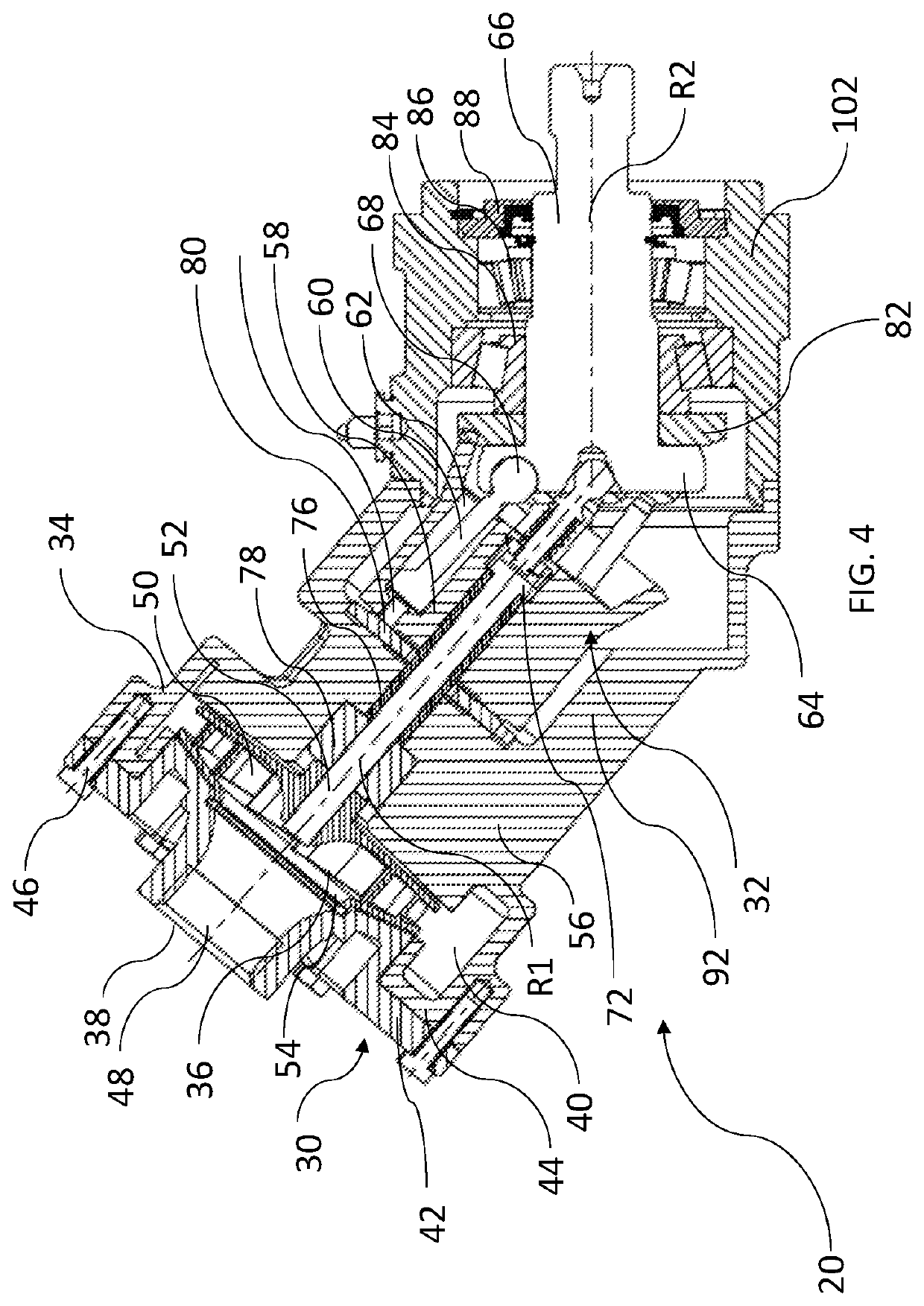

Bent axis hydraulic pump with centrifugal assist

ActiveUS20200340463A1Increase speedGuaranteed uptimePump componentsWorking fluid for enginesRotational axisDrive shaft

A pump and motor assembly (20) includes a centrifugal pump (30), a bent axis hydraulic pump 58, and a wet-type drive motor (228). The motor has a rotor and a stator that are submerged in hydraulic fluid for full lubrication and cooling. A drive shaft 66 is driven by the motor. The centrifugal pump has a rotatable impeller (50) for pumping hydraulic fluid from an inlet (48) to the bent axis hydraulic pump. The centrifugal pump also pumps fluid to the motor for lubrication and cooling. The bent axis hydraulic pump pumps the fluid and discharges the fluid from the system. The centrifugal pump and the bent axis hydraulic pump are rotatable along a common rotational axis R1 that is angled relative to the rotational axis R2 of the drive shaft.

Owner:PARKER INTANGIBLES LLC

Supercritical carbon dioxide semi-closed pure oxygen combustion power generation system based on staged combustion

InactiveCN108999701ALower capture costsEase of achieving zero emissionsTurbine/propulsion fuel supply systemsInternal combustion piston enginesCombustion chamberHigh pressure

A supercritical carbon dioxide semi-closed pure oxygen combustion power generation system based on staged combustion comprises a fuel supply system, an oxygen supply system, a power generation system,and a power generation component, wherein the power generation system comprises a main power generation system and a secondary power generation system. The pure oxygen combustion power generation system further comprises a multi-stage supercritical carbon dioxide compressor connected to the main power generation system and the secondary power generation system and used for backflow of supercritical carbon dioxide. A turbo pump is driven to work by high-temperature and high-pressure flue gas generated by oxygen-enriched combustion of a secondary combustion chamber, so that the efficiency and power density of the entire power generation system can be improved. The emission products are high-pressure carbon dioxide and clean water. The high-pressure carbon dioxide can effectively reduce thecost of carbon dioxide capture, facilitates capture and recycling of carbon, and achieves zero emission of carbon dioxide. A waste heat recovery component is provided, so as to realize gradient utilization of energy and improve the overall efficiency of the power generation system.

Owner:SHANGHAI MICROPOWERS

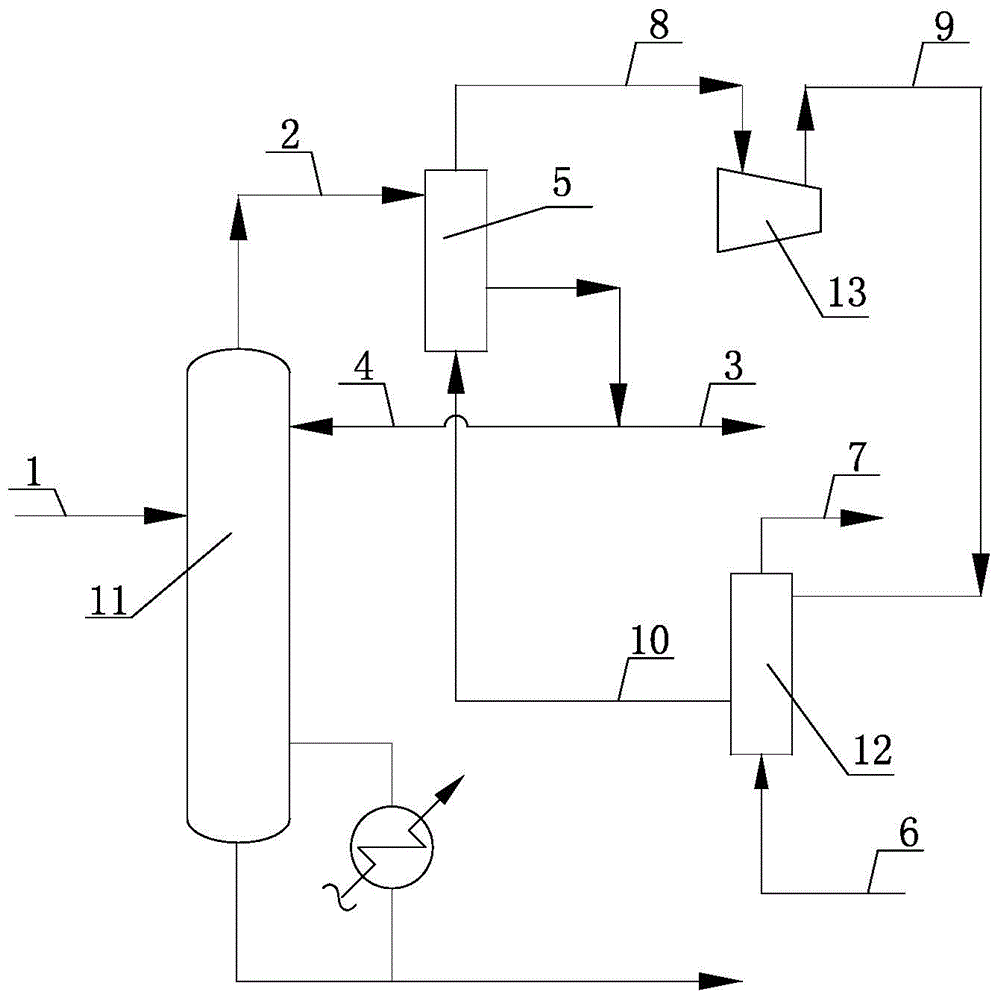

Crude styrene tower top heat recovery method and device

InactiveCN104876789AAvoid the disadvantages of being closely related and influencing each otherEasy to operateChemical industryDistillation purification/separationRecovery methodGas phase

The invention is mainly applied to the technical field of crude styrene tower top heat recovery, and particularly relates to a crude styrene tower top heat recovery method which comprises the following steps: a. a dehydrogenation solution enters a crude styrene tower to obtain a gas-phase stream containing benzene, toluene and ethylbenzene on the tower top, the gas-phase stream enters a tower top condenser to heat a heat pump working medium stream, most of the gas-phase stream is condensed, and the uncondensed gas-phase stream is further cooled by an after cooler, and the gas-phase stream physical distribution is partially used as a crude styrene tower top reflux and partially sent into an ethylbenzene recovery tower; b. the vaporized working medium stream enters a compressor, and is used for heating an ethylbenzene / water azeotrope after being compressed and heated; and c. the ethylbenzene / water azeotrope is vaporized and enters an ethylbenzene superheater, and meanwhile, the water vapor is condensed into a water vapor condensate. The method thoroughly solves the problem that the traditional heat pump technique can heat the tower bottom material only by greatly enhancing the compression ratio of the compressor, saves the investment and energy consumption, and makes the application of the heat pump technique possible.

Owner:SHANDONG QILU PETROCHEM ENG

Flow uniformity of air-cooled battery packs

ActiveUS9446681B2Increase flow ratePromote a more equitable distribution of cooling fluid pressuresHybrid vehiclesElectric devicesComputer moduleCooling fluid

A battery pack and method of cooling a battery pack. In one form, the battery pack is an assembly made up of numerous battery cells arranged within numerous modules. Cooling channels that receive cooling fluid from a ducted supply are placed between adjacent cells or cooling plates within each of the modules. The ducted supply includes beads or related area-increasing undulations that are designed to improve both the stiffness of the ducting as well as the uniformity of the flow rates of individual cooling channels within each of the modules. In one form, the pressure-enhancing beads are placed in an inlet portion of the ducting that is adjacent a forward portion of one or more of the sequentially-encountered modules in order to promote a more equitable distribution of the cooling fluid between the various cooling channels within each of the modules.

Owner:GM GLOBAL TECH OPERATIONS LLC

Dual integrated pump having a first and second pump portion connected in series and driven by a common shaft

ActiveUS10544788B2Increase inlet pressureLow costRotary piston pumpsRotary/oscillating piston combinationsGear pumpWorking fluid

A pump includes a housing, a drive shaft, a centrifugal pump portion having an impeller, and a gear pump portion having first and second gears. The impeller and one of the first and second gears are mounted to the drive shaft to drive the centrifugal pump portion and the gear pump portion at the same rotational speed. The gear pump can be a crescent internal gear (CIG) pump. The drive shaft can be rotated by a magnetic drive. The drive shaft can include a longitudinal bore in fluid communication with a cavity in the magnetic drive and with a discharge of the centrifugal pump portion to circulate working fluid through the magnetic drive to cool the drive. An impeller can be coupled to an inlet of the centrifugal pump portion.

Owner:CIRCOR PUMPS NORTH AMERICA LLC

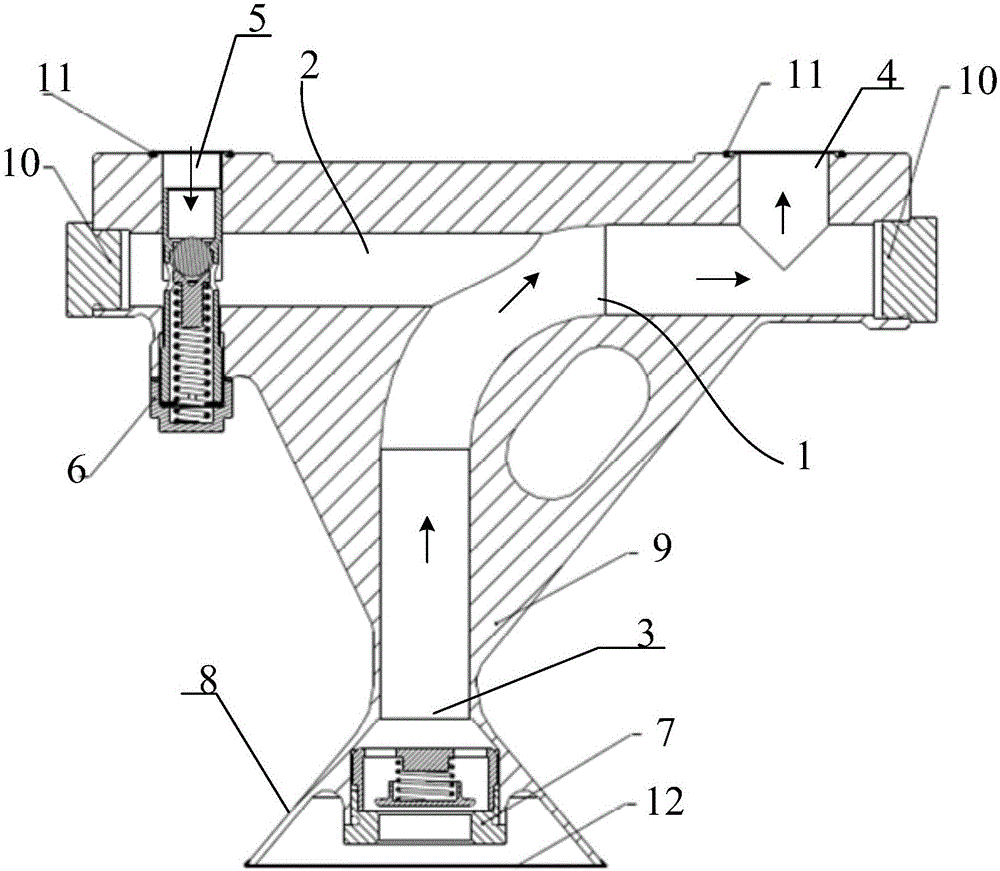

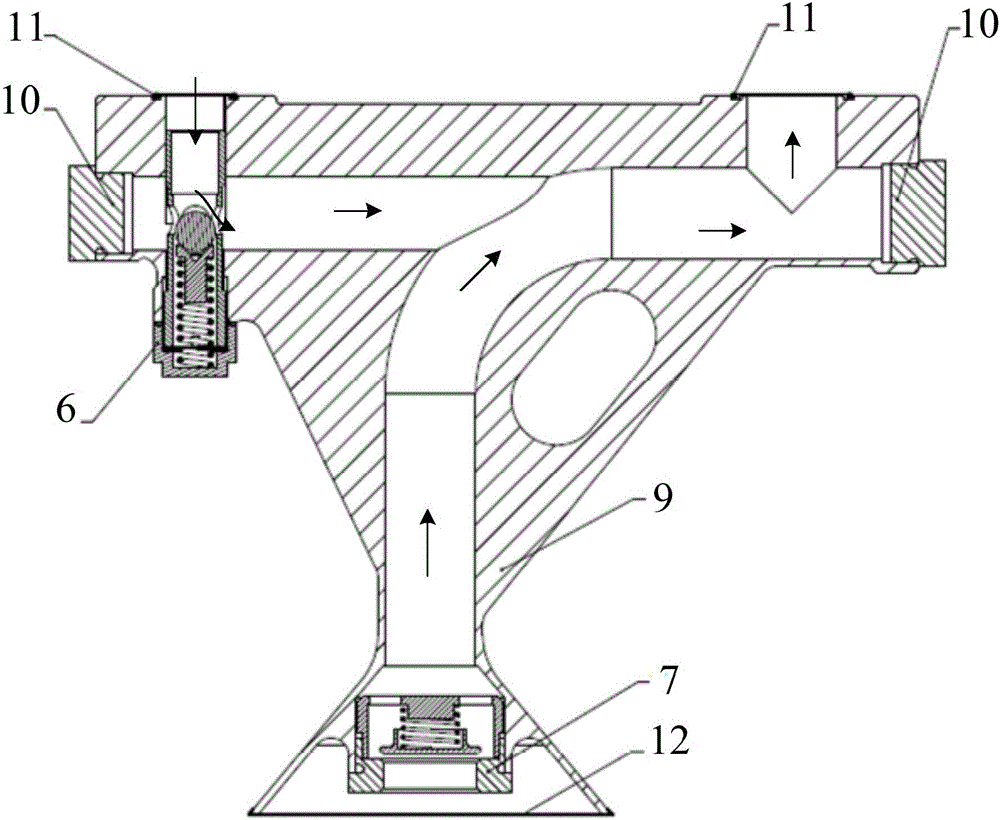

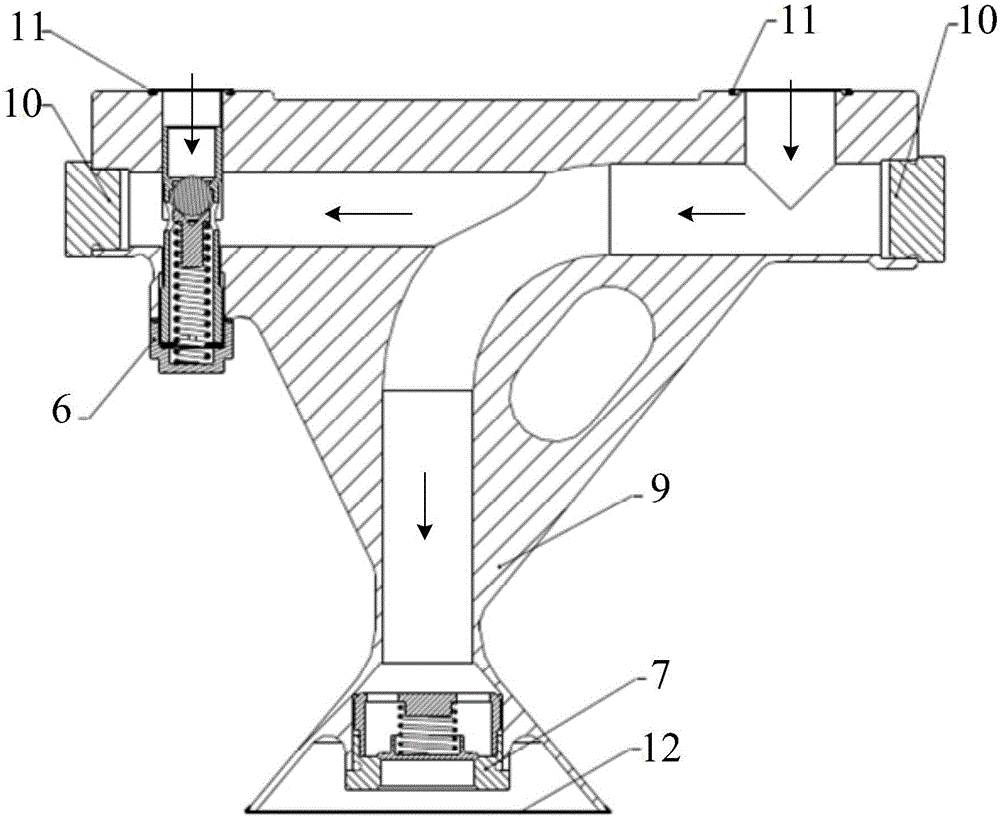

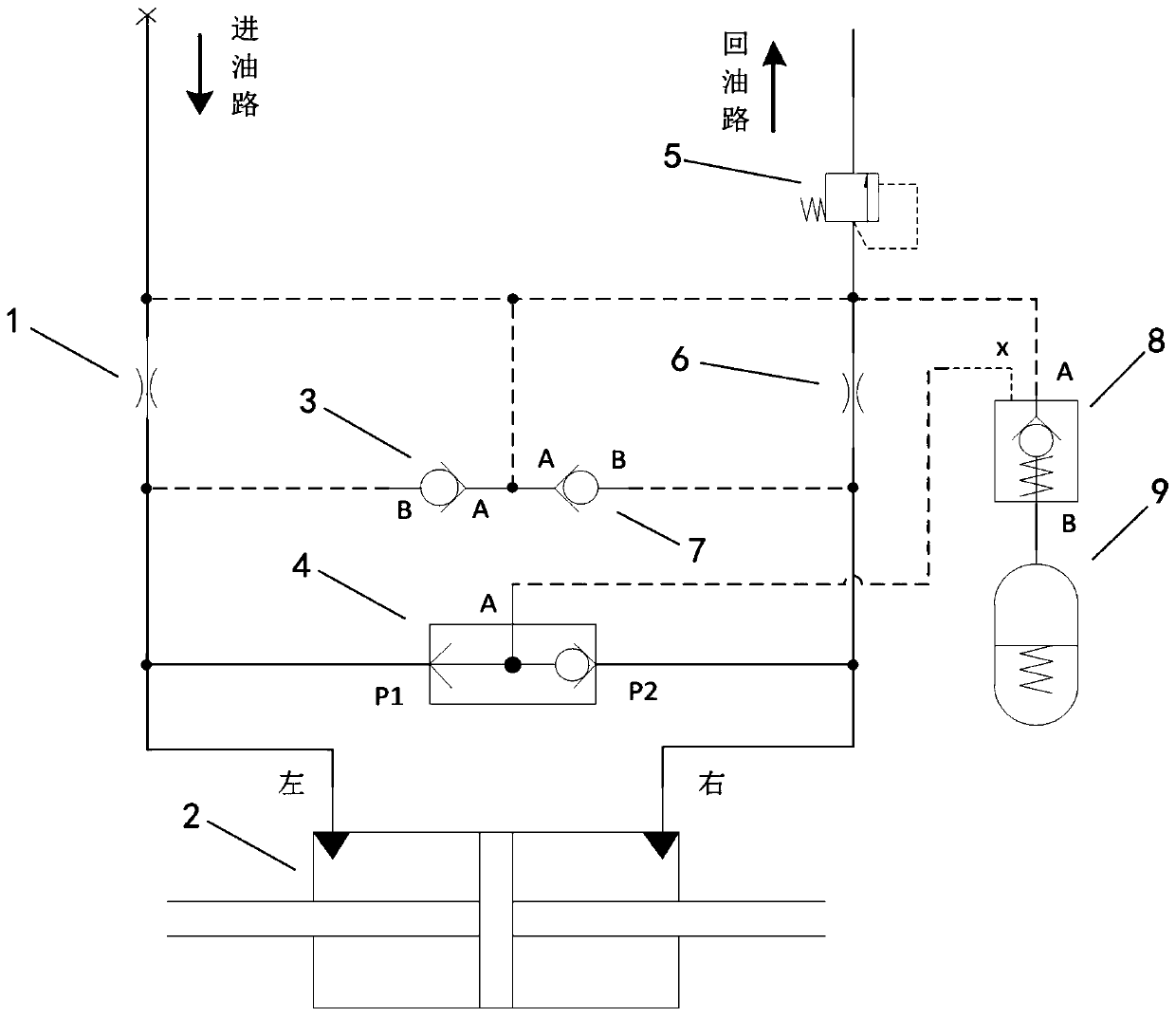

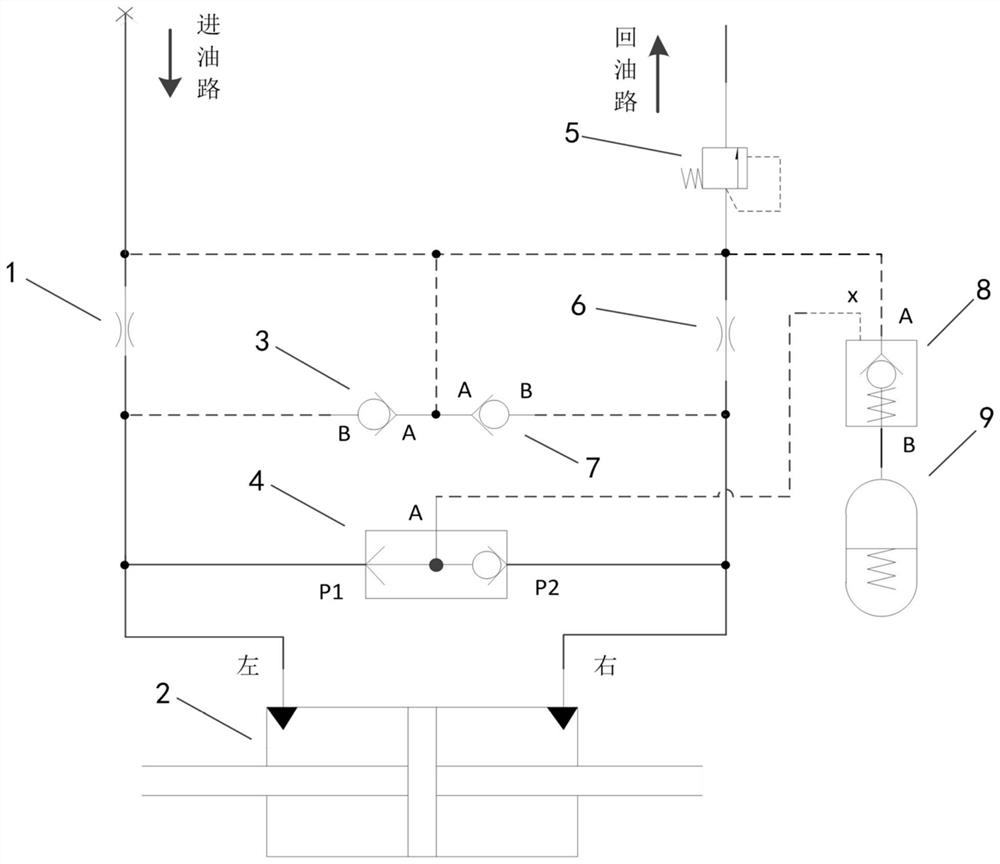

Low-leakage hydraulic shimmy damping compensation loop for aircraft nose wheel turning system

The invention relates to a low leakage hydraulic shimmy damping compensation loop for an aircraft nose wheel turning system. The hydraulic shimmy damping compensation loop comprises a turning actuator, pressure sensitive devices, an unloading valve, an anti-leakage device and a compensator. Hydraulic flow and hydraulic pressure are stored in the compensator; the anti-leakage device is arranged atan outlet of the compensator; the unloading valve is arranged at an oil return path of the aircraft hydraulic system; the hydraulic flow enters the compensator through the anti-leakage device under the action of back pressure generated by the unloading valve; the pressure sensitive devices are arranged in a left cavity and a right cavity of the turning actuator, and when the pressure of at least one cavity of the turning actuator exceeds a pressure threshold value, the cavity pressure controls the anti-leakage device to be started through the pressure sensitive devices, so that hydraulic flowin the compensator flows out of the compensator. The hydraulic shimmy damping compensation loop has the advantages that leakage of the compensator of the hydraulic shimmy damping compensation loop isreduced, and hydraulic flow needing to be stored by the compensator is reduced.

Owner:COMAC +1

Bent axis hydraulic pump with centrifugal assist

ActiveUS11460013B2Increase speedGuaranteed uptimePump componentsWorking fluid for enginesRotational axisDrive shaft

A pump and motor assembly (20) includes a centrifugal pump (30), a bent axis hydraulic pump 58, and a wet-type drive motor (228). The motor has a rotor and a stator that are submerged in hydraulic fluid for full lubrication and cooling. A drive shaft 66 is driven by the motor. The centrifugal pump has a rotatable impeller (50) for pumping hydraulic fluid from an inlet (48) to the bent axis hydraulic pump. The centrifugal pump also pumps fluid to the motor for lubrication and cooling. The bent axis hydraulic pump pumps the fluid and discharges the fluid from the system. The centrifugal pump and the bent axis hydraulic pump are rotatable along a common rotational axis R1 that is angled relative to the rotational axis R2 of the drive shaft.

Owner:PARKER INTANGIBLES LLC

Gas turbine engine arrangement

ActiveUS10513980B2Increase speedReduce power levelEngine fuctionsGas turbine plantsRadial positionEngineering

A gas turbine engine arrangement comprising a gas turbine engine and an inlet screen. The gas turbine engine comprises an engine core comprising an inlet having a radial extent extending from an engine longitudinal axis to a first radial position, and a fan duct comprising an inlet having a radial extent extending from the first radial position to a fan casing, the inlet screen comprising an at least part annular porous grid radially extending across at least part of the radial extent of the fan duct inlet, and not extending across any substantial part of the radial extent of the core inlet.

Owner:ROLLS ROYCE PLC

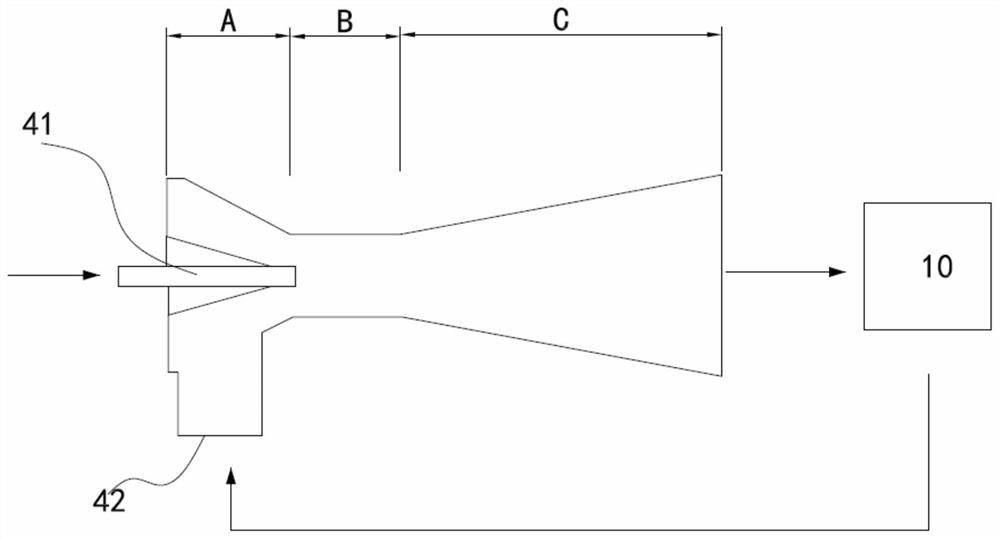

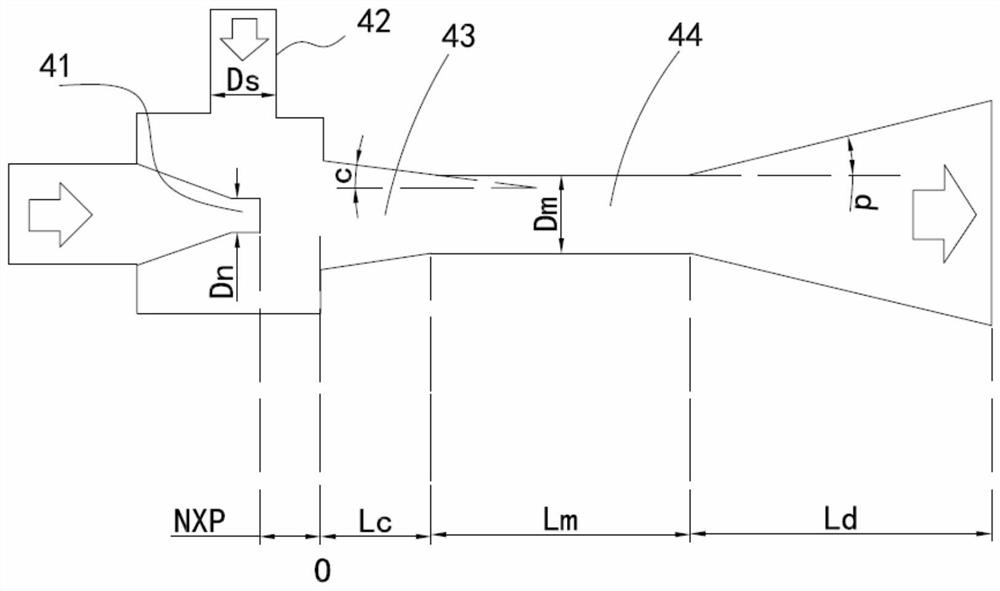

Negative pressure drainage equipment of hydrogen fuel system

InactiveCN113431711AReach full utilizationAvoid wastingInternal combustion piston enginesFuel supply apparatusChemical reactionHigh pressure hydrogen

The invention discloses negative pressure drainage equipment of a hydrogen fuel system. The negative pressure drainage equipment of the hydrogen fuel system comprises a high-pressure hydrogen source and an electric pile, and is characterized by further comprising an electric pile reaction route and a hydrogen injection route, wherein the electric pile reaction route comprises the high-pressure hydrogen source, an injector, a heating and humidifying device and the electric pile which are connected in sequence; the hydrogen injection route comprises the electric pile, a water-gas separator and the injector which are connected in sequence; and hydrogen enters the electric pile from the electric pile reaction route to complete chemical reaction, and the residual hydrogen after the reaction is sucked into the electric pile reaction route by the injector from the hydrogen injection route. According to the negative pressure drainage equipment of the hydrogen fuel system provided by the invention, by setting the circulating recovery route, the residual hydrogen in the electric pile returns to the injector through a back pressure device and the water-gas separator, and then participates in a new electric pile chemical reaction along the electric pile reaction route, so that the hydrogen is completely utilized, the waste of resources is avoided, and the use cost is saved.

Owner:SHUNDE POLYTECHNIC

Low-leakage hydraulic anti-sway compensation circuit for aircraft nose wheel steering system

The invention relates to a low-leakage hydraulic pressure reduction compensation circuit for an aircraft nose wheel steering system. The hydraulic sway compensation circuit includes a turning actuator, a pressure sensitive device, an unloading valve, an anti-leakage device, and a compensator; hydraulic flow and hydraulic pressure are stored in the compensator, and the anti-leakage device is arranged at the outlet of the compensator, and the unloading valve The unloading valve is set at the oil return circuit of the aircraft hydraulic system. Under the action of the back pressure generated by the unloading valve, the hydraulic flow enters the compensator through the anti-leakage device, and forms the required hydraulic pressure under the action of the compensator. The pressure sensitive device It is arranged at the left and right chambers of the turning actuator. When the pressure in at least one chamber of the turning actuator exceeds the pressure threshold, the pressure in the chamber controls the opening of the anti-leakage device through the pressure sensitive device, so that the hydraulic pressure in the compensator flow out of the compensator. The hydraulic anti-sway compensating circuit can have the following beneficial technical effects: reducing the leakage of the compensator of the hydraulic anti-swaying circuit and reducing the hydraulic flow required to be stored by the compensator.

Owner:COMAC +1

Ammonia water reheating-injecting power absorption circulation system driven by temperature difference of seawater

InactiveCN102116274BIncrease inlet pressureReduce power consumptionMachines/enginesMechanical power devicesVapor–liquid separatorWorking fluid

The invention relates to the field of working by using temperature difference of seawater, in particular to an ammonia water reheating-injecting power absorption circulation system driven by the temperature difference of the seawater. The system comprises a generator, gas-liquid separators and a steam turbine, wherein the steam turbine comprises a primary steam turbine and a secondary steam turbine. The gas channel outlet of the generator is communicated with an inlet of the primary steam turbine through the gas-liquid separator I. The outlet of the primary steam turbine is communicated with an inlet of a reheater through a pipeline. The outlet of the reheater is communicated with the gas-liquid separator II through a pipeline. The liquid outlet of the gas-liquid separator II is communicated with a working fluid inlet of a secondary injector through a pipeline. The gas outlet of the gas-liquid separator II is communicated with an inlet of the secondary steam turbine through a pipeline. The outlet of the secondary steam turbine is communicated with a gas inlet of an injecting absorption heat exchanger through a pipeline. The first outlet of the injecting absorption heat exchanger is communicated with a gas sucking inlet of the secondary injector through a pipeline. The outlet of the secondary injector is communicated with inlets of a solution pump and a solution heat exchanger through pipelines. By virtue of the system, the circulation efficiency is greatly improved.

Owner:OCEAN UNIV OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com