Liquid phase-change heat transfer type pumping cooling system with booster pump

A cooling system, liquid phase technology, used in refrigerators, refrigeration components, indirect heat exchangers, etc., can solve problems such as poor cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

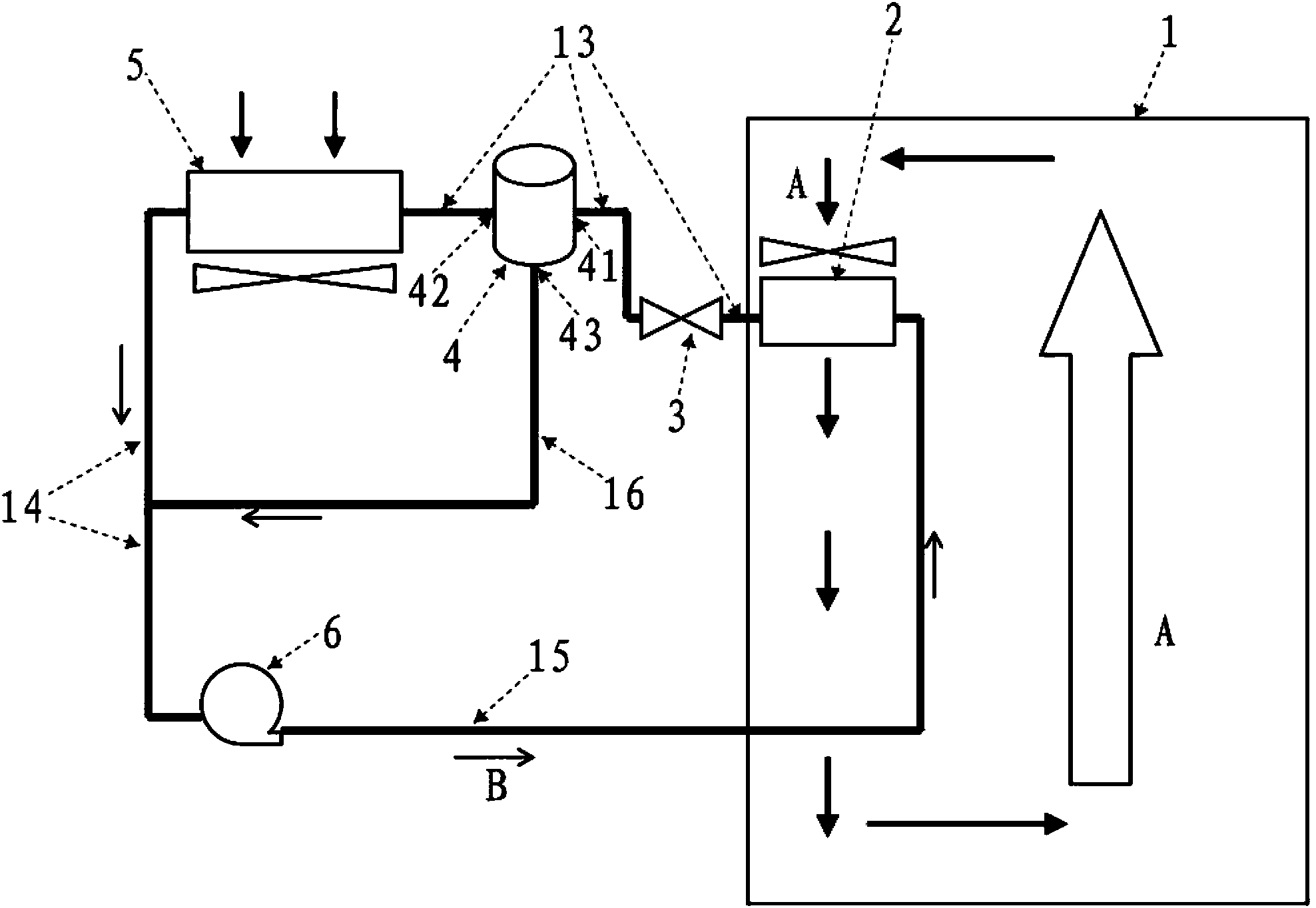

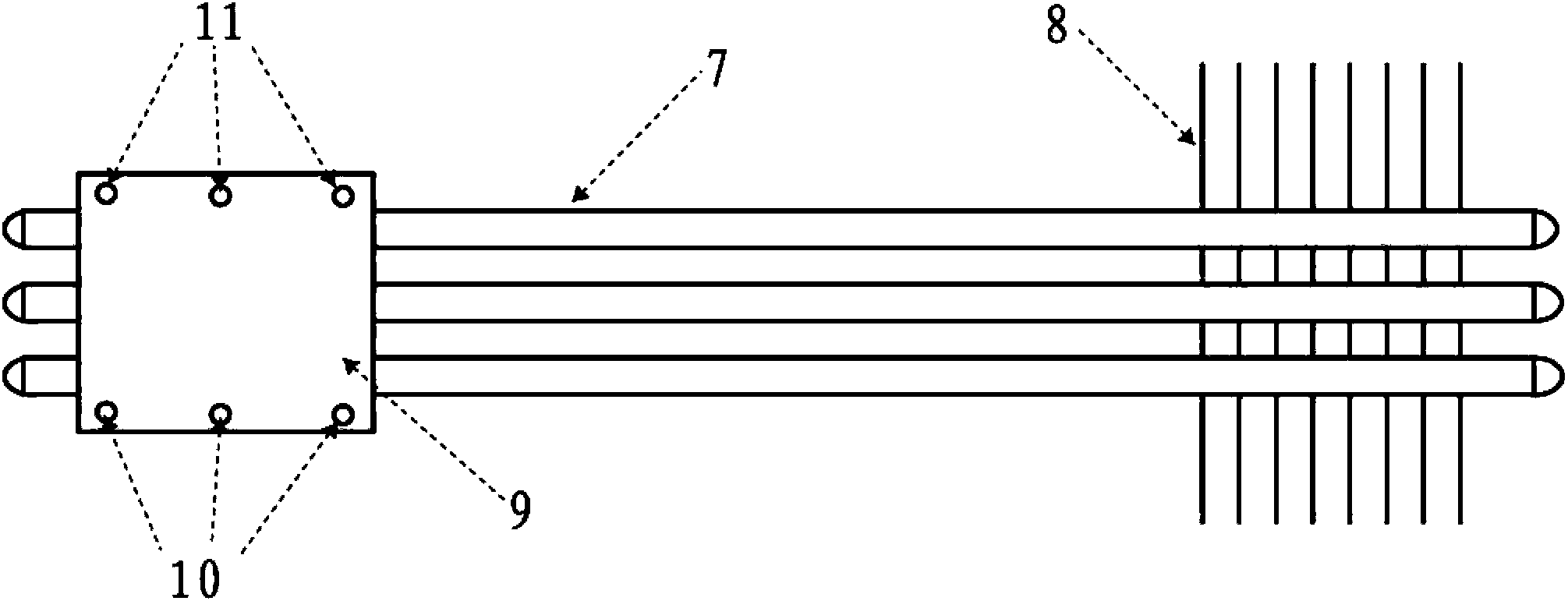

[0032] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0033] figure 1 is a schematic diagram of an embodiment of a liquid phase change heat transfer pumped cooling system according to the present invention. Such as figure 1As shown, the liquid phase-change heat transfer pumping cooling system mainly includes an evaporator system 2, which is arranged at the heat-generating part of the low-voltage or medium-voltage electrical equipment 1, and is used to make the evaporable cooling medium therein heated and evaporated to bring Dissipate heat, so as to achieve the purpose of cooling electrical equipment; liquid supply pump 6, used to overcome the flow resistance of the evaporable cooling medium to supply liquid to the evaporator system 2; evaporable cooling medium, which circulates through the liquid supply pump 6 to An evaporator system 2 whereby the evaporable cooling medium is evaporated by the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com