Propeller turbocharging device

A propeller and speed-increasing device technology, which is applied in the fields of ship engineering and fluid mechanics, can solve the problems of unused tangential and radial velocity components, and achieve the effects of improving energy utilization, increasing pressure, and increasing thrust coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

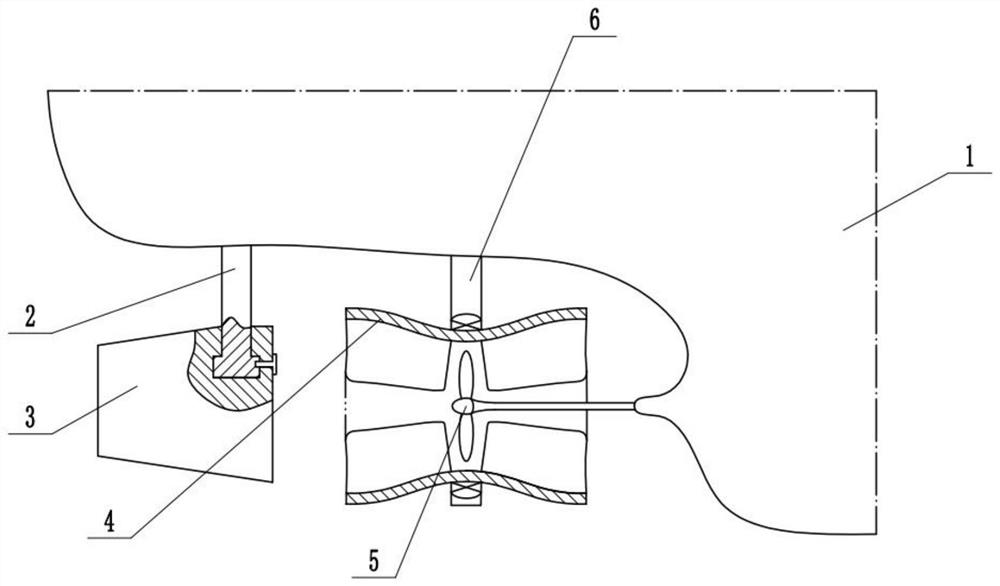

[0029] Such as figure 1 As shown, a marine propeller turbo speed increasing device includes a hull 1, a steering rudder driving rod 2 is installed on the hull 1, a steering rudder 3 is fixedly installed at the lower end of the steering rudder driving rod 2, and a bracket 6 and a bracket 6 are also installed on the hull 1. Propeller assembly 5, fairing assembly 4 is installed on the support 6, and one side of propeller assembly 5 is positioned at fairing assembly 4; Can realize the direction control to hull 1 by steering rudder 3; Steering rudder driving rod 2 can control steering rudder 3 Steering; the tangential and radial velocity components in the propeller wake can be extracted through the fairing assembly 4, and this energy can be used to increase the water inlet pressure of the propeller. On the one hand, the energy of the propeller wake can be extracted to improve energy utilization; On the one hand, the pressure at the water inlet of the propeller can be increased to e...

Embodiment 2

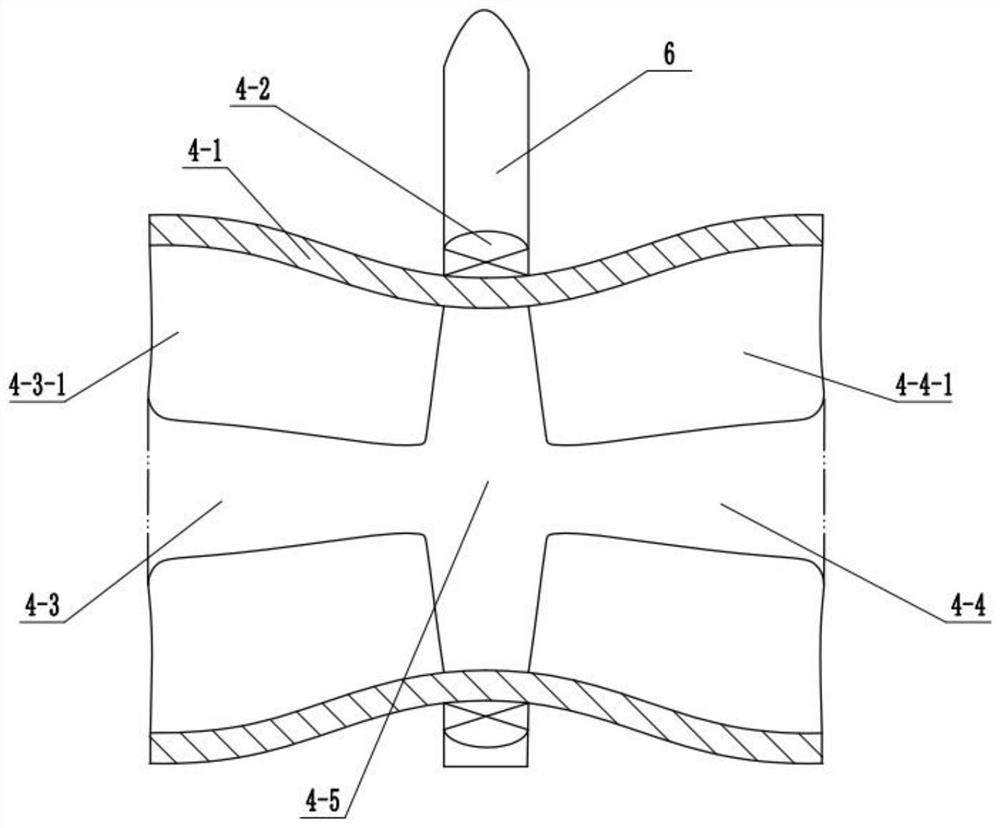

[0031] Such as figure 2 As shown, the fairing assembly 4 includes a fairing 4-1, and the fairing 4-1 is installed on the bracket 6 through a bearing 4-2, and a built-in cavity 4-5 is arranged in the fairing 4-1, and the propeller assembly 5 One side is located in the built-in cavity 4-5, and the built-in cavity 4-5 divides the fairing 4-1 into two regions: the wake area 4-3 and the turbine area 4-4; Concave barrel structure;

[0032] The wake area 4-3 is located on the side of the fairing 4-1 close to the steering rudder 3, and a plurality of rectifying blades 4-3-1 are evenly arranged in the circumferential direction of the wake area 4-3;

[0033] The turbine area 4-4 is on the side of the fairing 4-1 away from the steering rudder 3, and a plurality of turbine blades 4-4-1 are evenly arranged in the circumferential direction of the turbine area 4-4; the rectifying blades 4-3- 1 and the turbine blade 4-4-1 rotate in the opposite direction; the number and structure of the rect...

Embodiment 3

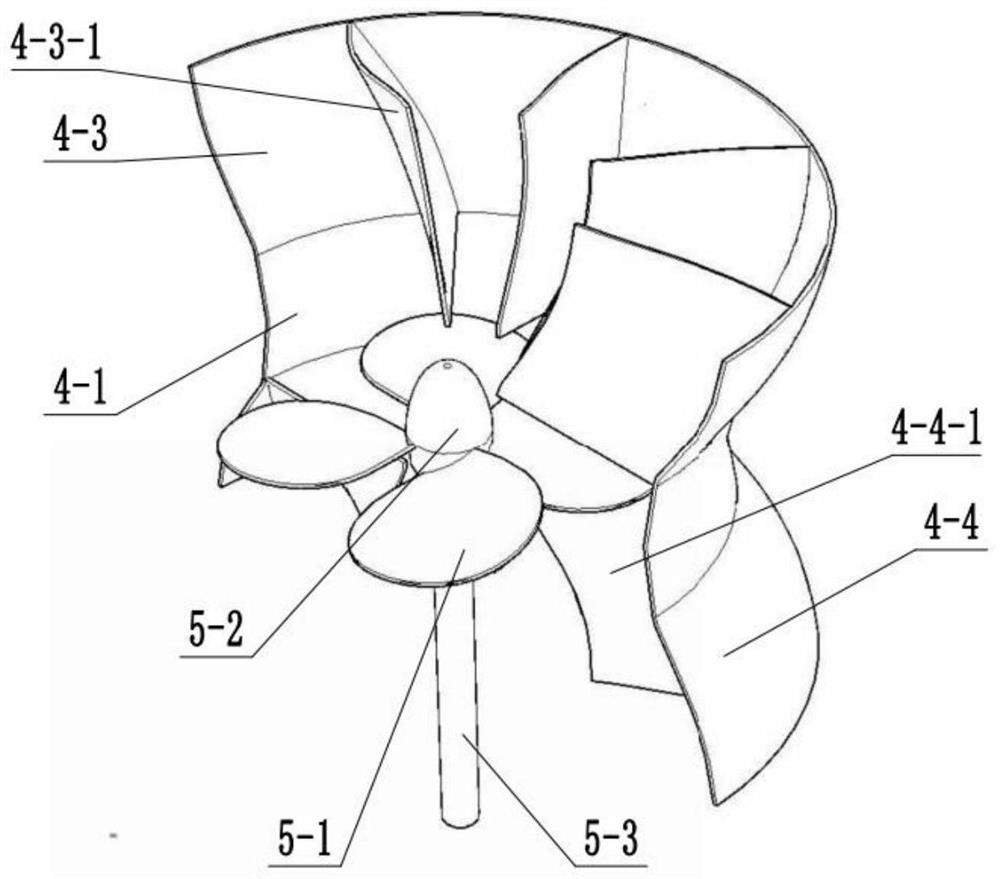

[0035] Such as image 3 and Figure 4 As shown, the propeller assembly 5 includes a propeller blade 5-1, a propeller blade hub 5-2 and a propeller blade drive shaft 5-3, and the propeller blade hub 5-2 is uniformly provided with a plurality of propeller blades 5-1 , the propeller blade hub 5-2 and the propeller blade 5-1 are located in the built-in cavity 4-5, and the propeller blade hub 5-2 is fixedly connected to the propeller blade drive shaft 5-3; the propeller blade hub 5-2 is Class cone; when in use, drive the propeller blade drive shaft 5-3 to rotate, and then drive the propeller blade hub 5-2 to rotate through the propeller blade drive shaft 5-3, and then drive the propeller blade 5-2 through the propeller blade hub 5-2 1 rotates, and then drives the water flow through the propeller blade 5-1, and then pushes the hull 1 forward through the reaction force of the water flow.

[0036] Working principle: drive the propeller blade transmission shaft 5-3 to rotate, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com