Crude styrene tower top heat recovery method and device

A technology of heat recovery device and styrene tower, which is applied in the chemical industry, climate sustainability, organic chemistry, etc., can solve the problems of limited application value, large investment, and high power consumption of compressors, so as to avoid the risk of styrene polymerization, The effect of reducing equipment investment, saving investment and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

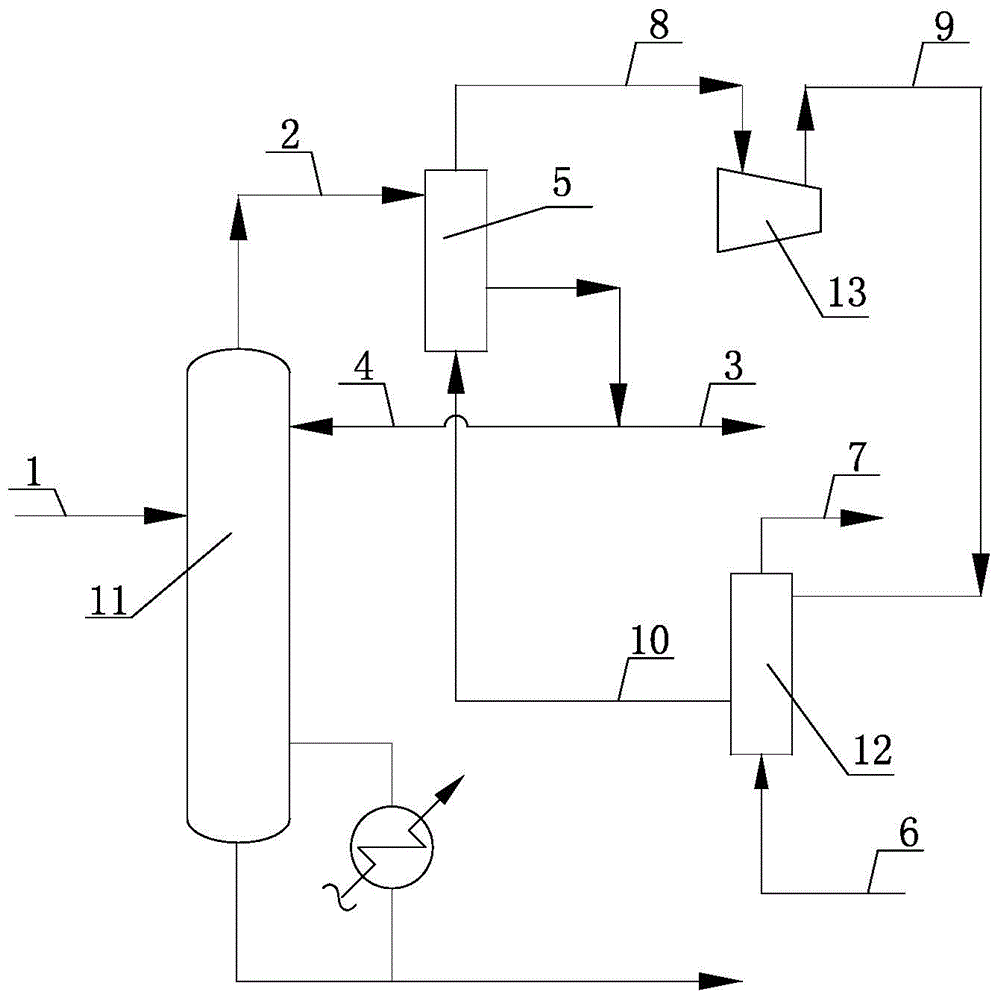

[0029] The present invention will be further described below in conjunction with accompanying drawing:

[0030] Such as figure 1 Shown, the crude styrene overhead heat recovery method of the present invention, comprises the steps:

[0031] a. The dehydrogenation liquid enters the crude styrene tower, and the gas phase stream containing benzene, toluene and ethylbenzene is obtained at the top of the tower, and the gas phase stream enters the tower top condenser. After heating the heat pump working fluid stream, most of the gas phase stream is condensed, and the uncondensed Part of the gas phase stream is further cooled by the aftercooler, part of the condensate of the gas phase stream is used as crude styrene top reflux, and part of it is sent to the ethylbenzene recovery tower;

[0032] b. The vaporized working substance stream enters the compressor, and after being compressed and heated, it is used to heat the ethylbenzene / water azeotrope;

[0033] c. After the ethylbenzene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com