Combine seedbed preparation machine with depth-limiting function

A soil preparation machine and depth-limiting technology, applied to agricultural machinery and implements, shovels, plows, etc., can solve problems such as the inability to adjust the depth, seeding dislocation holes, and the impact of seed germination rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

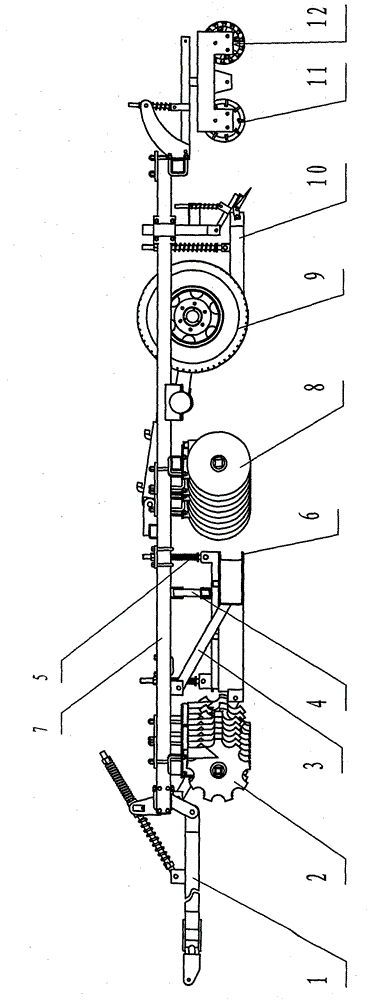

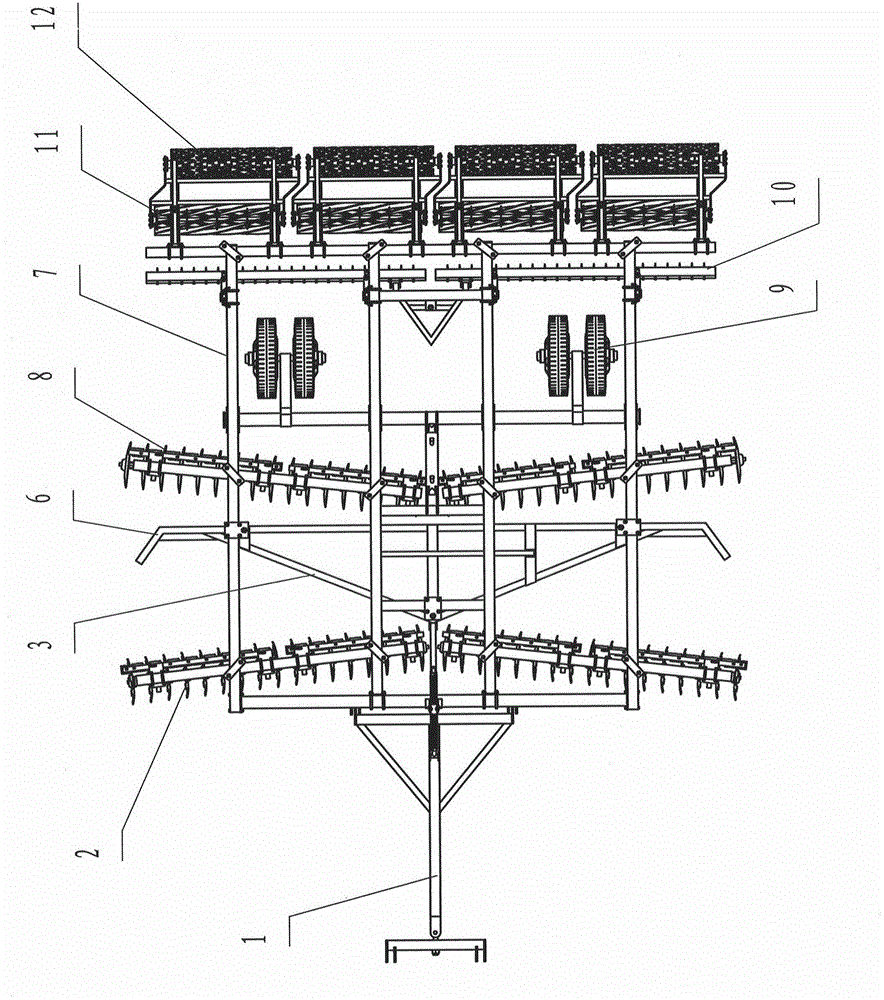

[0010] Embodiment: refer to attached Figure 1~2 , comprising a guide frame 1 and a frame 7, the frame 2 is sequentially provided with a notch rake group 2, a disc rake group 8, a walking ground wheel 9, a leveling bar 10, and a soil breaking wheel from front to back. 11 and the suppressing wheel 12, the frame 7 between the notch rake group 2 and the circular rake group 8 is provided with a depth-limiting device, and the depth-limiting device consists of a draw bar 3, a balance bar 4, an adjustment rod 5 and the stamping bar 6 are formed, the upper ends of the drawbar 3, the balance bar 4, and the adjustment bar 5 are connected with the frame 7 from front to back, and the stamping bar 6 is located on the drawbar 3, Balance bar 4, adjusting bar 5 lower ends, described draw bar 3 one ends are hinged on frame 7, so that adjust depth-limiting device; Flat imprints are smoothed out. By adjusting the adjustment rod 5 on the depth-limiting device, the rake blades under the frame 7 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com